Journal of Nutrition & Food Sciences

Open Access

ISSN: 2155-9600

ISSN: 2155-9600

Research Article - (2017) Volume 7, Issue 3

In this study, the effect of retailing packaging material on tomato quality was investigated. Specifically, nondefective tomato fruits were selected after harvest and packed in four different packaging materials; open market bag, open box, sealed box and Xtend bag. A total of six treatments were prepared by storing the packaged fruits at 4 or 17oC for 12 days. Quality attributes of tomatoes such as calyx freshness, weight loss, fruit firmness, Total Soluble Solids (TSS), colour and physiological damage were assessed. Generally both packaging material and storage temperature affected the quality of the tomato fruits. The quality of tomato fruits stored at 4oC was generally superior to those stored at 17oC. Calyx of tomato fruits stored in open market bag (stored at 17oC) and open box (stored at 17oC) were very dry after storage compared to the tomato fruits stored at 4oC. Tomato fruits packed in Xtend bag and sealed box were firmer than those packed in open box and open market bag. The carbon dioxide (CO2) concentration in sealed box was substantially higher (8.25%) than that in Xtend bag (2.07%). In contrast, the oxygen (O2) concentration in the Xtend bag was higher (18.90%) than that in the sealed box (14.75%). Tomatoes packed in Xtend bag and sealed box had minimal changes in colour intensity (C*), showed lower TSS values compared to tomato fruits packed in other packaging materials. Xtend bag and sealed box seems to be better packaging material for storing tomato fruits for a period of 10 days

Keywords: Retailing packaging materials; Tomato quality; Physiological damage; Storage temperature; Calyx freshness

Tomato (Lycopersicon esculenta) is an important fruit vegetable consumed all over the world. The consumption of tomato in recent time has increased due to the associated benefits of some phytochemicals including carotenoids. Carotenoids are responsible for the colour in tomatoes which are synthesized massively during fruit ripening [1]. Other notable component of tomatoes is vitamin C. Depending on variety and growing conditions, the vitamin C content of tomatoes may vary between 39-263 mg/100 g [1]. For instance, tomatoes grown on organic substrates were found to contain significantly more Ca and vitamin C than tomatoes grown on hydroponic media [2]. Tomatoes may be eaten either raw or cooked. Being a climacteric and perishable vegetable, tomatoes have a very short lifespan, usually 2-3 weeks [3]. Hence, tomato fruits must be properly handled after harvest in order to maintain quality and enhance consumer appeal during sale. The quality of tomato is determined by appearance, firmness, flavour and the nutritive value. These quality parameters are affected by several factors including, variety, agronomic practices, method of harvesting, time of harvesting, postharvest handling techniques, packaging materials and storage conditions. Packaging generally helps to protect and retain the quality of fresh horticultural produce and reduces damage during transport. Sammi and Masud reported that packaging can significantly reduce fruit weight loss of tomatoes when sealed in plastic films and can extend the marketable life [4]. Since consumers are interested in produce with good quality and long shelf life, it is important to package fresh commodities in materials that will meet these requirements. In general, packaging material will not only hold the food substance, but will also protect it from contamination. They also extend the marketable life of the product [5]. However, the type or quality of packaging material may also influence the product quality. For example, tomato packed in polyethylene bags showed significantly lower weight loss (approx. 10%) compared to tomato fruits packed in grease free papers, which showed approximately 20% weight loss after 28 days of storage at ambient temperature of 32 ± 2°C [6]. Commercially, different packaging materials are used in the wholesale and retail market for the sale of fresh produce such as tomatoes. As stated above, the properties of these packaging materials may influence the product quality. Hence, this study investigates the influence of retail packaging; open box, open market bag, Xtend bags and sealed box on the quality of freshly harvested tomato fruits.

Fresh produce quality generally decreases after harvest. The decrease in quality could be attributed to the respiratory activities that continue after harvest. Since there is a growing demand for fresh fruits and vegetables, due to the increased consumption of these commodities, many industries are employing different methods to improve the quality of fresh produce. Several methods including temperature control, use of efficient packaging materials, product pre-treatment and the use of fruits with initial good quality are being used to maintain or reduce the postharvest losses of fresh commodities. Tomato is an important commodity both for the fresh and processing markets [7]. The shelf life of tomatoes are relatively short [8] due to different postharvest physiological, physical and chemical changes that occurs during storage [7]. These changes are triggered by the production of ripening hormone called ethylene [9]. Hence, postharvest handling of tomatoes is essentially targeted at reducing the rate of respiration and the concomitant control of the ethylene production [7,10]. Many strategies and techniques are being investigated to reduce these changes in fruits and to enhance the keeping quality. The following section discusses the nutritional value, utilization, quality and the factors that can influence the quality of tomatoes.

Tomato fruits are rich sources of phytochemical that have several health benefits. Previous studies found that regular consumption of tomato decreased the incidence of chronic degenerative diseases such as cancer [11] and cardiovascular diseases [12]. These health benefits are associated with the high contents of carotenoids, which are able to reduce the risk of certain type of diseases [13,14]. Carotenoids are a class of phytonutrients found in the cells of a wide variety of plants, algae and bacteria. They help plants absorb light energy for use in photosynthesis. Carotenoids are produced mainly during ripening as result of physiological changes caused by enzymatic degradation. Carotenoids in tomatoes can be grouped into two main types. The first type is lycopene, which is the most abundant and represent more than 80% of the total carotenoids in a fully ripened tomato fruit [15]. β-carotene is the second type of carotenoid in tomato fruit and may its content may vary between 7 and 10% [7]. Lycopene and β-carotene has been reported to have strong antioxidant property and provitamin-A activity respectively [15,16]. These essential components have increased the consumption of tomato fruits over the years. Beside the carotenoids, the tomato fruit is also rich in vitamin C, vitamin E and phenolic compounds [17], which also possess beneficial health properties such as anti-inflammatory [18]. Vitamin C is very important in the diet of the population as it prevents scurvy and participates in many metabolic functions in the body. The amount of the various nutrients in tomato fruits will depend on several factors such as cultivar, harvesting time, postharvest handling procedures including packaging and storage. However, of these factors, postharvest handling seems to be the most important [19]. Therefore, controlling or maintaining the pre-harvest quality of fresh produce is very vital in providing fresh produce of good quality to the consumers. This approach will include rapid cooling and the use of good sanitary procedures for handling and packaging of fresh produce in the appropriate material.

Tomato fruits belong to the category of minimally processed foods. They can be consumed in various forms, ranging from raw or processed into puree, juice, paste sauce, ketchup jam, and used in salads. According to Thakur et al. [20], more than 80% of tomato fruits are consumed in the form of processed products. Differences in the various products depend on the extent and degree of processing. For example, depending on the amount of water removed from tomato pulp, either puree or paste is formed [20].

Quality attributes of food are very important as it influences the preference of consumers for a particular product. There are several factors that can be used as indices of good or bad quality in tomato. However, this project will be focusing on colour, firmness, weight, and total soluble solids since they were used in the course of the experiment. Other factors that are used as indices of quality include flavour, titratable acidity and vitamin C contents, visual aspects, size and shape.

Colour: The colour a fruit has a strong influence on the buyer or consumer [21]. Consumers notice colour first, and their observation is often translated into the quality of the product such as flavour or aroma [20] Tomatoes colour is used as index of total quality. Hence, the colour of tomato fruits must be preserved in order not to lose the confidence of the consumer in the product. The colour of tomato changes during different stages of development from chlorophyll to orange (β-carotene) or red colour (lycopene) [22]. Carotenoids accumulate in tomatoes during ripening due to the breakdown of chlorophyll. They are also produced as result of the transformation of chloroplasts into chromoplasts during the lag phase preceding maturation [18]. The colour of tomato fruit can be assessed either objectively using instrumental methods such as Tristimulus colorimeter or subjectively using colour chart.

Firmness: Firmness is another important quality attribute in tomato that the consumer uses as the final index of quality. It is used by the consumer by assessing the fruit through finger test at the time of selection [23]. The firmness of tomato determined by the pectin component which is the cementing layer in most fruits and vegetables. The firmness of tomato is affected by tissue softening which involves weight loss and enzymatic activity. The enzyme pectin methylesterase and polygalacturonase are responsible for the degradation of pectin. These changes in pectin degradation results in drastic changes in texture with an evident softening of the tomato tissues [24].

Weight loss: Weight loss is regarded as a non-physiological process associated with postharvest dehydration resulting in turgor loss and softening of tissue [22]. Reported that the fruit weight loss is affected by several pre and postharvest factors such as harvest date and storage temperature [25]. Hence, in order to prevent weight loss of tomato fruits, it is important to protect the fruit from dehydration by providing good shade during harvest as well as proper packaging during storage.

Total soluble solids: Fruits including tomato contain many compounds which are soluble in water; e.g. sugars, acids, vitamin C, amino acids and some pectin. These soluble compounds form the soluble solids content of the fruit. In most ripe fruits including tomatoes sugar forms the main component of soluble solids. Total Soluble Solids (TSS) are an important postharvest quality attribute in the screening of new tomato cultivars. Since the amount of TSS or sugar in fruits usually increases as they mature and ripen, the soluble solids content of the fruit can be a useful index of maturity or stage of ripeness. The refractometer is the instrument used to measure the total soluble solid content of fruits.

Factors affecting the quality of tomatoes: The quality of tomato after harvest is affected by several factors. Many of these factors have been discussed extensively in several literatures [4,18,26]. However, this section will discuss packaging and storage temperature as they influence the quality of tomato fruits.

Packaging: Packaging has been used to extend the storage life of many fresh fruits and vegetables through the inhibition of physiological deterioration and reducing weight loss [27,28]. The effectiveness of a packaging material in extending the shelf life of a food material will depend on the property of the package [6]. Investigated the quality attributes of tomato fruits stored in different wrapping materials (polyethylene, grease free paper, newspaper). Tomatoes not wrapped served as the control. The samples were stored at ambient temperature of 32 ± 2°C. According to their report, all the packaging material prevented loss of weight significantly compared to the unwrapped tomato fruit. Furthermore, tomatoes packaged in polyethylene bags was reported to enhance better quality with longer shelf life of 28 days compared to other wrapping materials [6]. Other studies on tomatoes also found that weight loss in wrapped tomato was significantly decreased and fruits were more firm than non-wrapped tomatoes [27,28]. There are different packaging materials used in retail marketing of fresh tomato fruits. The properties of these packaging materials need to be evaluated to determine their suitability for individual cultivar of tomato.

Storage temperature: Temperature control is one of the important factors that can influence spoilage of fresh produce. Most fresh produce are reportedly stored using low temperature in order to satisfy the consumer requirement for high quality produce [29]. With the exception of produce susceptible to chilling injury, fresh produce temperature should be kept as low as possible from harvest till consumption. Previous studies found that the best storage temperature for delaying ripening of tomatoes fruit is 12.7ºC [30]. However, higher temperatures, up to 25ºC may be required when the fruits are ripe. The appropriate temperature required for the storage of freshly harvested tomato will vary with the tomato cultivar, type of packaging as well as pretreatments given prior to packaging. Hence, it is important to investigate the influence of retail packaging on the quality of tomato fruits.

Materials and chemicals

Fresh matured pink tomatoes as identified using a color chart (Figure 1) with uniform color and sizes and without bruises or signs of infection were collected from the Postharvest laboratory. The tomatoes were sorted, cleaned and packaged in open box, open market bag, Xtend bags and sealed box (Figure 2). Distilled water was used for cleaning purposes and calibration of equipment.

Green: Surface of tomato is completely green in colour.

Breakers: Definite break in colour from green to tannish yellow, pink or red on not more than 10% of the fruit surface.

Turning: More than 10%, but not more than 30% of the surface, in the aggregate shows a definite change in colour from green to tannish yellow, pink or red or a combination thereof.

Pink: More than 30%, but not more than 60% of the surface, in the aggregate shows a pink or red colour.

Light red: More than 60% but not more than 90% of the surface in the aggregate shows red or pinkish red.

Red: More than 90%, of the surface, in the aggregate shows a red colour.

Methods

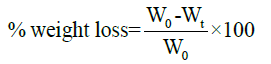

Weight loss: The individual weight of tomatoes used for the experiment was taken using a digital analytical balance. After weighing and performing other analysis on the fruits, the tomatoes were transferred to the storage room in different packaging materials. The weight loss was calculated as shown in Equation 1.

(1)

(1)

W0=Average weight of the tomatoes at day 0.

Wt=Average weight of the tomatoes after storage.

Firmness: Fruit firmness was determined using a hand pressure gauge by pressing the probe of the gauge against the fruits. The pressure gauge was applied around the circumference of the fruits on opposite sides. Firmness was determined using the scale 0-20 (very soft), 20-30 (soft), 30-40, (flexible), >50 (very firm).

Colour: Tristimulus L*, C* and h parameters of the tomatoes were determined using a colorimeter after calibration. Snapshots in triplicates were taken and values were read directly from a digital print.

Decay: Tomatoes were checked for decay by visualization before and after storage.

Calyx freshness: The freshness of the calyx was observed physically and graded as very fresh or less fresh with values ranging from 5 to 1 (1=very fresh, 2=fresh, 3=not fresh, 4=dry with some green, 5=dry.

Total Soluble Solids (TSS): The TSS of the tomatoes was determined using a digital refractometer after calibration using distilled water. Tomato fruits were cut with a sterile knife and the juice from the pulp squeezed out using gauze. The juice was placed on the surface of the refractometer and the value read directly from the instrument. The same procedure was repeated for the stored samples.

Storage: All the tomatoes in the primary packages were transferred into a secondary package (Figure 2), a box and stored at 4 or 17ºC for 12 days. Thereafter, the analyses described above were repeated to check for changes in quality.

Sensory evaluation: Tomato fruits were cleaned and sliced thinly and presented to taste panel members comprising of five panelists. The fruits were assessed for sweetness, sourness, off-flavour, texture and overall acceptability on a scale ranging from 1 to 5.

Physical damage

Tomato fruits used before the experiment had no bruises. However, after the storage period, some of the samples showed evidence of bruises. Some tomato fruits packed in open box and open market bag (stored at 17°C) and those packed in open market bag and sealed box (stored at 4°C) had bruises as shown in Figure 3. There were no bruises in any of the samples packed in open box (stored at 4°C) and those packed in Xtend bag (stored at 4°C).

Calyx freshness

The calyx of all the tomato fruits prior to storage were very fresh as observed using a scale of 1 (very fresh) to 5 (very dry). However, after packing and storage at different temperatures of 4 and 17°C, there were differences in their calyx freshness. Tomato fruits packed in open market bag (stored at 4°C) and Xtend bag (stored at 4°C) had values of 2 suggesting that they were fresh after storage (Figure 4). Samples packed in open box (stored at 17°C) and open box (stored at 4°C) were dry but still had some green (value of 4). However, tomato fruits packed in sealed box (stored at 4°C) had intermediate value of 3, which indicated that they were not fresh.

Physiological damage: There was no evidence of decay in the tomato fruits packaged in all the packaging materials used except the open market bag stored at 17°C (Figure 5).

Firmness: The average initial firmness of the tomato fruits was 43.25 N (Table 1). However, the firmness generally decreased after storage. Tomato fruits packed in Xtend bag (stored at 4ºC) were firmer (42.67 N) than samples packed in other packaging materials (32.56- 40.50 N). The reduction in firmness of the tomatoes occurred slowly at lower temperatures (4ºC) than at higher temperature (17°C), for the same period of storage (10 days).

| Treatment | Storage Temp. | Packaging | Weight loss (%) | Firmness (N) | TSS (°Brix) | |||

|---|---|---|---|---|---|---|---|---|

| D 0 | D 10 | D 0 | D 10 | D 0 | D 10 | |||

| 1 | 17 | Open box | 0.00 | 5.14 ± 0.99 | 43.25 ± 6.72 | 32.56 ± 5.82 | 3.90 ± 0.17 | 4.53 ± 0.23 |

| 2 | 17 | Open market bag | 0.00 | 1.02 ± 0.58 | 43.25 ± 6.72 | 34.44 ± 4.61 | 3.90 ± 0.17 | 4.11 ± 0.15 |

| 3 | 4 | Open box | 0.00 | 4.10 ± 1.10 | 43.25 ± 6.72 | 38.44 ± 3.72 | 3.90 ± 0.17 | 4.08 ± 0.25 |

| 4 | 4 | Open market bag | 0.00 | 0.60 ± 0.31 | 43.25 ± 6.72 | 39.17 ± 4.02 | 3.90 ± 0.17 | 4.05 ± 0.32 |

| 5 | 4 | Xtend bag | 0.00 | 0.64 ± 0.25 | 43.25 ± 6.72 | 42.67 ± 2.67 | 3.90 ± 0.17 | 3.99 ± 0.14 |

| 6 | 4 | Seal box | 0.00 | 0.51 ± 0.13 | 43.25 ± 6.72 | 40.50 ± 2.28 | 3.90 ± 0.17 | 4.01 ± 0.23 |

Table 1: Weight loss, firmness and total soluble solids of packaged tomato fruits stored at 4 or 17°C.

Weight loss

Tomato fruits packed in open box stored at 4 or 17°C showed higher weight loss than other samples (Table 1).

Total Soluble Solids (TSS)

The average TSS of the tomato fruits was 3.90°Brix (Table 1). TSS in all treatments increased after storage and varied from 3.99-4.53°Brix for tomatoes packed in Xtend bag (stored at 4°C) and tomatoes packed in open box (stored at 17°C) (Table 1). Tomatoes stored at 4°C had lower TSS values (3.99-4.08°Brix) compared to those stored at 17°C (4.11-4.53°Brix).

Gas composition

In order to understand the influence of respiration on changes in tomato quality, the gas compositions in Xtend bag (stored 4°C) and sealed box (stored 4°C) containing tomato fruits were determined. Other packaging materials were opened; hence, the gas compositions were not determined. The carbon dioxide (CO2) concentration in sealed box was substantially higher (8.25%) than that in Xtend bag (2.07%) (Figure 6). In contrast, the oxygen concentration in the Xtend bag was higher (18.90%) than that in the sealed box (14.75%).

Colour

Generally, the lightness (L*) and hue (H) angle values of tomatoes in different packaging materials at 4 and 17°C decreased after storage (Table 2). However, the Chroma (C*) values increased

| Treatment | Storage Temp. | Packaging | L* | C* | Hue angle | |||

|---|---|---|---|---|---|---|---|---|

| D 0 | D 10 | D 0 | D 10 | Day 0 | D 10 | |||

| 1 | 17 | Open box | 50.06 ± 1.96 | 46.10 ± 1.68 | 16.69 ± 2.59 | 19.47 ± 2.09 | 81.35 ± 10.25 | 36. 57 ± 7.29 |

| 2 | 17 | Open market bag | 50.55 ± 2.63 | 46.22 ± 2.10 | 18.01 ± 2.82 | 20.97 ± 1.91 | 80.24 ± 17.49 | 40.13 ± 7.62 |

| 3 | 4 | Open box | 50.4 ± 1.76 | 49.54 ± 2.13 | 17.56 ± 2.47 | 18.07 ± 2.42 | 85.95 ± 13.18 | 66.23 ± 10.85 |

| 4 | 4 | Open market bag | 49.66 ± 1.06 | 47.26 ± 1.04 | 15.85 ± 1.91 | 20.16 ± 2.41 | 83.32 ± 8.13 | 66.71 ± 6.53 |

| 5 | 4 | Xtend bag | 49.40 ± 1.28 | 49.39 ± 1.31 | 15.91 ± 2.53 | 16.29 ± 2.86 | 78.02 ± 16.70 | 60.33 ± 7.70 |

| 6 | 4 | Seal box | 50.04 ± 1.97 | 48.78 ± 2.87 | 15.40 ± 1.90 | 17.83 ± 2.39 | 71.93 ± 14.73 | 59.75 ± 8.35 |

Table 2: Colour changes of tomato fruits packaged in different packaging materials stored at 4 or 17°C.

Sensory evaluation

The tomato fruits were subjected to organoleptic assessment to ascertain the sweetness, sourness, off-flavour, texture and overall acceptability after storage. Tomato fruit packed in open box stored at (17°C) had higher rating for sweetness, while samples in sealed box (stored at 4°C) had the lowest rating (Table 3). The tomatoes packed in sealed box (stored at 4°C) were very sour compared to other treatments. All the treatments had similar ratings of 0 for off-flavour. Texture ratings for all the tomatoes stored at 17°C were softer than samples stored at 4°C. In the overall sensory evaluation, the rating for overall acceptability was not very different.

| Treatment | Storage Temp. | Packaging | Sweetness (1-5) | Sourness (1-5) | Off-flavour (0-3) | Texture (1-5) | Overall (1-5) | Preference |

|---|---|---|---|---|---|---|---|---|

| 1 | 17 | Open box | 4 | 2 | 0 | 1 | 4 | - |

| 2 | 17 | Open market bag | 3 | 1 | 0 | 2 | 3 | - |

| 3 | 4 | Open box | 3 | 3 | 0 | 4 | 3 | - |

| 4 | 4 | Open market bag | 3 | 2 | 0 | 4 | 3 | - |

| 5 | 4 | Xtend bag | 3 | 2 | 0 | 4 | 4 | - |

| 6 | 4 | Seal box | 2 | 5 | 0 | 4 | 3 | X |

| - | - | - | Very sweet-5 No sweet-1 | Very sour-5 No sour-1 | High off flavor-3 No off flavor-0 | Very firm-5 Soft-1 | Very good-5 bad-1 | X |

Table 3: Mean sensory scores of tomato fruits packaged in different packaging materials stored at 4 or 17°C.

Packaging can create modified gas atmospheres around the product which slows down the respiratory activity of fruits including tomatoes. Tomato is a climacteric fruit that is very perishable and requires adequate packaging and control of temperature to extend its shelf life. In this study, four retail packaging were used to pack tomato fruits and the packaging materials were stored at refrigeration (4°C) or ambient temperature (17°C). Generally, packaging material and storage temperature both influenced the quality of the tomato fruits. However, storage temperature contributed significantly to the maintenance of calyx freshness to some extent than did packaging materials. This seems plausible since the calyx of tomato fruits stored in open market bag (stored at 17°C) and open box (stored at 17°C) were very dry after storage compared to the tomato fruits stored at 4°C. Similarly, it was observed that temperature significantly influenced the extent of decay in the tomato fruits. Only tomato fruit stored in open market bag at 17°C showed evidence of decay. This possibly suggests the impact of temperature in reducing the growth of microorganisms during storage, since decay may be associated with the growth of microorganisms. The firmness of the tomato fruits were significantly affected by packaging material and temperature of storage (Table 1). Firmness is an important parameter used by the consumer to determine the final quality of tomato fruits. Tomato fruits packed in Xtend bag and sealed box were firmer than those packed in open box and open market bag. The lower firmness of tomato fruits packed in open box and open market bag may be attributed to two major factors. Firstly, these packaging materials are open and samples may lose water rapidly, leading to reduction in firmness. Another factor that could cause reduced firmness is the extent of tissue softening due to enzymatic degradation of pectic substances by pectinmethylesterase and polygalacturonase. According to Vu et al. [24], pectin degradation results in drastic changes in texture with an evident softening of the tomato tissues. These degradative enzymes are sensitive to oxygen. Thus, the availability of oxygen in the open box and open market bag may have enhanced the degradative process of pectin breakdown, leading to reduction in firmness. Furthermore, temperature also seems to play significant role in the reduction in the firmness of the tomato fruits. Irrespective of the packaging material, tomatoes stored at 4°C were firmer than those stored at 17°C (Table 1). This could be associated with the influence of temperature on the rate of reaction, suggesting higher water loss and higher enzyme activity at elevated temperature [22], used that Arrhenius model to describe the effect of temperature on changes in firmness and weight loss of stored tomato fruits. Previous research also associated higher weight loss in stored tomato at room temperature to increased transpiration rate [31,32].

In order to understand the influence of respiration on changes in tomato quality, the gas compositions in Xtend bag (stored 4°C) and sealed box (stored 4°C) containing tomato fruits were determined. Other packaging materials were opened; hence, the gas compositions were not determined. The carbon dioxide (CO2) concentration in sealed box was substantially higher (8.25%) than that in Xtend bag (2.07%) (Figure 6). In contrast, the oxygen (O2) concentration in the Xtend bag was higher (18.90%) than that in the sealed box (14.75%). Fresh commodities are living tissue which continue to use up available O2 for respiration after harvest. Thus, the lower CO2 with corresponding higher O2 in the Xtend bag suggest that the Xtend bag is capable of reducing the rate of respiration in tomato fruits and thus extend it shelf life. Changes in colour of tomatoes during storage were minimal in Xtend bag compared to other packaging materials (Table 3). The results suggest that Xtend bag is capable of controlling the exchange gases to maintain the quality of tomato fruits, especially at low temperature. Tomatoes packed in Xtend bag and sealed box were firmer (Table 1) and had minimal changes in colour intensity (C*) (Table 2) compared to tomato fruits packed in other packaging materials. The colour result correlates with the TTS result of the tomato fruits. TSS is one of the quality indices used to assess the sweetness in tomatoes. It appeared that the Xtend bag and sealed box were able to delay the ripening process during storage since the tomatoes packed in these packaging materials showed lower TSS values (Table 1) and minimal changes in colour intensity (C*) (Table 3) compared to tomato fruits packed in other packaging materials.

Packaging material type and storage temperature both significantly influenced the calyx freshness, colour, firmness and sensory quality of tomato fruits. Tomato stored at low temperatures of 4°C generally had better firmness, colour and calyx freshness than those stored at room temperature (17°C). Among the packaging materials, Xtend bag and sealed box seems to be better packaging material for storing tomato fruits for a period of 10 days.

Tomato fruit may be stored using Xtend bag or sealed box at 4°C for up to 10 days without significant changes in quality, since these conditions retained fruit firmness, delay fruit ripening and had no signs of decay during storage. Future studies using these packaging materials should focus on extended storage period up to one month to evaluate the possible occurrence of physiological changes such as chilling injury and changes in lycopene and ascorbic acid contents. Weight loss, decay and rapid deterioration are major factors that determine the storage conditions of tomato fruits.