Journal of Nutrition & Food Sciences

Open Access

ISSN: 2155-9600

ISSN: 2155-9600

Research Article - (2023)Volume 13, Issue 5

Mung bean (Vigna radiata L.) is a leguminous pulse crop for its use as a vegetable protein source and animal fodder. In Ethiopia, mung bean was recently introduced in Ethiopian pulse production and market system. In this study, the effect of different traditional processing methods, such as boiling, dehulling and germination on the proximate composition and mineral content of two mung bean varieties were investigated. Raw flour of Sho'a Robit variety had a protein content of 22.77% while N-26% had 25.77% respectively. Both varieties also have shown to contain high potassium and calcium content. Germination and boiling caused significant decrease (P<0.05) in crude fat content, total ash and minerals for both varieties while dehulling process significantly increased (P<0.05) the crude protein for Sho'a Robit and no significant difference (P>0.05) was observed for N-26. Significantly higher protein content was observed in germinated seed flour of both mung bean varieties (28.24% for Sho’a Robit and 29.44% for N-26 respectively) as compared to the protein content of raw. N-26 variety was determined to have significantly higher (P<0.05) proximate composition than that of Sho'a Robit variety in its raw and all its processed forms. The mineral composition of both of the raw mung bean varieties were significantly higher than the dehulled and boiled flours. In conclusion, mung beans had a considerable amount of nutritional composition and the traditional processing methods applied were shown to have an effect on both the proximate and mineral content of the beans where germination was identified to be the most appropriate technique to enhance the protein content and also retain the mineral content.

Mung bean; Traditional processing; Proximate composition; Mineral content

Legumes are good and inexpensive source of dietary proteins, carbohydrates, vitamins and minerals. They play an important role in the world food and nutrition requirements, especially in the dietary pattern of low-income group of people in developing countries. Legumes are an important source of affordable alternative protein to poor resource people in many tropical countries especially in Africa and Asia where they are predominantly consumed. That is why they are considered as ‘resource poor meat'. Whole or ground legume varieties commonly eaten in the semi-arid tropical regions of South America, Africa, the Middle East and Asia. In many regions of the world, legume seeds are the unique protein supply in the diet [1]. They contain almost 2 to 3 times more protein than cereals. Because of their high protein and lysine content, they also represent good sources of supplementary protein when added to cereal grains and root crops, which are low in essential amino acids. Legumes have been cultivated and consumed in large quantities in Ethiopia for many years, gifted with varied agro ecological zones and diversified natural resources; have been known as the home land and domestication of several crop plants [2].

Among the important legume crops, mung bean (Vigna radiata) is widely cultivated in Asia. This crop is native to the Indo- Burma region with India, Burma, Thailand and Indonesia producing almost 90 percent of the world's production. It has green skin and called green bean. The mung bean also called mung, moong and green gram in India and mungo in the Philippines. The crops are utilized in several ways, where seeds, sprouts and young pods are consumed as sources of protein, amino acids, vitamins and minerals and plant parts are used as fodder and green manure. Mung bean protein is easily digested without flatulence. It is an important protein source for people in the cereal-based society. Mung bean is very early maturing crop, which is also drought resistant requires a warm climate during its growing period and it has great potential for the semiarid areas due to its short growing cycle. It is currently growing in different parts of the world and it has large role in nutrition at developing countries [3].

To alleviate protein energy malnutrition and product diversification, greater attentions have been paid to the exploitation of legume beans launched from agricultural research centers in Ethiopia. In line with this, mung bean was recently introduced in Ethiopian pulse production as a market crop and it is grown in few districts of the country (North Showa, Showa Robit and Benishangul Gumuz); hence, its home processing and consumption scheme is not widely known like other pulses grown in the country (Ethiopian export promotion agency, 2004) [4]. Traditionally, local communities in Ethiopia consume legumes after applying different processing techniques. The combination of these attracted the interests of different scholars to work on the crop. This study was therefore to determine the nutritional composition of mung bean and to investigate the effect of the different traditional processing techniques (boiling, germination and dehulling) on the proximate and mineral content of mung bean grown in Ethiopia. The findingswas also aimed to introduce such legumes as an alternative daily staple to address the protein energy malnutrition and to recommend proper processing techniques [5].

Materials

Reagents and chemicals: The chemicals used for this experimental study were distilled water, ethanol, tap water, analytical grade Hydrochloric acid (HCl), Potassium Hydroxide (KOH), Sulfuric acid (H2SO4), Nitric acid (HNO3) and Perchloric acid (HClO4).

Apparatus and equipments: The apparatus and equipment’s used for this experiment include Soxhlet fat extraction apparatus, Kjeldahl protein analyzer, Air-dry oven, electric stove, 60 mesh size sieve, miller, analytical balance, Atomic Absorption Spectrophotometer (AAS), flame Photometer, beakers of different size, plastic sample bottles, wash bottle, thick cotton cloth and Different size bowls.

Sample collection

The two varieties of the mung bean ((Sho’a Robit and N-26) under this study was collected from Ethiopian agricultural research institute, Melkasa agricultural research center. The beans were the only varieties released from the research center that represent the mung bean varieties cultivated in Ethiopia. The sample was packed in polyethylene bags and transported to Wollega university food technology and process engineering laboratory and stored in cool dry storage until sample preparation and analysis (Figures 1 and 2).

Figure 1: N-26 variety.

Figure 2: Sho'a Robit variety.

Sample preparation

Sample preparation was taken place at food technology and process engineering department laboratory of Wollega university.

First mung bean samples were cleaned by hand to remove foreign matters and were sorted and visually inspected in order to remove contrasting color, damaged, immature/ underdeveloped, insect bored beans, debris and all extraneous materials. Then it was cleaned by washing with tap water and divided into four equal portions for the different treatments, raw (control), dehulling, boiling and for germination [6].

Dehulling: The portion for dehulling purpose was soaked in distilled water (1:10, w/v) for 12 hours at room temperature (25°C) according to the procedure followed by El-Beltagy and Mubarak after which the hulls of both mung bean varieties were removed manually. The seeds were dried in an electric air-dry oven at 50°C for 20 hours according to the procedure followed by Mubarak.

Boiling: Mung bean seeds were soaked in distilled water (1:10, w/v) for 12 hours at room temperature (~25°C). The soaked seeds were drained and rinsed three times with 600 mL distilled water. The soaked and rinsed seeds were boiled in tap water (100°C) in the ratio of 1:10 (w/v) on a hot plate until they became soft when felt between the fingers (90 min) as per the procedure of Mubarak. The boiled seeds were dried in an electric air-dry oven at 50°C for 20 hours.

Germination: Germination process of the mung beans were conducted using germination procedure followed by Mubarak. The seeds were sterilized by soaking in ethanol for 1 minute to minimize the microbial contamination that could occur during germination. The seeds were then soaked in distilled water (1:10, w/ v) for 12 hours at room temperature (25°C), then kept between thick layers of cotton cloth and allowed to germinate in the dark for three days. Germinated seeds were frozen for 12 hours to stop the germination process. After thawing at room temperature, the seeds were dried in an electric air-dry oven at 50°C for 20 hours.

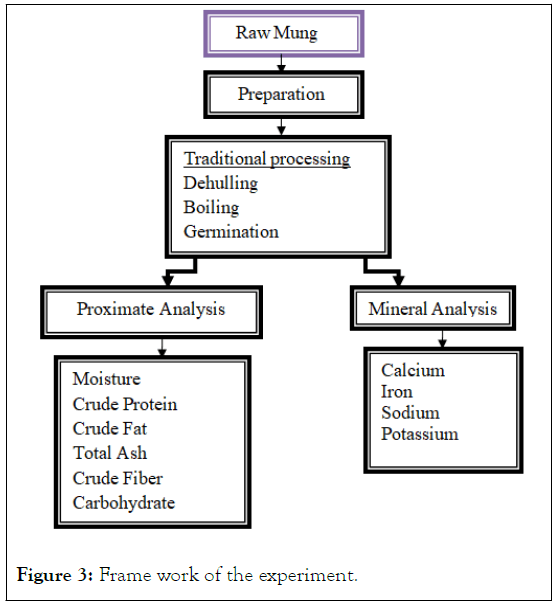

In general, the raw and all processed mung beans were ground in an electric mill (Braun, Model 1021, and Germany) and passed through a 60-mesh sieve to get uniform and conditioned flours that eases extraction of components for analysis (Figure 3).

Figure 3: Frame work of the experiment.

Experimentation

Analyses of the conditioned mung bean flours were conducted at Ethiopian Public Health Institute (EPHI). Proximate compositions (crude protein, crude fat, crude ash and crude fibre) and minerals (sodium, calcium, iron and potassium) of the raw and processed flours were the investigated parameters in this study. The experimental design were simple factorial design with four levels for (treatments/ processing methods) and two levels (for the two varieties) [7].

Proximate analysis

The proximate analysis of the flour samples for moisture, protein, fat, fiber, total carbohydrate, ash and energy content were determined in triplicate according to methods of the Association of Official Analytical Chemists (AOAC, 2000). Nitrogen was determined by micro-Kjeldahl method and the percentage nitrogen was converted into crude protein by multiplying by 6.25. The utilizable carbohydrate content was determined by difference (AOAC, 2000). All the chemicals used were of analytical grade.

Mineral analysis

Minerals were determined after wet-ashing by concentrated nitric acid and perchloric acid (1:1, v/v). Calcium, iron, sodium and potassium were determined by Flame Atomic Absorption Spectrometer (FAAS) (Varian Spectr AA. 20 plus), while Potassium (K) and Sodium (Na) were analyzed by flame photometer. The calibration solutions and the reagent blank solution were measured according to the instructions of the instrument and manufacturer. All determinations were done in duplicate and the minerals were reported in mg 100 g-1 sample.

Statistical analysis

Results were expressed as the mean values of triplicate determinations for proximate composition and mineral contents were determined in duplicate. Then the results were subjected to statistical analysis using one way analysis variance (One way ANOVA) using SPSS version 20. Significant differences were determined at the P<0.05 levels. Tukey‘s studentized, LSD or Duncan‘s multiple range test was used to check which means are significantly different (for multiple comparison).

Effect of the traditional processing on the proximate composition of mung beans

Protein: The proximate composition of raw and differentially processed mung bean samples were presented in Table1. The protein content of raw, boiled, dehulled and germinated seeds of Sho'a Robit variety was determined to be 22.77 g/100 g, 22.00 g/100 g, 23.42 g/100 g and 28.24 g/100 g while that of N-26 variety was determined to be 25.77 g/100 g, 25.17 g/100 g, 25.92 g/100g and 29.44 g/100 g respectively. The lower crude protein content was observed in raw Sho'a Robit (22.77 g/100 g) and the highest protein contents was observed in germinated seeds of N-26 (29.44 g/100 g). Germination of the two mung bean varieties significantly increased (P<0.05) the crude protein content by 24.02 % and 14. 24% respectively. Several other workers also observed increased protein content after germination of legumes. Gregory reported that the protein content of mung bean was increased for the sprouted seeds. The increase in protein content during germination process could be attributed to the activation of metabolic enzymes such as proteinases thereby release some amino acids and peptides that are used to synthesis and form new proteins [8].

Boiling process has significantly decreased (p<0.05) the crude protein contents of both the mung bean verities. This is in consensus with the reports of Komolafe and Obayanju that protein contents reduced after boiling in Odu (Solanum nigrum) and worowo (Solanecio biafrae). This finding was also concurrent with the works of mubarak and blessing and gregory that the protien content of mung beans was decreased after boiling treatment. During boiling cellular protein are denatured and the chlorophyll which are bound to protein may be released. The dehulling process has significantly increased (P<0.05) the protein content of Showa Robit but no significant difference was observed for N-26. This was in agreement with the findings of Nti who reported that dehulling increased the protein content of bambara products. The present finding was in opposite to the report by that dehulling of pulses resulted in a decrease in their protein content. This increase and decrease in protein content is associated with seed coat content of legumes [9].

Fat: The crude fat content of raw, boiled, dehulled and germinated seeds of Sho'a Robit variety was determined to be 1.83 g/100 g, 1.24 g/100 g, 1.39 g/100 g and 0.89 g/100 g while that of N-26 variety was determined to be 2.38 g/100 g, 1.33 g/100 g, 1.61 g/100 g and 1.03 g/100 g respectively (Table 1). Germination process has significantly decreased (P<0.05) the crude fat content of Showa Robit and N-26 by 27.32% and 56.72% respectively. This result was in agreement with the report on mung bean and that of on lentls, green gram and chickpea. The lowest fat content was exhibited by geminated mung bean of Sho'a Robit variety (0.89 g/100 g). Also reported the lowest fat content of different varieties of germinated mung bean seeds to be 0.99% [10]. These significant decreases in fat content of mung beans show that the fat was used as energy source for sprouting of germination process. The dehulling process significantly reduced the crude fat content for both varieties by 24.04% and 32.35% for Sho'a Robit and N-26 respectively as compared to the raw seed. In contrast to this, Oburuoga and Anyika reported that no significant difference between the crude fat content of raw and dehulled mung beans. Mubarak has also reported a comparable value for crude fat in raw mung bean and dehulled mung bean. The boiling process has significantly decreased (P<0.05) the crude fat content of both N-26 and Showa Robit mung bean varieties. This finding was in agreement with the reports of Blessing and Gregory that the crude fat content of mung bean significantly decreased from 1.93% to 0.53% by boiling treatment. It was also in corresponding to the findings of other workers for Lablab seed, Bengal gram and Indian bean respectively. These reduction in the fat content of boiled mung beans could be attributed to the leaching (diffusion) of fat into boiling water.

Ash: The total ash content of raw, boiled, dehulled and germinated seeds of Sho'a Robit variety was determined to be 4.76 g/100 g, 2.32 g/100 g, 4.31 g/100 g and 4.32 g/100 g while that of N-26 variety was determined to be 4.22 g/100 g, 3.42 g/100 g, 3.82 g/100 g and 3.97 g/100 g respectively (Table 1). The germination process applied have significantly decreased (P<0.05) the total ash content of both mung bean varieties under the study. This result agreed with the reports of Torres that germination process decreased the ash contents of Pigeon Pea. On the contrary, Oloyo reported that germination of Pigeon Pea significantly increased the ash content. Dehulling process has significantly decreased (p<0.05) the total ash contents of both mung bean verities. This was in accordance with the reports by Mubarak and blessing and gregory that showed dehulled mung beans seeds reduced the ash contents. The boiling process has significantly decreased (P<0.05) the ash content of both varieties. This is in agreement with the reports of Blessing and Gregory, that boiling treatments of undehulled mung beans reduced the ash contents compared to raw seeds. The different processing techniques employed in this study has decreased the total ash content in this order as compared to the raw: Boiling>dehulling>germination. The decrease in ash content might be due to the loss of minerals during the processing employed. It might be due to the leaching of both micro and macro elements into the water through the mechanically broken and enhanced permeability of seed coats when compared to the unprocessed seed sample.

Crude fiber: The crude fiber content of raw, boiled, dehulled and germinated seeds of Sho'a Robit variety was determined to be 5.54 g/100 g, 4.18 g/100 g, 1.19 g/100 g and 3.82 g/100 g while that of N-26 variety was determined to be 3.99 g/100 g, 4.04 g/100 g, 3.98 g/100 g and 3.93 g/100 g respectively (Table 1). The germination process employed has significantly decreased (P<0.05) the crude fiber content for the Sho'a Robit variety as compared to the raw while there was a reduction but no significance difference for that of N-26 variety. The reduction in crude fiber content of germinated mung bean were in agreement with the reports of Mubarak. But in opposite to this, Blessing and Gregory have shown that the crude fiber content of germinated seed of different mung beans were increased. The dehulling process applied has significantly decreased (P<0.05) the crude fiber content of the Sho'a Robit variety whereas there observed a general reduction but no significant difference (P>0.05) for that of N-26 variety as compared to the raw. The present finding was in agreement with the work of Oburuoga and Anyika, that it was reported a crude fiber reduction by dehulling process of mung beans. The decrease in crude fiber content of dehulled mung bean might be due to its higher concentration in outer cover than the inner or endosperm. Abiodun and Adepeju also discussed that fiber contents decreased drastically in the dehulled Bambara Nut (Vigna subterranea L. Verdc) flour due to the removal of the seed coat. The boiling process applied in this study has significantly decreased (P<0.05) for the variety Sho'a Robit, while there observed no significance difference for that of N-26 as compared to the raw. The decrease in crude fiber content of boiled Showa Robit variety was in concurrent with the report by Hamid, et al. on mung bean seeds. On the contrary to this, Blessing and Gregory reported that boiling mung bean samples significantly increased the crude fiber content. These differences could be attributed to the type of mung bean varieties studied [11].

Utilizable carbohydrate: The utilizable carbohydrate content of raw, boiled, dehulled and germinated seeds of Sho'a Robit variety calculated by difference was determined to be 61.63 g/100 g, 66.22 g/100 g, 62.48 g/100 g and 57.24 g/100 g while that of N-26 variety was determined to be 57.92 g/100g, 60.03 g/100 g, 60.22 g/100 g and 56.43 g/100 g respectively (Table 1). Germination process has significantly decreased (P<0.05) the total carbohydrate contents of both the studied mung bean varieties that was in agreement with the report of Oloyo who stated that germination of red gram (Cajanus cajan) deceased total carbohydrate content and the decrease continued with the course of the germination time. Mubarak also showed that germinating resulted reduction in the carbohydrate content of mung bean. This decrease in total carbohydrate during the germination process could be attributed to the use of carbohydrates as energy source for sprouting of the germination process. The dehulling process has significantly increased (p<0.05) the total carbohydrate contents of both the mung bean varieties, which is in agreement with the findings of Mubarak and Agugo and Onimawo who had reported an increase in total carbohydrate content by dehulling process of mung beans. Boiling process has significantly increased (p<0.05) the total carbohydrate contents of both the mung bean varieties. These results were in agreement with the reports by Mubarak. The increase in the total carbohydrate contents might be due to the heat involved which reduced the other components as a result of denaturation and leaching, leading to an increase in carbohydrate content (Table 1).

| Processing method | Moisture | Crude protein | Crude fat | Total ash | Crude fiber | Utilizable carbohydrates | Energy (Kcal) | |

|---|---|---|---|---|---|---|---|---|

| Sho'a Robit | Raw | 8.96 ± 0.05e | 22.77 ± 0.13f | 1.83 ± 0.07b | 4.76 ± 0.02a | 5.54 ± 0.16a | 56.09 ± 0.16c | 331.91 |

| Boiled | 8.17 ± 0.05g | 22.00 ± 0.15g | 1.24 ± 0.05e | 2.32 ± 0.02g | 4.18 ± 0.22b | 62.04 ± 0.21a | 347.32 | |

| Dehulled | 8.35 ± 0.04f | 23.42 ± 0.13e | 1.39 ± 0.09d | 4.31 ± 0.04b | 1.19 ± 0.00e | 61.29 ± 0.15b | 351.35 | |

| Germinated | 9.31 ± 0.08c | 28.24 ± 0.03b | 0.89 ± 0.07g | 4.32 ± 0.02b | 3.82 ± 0.13d | 53.42 ± 0.08f | 334.65 | |

| N-26 | Raw | 9.73 ± 0.09b | 25.77 ± 0.06c | 2.38 ± 0.14a | 4.22 ± 0.01c | 3.99 ± 0.07cd | 53.93 ± 0.26e | 340.22 |

| Boiled | 10.04 ± 0.03a | 25.17 ± 0.07d | 1.33 ± 0.07de | 3.42 ± 0.03f | 4.04 ± 0.01bc | 55.99 ± 0.10d | 336.61 | |

| Dehulled | 8.43 ± 0.10f | 25.92 ± 0.08c | 1.61 ± 0.05c | 3.82 ± 0.03e | 3.98 ± 0.05cd | 56.24 ± 0.19d | 343.13 | |

| Germinated | 9.15 ± 0.06d | 29.44 ± 0.17a | 1.03 ± 0.03f | 3.97 ± 0.01d | 3.93 ± 0.07cd | 52.50 ± 0.16g | 337.03 |

Note: All values are mean ± SD. Means within same column not followed by the same letters are significantly different (P<0.05).

Table 1: Proximate composition (g/100 g dry bases) of raw and processed mung bean varieties.

Gross energy: The gross energy value of raw Sho'a Robit variety flour was calculated to be 331.91 Kcal/100 g while that of N-26 was calculated to be 340.22 Kcal/100 g respectively (Table 1). The gross energy values were identified to be affected by the different processing methods applied. Changes in gross energy values of both raw and processed mung beans reflected the changes in the observed values of other proximate composition discussed.

Effect of the traditional processing on mineral composition of mung beans

Calcium: The calcium content of raw, boiled, dehulled and germinated seeds of Sho'a Robit variety was determined to be 32.23 mg/100 g, 21.49 mg/100 g, 30.98 mg/100 g and 33.19 mg/100 g while that of N-26 variety was determined to be 36.84 mg/100 g, 16.23 mg/100 g, 26.09 mg/100 g and 37.61 mg/100 g respectively. Germination process has significantly increased (P<0.05) the calcium content of both the Sho'a Robit mung and N-26 bean varieties. This result agree with the work of Khalil that the calcium content of guar and faba bean's were increased by germination process. The dehulling process has significantly decreased (P<0.05) the calcium of both the mung bean varieties. This result was in concurrent with the work of Siddhuraju, et al. that reported a sweeping decrease of calcium levels in dehulled white variety of Marthandam, white variety of Salem and black variety of Marthandam germplasm. Another work by Abiodun and Adepeju also reported dehulling process significantly reduced the calcium content of the bambara flour. The decrease in calcium content after dehulling of legumes may be due to removal of the seed testa. The calcium content of both varieties under the study was also significantly decreased (P<0.05) by the boiling process applied which was in consensus with the works of Abiodun and Adepeju on bambara flour. Decrease in calcium content by the boiling process might be due to leaching of some components into the boiling water [12].

Iron: The iron content of raw, boiled, dehulled and germinated seeds of Sho'a Robit variety was determined to be 5.10 mg/100 g, 3.33 mg/100 g, 4.30 mg/100 g and 5.22 mg/100 g while that of N-26 variety was determined to be 7.10 mg/100 g, 3.41 mg/100 g, 3.87 mg/100 g and 4.55 mg/100 g respectively (Table 2). The germination process has significantly decreased (P<0.05) the iron content of N-26 variety but no significant difference between the germinated flour and raw flour for that of Sho'a Robit variety. The increase in iron contents of germinated mung bean seeds as compared to the raw agrees with the reports of Mubarak. Dehulling and the boiling process has significantly decreased (P<0.05) the iron content for both varieties of the mung bean under the study. The decrease in the iron content during the boiling process might be attributed to the leaching out into the boiling water as also pointed by El-Adawy and Mubarak [13].

Sodium: The sodium content of raw, boiled, dehulled and germinated seeds of Sho'a Robit variety was determined to be 12.08 mg/100 g, 1.92 mg/100 g, 7.95 mg/100 g and 10.63 mg/100 g while that of N-26 variety was determined to be 17.51 mg/100 g, 2.26 mg/100 g, 6.45 mg/100 g and 7.39mg/100g respectively (Table 2). All the processing techniques applied have significantly decreased (P<0.05) the sodium content of both Sho'a Robit and N-26 varieties. The order of the decrease in the sodium content of the mung beans as compared to the raw was: Boiling>dehulling>germination. Audu and Aremu reported that germination reduced sodium contents of red kidney bean (Phaseolus vulgaris L.) flour compared with the raw sample which was similar to the present finding. Abiodun and Adepeju also reported that dehulling process has reduced the sodium content of bambara flour and it was pointed that the decrease during dehulling might be due to the removal of the hull [14]. Mansour and El-Adawy reported the significant reduction in sodium content of fenugreek seeds after the boiling process. Mubarak discussed that the decrease in the mineral including sodium contents of legumes during boiling process could be attributed to the leaching of the minerals into the boiling water and the higher solubility at increased boiling temperature.

Potassium: The potassium content of raw, boiled, dehulled and germinated seeds of Sho'a Robit variety was determined to be 1312.55 mg/100 g, 562.50 mg/100 g, 1229.27 mg/100 g and 1249.99 mg/100 g while that of N-26 variety was determined to be 1249.99 mg/100 g, 750.00 mg/100 g, 1104.28 mg/100 g and 1166.79 mg/100 g respectively (Table 2). Potassium was the most abundant element in both mung bean varieties but it was significantly (P<0.05) by all the processing methods applied in this study. The present finding was in the contrary to previous report by Mubarak and Khalil that germination process had reported to increase the potassium content of mung bean and faba bean seeds respectively [15]. Another researcher, Abiodun and Adepeju had reported that dehulling process has decreased the potassium content of dehulled bambara nuts which is in agreement with the present finding. It was also pointed that the decrease in mineral content could be attributed to the removal of the seed coats. Similar to the present finding, Abiodun and Adepeju had reported that the potassium content of dehulled bambara nuts was significantly decreased by boiling process when compared to the raw. Haytowitz and Matthews also reported that cooking in boiling water caused a great loss of potassium for legumes (Table 2).

| Variety | Treatment | Ca | Fe | Na | K |

|---|---|---|---|---|---|

| Sho'a Robit | Raw | 32.234 ± 0.98d | 5.098 ± 0.00b | 12.077 ± 0.18b | 1312.553 ±0.75a |

| Boiled | 21.493 ± 0.06g | 3.336 ± 0.11f | 1.917 ± 0.23g | 562.498 ± 0.03g | |

| Dehulled | 30.976 ± 1.07e | 4.297 ± 0.01d | 7.947 ± 0.75d | 1229.270 ± 1.46c | |

| Germinated | 33.187 ± 0.78c | 5.219 ± 1.77b | 10.632 ± 0.50c | 1249.988 ± 0.17b | |

| N-26 | Raw | 36.839 ± 0.37b | 7.064 ±1.00a | 17.513 ± 0.18a | 1249.998 ± 0.02b |

| Boiled | 16.235 ± 0.49h | 3.415 ± 0.16f | 2.259 ± 0.91g | 750.00 ± 0.00f | |

| Dehulled | 26.089 ± 0.54f | 3.871 ± 0.46e | 6.446 ± 0.72f | 1104.278 ± 1.57e | |

| Germinated | 37.614 ± 0.77a | 4.546 ± 1.21c | 7.395 ± 0.88e | 1166.792 ± 1.76d |

Note: All values are means ± SD. Means within same column followed by the same letters are not significantly different (P>0.05).

Table 2: Mean mineral contents of raw and processed mung bean varieties (mg/100 g).

The result indicated that both mung bean varieties (Sho'a Robit N-26 and) had good nutritional profile with higher amount of protein and carbohydrate. They were also determined to be a good source of important minerals like potassium and calcium. The traditional processing methods applied had shown an effect on the proximate composition and mineral content of the beans. Significantly higher protein content was observed in germinated seed flours of both mung bean varieties as compared to the raw flours. The mineral composition of both of the raw mung bean varieties were significantly higher than the dehulled and boiled flours while the minerals were relatively retained by the germination process and even an increase in calcium content of both varieties was observed by germination. N-26 variety was determined to have significantly higher (P<0.05) proximate composition than that of Sho'a Robit variety in its raw and all its processed forms. Generally the mung beans had a considerable amount of nutritional composition and have good potential as a cheap and alternate source of important nutrients and could be utilized to improve food and nutrition security. Of the processing methods applied, germination was identified to enhance the protein and calcium content of the mung beans and hence such economic and potential processing methods could be recommended for the versatile utilization of the mung beans. It was also recommended to popularize the production and consumption of both mung varieties particularly the N-26 in other parts of the country.

The authors are grateful to the department of food technology and process engineering, Wollega university and Ethiopian Public Health Research Institute (EPHI), Ethiopia; to show their good will to use their laboratory facilities. We are very grateful to the technical assistance provided to us during the laboratory analysis.

[Crossref] [Google Scholar] [PubMed]

Citation: Tural DC, Isho AA, Yetneberk S, Kebede A (2023) Effect of Traditional Processing Methods on Proximate Composition and Mineral Content of Mung Beans (Vigna radiata L.) Grown in Ethiopia. J Nutr Food Sci. 13: 046.

Received: 08-Jul-2019, Manuscript No. JNFS-23-213; Editor assigned: 11-Jul-2019, Pre QC No. JNFS-23-213 (PQ); Reviewed: 26-Jul-2019, QC No. JNFS-23-213; Revised: 01-Nov-2023, Manuscript No. JNFS-23-213 (R); Published: 21-Nov-2023 , DOI: 10.35248/2155-9600.23.13.046

Copyright: © 2023 Tura DC, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.