Advances in dairy Research

Open Access

ISSN: 2329-888X

ISSN: 2329-888X

Research Article - (2019)Volume 7, Issue 4

The aim is to investigate the effect of salting technique together with type of pre-acidification used acid on shreddability, texture profile and microstructure of the full fat cow’s Mozzarella cheese. Mozzarella cheeses were made conventionally from standardized full fat cow’s milk; pre-acidified with either citric, lactic or acetic acid drop-wise to pH of 6.3, using 2.5% activated Yoghurt starter culture and rennet (1.5 g/100 Kg). The milled curds were salted either by the brining technique or by dry salting. The obtained results indicated that, the brine salted cheeses were associated with significant increments in the values of dry matter, protein, fat, calcium, cohesiveness, springiness and adhesiveness. While the application of dry salting led to increase the values of ash, lactose, salt, sodium, hardness, cohesiveness, gumminess and shredding efficiency. Moreover, the microstructure of the brine salted cheeses was more porous, whereas the dry salted cheeses appeared with more homogeneous and continuous protein matrix as well as less pockets. The lactic pre-acidified cheeses were the most shreddable cheeses and distinguished with the highest dry matter, protein, ash, sodium, pH, hardness and cohesiveness, as well as reflected the densest protein network with narrow fat voids. The application of acetic acid was associated with significant increments in the values of fat, lactose, springiness and adhesiveness. Moreover, the citric pre-acidified cheese showed a combination of many larger channels and smaller pores giving an increased porous structure with more sharpened protein fibers.

Shredding efficiency; TPA; Salting technique; Pre-acidification

The consumption and demand of Mozzarella cheese in the form of Pizza toppings, salads, cheese blends have increased in the recent years due to dietary likeness, ease and flexibility in use. The functional properties of Mozzarella cheese are the ability to shred easily, melt rapidly, and reflect acceptable stretching, oiling-off and browning upon baking [1]. NaCl salt, starter cultures and acids are key ingredients in the manufacture of Mozzarella cheese and affect its functionality. Salting occurs eitherby brining or with dry salting.

Ramanauskas and Pesetskas [2] reported that salt acts as a regulator in the production of free amino acids and volatile fatty acids. Moreover, salt affects water distribution and the extent of proteolysis in cheese [3]. It was concluded by many researches that brine salting was better for some cheeses than dry salting. The salt distribution in cheese affects the concentration of sodium ions and thus has a great impact on the ionic balance among several cations within the cheese matrix. The exchange of calcium with sodium ions has an indirect effect on emulsification of fat [4]. On the other hand, the lower the acidification pH, the higher were the calcium losses, and the amount of calcium kept in the cheeses was affected by the type of acid used for acidification [5]. Pre-acidification of cheese milk is beneficial for removal of calcium, thereby helping to achieve a softer curd, which melts and stretches easily. Pre-acidification of milk to pH 6.3 was shown to produce a rubbery and less cohesive Mozzarella cheese while at very low pH of direct acidification there was an increase in bitterness perceived upon sensory evaluation of the cheeses, moreover reaching cohesive and tacky curd [6]. Shreddability is defined as a cheese’s ability to cut cleanly into long thin uniform strips, have low susceptibility to form curd fines, and resist sticking, matting or clumping when loosely packed; it is influenced by cheese composition and rheological properties [7]. Nevertheless, that key functional property was not studied directly before for Mozzarella type curd.

For that in view the present study was conducted to investigate the effect of salting method together with type of pre-acidification acid on shreddability, texture profile and microstructure of full fat cow’s Mozzarella cheese.

Fresh cow’s milk was obtained from the herd of the armed forces farms in Cairo-Ismailia desert road, (total solids 12.61 ± 1.32%, 4.00 ± 0.21% fat, 3.21 ± 0.12% protein and pH 6.8 ± 0.1). Concentrated lyophilized mixed yoghurt starter culture (YC-183) contains Str. thermophilus and Lb. delbrueckii ssp. bulgaricus, 1:1, was obtained from Chr. Hansen Lab., Denmark. Anhydrous citric acid (99% purity) was obtained from Guangzhou Rikewei Chemical Co., Ltd., China. Food grade L-lactic and acetic acids were obtained from BBCA Glactic (B&G) Co., Ltd., Road, Bengbu, Anhui,China. Sodium chloride (NaCl) was obtained from El- Nasr for Salt Production Co. Egypt. Dried microbial rennet was obtained from MAYSA GIDA San ve Tic. A.S., Tuzla Kimya Sanayicileri Organize Sanayi Bolgesi Melek Aras Bulvari No: 54 TUZLA, Istanbul, 34956, Turkey.

Experimental procedure

Manufacturing procedure of Mozzarella cheeses: Standardized cow’s milk (3% fat) was heattreated at 75°C for 2 min, the pasteurized milk was then cooled to 30°C, sent to the cheese vats, pre-acidified with either acetic, citric or lactic acid drop-wise to lower the milk pH to 6.3 (for the pre-acidified cheese treatments), and inoculated with 2.5% (w/v) activated YC starter culture. After 30 min, the rennet was introduced at rate of 1.5 g/100 Kg milk (the powdered rennet was diluted 40 times in d.H2O prior addition). Curd was allowed to set in 25-30 min, cut and allowed to heal for 10 min, cooked in whey at 40°C/20 min, cooled to 35°C and then curd was collected and whey was drained at the pH of 6.0-6.1. Curd was piled into slabs and the slabs were turned every 15 min with continuous whey drainage. Curd was milled at pH 5.3 - 5.4, salted at 2%(w/w) of curd weight, held for 20 min and stretched in 75°C water containing 4% salt for 5 - 10 min (if dry salted) or directly after milling the curd was dipped into hot water at 75°C and stretched for 5-10 min, followed by dipping in 20% NaCl solution at 4°C for 2 h (if brining method was followed for salting). The stretched curds were formed using custom made stainless steel molds (20 x 10 x 10 cm). All cheese samples were allowed to cool at 5°C overnight in barrier bags and vacuum packed with gas flush in the vacuum packing machine. Three replicates were done for each treatment.

Analytical methods

Dry matter, fat, total nitrogen, titratable acidity and ash contents were determined according to AOAC [8]. The pH values were measured using a microprocessor pH meter (model 8417, Hanna Instruments, Singapore) at 20°C. Lactose contents were determined according to Lawrence [9]. The sodium chloride contents in cheese samples were determined by Volhard method (Method No. 975.20; AOAC 1990). Sodium and calcium contents were determined using flame photometer (Sherwood Flame Photometer 410, Sherwood Scientific Ltd. Cambridge, UK) as described by Kirk and Sawyer [10]. For determination of shreddability of Mozzarella cheeses, the experimental 3-days old Mozzarella cheese samples were cut into blocks of about 4 cm width, 4 cm height and 8 cm length taking in consider that the cheeses were cut so that the fibers were parallel to the shredding blade along the length of the rectangle of cheese. This was done to eliminate any effects that fiber orientation may have on shreddability because of the anisotropic nature of Mozzarella cheese [11]. Before shredding, the blocks of cheese were weighed (about 500g) and placed in a refrigerator (5°C) for a day. The shredder was adjusted to produce long strips (5 mm wide x 20-30 mm long x 0.3-0.5 mm thick) and operated for 1 min; the shredded strips were allowed to go out of the shredder and weighed to calculate the percent of the cheese that adhered to the blades. The shredded cheese was shaken for 10 seconds through a sieve with opening of 6.35 mm2; the shreds that fell through the sieve were classified as fines, and weighed to calculate the percent of shred fines. The shredding efficiency and shreddability index were calculated as follows:

The adhesive force was measured using CT3 Brookfield-Texture analyzer, United States. The textural profile analysis test (TPA) for some textural properties (hardness, springiness, cohesiveness, gumminess and adhesiveness), were measured by CT3 Brookfield- Texture analyzer using computer interface software (Texturepro CT V1.2 Build 9) according to Bourne. Cheese samples were prepared for scanning electron microscopy (SEM) according to Brooker and Wells [12]. The samples were examined with JEOL scanning microscope T20, JEOL, Japan. The obtained data were exposed to the ANOVA procedure followed by Duncan’s multiple range tests according to statistical analyses system user's guide [13] (SAS). Design was completely randomized with replications.

Chemical composition of Mozzarella cheeses

Data given in Table 1 revealed that, all factors studied had led to significant differences in all criteria determined. The Mozzarella cheeses made through the Brine Salting (BS) technique obtained higher dry matter contents than those made with dry salting (DS) one. That could be attributed to the higher sodium chloride content of the DS-cheeses which helps in water retention into the cheese matrix. Similar observations were reported by Bähler et al. [14] who reported that the holding capacity of protein increased with increasing the sodium chloride salt content of cheese. The depending on lactic acid as pre-acidifier resulted in a significant increase in the dry matter content of the final cheese compared to either the application of the other acids or the control cheese which came in the latest order. That could be due to that the added acids led to reduce the time of scalding and cheddaring stages; leading to lower chances of production and activity of the starter culture lytic enzymes. The round figures of the dry matter results were in accordance with those previously found by Sheehan, Cogan and Karuna [15-17].

| Source of variation | Dry matter | Protein (TN × 6.38) | Fat | Fat on dry matter | Ash | Lactose | Sodium chloride | Calcium | Sodium |

|---|---|---|---|---|---|---|---|---|---|

| Salting technique (ST) | |||||||||

| Brine salting (BS) | 51.164b | 25.48a | 21.10a | 41.267a | 3.183b | 1.165b | 1.840b | 0.576a | 0.778b |

| Dry salting (DS) | 51.455a | 24.06b | 20.65b | 40.177b | 3.833a | 1.34a | 2.452a | 0.563b | 1.022a |

| P-value | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| Type of pre-acidifier (TP) | |||||||||

| Control* | 49.156d | 23.38c | 20.60c | 41.895b | 3.311d | 1.125d | 1.915d | 0.5835a | 0.811d |

| Acetic | 50.771c | 22.77d | 21.75a | 42.830a | 3.415c | 1.443a | 2.050c | 0.5725b | 0.862c |

| Citric | 52.251b | 25.51b | 21.20b | 40.565c | 3.531b | 1.227b | 2.210b | 0.5535c | 0.922b |

| Lactic | 53.058a | 27.41a | 19.95d | 37.600d | 3.775a | 1.216c | 2.410a | 0.5705b | 1.006a |

| P-value | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| ST × TP | |||||||||

| BS × Control* | 49.076 | 23.82 | 20.7 | 42.17 | 3.185 | 0.99 | 1.82 | 0.581 | 0.779 |

| BS × Acetic | 50.626 | 23.79 | 22 | 43.44 | 3.165 | 1.38 | 1.8 | 0.582 | 0.762 |

| BS × Citric | 52.236 | 26.32 | 21.5 | 41.15 | 3.087 | 1.132 | 1.81 | 0.563 | 0.758 |

| BS × Lactic | 52.716 | 27.99 | 20.2 | 38.31 | 3.295 | 1.161 | 1.93 | 0.58 | 0.814 |

| DS × Control* | 49.236 | 22.94 | 20.5 | 41.62 | 3.437 | 1.26 | 2.01 | 0.586 | 0.844 |

| DS × Acetic | 50.916 | 21.76 | 21.5 | 42.22 | 3.665 | 1.507 | 2.3 | 0.563 | 0.962 |

| DS × Citric | 52.266 | 24.71 | 20.9 | 39.98 | 3.975 | 1.322 | 2.61 | 0.544 | 1.086 |

| DS × Lactic | 53.4 | 26.83 | 19.7 | 36.89 | 4.255 | 1.272 | 2.89 | 0.561 | 1.198 |

| P-value | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

*Controls were made by Yoghurt starter culture without pre-acidification. Means with the same letter are not significantly different (p>0.05).

Table 1: Ls means values for salting technique, type of pre-acidifier and salting technique × type of pre-acidifier on the approximate composition (%) of Mozzarella cheese.

The results with respect to protein content stated that, the protein content of cheeses prepared by the BS technique were higher than those prepared by the DS one, possibly due to their comparatively high dry matter contents. Similar findings were obtained by Ahmad [18]. Moreover, the pre-acidified cheeses made using lactic acid gained the highest protein content, followed by cheeses made using citric acid, then the control cheeses, while the acetic acid pre-acidified cheeses obtained the lowest protein contents. That could be ascribed to the shorter times needed to make the lactic and citric acids pre-acidified cheeses which reduced the chances for production and activity of lactic acid bacteria proteolytic enzymes.

Regarding the fat content of Mozzarella cheeses, the statistical analysis confirmed that, the differences occurred due to the salting technique were significant, where the fat contents of the BS cheeses were higher than DS-ones. Likely due to the lower salt contents of the former cheeses which increase the openness of cheese matrix leading to increase the cheese ability to hold and emulsify fat. These findings are in accordance with those of Paulson [19] who found that there is a negative correlation between the salt content and the openness of cheese matrix. Significant differences in the fat content were established among the experimental Mozzarella cheeses upon the type of pre-acidifier, where the acetic acid cheese possessed the highest fat content of all cheeses followed by the citric acid one then the control cheeses, while the lactic acid cheese came in the latest order. Possibly due to the increase in protein content as well as the tightened protein matrix of the lactic acid cheese. Similar observations were reported by Bhaskaracharya and Shah [20].

Concerning the ash content, the salting technique led to obtain cheeses with significantly different ash contents, where the DS cheeses possessed higher ash than the BS ones. Likewise, the applied acids led to obtain cheeses with different ash contents, where the utilization of lactic acid led to the highest increase in cheese ash, while acetic acid cheese contained the lowest ash of the pre-acidified cheeses; however the control cheeses obtained the lowest ash contents of all cheese samples. Those differences in cheese ash could be ascribed essentially to the differences in the contents of the sodium chloride, where the DS cheeses had comparatively higher sodium chloride contents than the BS ones; especially the cheese made with lactic acid. It is noteworthy to mention that the pre-acidification caused the cheese to absorb more sodium chloride when compared to starter culturing, possibly due to the role of acids in removing some of the calcium phosphate complex from casein leading to more porous protein structure with larger serum channels. These results are in accordance with those found by Ponce De Leon-Gonzalez [21] in Muenster-type cheese.

The results with respect to lactose content revealed that, the BS cheeses possessed significantly lower lactose levels than cheeses made using the DS technique. That could be ascribed to the lower salt of the former cheeses which lead to faster lactose fermentation rate by the starter bacteria. This phenomenon is in accordance with that reported by AOAC [22]. Turner and Thomas found that the lower salt to moisture content was more suitable for lactose fermentation to L-lactate by lactic acid bacteria in cheese. The pre-acidified cheeses obtained higher lactose contents than those made using starter culture only, may be due to the reduction in cheeses making time as well as the growth rate and activity of the starter organisms when the pre-acidification procedure was applied. Moreover, the pre-acidification with acetic acid caused the highest increase in cheese lactose, then the use of citric and lactic acids respectively. That could be ascribed to the stronger antibacterial effect of acetic acid compared to other added acids. Similar was found by Levine and Fellers [23] who studied the antimicrobial activity of different acids and found that acetic acid was more toxic than either hydrochloric or lactic acid to different bacterial and fungal genera.

The results of calcium content of Mozzarella cheeses elucidated that, applying the BS method led to obtain cheeses with higher calcium contents than when the other method of salting was applied. That could be due to the higher protein contents as well as pH values of the BS cheeses in comparison with the DS ones. Similar was reported by Fröhlich-Wyder [24] who found that the highest degree of calcium removal from casein was obtained when the pH value was reduced dramatically after curdling during Raclette cheese making. On the other hand, pre-acidifying the cheese milk led to attain significant decrements in cheese calcium; citric acid caused the greatest calcium losses [25]. While, both acetic and lactic acids pre-acidified cheeses possessed significantly similar moderate calcium contents. That could be ascribed essentially to that acids especially citric form complexes with calcium causing an increase in non-micellar calcium, and such complexes are soluble and can be removed through whey drainage [26].

With regard to the results of cheeses’ sodium contents, it is noteworthy to refer to that, the amount of salt retained in cheese was directly correlated to the sodium content in cheese [27]. Therefore, the dry salted and pre-acidified cheeses possessed higher sodium levels compared to both the brine salted and non-pre- acidified ones. Amongst the pre-acidified cheese samples, the lactic and citric acids’ cheeses gained the highest sodium contents respectively.

Titratable acidity (TA) and pH value of Mozzarella cheeses

As shown in Table 2, the DS Mozzarella cheeses had TA% higher than those of cheeses made with the BS technique. That could be attributed to the lower sodium chloride contents of the BS cheeses which offer slower rate for the growth of added starter bacteria. Moreover, all the pre-acidified cheeses possessed lower TA% than the control cheeses. The lactic acid cheeses gained the highest TA% of the pre-acidified cheeses, followed by the citric acid ones, while the acetic acid cheeses came in the latest order having the lowest TA%. Possibly due to the crucial anti-bacterial effect of acetic acid compared to other added acids. By prolonging the cold storage period, the TA% of all cheese samples was gradually increased until the end of experimental period (4 weeks), likely due to residual carbohydrate fermentation. Similar observations were reported by El-Batawy and Ahmad [28,29].

| Source of variation | TA% | pH value | Hardness (g) | Cohesiveness | Springiness (mm) | Gumminess (g) | Adhesiveness (mJ) |

|---|---|---|---|---|---|---|---|

| Salting technique (ST) | |||||||

| Brine salting (BS) | 0.76b | 5.27a | 211.76b | 0.695b | 4.370a | 147.50b | 0.067a |

| Dry salting (DS) | 0.82a | 5.25b | 224.29a | 0.698a | 4.134b | 156.65a | 0.033b |

| P-value | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| Type of pre-acidifier (TP) | |||||||

| Control | 0.86a | 5.22c | 213.91c | 0.679c | 4.41b | 145.35c | 0.049b |

| Acetic | 0.72d | 5.25b | 182.85d | 0.697b | 4.51a | 127.54b | 0.063a |

| Citric | 0.77c | 5.25b | 235.69b | 0.698b | 4.14c | 164.62b | 0.047c |

| Lactic | 0.81b | 5.32a | 239.66a | 0.712a | 3.93d | 170.79a | 0.043d |

| P-value | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| Cold storage period (CSP) | |||||||

| Fresh | 0.76c | 5.27b | 241.42a | 0.688c | 3.98c | 166.30a | 0.044c |

| 2 Week | 0.79b | 5.23c | 221.01b | 0.704a | 4.28b | 155.77b | 0.050b |

| 4 Week | 0.82a | 5.29a | 191.66c | 0.698b | 4.48a | 134.16c | 0.057a |

| P-value | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| ST × TP | |||||||

| BS × Control | 0.84 | 5.2 | 197.83 | 0.675 | 4.5 | 133.87 | 0.062 |

| BS × Acetic | 0.7 | 5.26 | 179.85 | 0.697 | 4.74 | 125.4 | 0.088 |

| BS × Citric | 0.74 | 5.27 | 232.75 | 0.698 | 4.28 | 162.43 | 0.062 |

| BS × Lactic | 0.78 | 5.36 | 236.63 | 0.711 | 3.95 | 168.3 | 0.059 |

| DS × Control | 0.88 | 5.24 | 185.85 | 0.682 | 4.32 | 156.83 | 0.037 |

| DS × Acetic | 0.75 | 5.24 | 229.99 | 0.698 | 4.28 | 129.68 | 0.038 |

| DS × Citric | 0.81 | 5.24 | 238.63 | 0.699 | 4 | 166.81 | 0.031 |

| DS × Lactic | 0.84 | 5.28 | 242.69 | 0.714 | 3.91 | 173.29 | 0.027 |

| P-value | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| ST × CSP | |||||||

| BS × Fresh | 0.74 | 5.29 | 248.05 | 0.694 | 4.07 | 172.3 | 0.057 |

| BS × 2 Week | 0.77 | 5.22 | 210.28 | 0.7 | 4.38 | 147.44 | 0.067 |

| BS × 4 Week | 0.78 | 5.31 | 176.96 | 0.692 | 4.64 | 122.76 | 0.079 |

| DS × Fresh | 0.78 | 5.25 | 234.79 | 0.682 | 3.89 | 160.29 | 0.032 |

| DS × 2 Week | 0.82 | 5.24 | 231.73 | 0.707 | 4.18 | 164.11 | 0.034 |

| DS × 4 Week | 0.86 | 5.26 | 206.36 | 0.705 | 4.32 | 145.55 | 0.034 |

| P-value | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| TP × CSP | |||||||

| Control × Fresh | 0.82 | 5.23 | 239.82 | 0.664 | 4.15 | 159.34 | 0.047 |

| Control × 2 Week | 0.86 | 5.19 | 217.17 | 0.693 | 4.47 | 150.56 | 0.05 |

| Control × 4 Week | 0.9 | 5.25 | 184.75 | 0.679 | 4.61 | 126.16 | 0.051 |

| Acetic × Fresh | 0.7 | 5.25 | 206.72 | 0.691 | 4.25 | 142.86 | 0.053 |

| Acetic × 2 Week | 0.73 | 5.23 | 186.54 | 0.702 | 4.55 | 131.06 | 0.063 |

| Acetic × 4 Week | 0.75 | 5.27 | 155.3 | 0.7 | 4.73 | 108.71 | 0.073 |

| Citric × Fresh | 0.75 | 5.28 | 256.17 | 0.693 | 3.84 | 177.55 | 0.042 |

| Citric × 2 Week | 0.78 | 5.22 | 237.9 | 0.705 | 4.13 | 167.74 | 0.045 |

| Citric × 4 Week | 0.8 | 5.26 | 213 | 0.697 | 4.45 | 148.58 | 0.054 |

| Lactic × Fresh | 0.78 | 5.33 | 262.97 | 0.705 | 3.68 | 185.45 | 0.037 |

| Lactic × 2 Week | 0.81 | 5.27 | 242.42 | 0.716 | 3.97 | 173.75 | 0.044 |

| Lactic × 4 Week | 0.84 | 5.36 | 213.6 | 0.717 | 4.14 | 153.19 | 0.048 |

| P-value | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

*Controls were made by Yoghurt starter culture without pre-acidification. Means with the same letter are not significantly different (p>0.05).

Table 2: Ls means values for salting technique (ST), type of pre-acidifier (TP), cold storage period (CSP), ST × TP, ST × CSP and TP × CSP on the Titratable acidity (TA), pH value and texture profile analyses of Mozzarella cheese.

The results with regard to the pH values stated that, the BS cheeses showed comparatively higher values than the DS ones. That could be ascribed to the higher buffering capacity of the former cheeses due to its relatively higher protein contents in comparison with the latter ones. Similar was reported by Bourne [30] Ahmad who confirmed that there is a positive correlation between protein content and buffering capacity of milk. Likewise, the pre-acidified cheeses had higher pH values than those of control cheeses, due to the higher protein contents of the former cheeses which led to increase the buffering capacity in cheese, as well as their lower titratable acidity contents. Moreover, the application of lactic acid as pre-acidifier led to obtain the highest pH of all cheeses, followed by both citric and acetic acids’ cheeses which gained significantly similar pH values. During the cold storage, the pH of all cheeses attained its lowest value at the middle of storage period and then rose again, That decrease in pH during the first 2 weeks of storage could be ascribed to the increase in lactic acid due to the growth and activity of starter bacteria [31], while the increase in cheeses’ pH at the end of storage may be associated with a reduction in the lactate to protein ratio and a loss of buffering capacity of cheese [32] as a result of the removal of lactic acid soluble calcium which considered a major determinant of the buffering capacity of cheese.

Similar observations were reported by Guinee, Fox and McMahon et al. [33-35].

Texture profile of Mozzarella cheeses

Data of Table 2 demonstrate that hardness values of Mozzarella cheese differed significantly by the applied salting technique. Mozzarella cheeses manufactured using the BS procedures were softer than those of the other salting procedure. That could be attributed to the relatively low salt levels of the former cheeses which increase the openness of cheese structure and hence decrease the cheese hardness. Similar observations were reported by Guinee et al. [36] who reported that unsalted and low salt cheeses have more opened cheese matrix, and thus such cheeses may show reduced hardness. The lactic-pre-acidified cheeses gained the highest hardness of the pre-acidified cheeses, possibly due to its comparatively high protein as well as calcium contents. Moreover, depending on the starter culture alone i.e., without pre-acidification resulted in obtaining cheeses with lower hardness values than either lactic or citric acid pre-acidified cheeses. That could be ascribed essentially to the significant low pH of the controls, where the decrease in pH could have caused increased interaction of the negatively charged casein micelles with the serum phase, while opposing interactions between the casein micelles, leading to a reduction in cheese hardness [37]. All cheeses showed significant decrease in their hardness values upon storage. These observations were supported by those of Tunick et al. [38,39] who reported that during refrigerated storage hardness and gumminess decreases as a result of proteolysis occurs in cheese by starter bacteria through exocellular proteinases resulting in hydrolysis of proteins to oligopeptides, which are in turn hydrolyzed into smaller peptides having low molecular weights and amino acids through cell wall associated amino peptidases [40].

The results of cohesiveness reveal that, the salting technique did not cause any significant differences in the resultant cheeses. Moreover, the lactic pre-acidified cheeses gained the highest cohesiveness of all cheeses. That could be due to its relatively high protein content which was available for compression [20], as well as its comparatively low fat content. Cheese cohesiveness was increased slightly after 2 weeks of storage and then decreased again at the end of the studied cold storage period.

Concerning the springiness of Mozzarella cheeses, data demonstrated that, all factors studied had significant effects on the springiness of cheese. The depending on brine salting method during cheese making led to increase the springiness of the resultant cheeses as compared to when the dry salting method was applied. That could be ascribed to the considerable high fat levels of the brine salted cheeses which gave resilience to those cheeses. Likewise, the acetic pre-acidified cheeses were the springiest ones of all samples, while the lactic pre-acidified ones had the lowest springiness values. These results were supported by the previous findings of Fox and Emstrom [41]. The springiness values of all cheeses were gradually increased upon storage. That could be due to the dynamic interactions within the cheeses occurs during storage, namely a transition of intact caseins and calcium to the serum phase while moisture and sodium are transferred to the casein micelles as reported by Kindstedt and Guo [42].

The gumminess values of the brine salted cheeses were lower than those of the dry salted ones. Likely due to the higher hardness levels observed in latter cheeses versus those salted by brining. Likewise, the lactic pre-acidified cheeses were the gummiest of all cheeses, while the application of acetic acid led to obtain cheeses with the lowest gumminess. Similar findings were reported by Ren et al. [43] who found that there is a positive correlation between hardness and gumminess of cheese. The gumminess of Mozzarella cheeses was gradually decreased by prolonging the cold storage period as a result of the changes occur in the protein matrix.

Regarding the adhesiveness of cheeses, the brine salting led to obtain more adhesive cheeses versus the dry salting method. That could be ascribed essentially to the higher fat contents of the former cheeses than the latter ones. Similarly, the acetic pre-acidified cheeses got the highest adhesiveness, followed by the citric and lactic acids pre-acidified cheeses respectively. The adhesiveness of all cheese samples was gradually increased through the cold storage. Possibly due to an increase in small peptides in the serum channels resulting from proteolysis, which in turn increase the binding forces within the cheese matrix by increased absorption of moisture [44].

Shreddability of Mozzarella cheeses

As shown in Table 3, the brine salted cheeses showed higher adhesion with the shredder’s blades than the dry salted ones. That could be attributed to the higher sodium chloride contents of the latter cheeses, where the high salt concentrations especially those in the outer layer of cheeses led to more shortness, crumbliness and drying, and hence less ability to adhesion [33]. Similarly, the lactic acid cheeses produced the lowest adhered cheese weights of all samples. These results are in parallel with the findings from the instrumental adhesiveness in the texture profile analysis. Concerning the lost cheese as fines through shredding, the results elucidate that, the dry salted cheeses produced higher cheese fines amounts than the brine salted ones. That could be attributed to the relatively high hardness degree of the former cheeses which increased the resistance of cheese cubes to the shredder’s blades leading to non-uniform shreds with fines. Likewise, the lactic pre-acidified cheeses showed the highest shredding loses as fines of all samples. Concerning the adhesive force, it is the maximum force required to separate teeth after biting sample. It represents the maximum negative force generated during the probe of the texture analyzer return. The obtained results reveal that, the adhesive force of cheese samples differed by the salting technique as well as applied pre-acidifier type, where the brine salted control cheese possessed higher adhesive force than the dry salted pre-acidified cheeses. Amongst the pre-acidified cheeses samples, the lactic acid cheeses were characterized with the lowest adhesive force values. It is noteworthy to mention that, the pre-acidification led to obtain cheeses with lower adhesive forces as compared with those made with starter culture only. That could be attributed to the higher proteolysis rate occurred in the latter cheeses which increases small peptides in the serum channels leading to increase the binding forces within the cheese matrix by increasing the absorption of moisture [45,46]. With respect to the overall shredding evaluation indicators namely, the shredding efficiency and shreddability index, the results elucidate that, the brine salted cheeses had lower shredding efficiency than the dry salted ones. Moreover, both the lactic and citric acids pre-acidified cheeses gained higher shredding efficiency than both the control and acetic acid cheeses. Concerning the shreddability index, the obtained data demonstrated that, the calculated index was able to view lower significant differences than the shredding efficiency at the same level of probability when used to evaluate the shreddability of the pre-acidified Mozzarella cheeses. The results showed that, the brine salting method led to obtain cheeses with lower shreddability index values than those of the other salting method. Moreover, the acetic acid and control cheeses got the lowest values of all samples. It is obvious from the two indicators that the lactic acid cheese which made with dry salting was the most shreddable one of all experimental cheese samples.

| Source of variation | Adhered cheese weight (g/500 g) | Cheese fines weight (g/500 g) | Adhesive force (g) | Shredding efficiency (%) | Shreddability index (g-1) |

|---|---|---|---|---|---|

| Salting technique (ST) | |||||

| Brine Salting (BS) | 23.41a | 3.67a | 5.97a | 94.58b | 15.94b |

| Dry Salting (DS) | 16.91b | 2.77b | 4.64b | 96.06a | 20.89a |

| P Value | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| Type of pre-acidifier (TP) | |||||

| Control* | 21.05b | 2.52c | 5.80a | 95.28c | 16.78d |

| Acetic | 23.20a | 2.06d | 5.59b | 94.94d | 17.15c |

| Citric | 18.95c | 3.23b | 5.16c | 95.56a | 18.82b |

| Lactic | 17.44d | 5.07a | 4.67d | 95.49b | 20.90a |

| P Value | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| ST × TP | |||||

| BS × Control* | 24.11 | 2.22 | 6.63 | 94.73 | 14.29 |

| BS × Acetic | 27.65 | 2.15 | 6.11 | 94.04 | 15.39 |

| BS × Citric | 21.89 | 3.45 | 5.8 | 94.9 | 16.37 |

| BS × Lactic | 20.02 | 6.87 | 5.34 | 3 | 17.72 |

| DS × Control* | 18 | 2.82 | 4.97 | 94.62 | 19.28 |

| DS × Acetic | 18.76 | 1.98 | 5.07 | 95.84 | 18.91 |

| DS × Citric | 16.01 | 3.01 | 4.52 | 95.85 | 21.28 |

| DS × Lactic | 14.87 | 3.28 | 4 | 96.2 | 24.09 |

| P value | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

*Controls were made by Yoghurt starter culture without pre-acidification. Means with the same letter are not significantly different (p>0.05).

Table 3: Ls means values for salting technique, type of pre-acidifier and salting technique × type of pre-acidifier on the shredding indicators of Mozzarella cheese.a

Microstructure of Mozzarella cheeses

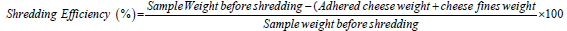

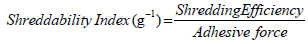

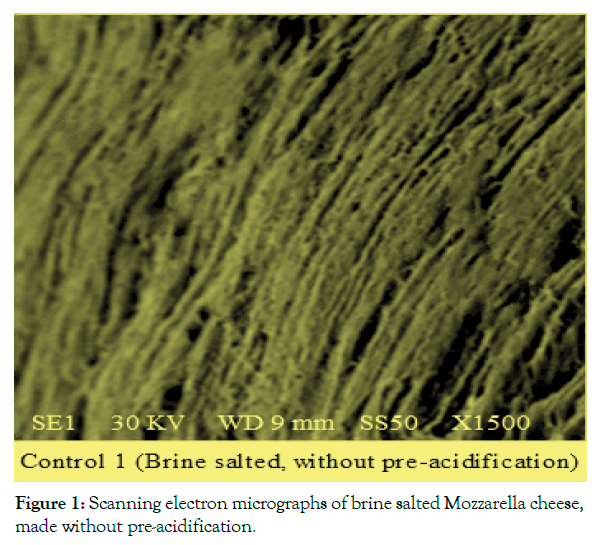

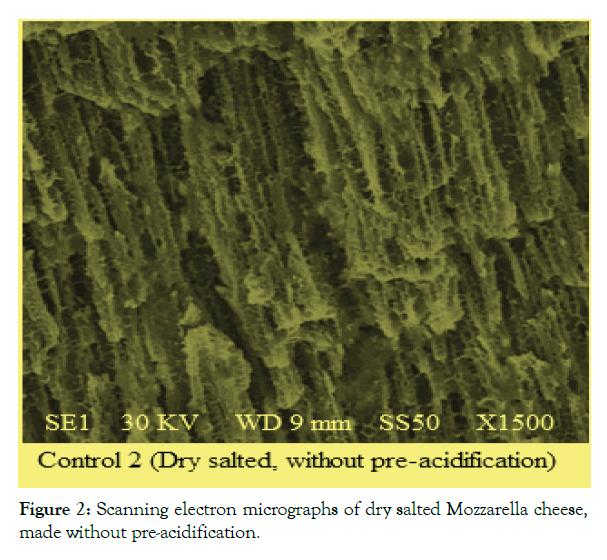

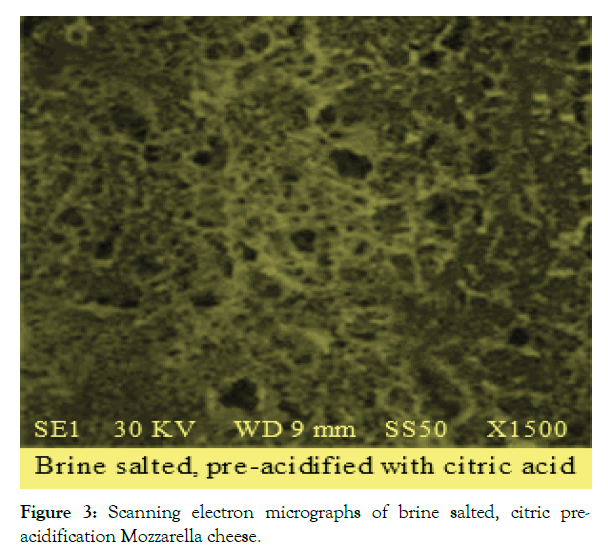

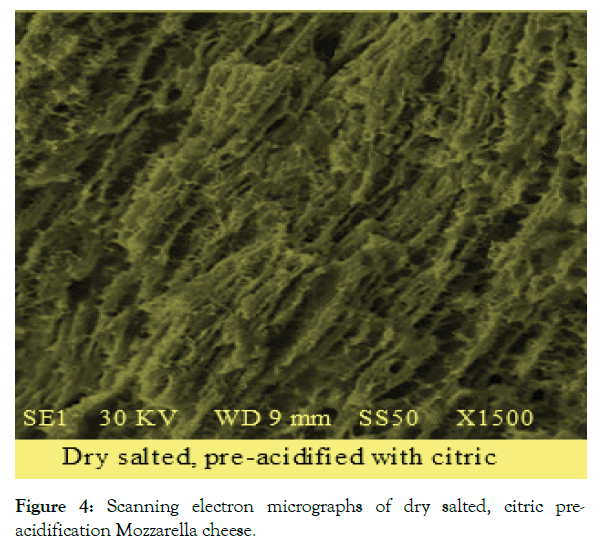

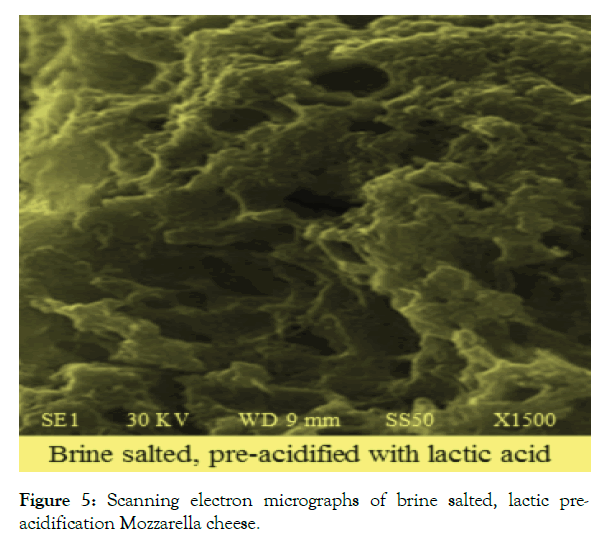

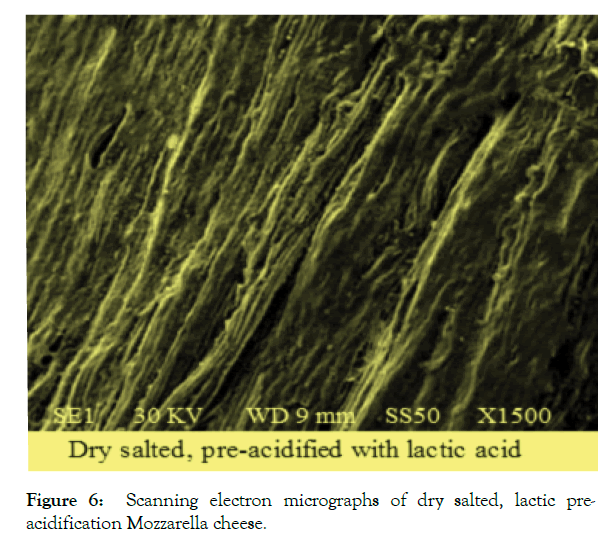

The micrographs pictured in Figures 1-6 show the microstructure of 3-days old Mozzarella cheeses as affected by salting technique and type of pre-acidifiers. It could be observed that, brine salted cheese was more porous than the dry salted one. That could be ascribed to the relatively low NaCl salt content of the brine salted cheese as compared to the dry salted one. That observation was in parallel with the considerable low instrumental hardness of the brine salted cheese (Table 2). Similar was found by Paulson who reported that unsalted cheeses showed increased open structures compared to salted ones. On the other hand, the dry salted cheese appeared with more homogeneous and continuous protein matrix as well as less pockets, possibly due to its relatively high NaCl level which promoted solubilization of casein and increased protein-to-water interactions, leading to increasing the hydration and swill of protein fibers. These results were supported by the previous findings of Pastorino who reported that, the high salt levels would help in impairing interactions between protein molecules and promoting protein-to-water interactions; leading to a partial relaxation of the protein matrix and that consequently would allow water to leave the pockets to the protein matrix. With regard to the type of pre-acidifier effect, the control cheeses which made without pre-acidification reflected more protein folds and serum pockets as compared to the pre-acidified cheeses. That could be ascribed essentially to the relatively high calcium contents of the control cheeses. Likewise, the citric pre-acidified cheese showed a combination of many larger channels and smaller pores giving an increased porous structure with more sharpened protein fibers, possibly due to the reduction in colloidal calcium by the strong chelating effect of citric acid. Similar observations were reported by McMahon who studied the effect of calcium on the protein matrix structure of non-fat Mozzarella cheese. The densest protein network was observed in the lactic acid cheese which also appeared with narrow fat voids, may be due to its comparatively high protein content which in turn lowers the volume fraction of the aqueous phase leading to lowering the mean distance between casein micelles and consequently increase their degree of aggregation.

Figure 1: Scanning electron micrographs of brine salted Mozzarella cheese, made without pre-acidification.

Figure 2: Scanning electron micrographs of dry salted Mozzarella cheese, made without pre-acidification.

Figure 3: Scanning electron micrographs of brine salted, citric pre-acidification Mozzarella cheese.

Figure 4: Scanning electron micrographs of dry salted, citric pre-acidification Mozzarella cheese.

Figure 5: Scanning electron micrographs of brine salted, lactic pre-acidification Mozzarella cheese.

Figure 6: Scanning electron micrographs of dry salted, lactic pre-acidification Mozzarella cheese.

In this study, Mozzarella cheeses were made from standardized full fat cow’s milk; pre-acidified with either citric, lactic or acetic acid drop-wise to pH of 6.3, using 2.5% activated Yoghurt starter culture and rennet (1.5 g/100 Kg). The milled curds were salted either by the brining technique or by dry salting. The control cheeses were made using the starter culture only without pre-acidification and salted with both the two studied salting techniques. The study findings led to conclude that, Mozzarella cheeses which made by pre-acidification with lactic or citric acid and dry salted were hard and gummy enough to be shredded easily with low losses during shredding.

Citation: Emam OA, Nasser AS (2019) Effect of Salting Technique on Shreddability, Texture Profile and Microstructure of the Pre-Acidified Cow ’s Mozzarella Cheese. Adv Dairy Res. 7:230. doi: 10.35248/2329-888X.19.7.230

Received: 18-Sep-2019 Accepted: 16-Oct-2019 Published: 23-Oct-2019

Copyright: © 2019 Emam OA, et al. This is an open access article distributed under the term of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.