Poultry, Fisheries & Wildlife Sciences

Open Access

ISSN: 2375-446X

ISSN: 2375-446X

Research Article - (2021)Volume 9, Issue 10

The present study was conducted to study the effect of varying levels of moisture content on extrusion properties of CIBA developed Asian seabass (Lates calcarifer) feed. The effect of addition of moisture was studied at 10%, 15%, 20%, 25%, and 30%. The trial was carried out in a pilot scale twin screw extruder (M/S. Jinan saibainuo Technology, China) with a capacity to produce 250 kg per hour. All the machinery parameters and feed processing factors were kept constant but for the moisture content. All the six feed mix were subjected for extrusion and the trial was repeated thrice. The results of the extrusion trials revealed that there was no extrusion of the feed mix containing moisture up to 15% and the extrusion process has just started at 20% moisture level. Feed mix containing 25% and 30% moisture showed efficient extrusion resulting in good expansion of the finished product. Moisture addition of 35% showed difficulty in an operation as the feed material is getting choked in the extruder. As the level of moisture content increased the bulk density with floating buoyancy was observed in the feed mix containing 25% and 30% moisture. Feed pellet extruded at 25% and 30% moisture showed significantly better water stability compared to the rest. In the second trial effect of preconditioning on the extrudate properties revealed that conditioning for 30 minutes helps in improving the extrudate properties. The results revealed that a total moisture content of 25-30% is optimal for the better extrusion and preconditioning for 30 minutes had a beneficial effect on the extrudate properties of CIBA developed seabass feed with 40% protein.

Extrusion; Twin screw; Moisture; Water stability; Gelatinization

Asian seabass Lates calcarifer (Bloch) popularly called as barramundi is a carnivorous, euryhaline, commercially valuable food fish widely cultured in tropical and subtropical regions of Asia and Pacific countries in marine, brackish and fresh water resources [1]. Because of its high market value and excellent growth potential seabass is considered as an alternate candidate species in brackishwater aquaculture in India [2,3]. In the brackishwater aquaculture sector there will be most reliable growth market for prepared feeds [4]. In this context it is to be noted that there are two major challenges for profitable fish feed production that includes feed formulation and processing [5]. Extrusion cooking is a High-Temperature Short- Time (HTST) process in which a final product is obtained by heating, mixing, shearing, and forcing material through a die [2]. Extrusion technology is commonly used to prepare fish feeds, since physical properties, such as water stability, durability, hardness, oil absorption capacity, nutrient digestibility and buoyancy control, usually are improved compared to steam pelleted diets [6]. Extrusion eliminates microbial load, reduces the level of thermo labile anti-nutrients present in plant material and improves the digestibility of dietary components [7]. Extrusion processing and ingredient formulation are the two greatest factors that affect the quality of feeds. The extrudate property is determined by an array of operating parameters among which moisture and temperatures are the major physical factors that have direct effect on the quality of the extrudate [2].

Extensive research has been conducted on the effect of moisture content on the extrudate properties for several starches and protein-based feed materials [8]. Determining the effects of various moisture levels and extrusion temperature will help in preparation of quality extruded feeds. For most cultured fish species, the extruded pellets must remain intact in water for approximately four hours. Proper operation of processing equipment and selection of ingredients can extend this time.

Hence an attempt was made to study effect of varying levels of moisture content on the extrude property of standard CIBA developed seabass using a twin screw extruder (M/S. Jinan saibainuo Technology, China).

Preparation of experimental diets

The standard Central Institute of Brackishwater Aquaculture (CIBA) developed seabass feed was formulated to contain 41% protein with 5% lipid. The feed was prepared using indigenous ingredients. The ingredient composition of experimental diet is presented in Table 1. The feed was prepared using standard protocols followed at our feed mill. Six different experimental diets were formulated to contain 10%, 15%, 20%, 25%, 30% and 35% moisture. The required level of moisture content was adjusted by adding the required quantity of portable water. This trial was carried out in a pilot scale twin screw extruder (M/S. Jinan saibinuo Technology China) (Figure 1). All the parameters but for the moisture content were uniform in the different experimental diets. The temperature of the extruder was kept at 130°C and 150°C respectively in the heater I and II with the motor speed 1000 RPM. This trial was repeated thrice and the average values of the three trials were taken for analysis.

| Ingredients | (%) |

|---|---|

| Fish meal* | 13 |

| Dry fish | 13 |

| Acetes | 12 |

| Squid | 3 |

| Soya bean meal | 20 |

| Wheat | 25 |

| Groundnut oil cake | 3 |

| Rape seed meal | 4 |

| Fish oil* | 4 |

| Lecithin | 1 |

| Vitamin and Mineral# | 2 |

*Sardine fishmeal and fish oil. Bismifisheries, Mayiladuthurai, Tamil Nadu, India.

#Commercially sourced premix and each kg contains Vitamin A-2000000 IU, Vitamin D-400000 IU, Vitamin E – 300 U, Vitamin K-450 mg, Riboflavin-800 mg, Pantothenic acid-1 g, Nicotinamide-4 g, Vitamin B12-2.4 mg, Choline chloride-60 g, Ca-300 g, Mg-11 g, I-400 mg, Fe-3 g, Zn-6 g, Cu-800 mg, Co-180 mg.

Table 1: Ingredient composition of experimental diet.

Figure 1: Pilot scale extruder units for the prepared experimental diets.

Based on the results a second experiment was conducted to study the effect of preconditioning on the extrudate properties. The optimal moisture content arrived in the first experiment was selected for this trial. This diet was preconditioned for 0, 15, 30, 45 and 60 minutes and subjected for extrusion and the effect was studied after extruding through the extruder (Figure 2).

Figure 2: Extrudate coming from the extruder.

Proximate composition of experimental diets

The proximate composition of the experimental diets was analyzed by following standard procedures of Analysis of the Association of Official Analytical Chemists [9].

Measurement of extrudate properties

The extrudate properties Bulk Density (BD) was measured by following the method prescribed [10]. Water-Solubility Index (WSI) was determined by following standard procedures of [11]. Pellet durability index (PDI) was determined according to Method of American Society of Agricultural Engineers-Standards [12]. Sinking Velocity (SV) was measured following the method of Jones et al., [13].

Statistical analysis

Data were analyzed using one-way ANOVA to compare significant differences between treatments, whereas Duncan’s multiple range tests was used to compare the means of the treatments. All the data were analyzed using SPSS version 16.0 software.

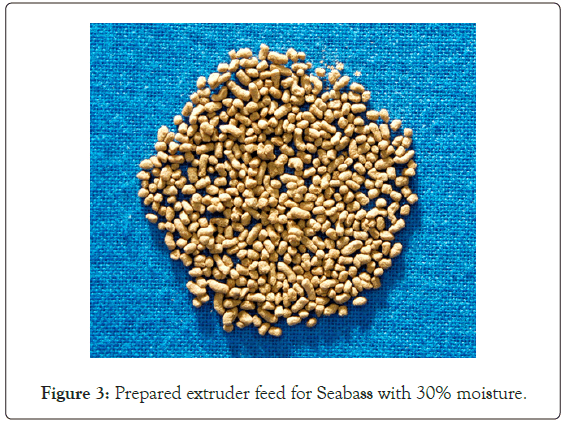

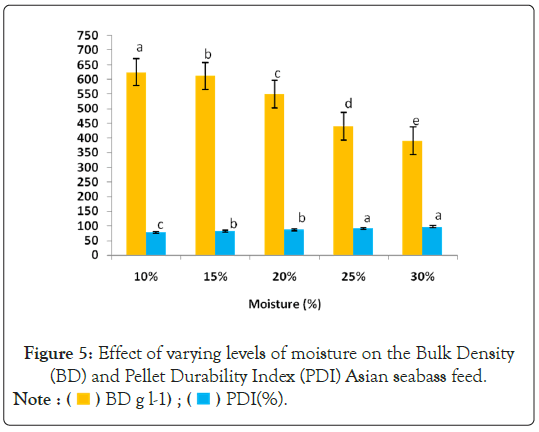

The results of the proximate composition of experimental diets is in Table 2 showed that it contains 7.6% moisture, 41.8% crude protein, 5.2% crude lipid, 14.4 total ash, 3.2% crude fiber and 27.8% nitrogen free extract (NFE) respectively. The results of the extrusion trails revealed that there was no extrusion of the feed mix containing moisture up to 15% and the extrusion processes has just started at 20% moisture level. Feed mix containing 30% moisture showed difficulty in operation as the feed material is getting chocked in the extruder. As the level of the moisture content increased there was a significant (P<0.05) effect on BD, WSI, PDI and SV (Table 3) when the feed mash was subjected to varying levels of moisture (Figures 3 and 4). Significantly lower bulk density with floating buoyancy was observed in the feed mix containing 25% and 30% moisture (Figure 5). Feed pellet extruded at 25 and 30.0% moisture showed significantly better water stability compared to the rest.

| Proximate composition | % |

|---|---|

| Moisture | 7.6 |

| Crude protein | 41.8 |

| Crude lipid | 5.2 |

| Crude fiber | 14.4 |

| Total ash | 3.2 |

| NFE | 27.8 |

Table 2: Proximate composition (%) of experimental diet.

| Properties | 10% | 15% | 20% | 25% | 30% |

|---|---|---|---|---|---|

| BD (g l-1) | 625.5 ± 1.41a | 612.7 ± 2.62b | 550.8 ± 1.67c | 440.3 ± 1.94d | 390.8 ± 2.10e |

| Length (mm) | 6.61 ± 0.16 | 6.73 ± 0.15 | 6.12 ± 0.18 | 6.31 ± 0.25 | 6.41 ± 0.27 |

| Diameter (mm) | 6.13 ± 0.09 | 6.31 ± 0.03 | 6.34 ± 0.05 | 6.31 ± 0.12 | 6.29 ± 0.14 |

| WSI (%) | 8.29 ± 0.03a | 7.67 ± 0.06a | 5.25 ± 0.02b | 2.63 ± 0.09c | 2.11 ± 0.07c |

| PDI (%) | 78.19 ± 0.52c | 82.23 ± 0.12b | 87.39 ± 0.52b | 92.22 ± 0.76a | 97.18 ± 0.51a |

| SV (sec) | 8.09 ± 0.03a | 8.05 ± 0.04a | 7.08 ± 0.03b | Floating for 3 hours | Floating for 3 hours |

| Color | Brown | Brown | Brown | Brown | Brown |

| Odour | Fishy odour | Fishy odour | Fishy odour | Fishy odour | Fishy odour |

| Feed property | Sinking | Sinking | Sinking | Floating | Floating |

All values are means ± SE of three observations. Means bearing different superscript in a row differ significantly (p<0.05); a, b, c, d, e is the feed mash soaked in water for different time intervals with moisture at varying intervals.s

Table 3: Effect of moisture on the physical properties of Asian seabass feed.

Figure 3: Prepared extruder feed for Seabass with 30% moisture.

Figure 4: Preconditioning feed for 30 minutes.

Figure 5: Effect of varying levels of moisture on the Bulk Density

(BD) and Pellet Durability Index (PDI) Asian seabass feed.

Note : PDI(%).

PDI(%).

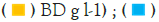

In the second trial, the effect of preconditioning on the extrudate properties revealed that conditioning for 30 minutes helps in improving the extrudate properties (Figure 4). The water soluble index was lower at 30 minutes of conditioning and the bulk density showed a decreasing trend as the conditioning time increased (Table 4). However there was not much reduction in bulk density in the diets conditioned for 30, 45 and 60 minutes (Figure 6). The water soluble index also significantly lowers in the diets conditioned for 30, 45 and 60 minutes compared to 0 and 15 minutes preconditioned diets.

| Properties | 0 min | 15 min | 30 min | 45 min | 60 min |

|---|---|---|---|---|---|

| BD (g l-1) | 455.6 ± 1.23a | 440.7 ± 1.46a | 390.5 ± 1.10b | 389.4 ± 0.09b | 385.5 ± 1.02b |

| Length (mm) | 6.51 ± 0.11 | 6.63 ± 0.14 | 6.22 ± 0.12 | 6.21 ± 0.28 | 6.31 ± 0.21 |

| Diameter (mm) | 6.03 ± 0.08 | 6.11 ± 0.01 | 6.24 ± 0.02 | 6.11 ± 0.13 | 6.21 ± 0.17 |

| WSI (%) | 8.17 ± 0.01a | 7.23 ± 0.05a | 5.01 ± 0.04b | 2.12 ± 0.03c | 2.18 ± 0.06c |

| PDI (%) | 77.19 ± 0.32c | 80.13 ± 0.18b | 84.34 ± 0.42b | 93.25 ± 0.66a | 98.38 ± 0.71a |

| SV (Sec) | 8.18 ± 0.02a | 8..26 ± 0.06a | 6.98 ± 0.08b | Floating for 3 hours |

Floating for 3 hours |

| Color | Brown | Brown | Brown | Brown | Brown |

| Odour | Fishy odour | Fishy odour | Fishy odour | Fishy odour | Fishy odour |

| Feed property | Sinking | Sinking | Sinking | Floating | Floating |

All values are means ± SE of three observations; Means bearing different superscript in a row differ significantly (p<0.05); a, b, c, d, e is the feed mash soaked in water for different time intervals with moisture at varying intervals.

Table 4: Effect of preconditioning on extrudate properties of Asian seabass feed.

Figure 6: Effect of preconditioning on the bulk density (BD) and

pellet durability index (PDI) Asian seabass feed.

Note :  PDI(%).

PDI(%).

This was the first study to investigate the effect of moisture on the extrudate properties of seabass feed in a twin-screw extruder. Results of the present study showed that there was a significant effect on BD, WSI, PDI and SV when the feed mash was subjected to varying levels of moisture. Bulk density is another key factor, as it influences storage space required at the processing plant, during shipping, and at animal production facilities. BD depends on the size, shape and the extent of expansion during extrusion. Increasing temperature had a significant effect on the BD [14]. Water satiability index of extrudates increased with decrease in feed moisture and increase in temperature. In general, addition of pea grit reduced the WSI of extrudates [15]. Water stability is another measurement for quality of fish feed and is defined as the amount of time a pellet requires before breaking up after it has been placed in water [16]. Water stability quantifies the dissolving period and loss of nutrients once they are exposed to water. Generally, long time for water stability demonstrate high physical stabilities of extrudates [17]. Besides, the time fish need to consume their rations is decisive for the duration of feed stability in water. In the terms of product color, visual judgment of the products point to ongoing lightening with rising temperature but to definite level [2].

Extruded pellets are made in the same general way as compressed pellets, but the use of different dies and physical conditions results in a very different product [18]. Extrusion requires more elaborate equipment and higher inputs of moisture, heat and pressure than simple pelleting [14]. Usually, mixed ingredients are finely ground before entering the pre-conditioner where steam treatment takes place until the mixture is converted into a mash that may or may not be pre-cooked (pre-conditioning) before entering the extruder [19]. The mash, which contains around 25% moisture, is compacted and heated to 110°C-130°C under pressure in the barrel of the extruder. As the materials squeezed through die holes at the end of the barrel, and external pressure decreases, part of the water in the superheated dough immediately vaporizes and causes expansion of the feed particles [20]. The quality of extrudate produced can be determined using different methods according to their applicability in a variety of feed-industry sectors [21]. Sensory qualities include aspects of the feed product that can be adequately evaluated. These include colour, size, shape, taste, odour and structure. Such qualities vary considerably among products, significantly affecting their status and success [2]. Evaluation of sensory characteristics is a difficult task, and some of the characteristics are very hard to estimate [18].

For most cultured fish species, the extruder pellets must remain intact in water for approximately four hours [8]. Proper operation of processing equipment and selection of ingredients can extend this time. Addition of fat during extrusion cooking is very critical. Fat should be added close to discharge of the preconditioner to achieve maximum cooking [14]. For making high fat feed, extended preconditioner and long extruder barrel are recommended for increased time during cooking [22]. Fat acts as a lubricant during extrusion cooking fat content more than 8%-10% will weaken the mixture and reduce the expansion [23]. To increase the fat content of the fish feed oil spraying on the pellets after extrusion. Because of the greater amount of surface area, floating pellets can absorb about 30% liquid fat sprayed on after extrusion while sinking pellets can absorb about 15%.

The results revealed that a total moisture content of 25%-30% is optimal for the better extrusion and preconditioning for 30 minutes had a beneficial effect on the extrudate properties of CIBA developed seabass feed with 40% protein and 5% lipid.

The authors are grateful to the Indian Council of Agricultural Research, New Delhi for the project on Outreach activity on Fish feeds. Authors express their sincere thanks to Dr. A.G. Ponniah, Former Director and Dr. K.K. Vijayan, Director, Central Institute of Brackish water Aquaculture for providing necessary facilities for carrying out this work.

Citation: Ali SSA, Ambasankar K, Nandakumar S (2021) Effect of Varying Levels of Moisture Content on the Extrusion Properties of Asian Seabass (Lates calcarifer) Feed in Twin Screw Extruder. Poult Fish Wildl Sci. 9:225.

Received: 01-Sep-2021 Accepted: 15-Sep-2021 Published: 22-Sep-2021 , DOI: 10.35248/2375-446X.21.9.225

Copyright: © 2021 Ali SSR, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.