Journal of Agricultural Science and Food Research

Open Access

ISSN: 2593-9173

ISSN: 2593-9173

Research Article - (2023)Volume 14, Issue 1

In approach to adapt a healthy product incorporation of lentils in buns was performed. Supplementation of lentils with all-purpose flour was added with 30% and 40% of mung and mash (Vigna radiata and Vigna mungo) individually to enhance nutritional, textural and final quality of buns. Chemical and functional properties of the buns as well as sensorial characteristic made from the above combination were determined. The results revealed that the thickness of final product increased with incorporation of lentil flour while volume of the buns decreased. The after effects of proximate composition showed that protein content were increased as the percentage of lentils increased which could be helpful for cure of malnutrition problem in all age groups. Results also showed that carbohydrate content decreased by the addition of lentils which could be beneficial for controlling obesity. Sensorial characteristic was also determined and 30% mash formulation showed best acceptability by the panelist.

Supplementation; Vigna radiata; Obesity; Malnutrition

Malnutrition and under nutrition is one of the highlighted problem that is arising and increasing day by day around the world. The major cause is due to the insufficient availability of food and nutrient especially protein. Malnutrition is classified into two groups. Protein/energy malnutrition which is cause by lack of energy and protein and considered most lethal type and another one is micronutrient malnutrition which is due to deficiency of micronutrients in daily diet.

Legumes play an important part to overcome the protein deficiency and malnutrition in a low income group of under developed country. Combination of legumes with a cereal grain is an innovative approach for providing protein and they complete each other with essential amino acids, carbohydrates, minerals like calcium and iron, water soluble vitamins like vitamin B complex especially in baked product like cakes, biscuits, bread and buns due to their high rate of consumption. For enhancing the nutritional composition of wheat flour, composite flour is an intentional scheme [1].

Mung bean is one of the main legume crops in area of Asia, where Pakistan is second largest producer of mung bean after India. Usage of Mung bean in Pakistan is 16% in the categories of legumes (United States department of agriculture, 2011). The other name of mung bean is moong, chop soy bean, green gram, golden gram and oregon pea. The digestibility of Mung bean is higher than other legumes with less flatulence property and well tolerated by children to treat acute diarrhea and dehydration condition. Mung bean contains 24%-28% dietary protein, 59%-65% carbohydrate, 3.5%-4.5% fibre, 1%-1.5% fat, 4.5%-5.5% ash and provides about 3400 Kcal. Mung bean contains high concentration of lysine (essential amino acid) as compare to cereals. Combination of Mung bean and cereals enhance overall dietary protein quality. The other name of mash bean is a sabut mash and it’s too popular legume due to its therapeutic effect. Other use of this seed can be used as culinary dishes. Due to its nutritional potential it is used for treating several problems like anorexia, piles, constipation, asthma, neuropathy, partial paralysis, weakness of memory. Its seeds play a vital role in hair treatments like increase length of hair, controlling dandruff and keep them black [2]. Study demonstrates that they have high protein value, adequate measure of dietary fiber so in a split second have extraordinary significance in human nourishment. These beans have less fat substance and high nitrogen dissolvability; which is a trademark normally needed for great sustenance. Due to high content of carbohydrate in mash consider as prime source of energy. Adequacy in food industry builds as a result of its high practical properties [3].

The food industry is globally increasing day by day for their innovative production like functional and nutraceutical food varieties to fulfill the needs of purchasers for normal and wellbeing advancing plant based food items. Taking into account above perspectives the wholesome traits of herbs and legumes were read for the intend to decide the functional and nutritional properties of various legumes and their impact on the final quality of buns just as on its sensorial trademark. The after effect of the investigation may give opportunity to promote the beneficial impact of legumes in corporate buns for accomplishing nourishing and defeat of hunger [4].

To develop buns, the necessary materials were bought from a local market. All-purpose flour, mung bean, mash bean, sugar, yeast, butter and soya leaf. The pulses were graded, sorted, and cleaned [5]. They were soaked for 15 minutes in water. After soaking pulses boiled at 100°C for 30 minutes then allow it to cool down. Grind the boiled pulses by adding same water used for boiling pulses till 3 minutes to obtain paste of uniform and smooth texture. Fresh soya leaves dried at room temperature and grinded in powder form. Four samples of flour was prepared (Table 1).

| Sample | All-purpose flour (gm) | Lentil (gm) |

|---|---|---|

| Control | 100 gm | - |

| Mong 30% | 70 gm | 30 gm mong |

| Mong 40% | 60 gm | 40 gm mong |

| Mash 30% | 70 gm | 30 gm mash |

| Mash 40% | 60 gm | 40 gm mash |

Table 1: Formulation of flour.

Bun preparation

Dough was prepared by mixing all-purpose flour (100 gm), mung and mash (30%, 40%), sugar (10 gm), yeast (1 gm), salt (2 gm), melted butter (50 gm), soya leaf powder (3%) and water for 4 min in a mixer and left for fermentation for 1 h. Dough pieces were round, proved for 1 h and baked at 200°C for 15 min [6].

Physio chemical analysis of sample

Determination of moisture content: Moisture contents were determined by oven dry or by LOD (Loss On Drying) strategy. First samples were weighed 3 g and placed for one hour in an oven to acquire the final weight [7]. The moisture content was measured by using the formula: Moisture contentsinitial weight-weight after drying (bit stream) (Figure 1).

Figure 1: Effect of treatments on proximate composition of products in percentage of value.

Determination of protein content: Protein contents were estimated from nitrogen using Gerhardt semi-micro Kjeldahl method which is based on combustion method [8].

Percentage of Protein=(A-B) × N × 1.4007 × 6.25/W

Determination of ash content: Ash content was measured with technique described. First the weight of empty crucible with lid taken. 5 gm sample added into the crucible and place the crucible in furnace at 550°C for 4 hr. Take out crucible from furnace when sample turns to grey and allow to cool down into the desiccator. Note ash’s weight with crucible and lid.

Ash=Weight of ash × 100/Weight of samples

Determination of crude fiber: Take 5 gm of sample into a beaker and add 40 ml of boiling 0.255 N sulphuric acid. Boiled the mixture of 5 gm sample and 40 ml of 0.255 N sulphuric acid into a beaker for 30 min [9]. The volume of boiled mixture keep constant by adding hot water and for smooth boiling stirred the mixture continuously. Then the mixture was filtered and washed residue with hot water till free from acid. After that the mixture add 40 ml of boiling 0.313 N of NaOH in a beaker then boil for 30 min. The mixture was filtered and transfer to a crucible and placed it on a muffle furnace at 550°C for 3 hr. Then placed the crucible in a desicators to cooled and weight [10]. The weight of crude fiber is obtained from the difference in ash and residue weight (Tables 2 and 3).

| Sample | Bulk density (gm/ml) | WBC (%) | pH |

|---|---|---|---|

| Control | 0.82 ± 0.03 | 110 ± 0.09 | 6.1 ± 0.1 |

| Mong 30% | 0.86 ± 0.02 | 115 ± 0.07 | 6.55 ± 0.09 |

| Mong 40% | 0.79 ± 0.04 | 117 ± 0.05 | 6.6 ± 0.07 |

| Mash 30% | 0.83 ± 0.02 | 117 ± 0.1 | 6.8 ± 0.05 |

| Mash 40% | 0.85 ± 0.04 | 119 ± 0.08 | 6.85 ± 0.1 |

Table 2: Functional properties of flour.

| Sample | Moisture | Protein | Lipids | Mineral | CHO |

|---|---|---|---|---|---|

| Control | 18.3 ± 0.55 | 8.2 ± 0.1 | 3.2 ± 0.07 | 0.69 ± 0.01 | 82.4 ± 0.1 |

| Mong 30% | 17.9 ± 0.4 | 16.6 ± 0.25 | 5.5 ± 0.1 | 4.1 ± 0.06 | 56.2 ± 0.99 |

| Mong 40% | 17.2 ± 0.2 | 17.02 ± 0.1 | 5.8 ± 0.99 | 4.4 ± 0.09 | 58.3 ± 0.1 |

| Mash 30% | 18.3 ± 0.1 | 17.5 ± 0.09 | 4.5 ± 0.1 | 5.3 ± 0.08 | 57.1 ± 0.09 |

| Mash 40% | 18.8 ± 0.09 | 18.1 ± 0.1 | 5.5 ± 0.09 | 5.55 ± 0.1 | 57.8 ± 0.1 |

Table 3: Proximate chemical composition of final product.

Determination of fat content: This technique was elaborated by soxhlet extraction of 3 gm-5 gm sample with 250 ml of petroleum ether for 4 hr-6 hr at 60°C-80°C was done. Evaporate the solvent by vacuum condenser and take weight of fat into measuring cylinder [11].

Fat=Weight of fat × 100/Weight of sample

Determination of total carbohydrate: Total carbohydrate content was estimated from:

% Total carbohydrate=100%-(% moisture+% ash+% crude protein+% crude fat)

Bulk density: The mass of a dry sample is obtained by weighting, whereas the total volume of the sample, including moisture, is observed by indirect measurement.

ρ=Ms/V

Free fatty acid determination

Lipid extraction: Lipid extraction was done out by hexane extraction and method is specified in [ICC Standard No. 136.] Total fat contents are expressed as a percentage by mass of the product as received (Figure 2).

Figure 2: Effect of treatments on proximate composition of products.

Preparation of fatty acid methyl esters: Fatty acid methyl esters were obtained from the fats after alkaline hydrolysis, and then methylation in methanol with BF3 as catalyst was done. The concentration of the FAME was approximately 7 mg/ml in heptane [12].

Stability to oxidation: (Automated swift test with rancimat) 2.5 g of fat was heated for 10 min at 120°C (679 rancimat instrument, metrohm-herisau, Switzerland). Fat samples extracted from the bakery foods were subjected to analyses for free fatty acids and peroxide value according to IUPAC methods no. 2.201 and 2.501, respectively [13].

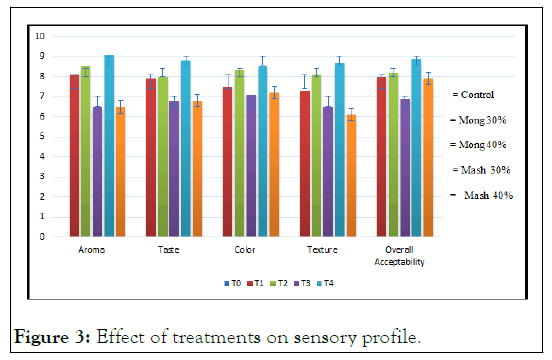

Sensory evaluation: A nine-point hedonic test based on the color, flavor, taste, texture and overall acceptability from 10 untrained panelists was done for sensory evaluation of buns (Tables 4 and 5).

| Sample | Volume (cm3) | Bulk density (gm/ml) | Free fatty acid % |

|---|---|---|---|

| Control | 58.88 ± 0.1 | 0.37 ± 0.02 | 0.018 ± 0.03 |

| Mash 30% | 46.98 ± 0.09 | 0.40 ± 0.02 | 0.052 ± 0.01 |

| Mash 40% | 40.05 ± 0.07 | 0.48 ± 0.04 | 0.067 ± 0.07 |

| Mong 30% | 50.73 ± 0.4 | 0.53 ± 0.01 | 0.028 ± 0.03 |

| Mong 40% | 49.28 ± 0.09 | 0.54 ± 0.02 | 0.035 ± 0.05 |

Table 4: Functional properties of final product.

| Control | Even pore size |

|---|---|

| Mong 30% | Even pore size |

| Mong 40% | Dense |

| Mash 30% | Little dense |

| Mash 40% | Dense |

Table 5: Pore size of mong and mash.

Proximate composition of flours is presented. The results showed that there was no significant difference in moisture content, fat and carbohydrate content of different blend of flours. Legumes contain more protein and ash content than cereals and protein content is increasing as amount of lentil is increasing in formulation (Table 6).

| Sample | Cfu/ml/gm (avg) |

|---|---|

| Control | 1.5 × 107 cfu/ml ± 0.05 |

| Mong 30% | 1.2 × 108 cfu/ml ± 0.07 |

| Mong 40% | 3.0 × 106 cfu/ml ± 0.1 |

| Mash 30% | 3.2 × 109 cfu/ml ± 0.09 |

| Mash 40% | 1.8 × 108 cfu/ml ± 0.06 |

Table 6: Microbiological analysis (total plate count).

Functional properties of flour displayed shows the bulk density of different composition of flour. Results shows that there is no significant difference in bulk density of different blend of flours [14]. Water binding capacity of blend of all-purpose flour and legumes is greater than control sample because as the amount of legume is increasing protein content of flour is also increasing. Water binding capacity relates to protein content. As protein content increases WBC also increases. The quality of flour is estimate by the level of pH. Results showed that as the lentils were added in formulation increase in pH taken place but the change in pH was not significant (Table 7).

| Test | Mong | Mash | Control |

|---|---|---|---|

| Alkaloids | - | - | - |

| Steroids | ++ | + | - |

| Flavanoids | ++ | ++ | - |

| Amino acid | + | + | - |

| Phytosterol | + | + | - |

| Saponins | - | - | - |

| Glycosides | + | + | - |

Note: ++ Shows dark coloration; + Shows light coloration; - Shows absence of polyphenol.

Table 7: Phytochemicals analysis of final product.

Chemical analysis of final products (buns) of different composition including moisture, protein, lipids, mineral and carbohydrate were carried out. Results showed that there were significant difference between buns made from all-purpose flour and blend of lentils. Protein and mineral content were increased by the addition of mong and mash with all-purpose flour but showed decrease in carbohydrate level by the addition of lentils.

There were no significant difference in moisture and lipid content of buns made from all-purpose flour and blend with lentils. Significant difference in volume of all-purpose flour buns and lentils blend buns. As protein content increased by the addition of mong and mash decreased in volume of final product and bulk density also increased but showed no significant difference. This shows results for free fatty acid content which increased as amount of lentils increased but it was not significant. 30% mong showed more even pore size than 30% mash, 40% mong and mash (Table 8).

| Sample | Aroma | Taste | Color | Texture | Overall acceptability |

|---|---|---|---|---|---|

| Control | 8.1 ± 0.2 | 7.9 ± 0.17 | 7.5 ± 0.16 | 7.3 ± 0.08 | 8.0 ± 0.06 |

| Mong 30% | 8.5 ± 0.15 | 8.0 ± 0.1 | 8.3 ± 0.18 | 8.1 ± 0.14 | 8.2 ± 0.16 |

| Mong 40% | 6.5 ± 0.13 | 6.8 ± 0.08 | 7.1 ± 0.14 | 6.5 ± 0.1 | 6.9 ± 0.15 |

| Mash 30% | 9.1 ± 0.16 | 8.8 ± 0.09 | 8.5 ± 0.1 | 8.7 ± 0.09 | 8.9 ± 0.09 |

| Mash 40% | 6.5 ± 0.1 | 6.8 ± 0.07 | 7.2 ± 0.1 | 6.1 ± 0.06 | 7.9 ± 0.07 |

Microbial analysis was carried out by total plate count methods and count number of colonies for each formulation. This showed that 30% mong contains less number of colonies as compare to mong and mash 40%. This shows the results of phytochemicals present in mong and mash. Results showed that dark coloration is obtained for the presence of flavonoids in both mong and mash means flavonoids were present in large amount (Figure 3).

Figure 3: Effect of treatments on sensory profile.

Dark coloration also shows more steroids contents in mong as compare to mash. Positive results for presence of amino acid, phytosterol and glucosides are also observed for all of the samples. Alkaloids and saponins were not detected in both mong and mash. The acceptability of the consumers in the sensory attributes of aroma, taste, color, texture and overall acceptability was evaluated by a nine point hedonic scale. The results showed that 30% mash and 30% Mong lentils are considered as best samples of buns because their sweetness and aftertaste are in balance and moderate neither too much nor too much blend aftertaste. As percentage of lentils is increasing their texture becomes dense, taste and color is also going towards non acceptability.

Bakery products are one of the most popular demanding products in all age groups among all these. A bun is one of the consumable product. In this regard we utilize different legumes in preparation of buns for which we determined proximate analysis and its physiochemical, photochemical characteristic has been analyzed. The present study showed tremendous results. We summarized that incorporation of mong and mash lentils and fresh soya with different variations effect nutritional quality and end result of the product. Therefore as quantity of lentils (mong and mash) increased, the protein content increased and carbohydrate content decreased in bun samples. Increased in protein content is beneficial for controlling malnutrition problem but it effected some other quality parameters of final product like buns containing 40% mong and mash showed dense texture, volume of buns also decreased, mash 30% showed greater acceptability by consumer and showed best results.

Mehak Ahsan, Nida Iqbal and Anum Liaquat conceived the idea, conducted the research and collected the data of the bench work. Co-supervised and designed the study, Seema Ashraf and Dr. Rashida Ali supervised and analyzed the entire data and also reviewed the article. All authors approved the final version of the manuscript.

[Crossref] [Googlescholar] [Indexed]

[Crossref] [Googlescholar] [Indexed]

[Crossref] [Googlescholar] [Indexed]

[Crossref] [Googlescholar] [Indexed]

[Crossref] [Googlescholar] [Indexed]

[Googlescholar] [Indexed]

[Crossref] [Googlescholar] [Indexed]

Citation: Ahsan M, Liaquat A, Iqbal N, Ali R, Ashraf S (2022) Effect of Incorporation of Lentils in Formulation of Buns to Enhance Nutritional and Quality Characteristics. J Agric Sci Food Res. 13: 504.

Received: 26-Jul-2021, Manuscript No. JBFBP-21-11838; Editor assigned: 29-Jul-2021, Pre QC No. JBFBP-21-11838(PQ); Reviewed: 12-Aug-2021, QC No. JBFBP-21-11838; Revised: 30-Nov-2022, Manuscript No. JBFBP-21-11838(R); Published: 17-Mar-2023 , DOI: 10.35248/2593-9173.23.14.135

Copyright: © 2022 Ahsan M, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.