Fungal Genomics & Biology

Open Access

ISSN: 2165-8056

ISSN: 2165-8056

Research - (2023)Volume 13, Issue 4

Wood-decay fungi may show potential in the degradation of rubber products in a natural and environmentally friendly process. Therefore, this study investigated the degradation of vulcanized natural rubber sheets by wood-decay fungi Trichaptum abietinum and Trichaptum biforme and the action of these fungi on the internal and external morphology, chemical composition and physical properties of the rubber sheets. Scanning Electron Microscopy (SEM)-energy dispersive X-ray spectroscopy analysis demonstrated that T. abietinum and T. biforme caused significant changes in the morphology of whole rubber. Crystals including calcium elements were formed on the rubber sheet after fungal treatment. Thermogravimetric Analysis (TGA) revealed a decrease in ash ingredient content corresponding to calcium carbonate in rubber treated with T. biforme for 3 months. These results suggest that the removal of the calcium carbonate filler from the rubber was associated with the deterioration of vulcanized natural rubber sheets by fungi. Furthermore, physical characteristics, durometer hardness and tensile strength at the breakage point in rubber sheets were clearly altered after fungal treatment, although weight loss was not remarkable. We herein report for the first time that T. abietinum and T. biforme deteriorate vulcanized rubber sheets accompanied by transformation and translocation of calcium carbonate in vulcanized rubber.

Deterioration; Vulcanized natural rubber sheet; Wood-decay fungi; Filler; Calcium carbonate

Rubber represents one of the most indispensable polymers in various industries. Vulcanized rubber, in which rubber polymer chains are cross-linked by sulfide bonds, combine elasticity with durability; however, recycling of vulcanized rubber after disposal is a major issue [1]. Various methods have been developed for the recycling of vulcanized rubber wastes, conversion to energy and chemicals via combustion and material recycling of waste via physicochemical processes [2]. In addition, biological processes are considered an alternative approach to recycle waste rubber owing to their low hazard to the environment.

Over decades, several studies have focused on the characterization of the function of various enzymes and their genes involved in bacterial degradation of rubber molecules and the associated metabolic mechanisms [3-8]. Rubber molecules are susceptible to oxidative breakdown, while vulcanization of rubber suppress microbial activity for rubber decomposition. The network of cross-linkages between polymers retards microbial degradation and additives such as fillers, antioxidants and curing agents further protect vulcanized rubber products from microbial decomposition [9,10]. Therefore, data on bacterial degradation of solid vulcanized rubber remain limited [11-13].

Wood-decay fungi play a role in the natural mineralization of woody materials. These fungi decompose lignin, which is a recalcitrant natural polymer in wood and can also degrade synthetic polymers such as nylon and polyethylene [14-16]. The potential degradation and desulfurization of vulcanized rubber materials by a white rot fungus Ceriporiopsis subvermispora have also been revealed [17]. Owing to the fact that C. subvermispora has never been isolated in Japan, the application of C. subvermispora in a practical recycling process in Japan is unrealistic. Consequently, the screening for wood-decay fungi, capable of degrading vulcanized rubber in Japan have been attempted and two wood-decay fungi, Trichaptum abietinum and Trichaptum biforme have been found to be effective degraders of solid vulcanized rubber. To the best of our knowledge, there are no studies on the biodegradation of artificial materials by Trichaptum species.

In this study, we investigated the degradation of vulcanized solid rubber accompanied by a change in both internal and external morphology, composition and of physical property of rubber mediated by T. abietinum and T. biforme.

Fungal treatment of vulcanized solid rubber

A commercial Vulcanized Natural Rubber (VNR) sheet, KGR-1300, (Itec, Tokyo, Japan) composing 40.3% organic ingredients, 33.1% carbon black and 26.6% ash was used in this study. The VNR sheets of 1 mm thickness were cut into 60 mm × 15 mm sections. The sheets were soaked in 99.5% ethanol once, rinsed with double-distilled H2O and dried at 25°C overnight.

Two wood-decay fungi, T. abietinum TUES-023 and T. biforme TUES-016 present in a type culture collection of Tottori University of Environmental Studies were used in this study. The species T. abietinum and T. biforme were confirmed via genetic identification based on 99.61% and 99.86% homology of an internal transcribed spacer of 18s Recombinant Deoxyribonucleic Acid (rDNA), respectively. Each fungus was maintained on malt extract agar (Oxoid, Basingstoke, UK) as a stock culture. Agar containing fungi was punched out using a 7 mm diameter cork baller and 10 of the agar pellets were added to 50 mL of liquid culture containing 2% (w/v) malt extract (BactoTM, Detroit, MI, USA). The liquid culture was statically incubated at 28°C for one week.

Solid wood culture composing 10 g of beech wood saw dust, 1 g of wheat bran and 8 mL of double-distilled H2O was added to a 300-milliliter Erlenmeyer flask and mixed with shaking. Two VNR sheers were placed in a wood/wheat bran medium and autoclaved at 121°C for 20 min. The liquid inoculum containing fungi was mixed thoroughly by pipetting and then 10 mL of the liquid including fungal hyphae was inoculated into each flask. The flasks were incubated statically at 25°C for 1-3 months.

After incubation, VNR sheets were harvested from flasks and then fungal mycelia on the rubber surface were removed carefully. The rubber sheets were washed with double-distilled water and weighed after drying at 28°C overnight.

Scanning electron microscopy

The VNR sheets exposed with and without fungi were dried in vacuo once, then cut into small pieces (2 × 2 × 1 mm). Each sample was fixed on a brass stub, coated with OsO4 and then analyzed using the scanning electron microscope S-3400N (Hitachi High-Tech, Tokyo, Japan) at an acceleration voltage of 20kV. Elemental analysis was performed using SEM S-3400N equipped with Energy Dispersive X-ray Spectroscopy (EDS) EX250 (Horiba, Kyoto, Japan).

Thermogravimetric analysis

TGA was performed for 5 mg of VNR sheets using EXTER TG/DTA 6200 (Seiko, Tokyo, Japan). The sample was heated from 30 to 600°C at a rate of 20°C per min in N2 and then heated from 600 to 900°C at a rate of 20°C per min in air. The proportions of volatile carbon, non-volatile carbon and ash ingredients in the VNR sheets were calculated based on the weight loss curve according to changes in temperature.

Hardness measurement of rubber

Hardness of the surface layer of rubber was measured using a Type-A durometer (Muratech-KDS, Kyoto, Japan). Three points of hardness from two of ten-millimeter inner parts from both edges and one of a central part were measured and the average of those measurements was calculated.

Force measurement of tensile strength

Force measurement of tensile strength of the rubber sheets was performed using the digital force gauge ZTA-500 (Imada, Toyohashi, Japan). The rubber sheet was molded into dumbbells using a cutting blade of JIS-7 type. One side of the molded sheets was bound using the knurled cam grip, GP-15 equipped with a digital force gauge and the other side was bound using the knurled cam grip, GP-30 fixed to the vertical motorized test stand MX2 (Imada). The measurement was performed at a rate of 1 mm per second and terminated at the time of breakage. A force curve between stress (MPa) and strain (%) for each VNR sheet was generated using the software Force Recorder Standard ver. 1.03 (Imada). The tensile strength at breakage was calculated using the force curve.

VNR sheets were exposed to the cultures of T. abietinum and T. biforme and the interaction of fungi with sheets in terms of morphology, chemical composition and physical characteristics was investigated.

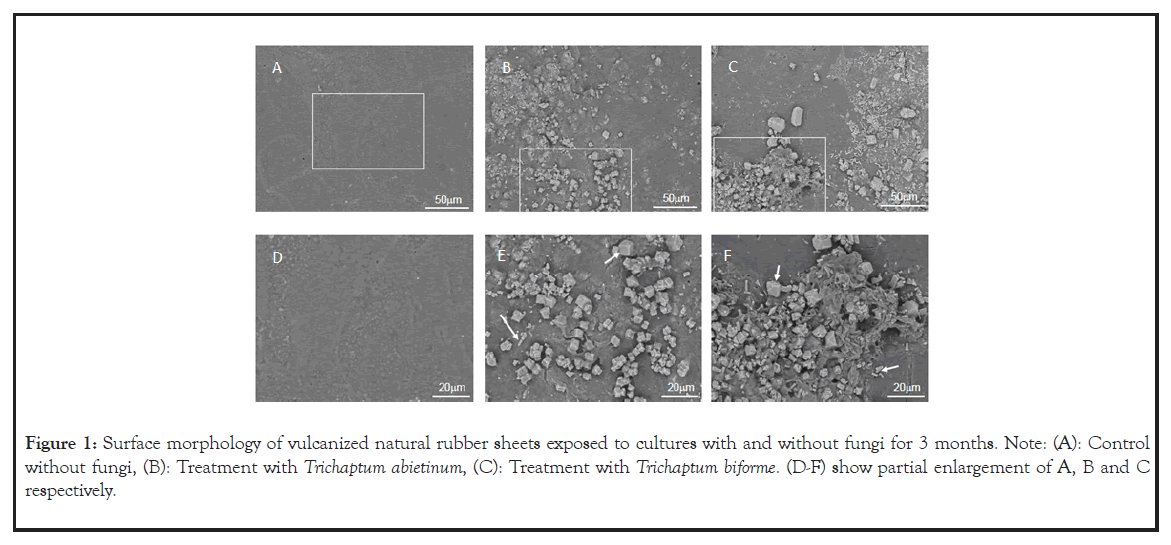

The morphology of the rubber surface with and without fungal treatment for 3 months is shown (Figures 1A-1F). The surface of the rubber sheets without exposure to fungi was smooth even after 3 months. In contrast, the rubber surface exposed to fungal cultures varied considerably. There were small cracks and a large number of crystals formed on the rubber sheets (Figures 1A-1C). Scanning Electron Microscopy-Energy Dispersive X-Ray Spectroscopy (SEM-EDS) analysis revealed that the crystalline substances A, B and C were mainly composed of the elements Ca, C and O, suggesting that these crystals were associated with CaCO3 added in the rubber (Table 1). The composition of crystalline substance D was suggested to contain certain metal carbonates as well.

Figure 1: Surface morphology of vulcanized natural rubber sheets exposed to cultures with and without fungi for 3 months. Note: (A): Control without fungi, (B): Treatment with Trichaptum abietinum, (C): Treatment with Trichaptum biforme. (D-F) show partial enlargement of A, B and C respectively.

| Solid | Crystal Form | Elements (% in weight) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Carbon | Oxygen | Aluminium | Silicon | Sulfur | Potassium | Calcium | Iron | Zinc | ||

| A | Tetrahedron | 35.6 | 42.1 | - | - | 0.6 | - | 21.3 | - | 0.5 |

| B | Needle | 30.2 | 52.6 | - | - | 0.2 | - | 17.0 | - | - |

| C | Tetrahedron | 29.3 | 57.2 | - | - | - | - | 13.5 | - | - |

| D | Needle | 57.9 | 36.7 | - | 0.1 | 0.7 | - | 4.0 | - | 0.4 |

Note: The data were obtained via Scanning Electron Microscopy (SEM)-Energy Dispersive X-ray Spectroscopy Analysis (EDSA).

Table 1: Composition and relative amount of elements in the vulcanized natural rubber sheets after treatment with Trichaptum abietinum and Trichaptum biforme for 3 months.

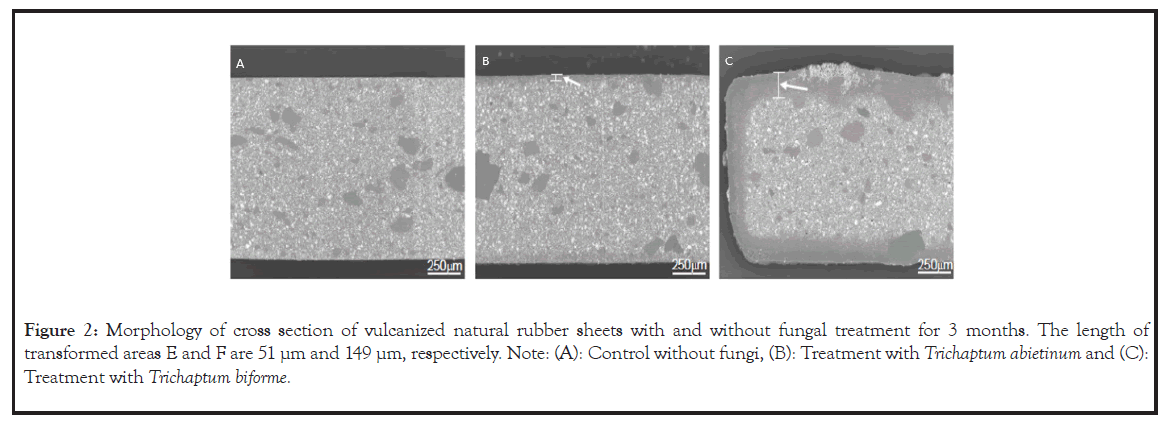

The cross section of the rubber exposed to the fungal cultures for 3 months is shown (Figure 2). There were large differences in the morphology of VNR sheets between exposure with and without fungi. A structural modification at 51 µm depth from the outer rubber surface was observed in VNR sheets exposed to T. abietinum for 3 months (Figure 2B, panel E). Notably, considerable deterioration of the rubber structure by T. biforme was found at a 149 µm depth in the rubber (Figure 2C, panel F).

Figure 2: Morphology of cross section of vulcanized natural rubber sheets with and without fungal treatment for 3 months. The length of transformed areas E and F are 51 μm and 149 μm, respectively. Note: (A): Control without fungi, (B): Treatment with Trichaptum abietinum and (C): Treatment with Trichaptum biforme.

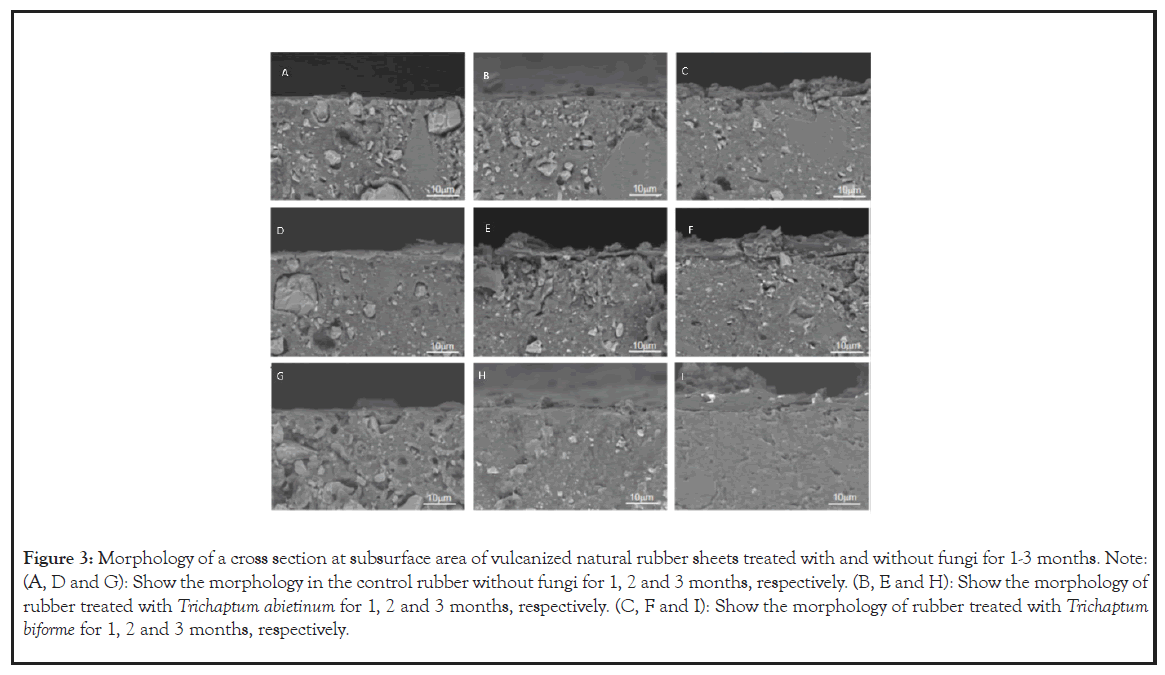

The comparison of cross sections closes to the VNR subsurface with and without fungal treatment from 1–3 months is shown (Figure 3). There was no noticeable change over the period of 3 months. The photos show the morphology of rubber treated with T. abietinum for 1, 2 and 3 months, respectively (Figures 3B, 3E and 3H). When comparing the photos in Figures 3B and 3E, the collapse of the rubber structure was only found at 2 months of incubation, suggesting that fungal degradation had proceeded after 1 month of incubation. At 3 months of incubation, the rugged chunks in the rubber had disappeared and then the morphology appeared flat.

Figure 3: Morphology of a cross section at subsurface area of vulcanized natural rubber sheets treated with and without fungi for 1-3 months. Note: (A, D and G): Show the morphology in the control rubber without fungi for 1, 2 and 3 months, respectively. (B, E and H): Show the morphology of rubber treated with Trichaptum abietinum for 1, 2 and 3 months, respectively. (C, F and I): Show the morphology of rubber treated with Trichaptum biforme for 1, 2 and 3 months, respectively.

The cross section of the rubber in photos represent the rubber treated with T. biforme for 1, 2 and 3 months, respectively (Figures 3C, 3F and 3I). After incubation for 1 month, the morphology of the rubber treated with T. biforme was clearly altered (Figure 3C). Most rugged lumps in the rubber disappeared at incubation for 2 months (Figure 3F) and few lumps were left after 3 months (Figure 3I).

Fungal treatment for 3 months led to total weight loss and changes in physical properties of the rubber sheets (Table 2). Durometer hardness of the rubber was increased by 11% and tensile strength at the breakage point of the rubber was decreased by 27% after treatment with both fungi, while the highest weight loss in the rubber after fungal treatment was 5%. The composition of rubber determined via thermogravimetric analysis is shown (Table 3). The VNR sheet comprised volatile organic carbon including oil, antioxidants, curing agents and polymers, non-volatile carbon such as carbon black and carbonate and ash from fillers such as calcium carbonate. The proportions of volatile organic carbon, non-volatile carbon and ash in the rubber before fungal treatment were 39.8%, 33.5% and 26.7%, respectively. In rubber treated with T. abietinum, there was a minor change in the proportions of the three components during 3 months of incubation. In contrast, the proportions of these components varied in rubber treated with T. biforme. The proportion of ash ingredient corresponding to calcium carbonate content decreased from 26.0% to 23.6% after 3 months, whereas the proportion of volatile carbon increased. Therefore, calcium carbonate content may have been preferably reduced by the action of T. biforme.

| Treatment | Weight loss (%) | Hardness (Relative Value) |

Strength at breakage point (MPa) |

|---|---|---|---|

| Control | 0 | 67.3 | 3.6 |

| T. abietinum | 3.0 ± 0.6 | 74.5 | 2.6 |

| T. biforme | 5.0 ± 0.3 | 75 | 2.6 |

Note: Control refers to the treatment without fungi.

Table 2: Weight loss and physical characteristics of the vulcanized natural rubber sheets with and without fungal treatment for 3 months.

| Treatment | Period (Month) | Proportions (% in weight) | ||

|---|---|---|---|---|

| Volatile Carbon | Non-Volatile Carbon | Ash | ||

| Control | 0 | 39.8 | 33.5 | 26.7 |

| T. abietinum | 1 | 40.3 | 33 | 26.7 |

| 2 | 40.1 | 33 | 26.9 | |

| 3 | 40.9 | 32.9 | 26.2 | |

| T. biforme | 1 | 41.1 | 32.9 | 26 |

| 2 | 41 | 33 | 26 | |

| 3 | 44.7 | 31.7 | 23.6 | |

Note: The data were determined via Thermogravimetric Analysis (TGA). Control refers to the treatment without fungi.

Table 3: Comparison of the relative proportions of three main components, volatile carbon, non-volatile carbon and ash in the vulcanized rubber sheets before and after fungal treatment.

Recycling of rubber materials represents a major issue in the rubber industry based on the need for environmental conservation and de-carbonization as sustainable developmental goals. Among several methods, biodegradation of solid vulcanized rubber represents a promising approach to recycle waste rubber into other resources. The wood-decay fungi, T. abietinum and T. biforme may have potential in the recycling of vulcanized rubber wastes. Therefore, the effect of fungal growth on a VNR sheet was investigated in this study.

Regarding morphology, fungal treatment caused major changes in both the external and internal regions of the rubber. Scattered small cracks and a large number of crystal deposits were found on the rubber surface exposed to both fungi even at one month of incubation (Figures 1B and 1C). The deposits were suggested to be crystals of calcium based on SEM-EDS analysis (Table 1). Furthermore, the internal morphology of the rubber sheets varied after fungal treatment. Observation of cross sections of the rubber revealed that rugged lumps added as a filler were eliminated from the rubber after fungal treatment (Figures 2 and 3). These results suggested that fungal degradation occurred together with weight loss mainly caused by elimination of the calcium carbonate filler.

Regarding the metabolism of calcium carbonate by wood-decay fungi, it has been reported that wood-decay fungi can accumulate and translocate metal ions such as manganese, copper and calcium in woody substrates [18]. Wood-decay fungi produce organic acids in the presence of metal oxides and the formation of calcium oxalate crystals by white and brown rot fungi grown on media containing high levels of toxic metals such as calcium carbonate has been reported [19-21]. Considering the inherent function of wood-decay fungi, the accumulation of calcium crystals on the rubber after treatment with T. abietinum and T. biforme can be explained in the same manner. A trace amount of metals is essential for fungal growth, whereas an excessive amount of metals may lead to toxicity. The organic acids produced by T. abietinum and T. biforme may solubilize the metals in the rubber, then form acid-chelated metal complexes such as calcium oxalate that are incorporated into cells, while excess amounts of solubilized metals are transferred and excluded from the material via fungal mycelia. The metals are accumulated on the outer surface of rubber materials, resulting in aggregate of calcium crystals. We confirmed that the pH of the cultures of T. abietinum and T. biforme were approximately 3 after incubation for 28 d and the acidic conditions were maintained for more than 3 months. Therefore, it may be possible that fungal metabolites are responsible for the transformation of calcium carbonate in the rubber, although we have not obtained evidence that these fungi can produce oxalic acid. The removal of calcium carbonate from rubber by fungi may also be associated with the weakening of physical performance of the rubber. Formation of cracks on the rubber is associated with partial breakdown of polymer chains by fungi. The damage may reduce the tensile strength.

The wood-decay fungus C. subvermispora has been previously shown to degrade vulcanized natural rubber and the degradation is associated with weight loss, decrease in ash content in the rubber and oxidative scission of sulfide bonds in vulcanized solid rubber. Recently, the white rot fungi Trametes versicolor and Pleurotus ostreatus have also been reported to represent potential degraders of vulcanized rubber [22-24]. The presence of vulcanized rubber in the cultures that T. versicolor and P. ostreatus grow increases the activity of ligninolytic enyzmes of Laccase and peroxidase, thus allowing for the prediction of the affinity of these ligninolytic enzymes for aromatic substrates present in rubber composition. We tested T. versicolor and P. ostreatus to screen fungi capable of degrading vulcanized rubber sheets, however, clear evidence of weight loss and damage to surface morphology owing to the two fungi has not been obtained. The degradation mediated by wood-decay fungi may depend on compatibility between fungal strains and the composition of the rubber materials. In addition to C. subvermispora, T. versicolor and P. ostreatus, degradation of rubber by T. abietinum and T. biforme was demonstrated for the first time in this work. With respect to the extracellular mechanism, the activity of the ligninolytic enzyme manganese peroxidase is detected in the woody cultures of T. abietinum and T. biforme, regardless of the presence or absence of vulcanized rubber. The participation of the enzymes in the degradation of vulcanized rubber is unknown. However, it is speculated that the fungal degradation of vulcanized rubber may remove filler components such as calcium carbonate and mediate the breakdown of sulfur cross-linkages and polymer chains. Calcium carbonate is a representative filler widely used in commercial rubber products and plastic materials. The removal of calcium carbonate from multi-component commercial rubber products mediated by T. abietinum and T. biforme is a desirable characteristic that has not been reported in bacterial degradation of vulcanized rubber and may contribute to feedstock recycling of various industrial products containing fillers.

Microbial degradation in feedstock recycling of waste rubber materials represents an attractive approach to attaining sustainability goals. In this study, we demonstrated that the wood-decay fungi T. abietinum and T. biforme represent potential degraders of VNR. The degradation of rubber by these two fungi may be attributed to the removal of calcium carbonate filler, leading to weight loss, change in morphology and decrease in tensile strength. Transformation of calcium carbonate by fungal action may be applicable to other materials. To the best of our knowledge, this is the first study to show that the wood-decay fungi T. abietinum and T. biforme mediate the degradation of vulcanized solid rubber. Further studies should elucidate the fungal mechanisms associated with the breakdown of sulfur crosslinks and polymer chains and apply the fungal action to a practical recycling system. However, this study provides a new biological approach towards the feedstock recycling of vulcanized rubber.

This study was partly supported by a Grant-in-Aid for Scientific Research (C) (grant No 20K06170) from the Japan Society of the Promotion of Science.

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

Citation: Sato S, Tien HK, Inamori W, Yoneyama F, Mase A (2023) Deterioration of Vulcanized Natural Rubber Sheets is Associated with Removal of Calcium Carbonate Filler by Wood-Decay Fungi Trichaptum abietinum and Trichaptum biforme. Fungal Genom Biol. 13.236.

Received: 14-Nov-2023, Manuscript No. FGB-23-28638; Editor assigned: 16-Nov-2023, Pre QC No. FGB-23-28638 (PQ); Reviewed: 30-Nov-2023, QC No. FGB-23-28638; Revised: 07-Dec-2023, Manuscript No. FGB-23-28638 (R); Published: 14-Dec-2023 , DOI: 10.35248/2165-8056.23.13.236

Copyright: © 2023 Sato S, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.

Sources of funding : This study was partly supported by a Grant-in-Aid for Scientific Research (C) (grant No 20K06170) from the Japan Society of the Promotion of Science.