Journal of Ergonomics

Open Access

ISSN: 2165-7556

ISSN: 2165-7556

Research Article - (2019)Volume 9, Issue 4

The use of arm-support exoskeletons could be a strategy to unload the shoulder in elevated arm work. In this paper the effects of these type of exoskeletons on objective parameters of shoulder load, subjective measures and performance measures were reviewed. The review resulted in eleven papers addressing ten arm-support exoskeletons. Seven of these exoskeletons were passive (spring-based) exoskeletons, one was an active exoskeleton mounted to the wall and two exoskeletons were equipped with a supernumerary limb (snl) attached to the waist. For the exoskeletons with a snl, the concept of transferring loads from the shoulder to the waist did not result in the expected reductions in shoulder muscle activity. The passive exoskeletons did show reduced levels of activity in the agonistic muscles (those involved in arm elevation), ranging from 16% to 130%, both in quasi-static tasks like overhead drilling and overhead assembly, but also in lifting and stacking tasks that involved elevation of the arms. However, the activity in antagonistic muscles was found to increase by up to 107%. The adoption of arm support exoskeletons in practice depends on whether the positive effects of lowered muscle activity would outweigh negative effects like increased antagonistic muscle activity and other potentially adverse effects regarding discomfort or usability. With regards to subjective experiences and performance related measures, mixed results were reported. The effectivity and subjective experience seem to be task-dependent. Therefore, it is important to consider the specific working environment and envisioned results, to select the exoskeleton that best suits the specific working conditions.

Exoskeletons; Workforce; Muscle activation; Work station

Despite the ongoing robotization of manual labor, physically demanding work is still prevalent in industry. The proportions of the EU workforce that are exposed for more than a quarter of their working time to ‘tiring or painful positions’, ‘carrying or moving heavy loads’, and ‘repetitive hand or arm movements’ are 43%, 32% and 61%, respectively [1]. These exposures relate to increased risks for developing musculoskeletal disorders in various body regions [1].

The shoulder area is one of the main regions susceptible to workrelated musculoskeletal disorders. Yearly, more than 42% of the workers in the EU suffer from shoulder pain [1]. The work-related musculoskeletal shoulder disorders can be classified into various subcategories, mainly: sub-acromial impingement syndrome (SIS), a tear in one of the rotator cuff muscles, and supra-scapular nerve compression [2]. In addition, Van Rijn et al. (2010) consider SIS as a broader term that includes rotator cuff syndrome, bursitis and tendinitis of the musculus infraspinatus, musculus supraspinatus and musculus subscapularis [3].

A well-documented risk factor for developing musculoskeletal shoulder disorders is work with elevated arms [3,4]. Working with the hands above shoulder level for more than one hour per day, has been associated with the occurrence of SIS [3]. In guidelines for occupational health, the risk for developing shoulder problems is assumed to be particularly increased when the arms are repetitively or statically elevated over 60˚ (enclosed angle between the upper arm and the vertical), but the risk would already be increased at lower angles as well, depending on the frequency and the duration of arm elevation (ISO11228-1, ISO11228-3).

Elevated arm work frequently occurs in construction, maintenance and manufacturing (e.g. car and aircraft assembly). It often appears to be difficult or even impossible to solve the problem by redesigning the work or the work station. A new strategy, which gains interest, is the use of industrial exoskeletons.

Industrial exoskeletons are worn on the body and aim to reduce the mechanical loads on human body structures in work. In fact, they aim to contribute to the generation of the joint moments that are required to maintain a working posture or move a body segment. As a result, less muscle force needs to be generated and therefore the internal loads on joints, muscle ligaments, tendons, and other tissues would decrease [5]. The mechanical contribution of the exoskeleton to the joint moment could be supplied actively, for example by electric motors, hydraulic actuators or pneumatic muscles, but could also be applied through mechanisms using passive spring [5-7]. Moreover, exoskeletons may follow the anatomic shapes of the human body (anthropomorphic exoskeletons) to some extent or may not. The latter include exoskeletons with supernumerary limbs.

Arm-support exoskeletons are specifically aimed to reduce the loads on shoulder structures by contributing to the shoulder moment that elevates the arms. Despite the complexity of the shoulder joint, various arm-support exoskeletons have been developed or are being developed over the past recent years. These include both passive and active exoskeletons [8,9]. Compared to active exoskeletons, passive ones have the benefit of being lighter, being less complex regarding sensing and control, and do not require external power sources. Some of the currently existing passive armsupport exoskeletons are entering the market now.

The effectivity of arm-support exoskeletons in unloading the shoulder region has been analyzed during static elevated arm postures in several studies. Huysamen et al. studied the effect of a passive arm-support exoskeleton on the activation of shoulder muscles while maintaining the arms in an elevated posture (elbow and shoulder at 90° flexion) with or without a load in the hands. They found a significant reduction in muscle activity of 62% and 49% for the MD and BB, respectively, while the perceived effort to keep that posture was reduced by 42%. Positive effects during static arm elevation postures have also been found for several active arm support exoskeletons, particularly in terms of reduced shoulder muscle activity and increased endurance [10,11]. In other studies, more realistic working activities like drilling, screwing or lifting have been applied to study the effectivity of arm-support exoskeletons.

In this literature review, we focus on studies in which the effects of arm-support exoskeletons on objective parameters related to physical load were investigated in realistic work activities. We also consider the effects on subjective measures like perceived effort and local discomfort as well as the effects on performance measures like speed of work and numbers of errors. The aim of this review is to determine these effects and discuss these effects in relation to the benefits and shortcomings of arm-support exoskeletons to be applied in practice.

An electronic literature search of the SCOPUS and PUBMED database was performed in July 2019. For this search the following search terms were used: wearable robot, exoskeleton, arm, upper body, shoulder, industrial, lifting, transport, manual labor. The authors also searched in their personal databases for additional publications of relevance. This search resulted in 213 peer-reviewed papers.

In the next step the titles and abstracts of all the papers retrieved were screened according to the following criteria for inclusion. To be retrieved in this review, the paper needs to describe a field or laboratory experimental study in which the effects of the exoskeleton on parameters for physical loading, subjective experiences and parameters for performance were analyzed. Another inclusion criterion was that the paper needs to describe a study on some kind of realistic industrial activity. Such activity is an activity that may occur in various sectors of industry, e.g. maintenance, manufacturing, construction, or logistics. Examples could be: assembly, drilling, screwing, lifting or stacking tasks. Papers considering other settings, such as rehabilitation, medical, tele-operations, military and virtual reality were excluded. We included all exoskeleton papers irrespective of the stage of design of the exoskeleton, ranging from early stage prototypes tested only in a laboratory setting to commercially available products ready to be used in practice. Similarly, we decided not to exclude any papers based on the quality of the studies (e.g. numbers of subjects, statistics), but to take quality issues into account when discussing the results.

The outcome measures used in the included studies were divided into three categories: objective load parameters (muscle activity, kinetics, kinematics, cardiac cost, body sway), objective parameters for performance (efficiency, number of errors, precision, endurance time, work pace), and subjective measures (discomfort, perceived exertion).

Eleven studies were identified in which the effectivity of an arm support exoskeleton was evaluated during one or more industrial activities Table 1. Remarkably, eight of these were published in 2018 or later, while the oldest one was published in 2014.

| exoskeleton (developer) | study | activity | sub-jects | effects on objective load | effects on subjective measures | effects on performance | |||

|---|---|---|---|---|---|---|---|---|---|

| FORTIS (Lockheed Martin) passive full-body exoskeleton with a super numerary limb |

Alabdulkarim S et al.,[14] | overhead drilling tool weight: 2 or 5 kg |

8♂ 8♀ |

EMG amplitude (peak, 90th percentile) ± 51% ▲AD (L) heavy tool only ± 27% ▲MD (L) ± 71% ▲ILL R) ± 63% ▲ILL (L) EMG amplitude (median, 50th percentile) ± 100% ▲ AD (R) only in♀ ± 80% ▲ AD (L) ± 135% ▲ MD (R) only in♀ ± 100% ▲ MD (L) ± 25% ▲ ILL (R) |

- - - - - - - - - |

rating perceived discomfort ± 28% ▼ hand/wrist ± 24% ▼ upper arm ± 40% ▲ thigh ± 118% ▲ lower leg |

+ + - - |

maximum acceptable frequency ± 20% ▼ only in♀ number of errors ± 100% ▲ |

- - |

| EXOVEST (Tiffen) passive upper-body exoskeleton with a super numerary limb | Alabdulkarim S et al.,[14] | overhead drilling tool weight: 2 or 5 kg | 8♂ 8♀ | EMG amplitude (peak, 90th percentile) ± 39% ▲ AD (L) heavy tool only ± 35% ▲ ILL (R) EMG amplitude (median, 50th percentile) ± 70% ▲ AD (L) ± 100% ▲ MD (L) ± 33% ▼ TB only in♀ ± 140% ▲ ILL (L) only in♀ |

- - - - + - |

rating perceived discomfort ± 45% ▲ low back only in ♀ ± 21% ▼ upper arm |

- + |

maximum acceptable frequency ~ number of errors ~ |

~ ~ |

| Rashedi E et al.,[12] | overhead work with 2 handed weighted tool (1.1, 3.4 and 8.1kg) | 12♂ | EMG amplitude ± 25-50% ▼ in AD (R) (from 1.1 to 8.1 kg) ± 81 - 31% ▲ in ILL (from 1.1 to 8.1 kg) ± 29% ▼ TB (R) at 8.1kg ± 43% ▼ TB (L) at 8.1kg EMG rate of amplitude decrease ▼ AD (R) ▼ AD (L) EMG power frequency change over time ~ |

+ - + + + + ~ |

rating perceived discomfort ± 57% ▼ upper arm at 3.4kg ± 64% ▼ upper arm at 8.1kg ± 42% ▼ shoulder at 3.4kg ± 50% ▼ shoulder at 8.1kg |

+ + + + |

|||

| SHOULDERX (US Bionics) passive arm-support exoskeleton |

Alabdulkarim S et al.,[14] | overhead drilling tool weight 2 or 5 kg | 8♂ 8♀ | EMG amplitude (peak, 90th percentile) ± 16% ▼ AD (R) ± 30% ▼ MD (R) ± 27% ▼ MD (L) EMG amplitude (median, 50th percentile) ± 25% ▲ TB (R) only in♀ |

+ + + - |

rating perceived discomfort ± 26% ▼ upper arm ± 30% ▼ low back only in ♂ |

+ + |

maximum acceptable frequency ~ number of errors ~ |

~ ~ |

| Van Engelhoven L et al.,[18] | overhead assembly (drill 0.45kg or 2.25 kg) support: 8.5, 13 or 20Nm peak torque | 13♂ | EMG amplitude 32-80% ▼AD (support 8.5–20 Nm, light tool) 24-64% ▼ AD (support 8.5–20 Nm, heavy tool) 23-46% ▼ UT (support 8.5–20 Nm, light tool) 18-42% ▼ (support 8.5–20 Nm, heavy tool) ± 80% ▲TB (support at 20Nm) up to 24% ▼ IS (support 13 and 20Nm) |

+ + + + - + |

preferred support level Light tool: 75% preferred medium support and 75% least preferred high Heavy tool 63% preferred medium support, 58% least preferred no support |

||||

| EKSOVEST (Eksobionics) passive arm-support exoskeleton |

Kim S et al., [13] | overhead drilling (heavy 5.9kg and light 3.63kg) and wiring | 6♂ 6♀ |

EMG amplitude (peak: 95th percentile) ±30% ▼for eight shoulder muscles (all tasks) ±30-33% ▼TB (R) (heavy to light drill) |

+ + |

discomfort (rpd) ±40% ▼ forearm (heavy drill) | + | number of errors ±40% ▲ | - |

| Kim S et al.,[19 | overhead drilling (heavy 5.9kg and light 3.63kg) and wiring | 14♂ 3♀ | spinal shear force (lumbosacral level) ± 26% ▼ AP shear (all tasks) ± 70% ▲ ML shear (wiring task) spinal compression force (lumbosacral level) ± 16% ▼ Peak (tasks at shoulder height) ± 19% ▼ Peak (heavy drilling) ± 20% ▼ Peak(F) (light drill) ± 18% ▼ Median(F) (heavy drill) ± 20% ▼ Median(F) (light drill) range of motion 2% ▼ in shoulder flexion 10% ▼ in shoulder abduction 10% ▼ in shoulder abduction body sway (COP speed) 12% ▲ in AP (mm/s) |

+ - + + + + + - - - |

|||||

| SKELEX (Skelex) passive arm-support exoskeleton |

Moyon A et al.,[20] | overhead sanding | 2♂ | cardiac cost ▼ | + | ||||

| AIRFRAME (Levitate) passive arm-support exoskeleton | Spada S et al.,[9] | manual lifting (3.4kg), precision task. (by factory floor workers) | 31♂ | repetitions on lifting task ~ precision task (# arches traced) 33.6% ▲ (time was similar) precision Index 16.7% ▲ |

~ + + |

||||

| Spada S et al.,[17] | manual lifting (3.4kg), precision task. (by office workers) | 11♂ | repetitions on lifting task no statistics precision task (# arches traced) 17.5% ▲ (time was similar) precision Index no statistics |

?

+ ? |

|||||

| unnamed exoskeleton (IIUVO) passive arm-support exoskeleton |

Spada S et al.,[16] | static holding, manual lifting (3.4kg), precision task. support up to 70% of weight of the arm | 18♂ | repetitions on lifting task no statistics precision task (# arches traced) 26.5% ▲ (time was similar) precision Index 20.8% ▲ |

? + + | ||||

| ABLE (Haption) Active wall-mounted arm-support exoskeleton |

Sylla N et al.,[21] | overhead drilling Set at gravity compensation for different preset loads (1.335 kg.m, 1.635 kg.m =1.935 kg.m) | 8♂ | Required torque generation by subject (peak) up to ± 21% ▼ in the shoulder up to ± 34% ▼ in the elbow ground reaction forces up to 19.07% ▼ joint angles slight modifications in joint angles |

+ + + |

||||

| EXHAUSS passive arm-support exoskeleton | Theurel J et al.,[15] | lifting 9kg (♂) and 5kg (♀) carrying(♂ 15, ♀ 8kg) stacking (♂ 15, ♀ 8kg) supportive force at distal end of the end effector at 90⁰ (♂ ~ 9, ♀ ~5kg) | 4♂ 4♀ | EMG amplitude ± 53% ▼AD (L) (Lifting) ± 97% ▲TB (Lifting) ± 110% ▲TA (Lifting) ± 64% ▼TB (carrying) ± 73% ▼ AD (stacking) ± 107% ▲ TB (stacking) cop displacement 68% ▲ area of confidence ellipse 34% ▲AP oscillation cardiac cost Lifting: 13.8% increased (p=0.058) Carrying: ~ Stack: ~ |

+ - - - + - - - - |

rated perceived exertion Lifting: ~ Carrying: 17.6% ▲ Stack: ~ |

- | ||

▼and ▲ means significantly higher and lower value, respectively, for the with-exoskeleton condition.

▼and ▲ means higher and lower value, respectively, but not statistically evaluated.

~ means that no statistical difference was found between with and without-exoskeleton conditions.

± means that the presented effects are estimates by the authors based on figures in the original papers.

+ means that the observed effects are considered as desired effects

- means that the observed effects are considered as undesired effects

Anterior-Posterior (AP), Left side (L), Right side (R)

Table: Overview of studies and study outcomes

These studies include a total of nine exoskeletons. Four of these (EXOVEST, SHOULDERX, AIRFRAME and EKSOVEST) were evaluated in two different studies, all others were evaluated in one study only. The only active exoskeleton in the table, i.e. using actuators to actively generate a torque around the shoulder, is ABLE. This exoskeleton is worn on the body, but also externally mounted to a wall (Sylla et al. 2014) [21]. FORTIS and EXOVEST, a full body and an upper body exoskeleton respectively, are exoskeletons with a supernumerary limb (extra arm, snl) attached to the trunk at waist level. At the other side, the snl is directly attached to a hand tool, while the user moves this tool with his hands. The remaining six exoskeletons are more or less similar: these are worn on the trunk and support the arms through a spring-based mechanism, which provides a supportive torque when the arms are brought into an elevated posture. Differences among these exoskeletons concern the level of support, supported range of motion, the points of attachment and general design.

The tasks that were investigated in the various studies include overhead drilling (six studies), overhead sanding (one study), manual lifting (four studies), carrying weights (one study), stacking and turning (one study), performing a laboratory-simulated gluing task (three studies).

To define the effects on objective load parameters, subjective experiences or performance measures, all included studies applied a repeated measures design in which with-exoskeleton and withoutexoskeleton conditions were compared. The number of subjects was only 2 in one study, while in the other studies this number ranged from 8 to 27. Nine studies reported an effect on one or more objective load parameters, which included mainly muscle activity (EMG amplitudes and power frequency), but also kinetics (joint moments, internal forces on the spine), posturography, cardiac cost, and joint kinematics.

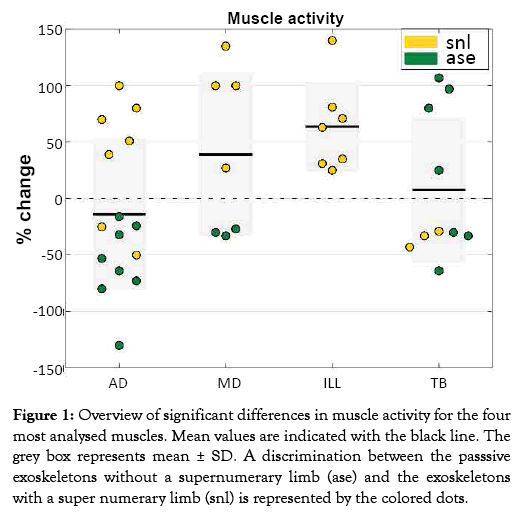

The reported changes in muscle activation (EMG amplitudes) ranged across studies and muscles from 140% increase to 130% reduction. The muscles that were most frequently analyzed were the Anterior Deltoid (AD), the Medial Deltoid (MD), the Triceps Brachii (TB) and the Illiocostalis Lumborum pars Lumborum (ILL). For the AD, MD and TB both increased muscle activity as well as reductions were found. The reported effects across studies ranged from +100% to -130% for AD, from +135% to -62% for MD, and from +107 to -43 for TB:). For the ILL only increases in muscle activity (ranging from 25% to 140%) were reported however it should be noted that in with and without exoskeleton conditions muscle activation remained low in terms of %MVC. Figure 1 summarizes the results for these muscles across the various types of exoskeletons.

Figure 1: Overview of significant differences in muscle activity for the four most analysed muscles. Mean values are indicated with the black line. The grey box represents mean ± SD. A discrimination between the passsive exoskeletons without a supernumerary limb (ase) and the exoskeletons with a super numerary limb (snl) is represented by the colored dots.

Exoskeleton effects on subjective outcome measures, such as local perceived discomfort or perceived exertion, were reported in five papers, of which two reported beneficial effects regarding rated perceived discomfort [12,13]. Alabdulkarim & Nussbaum et al. showed positive results for an anthropomorphic exoskeleton, while a full body exoskeleton with snl as well as an upper body exoskeleton with snl resulted in mixed results (depending on which body region was studied) [14]. In another study the rated perceived exertion was shown to be similar during lifting and stacking tasks, whereas it was increased during carrying [15].

Five studies report the effect of exoskeletons on performance-related measures. One study showed negative results in terms of maximum acceptable frequency as well as the number of errors made when using a full body exoskeleton with a supernumerary limb, while these effects were not present when using an anthropomorphic upper body exoskeleton or upper body exoskeleton with a supernumerary limb [14]. An increase in the number of errors during an overhead drilling tasks was also shown by Kim et al. [13], in which an anthropomorphic exoskeleton was used. The three remaining studies reported beneficial results for performance measures, without providing statistical significance [9,16,17].

The development of arm-support exoskeletons shows a steep increase in the past few years. For ten of these exoskeletons, the effectivity in reducing the physical load in the shoulder region has been evaluated in realistic industrial tasks. In particular, the effects on the activation of the main muscles in the shoulder region have been investigated. The findings were highly different across studies. Mixed results were also found for the effects on subjective measures and performance parameters.

Muscle activation

Among the factors that may affect whether or not an exoskeleton would be effective in reducing the amount of muscle activation are the type of exoskeleton and the type of activity.

Regarding the type of exoskeleton, our review included six passive, more or less similar, anthropomorphic arm support exoskeletons, one active one with an attachment to the wall, and two exoskeletons with a supernumerary limb (snl). Figure 1 illustrates that increased levels of muscle activation were mainly found for the two exoskeletons with a supernumerary limb, specifically for the AD, MD and ILL muscles. According to the authors, the additional weight of the mechanical arm, an asymmetrical loading and more complex articulations with associated inertial properties contribute to the adverse effects of this design [14]. On the other hand, the four passive exoskeletons without snl that were involved in the analysis of muscle activity were found to be successful in reducing either the AD or MD activity without any increase in ILL. Apparently, these exoskeletons reach their goal of taking over at least part of the required shoulder torque generation from the AD and MD muscles. In contrast, these exoskeletons lead in most cases to an increase in TB activity. This can be explained by the function of this muscle. For overhead work, TB is involved in lowering the arms, which is opposite to the exoskeleton’s function of raising the arms or keeping them elevated. Hence, in arm raising and lowering activities, larger supportive moments provided by the exoskeleton, would reduce agonist muscle activity and increase antagonist activity [18]. In relation to this trade-off, it is the challenge in passive exoskeletons to select optimal support setting at which the beneficial effects outweigh the adverse ones and the user experience is positive.

Regarding the type of task, in most studies on muscle activity a quasistatic overhead activity was applied. The effects in the overhead activities on agonist muscle activity were generally positive, particularly in the exoskeletons without snl as explained before. In one study on the effect of a passive exoskeleton on muscle activity [15], other tasks were applied, namely lifting (from about knee to chest height), stacking boxes, and carrying boxes while walking. In these tasks, reduced muscle activities were also found in AD (in all three tasks), which can be explained by the fact that the tasks that were defined involved moderate to significant amounts of arm elevation. The TB muscle generally involved in the lowering of the arms was found to increase in lifting and stacking and to decrease in the carrying task [19-22].

The weight to be hold in the hands, ranging from 0.45 to 9kg across the included studies, might also have contributed to the differences in results. Huysamen et al. showed for static holding with a passive exoskeleton that heavier weights with adjusted (increased) exoskeleton support resulted in larger reductions in muscle activity compared to lighter weights with less exoskeleton support [23]. Here again it should be noted that in practical situations the increased support levels would be at the costs of higher antagonist muscle activities when lowering the arms.

Another factor affecting the effect of an exoskeleton on muscle activity is arm posture. Particularly in passive (spring-based) exoskeletons the amount of supportive torque would be directly affected by the arm elevation angle. De Vries et al. studied this posture dependency for an envelope of 15 combinations of vertical elevation and horizontal abduction and mainly observed significant effects of vertical elevation on various muscles [24].

Effects on subjective and performance measures

For five exoskeletons, the experienced discomfort was evaluated. Three of those were passive exoskeletons (without snl). Two were tested in overhead drilling tasks, showing a reduction in perceived discomfort when wearing the exoskeleton [13,14]. The third one was tested during carrying. Here, an adverse effect was found, namely an increase in the rating of perceived exertion [15]. Increased perceived exertion can be explained because carrying is not the primary task for which arm support exoskeletons provide support, whereas the wearer still has to carry the weight of the exoskeleton with them. This emphasizes that the effectivity of an exoskeleton is task dependent. To enhance the adoption of exoskeletons in the working environment subjective experiences are essential. In the end, the workers need to be convinced that the exoskeleton will help them and above all, is not in the way of their working activities. To this end, it is also important that the worker’s performance is not negatively affected by the exoskeleton. Of the seven exoskeletons that were evaluated on performance measures, two were found to elicit negative results. Both resulted in an increase in the number of errors made during a drilling task, defined as an angular deviation of the drill of more than 2 degrees [13,14]. One of these findings regarded a passive exoskeleton (without snl) , whereas the other regarded an exoskeleton with snl [14]. Alabdulkarim & Nussbaum, also showed that for this exoskeleton the maximum acceptable frequency was decreased by 20% for women [14]. In the same study it was shown that two passive arm support exoskeletons had no effect on performance measures. Others studied the effect of three different exoskeletons and report mainly positive effects on performance measures [16,17,25]. However, no inferential statistics are provided to support these results. An exoskeleton, which is per definition is worn on the body, might affect precision control over the limbs on which they are attached. For optimal control, it is important to keep the weight, articulations and inertial properties as close as possible to the natural properties of the arm. Altering the characteristics of the limb could explain the negative effects on performance measures. However, it is possible that after a familiarization period, users will adapt their control to the exoskeleton and improve their performance.

The relevance of the published effects

In most studies, the shoulder load was objectively evaluated by studying the level of muscle activation, based on the amplitudes of the EMG signals deduced from the larger and accessible shoulder muscles. Clear reductions in muscle activation were found for the agonist muscles involved in arm elevation as a result of the passive spring-based exoskeletons. It is likely that lower muscle activation levels would imply lowered or postponed muscle fatigue and increased endurance. Such effects would be practically relevant in itself when leading to less fatigue at work and therefore higher job quality. One could also speculate on positive performance effects in terms of higher quality (less mistakes) and higher productivity levels due to reduced levels of fatigue during the working day. As discussed, the included studies show mixed results regarding performance related outcome measures. Furthermore, the studies included here provide no evidence on the effect of the exoskeletons on muscle fatigue nor endurance. However, for back support exoskeletons, it was shown that when wearing an exoskelet, the endurance time was extended to almost three times longer compared to without an exoskeleton [25].

The relevance of the above results in terms of prevalence rates of shoulder injury is not clear. Basically, any health effect of wearing an exoskeleton could only be determined in epidemiological studies with relatively high numbers of participants equipped with an exoskeleton for longer periods of time (experimental) or not (controls). Such studies have not yet been performed. Theoretically, one could speculate on any potential effect on shoulder injury prevalence in case the observation of reduced agonist muscle would fit in one of the etiological models behind shoulder injury. However, there is no evidence of a relationship between muscle activity and the most common work-related musculoskeletal shoulder disorders.

Obviously, exoskeletons will not be effective as long as they are not accepted in practice. Therefore, the effects on subjective experiences and performance summarized in this review, would be of relevance. In the included studies, mixed results were reported regarding performance measures as well as subjective measures such as precision, perceived effort and discomfort. These points need to be addressed to be accepted in practice. Workers will have to experience beneficial effects and above all should not feel obstructions or discomfort during their work that is attributable to the exoskeleton.

In general, exoskeletons would be acceptable in case beneficial effects are larger than the adverse ones. In arm-support exoskeletons: the reductions in agonistic muscle activity should outweigh any potential negative effects. The latter may include the increased antagonistic activity in arm lowering as mentioned before, but also any shift of mechanical loading from the shoulder to another region. In his respect the finding of Kim et al. is of relevance [19]. In this study the shear and compression forces in the spine were studied, as well as other unwanted effects, such as changes in the range of motion and postural sway. For one of the investigated tasks, the medio-lateral shear forces in the spine were increased. Furthermore, the range of motion and postural sway were negatively affected. However, most measures related to spinal compression and shear forces did not change or were reduced [19]. Among the potential negative effects that may arise in practice however are many more, including for instance mechanical pressure points leading to local discomfort, any hindrance in other activities, high temperatures, donning and doffing times, reductions in performance productivity and quality, and so on.

Further exoskeleton development

The current review included various types of arm-support exoskeletons. The only active exoskeleton that was evaluated in a realistic industrial exoskeleton and thus included here, was an exoskeleton that was mounted to a wall [21]. This might be interesting in specific work situations with relatively high pay-loads, but one of the main advantages of exoskeletons in general, being easy to carry with you in mobile work, is hereby lost.

The exoskeletons with a snl are interesting and might also be interesting in specific work situations, for instance when carrying hand tools for longer periods of time. They can also reduce the number of times one has to reach down to pick up a tool. Remarkably, the intended transfer of loads from the shoulder to waist level by using the snl did not lead to the intended reduced shoulder muscle activity in none of the two exoskeletons.

The passive exoskeletons show the most positive results in the terms of reduction of agonistic muscle activation. A short-coming of this type of exoskeleton is its limited adaptability. They give support in quite specific activities and postures (arm elevation) but in other activities the support drops to zero or the exoskeletons might lead to extra loads (in lowering). Moreover, the amount of support could be installed beforehand in passive exoskeletons, but if loads (e.g. external forces on the hands while drilling) are constantly variable in a work setting, one would prefer an exoskeleton that automatically adjusts its support to these loads.

In principle, an active exoskeleton is more adaptive compared to a passive exoskeleton, depending on its sensing and control mechanism. The questions to answer here are: what is the minimal set of kinematic and/or EMG input parameters needed to reach the required level of adaptability in practical work settings and what control algorithms would generate the required level of support. Various active exoskeleton have been developed in the past years, but not evaluated in realistic work activities (and therefore not included in this review). However, the effect of active arm supportexoskeletons, on muscle activity during isolated movements has been evaluated in several case studies [10,26]. These studies show a potential reduction in muscle activity when using the active arm support exoskeletons. However isolated activities, such as elbow flexion/extension or shoulder flexion/extension, do not reflect the complex movements made during working situations. Eventually, active exoskeletons have the potential to be effective in a wider range of applications due to the ability to adjust to the task at hand. However, for these adjustments to be effective, exoskeletons need to be able to interpret the human intentions and be able to translate this into the desired support, which requires advanced sensing and control algorithms. Currently, active exoskeletons do not yet show great adaptability and are heavier, due to the required motors, batteries, and sensors, which put them further away from practical applications. Finally, exosuits might constitute the future generation of wearable and assistive devices in the industry. Exosuits are soft exoskeletons that are worn like clothes made of fabric or elastomers. Exosuits rely on the structural integrity of the human body, as opposed to exoskeletons, which are constructed from rigid segments [27-30]. In active exosuits supportive forces can be transmitted from actuators to the human body by cables [27-30], or can be generated by pneumatic, muscle like, actuators [31]. Compared to exoskeletons constructed from rigid segments, soft exoskeletons might sacrifice accuracy and maximum support to improve flexibility, lightness and thus portability [27]. Research and development on exosuits took place in the field of medicine and rehabilitation, thus far. To our knowledge, no exosuits have been developed or tested yet with an industrial purpose in mind.

Most of the included articles were published in the past three years, indicating the growing interest in this field. In general, a reduction in agonist muscle activity is observed for the passive exoskeletons (without snl). However, antagonist muscle activity might actually increase. The impact of reducing muscle activity on work-related musculoskeletal diseases is not clear. With regards to subjective experiences and performance related measures, mixed results were reported. The effectivity and subjective experience seem to be taskdependent. Therefore, it is important to select the exoskeleton that best suits the specific intended application. Finally, epidemiological studies with relatively high numbers of participants equipped with an exoskeleton for longer periods of time (experimental) or not (controls) are needed to truly conclude whether exoskeletons have the potential to reduce work-related musculoskeletal diseases.

Citation: de Vries A, de Looze M (2019) The effect of arm support exoskeletons in realistic work activities: A review study. J Ergonomics 9:255. doi: 10.35248/2165-7556.19.9.255

Received: 09-Oct-2019 Accepted: 12-Nov-2019 Published: 19-Nov-2019

Copyright: © 2019 de Vries A, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.