Journal of Pollution Effects & Control

Open Access

ISSN: 2375-4397

ISSN: 2375-4397

Research Article - (2020)Volume 8, Issue 6

Objectives: The objective of this study was to assess the occupational safety and health management system among chemical industries in Bahir Dar city, the national regional state of the Amhara region.

Method: A cross-sectional survey study was conducted in chemical industries from 31 March to 15 May 2019. The data were collected by using a self-structured and pilot-tested questionnaire from 242 chemical industry workers.

Results: The results of the study showed that there were no hazard identification system (72.1%), top management support for safety (75.8%), appropriate occupational safety and health training programs (75.8%), and had no written procedures to respond to emergencies (65.8%). Resulting from management failure, a significant number (85.5%) of workers never used personal protective equipment at their workplace due to unavailability (66.1%). The majority (53.0%) of chemical industry workers had no adequate knowledge about occupational safety and health. Moreover, the use of personal protective equipment in the chemical industries was significantly associated with sex, age, safety awareness, accessibility of safety equipment, and educational levels of workers (p<0.05).

Conclusion: Failure in establishing effective occupational safety and health system in the chemical industries was

observed in Bahir Dar city. Thus, chemical industries in city should be concerned about the effective implementation of occupational safety and health management system to ensure a healthy workplace and sustain legislative compliance.

Safety training; Personal protective equipment; Management; Awareness of workers

Nowadays, there is a rapid change in working conditions, work processes, and organization due to technological progress and intense competitive pressures. International Labor Organization (ILO) stresses the roles of organizations to control occupational hazards and risks through dynamic management strategies continuously and to build effective responses. Work-related health risks should be recognized and measured on a persistent basis. To prevent the safety crisis, the management should control and minimize the risk through the plan of safe work systems and provide for appropriate personal protective equipment [1]. Occupational safety and health and management system are important to ensure that the workplaces are safe for operations and that the operations do not impact negatively on the workers. The elements for occupational safety and health management system include formulation of safety and health policy in line with the national laws, organization that involves the safety and health committee and other workers of an organization, planning and implementation, monitoring and evaluation and action for continuous improvement [2]. There is a need to provide workers with information, education, and training so that they would know best how to protect themselves. Through the implementation of safe work procedures and usage of PPE, workers would be prevented from accidents. Making the workplace safe is a joint responsibility of both the employers and the workers. Safety should be a key issue in every workplace. Safety training for employees is the key to achieving a successful safety program and management must invest in safety. It is the responsibility of management to ensure that safety must be a culture of the organization, not just a priority [1,3].

Earnestly, occupational safety and health management system must be an appendage for chemical industries where workers are exposed to a vast majority of extremely harmful chemicals used. Research reports showed that little or nothing is known about their possible immediate or long-term effects on the health of the workers. Nonetheless, workers continue to be required to work with potentially toxic substances [4]. It was globally estimated that 4.9 million deaths and 86 million disability-adjusted life years were attributable to environmental exposure and management of selected chemicals [5]. The problem is more dangerous in the paint, plastics, and tannery industries where a large number of hazardous chemicals are used largely. It is estimated that about 2000-3000 metric tons of sodium sulfide and nearly 3000 metric tons of basic chromium sulfate are used each year [6-8]. To the knowledge of the researcher, there was no previous research work attempted to investigate the practices of occupational safety and health management system in manufacturing industries in Ethiopia. Therefore, the main objective of this study was to examine the occupational safety and health management practices among chemical industries in Bahir Dar city, the national regional state of the Amhara region.

Study design and setting

The descriptive cross-sectional survey study design was conducted for this study to present a complete description and an accurate picture of the situation [9,10]. The data was collected at one point in time, from 21 March to 21 May 2019. The study was conducted in Bahir Dar city which is situated at 578 km northwest of Addis Ababa, the capital of Ethiopia. In its absolute location, it is found 11033'15'' and 11036'53'' north latitude and 37021'11'' and 37025'49'' east longitude. The city has been the capital of Amhara National Regional State since 1991. Currently, the city has a population of 313,997 and covers a total area of 256.4 km2. In Bahir Dar city, there are several manufacturing industries established. Among these, plastics, tannery, and paint industries are the most common business in the city and located on the outskirts of the city.

Population and sampling

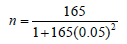

The population of the study was three purposefully selected chemical industry workers who were involved in the production of different products: paints, plastics, and leather goods. These chemical industries found in Bahir Dar city include tannery, plastics, and paint industries which could be the most hazardous workplace than other manufacturing industries. The total population of the study was 444 employees directly involved in the respective production departments. From this population, 373 were male and 171 were female workers. By using the sample size determination formula proposed by, the number of participants was determined [11]. During sampling procedures, 10% of the non-response rate was also considered.

S = 210 +10%non − response rate = 254

Where:

n=required a sample size

N=the population size

E=the level of precision expressed as a proportion (0.05)

Therefore, 254 samples were selected by using a systematic random sampling procedure from the total population of chemical industry workers. The sample size of each chemical industry was determined based on the method of proportional allocation [12].

Instrument

For a quantitative data collection instrument, a five-point Likert scale questionnaire ranging from strongly disagree (1) to strongly agree (5) was developed and used. It was a self-structured and pilot-tested questionnaire that was employed to collect data on the assessment of occupation safety and health management system, utilization of personal protective equipment, and knowledge of occupational safety and health among three chemical industries (paints, tannery, and plastics) in Bahir Dar city.

Data collection procedures

To avoid the language barrier, the questionnaire was translated into the Amharic language which is the mother tongue language of all participants. The questionnaire was also reviewed to ascertain the content and meaning similarity with the original one. Contacts with each personnel department and management of the three industries were made to get permission and access to workers and other information related to their organizations. Before data collection, short training was given for data collectors. Before involving in, the objective of the study was explained to all participants and informed consent was taken. All necessary information and explanations were offered to all participants before the filling of the survey questionnaire. The survey questionnaire was disseminated to all participants. After this, the data collectors would help the participants in filling out the questionnaire, and they interviewed the respondents who were not literate.

Validity and reliability

Since the questionnaire was developed by the researcher, the validity and reliability of the instrument were considered. The occupational safety and health questionnaire were initially submitted to two occupational safety and health experts who worked in the Bureau of Social Affairs in the Amhara Region and two psychology lecturers in Bahir Dar University to ascertain the accuracy of the instrument, i.e., face and content validity. Before actual data collection, thereafter, a pilot study among 30 workers was conducted. From the pilot study, the reliability (Cronbach’s alpha coefficient) of the survey instrument was 0.844.

Statistical analysis

The collected data was entered and cleaned in Microsoft excel sheet before entering to SPSS. Then, it was exported to Statistical Package for Social Sciences (SPSS) Software Version 20.0 for analysis. To answer the research questions, descriptive statistics were worked out. Descriptive analysis of the variables was conducted using frequencies and percentages by making all variables categorical. Based on such statistical analysis, occupational safety and health management practices including the use of personal protective equipment and awareness of workers on occupational safety and health in the chemical industries were estimated. A chi-square test was also computed to see the association between sociodemographic and workplace characteristics and the use of safety clothes among workers. The statistical level of significance was set at p ≤ 0.05, and only significant values were reported in this study.

Ethical considerations

To avoid ethical dilemmas, the researcher prepared informed consent for participants of the study. After reading and explaining the purpose of the study in detail, informed consent was signed between the researcher and the participants. In addition to this, the right to self-determination of participants was respected. They told to withdraw from the research if they felt uncomfortable to share their views. Their agreement to a statement of consent to confirm their understanding of the study, as well as their readiness to participate, was recognized.

A total of 254 respondents participated in the study yielding a response rate of 95.3%. A descriptive analysis was employed to evaluate the chemical industries based on their practices on occupational safety and health management system. To evaluate the effectiveness of the management, the use of personal protective equipment and safety awareness of workers were also surveyed. Table 1 shows the socio-demographic and workplace characteristics of the respondents. The table summarizes the descriptive characteristics of socio-demographic variables, safety awareness, and use of personal protective equipment among chemical industry workers. The majority of the workers were male (64.5%) and young (65.3%) whose age was not beyond 27 years. Moreover, most of the workers (86.0%) in the chemical industries worked for a maximum of five years. The chemical industries showed poor utilization of protective equipment. Shockingly, only fourteen (14.5%) workers used protective equipment regularly at their workplace. This was mainly related to the inaccessibility of safety clothes in the chemical industries (66.1%). Also, the majority (53.0%) of chemical industry workers reported that they did not have a good awareness of occupational safety and health.

| Variables | N (%) |

|---|---|

| Sex | |

| Male | 156 (64.5) |

| Female | 86 (35.5) |

| Age | |

| ≤27 | 158 (65.3) |

| >27 | 74 (34.7) |

| Educational status | |

| Not literate | 7 (2.6) |

| Literate | 235 (97.4) |

| Duration of work | |

| ≤ 5 years | 208 (86.0) |

| >5 years | 34 (14.0) |

| Safety awareness | |

| Yes | 104 (47.0) |

| No | 138 (53.0) |

| PPE accessibility | |

| Yes | 82(33.9) |

| No | 160(66.1) |

| PPE use | |

| Yes | 35 (14.5) |

| No | 207 (85.5) |

Table 1: Descriptive characteristics of socio-demographic variables, safety awareness, and use of personal protective equipment among chemical industry workers (N=242) in Bahir Dar city, Northwestern Ethiopia.

Four items were provided to respondents to assess occupational safety and health management system in the chemical industries. The majority (71.5%) of respondents agreed that there is no hazard identification system implemented in their organization. More than two-thirds (76.4%) of the respondents agreed that top management did not assign roles and allocates responsibilities and accountability to facilitate effective implementation of the occupational health and safety system. Similarly, 76.4% of respondents agreed there were no appropriate training programs given regarding occupational health and safety for chemical industry workers. Finally, one hundred seventy-seven respondents (64.9%) reported that chemical industries had no written procedures to respond to emergencies (Table 2). Furthermore, sex, age, educational levels, availability of safety equipment, and safety awareness of workers were found to be significant (p<0.05) factors for the use of personal protective equipment in chemical industries under study (Table 3).

| Variables | N (%) |

|---|---|

| Hazard identification | |

| Yes | 69(28.5) |

| No | 173(71.5) |

| Management support | |

| Yes | 57(23.6) |

| No | 185(76.4) |

| Safety training | |

| Yes | 57(23.6) |

| No | 185(76.4) |

| Emergency readiness | |

| Yes | 85(35.1) |

| No | 157(64.9) |

Table 2: Elements of occupational safety and health management system practiced by chemical industries in Bahir Dar city, Northwestern Ethiopia.

| Associated factors | Significance (p-value) |

|---|---|

| Sex | 0.001 |

| Age groups | 0.000 |

| Education levels | 0.030 |

| Safety awareness | 0.028 |

| PPE availability | 0.000 |

Table 3: Significance of factors associated with the use of personal protective equipment among chemical industry workers (N=242) in Bahir Dar city, northwestern Ethiopia.

The chemical industries were characterized by male and young workforce dominated owing to two main reasons. First, the availability of surplus labor force in Bahir Dar city resulting from the presence of newly graduated and unemployed youths in the labor market. Second, young as well as male workers were primarily preferred in the chemical industries resulting from the presence of strenuous tasks demanding masculine power (moving a large number of goods and chemicals from the warehouse to machines) as there were no effective and sufficient ergonomic aids in the chemical industries. Strengthening this point, it is indicated that the work system in many poor countries has become more challenging from the physical workload standpoint [13]. To protect these young workforces from work-related accidents and risks, effective safety culture appears to be the most fundamental concern of chemical industries. This is well articulated in the labor regulation (Labour Proclamation No. 377/2006) of the country. According to this legal instrument, the main objective of occupational safety and health management system is to promote and develop workplace safety [14]. However, the practice of occupational safety and health management system in the chemical industries under investigation was constrained. In the literature, it is specified that the management is responsible for organizing schedules, assignments, and procedures and minimizing the frequency and duration of workers’ exposure to specific hazards [2,3]. Largely, occupational safety and health management system provides a framework that allows organizations to consistently identify and control their occupational safety and health risks, reduce the potential for accidents, and aid in legislative compliance [4].

As a sign of management failure, lack of top management support for safety and safety training was evident in the chemical industries. These were well manifested in the improper utilization of personal protective equipment and poor awareness of chemical industry workers on occupational safety and health. Chemical industry workers did not have adequate knowledge about occupational safety and health. They were not well cognizant about the effects of harmful chemicals, their obligations at their workplace, and employer obligations to lessen accidents and risks. It is indicated that there is a need to provide workers with information, education, and training so that they would know best how to protect themselves. Through the implementation of safe work procedures and usage of PPE, workers would be prevented from accidents [14,15]. Local research findings also show that industry workers who do not use PPE properly during their job, and they are exposed three times to workplace hazards than who used it properly and consistently [16]. Similarly, in Ethiopia, industry workers do not use PPE all the time at their workplace [17]. Local research was conducted on workplace risks, hazard exposure, knowledge of occupational health and safety practice, and safety measures among workers of Sheba leather factory in Wukro, Tigray region [18]. Regarding the awareness of workers, however, a reverse finding with the current study was reported. Unlike Bahir Dar chemical industry workers, Sheba tannery workers had a good level of knowledge of occupational health and safety issues (66.7%). Similarly, another survey study in Nigeria also revealed that more than half (58.5%) of the respondents were aware of occupational hazards [19].

Though management plays a vigorous role in the fruition of safety at work, the study showed that occupational safety and health management practices in chemical industries found to be inadequate. There was no set of plans, actions, and procedures that guide the organizations to systematically manage safety and health risks associated with their business. As well, the weak role of the management for safety practices was manifested by poor use of personal protective equipment and poor awareness of workers on occupational safety and health. Based on the findings of this study, it can be recommended that the management should pay high attention to occupational safety and health issues to ensure a healthy workplace. Chemical industries must establish a safety framework that allows them to consistently identify and control their occupational safety and health risks, reduce the potential for accidents, aid in legislative compliance and improve the overall performance of occupational safety and health management system.

Citation: Abebe BA (2021) The Cart before the Horse: Safety and Health Management System among Chemical Industries in Bahir Dar City, Northwestern Ethiopia. J Pollut Eff Cont 9:261. doi: 10.35248/2375-4397.20.9.261.

Received: 28-Nov-2020 Accepted: 28-Dec-2020 Published: 30-Dec-2020 , DOI: 10.35248/2375-4397.20.9.261

Copyright: © 2020 Abebe BA. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.