Journal of Information Technology & Software Engineering

Open Access

ISSN: 2165- 7866

ISSN: 2165- 7866

Research Article - (2019)Volume 9, Issue 1

Supply chain innovation comes with several benefits. Notably, it promotes agile response to customer demands, competitiveness and business continuity. However, what fundamental capabilities or competencies do businesses require to successfully achieve supply chain innovation? An in-depth desk research was conducted to investigate these capabilities in addition to the eventual business performance outcomes. A theoretical research model was developed, extending current literature relating to supply chain innovation. The model comprises of eight hypotheses that are split into two sets-capabilities (or competencies) required for successful supply chain innovation and positive outcomes driven by such innovation. Findings show that constant SC process improvements, collaboration and communication, new business models, demand management, and SC performance measurement contribute to consequently supply chain innovation. The resultant SC innovation capability results in greater SC agility and resiliency, value creation, and overall business sustainability.

Partnering; Supplier management; Demand management; Cross functional interfaces; Performance measurement; Sustainability; Logistics

The complex and uncertain global market has seen customer expectations proliferate as manifested by growing demand for lower prices, higher product and service quality, and faster delivery times [1]. The supply chain forms the backbone of every organization. When a supply chain is managed poorly, the negative impacts are too costly to an extent that business continuity might be truly threatened. For example, persistent late delivery of ordered items due to logistic inefficiencies may badly ruin a company’s reputation, and subsequently drive away existing and prospect customers [2,3]. Therefore, innovative supply chain practices promote competiveness, but also contribute to business survival.

This research aims to investigate the fundamental preconditions for realizing successful supply chains in addition to expected outcomes. The report is organized as follows. After introduction, background information is provided, and a theoretical model formulated. The next chapter details the research methodology followed by a results and discussion section. Finally, conclusions and recommendations are discussed.

The aim of this research was to investigate the core capabilities required for successful supply chain innovation in addition to the outcomes such innovation is expected to drive. To accomplish this aim, the following main objectives were carried out:

• To critically evaluate the role of supply- and demand-side capabilities on successful supply chain innovation by reviewing relevant literature.

• To critically explore the positive outcomes that may be driven by successful supply chain innovation by reviewing relevant literature.

• To recommend fundamental strategies, which organizations should prioritize to achieve successful supply chain innovation and associated benefits.

Significance of this research

The importance of this research is underscored by the fact that it presents the capabilities essential to realizing successful supply chain innovation. Moreover, the research proposes a number of strategies that business leaders should prioritize to optimize the identified capabilities. This way, this study provides a coherent picture of the primary preconditions for and consequences of successful supply chain innovation.

Supply chain innovation

Today, businesses are operating in a highly complex, turbulent and competitive global environment. Consequently, business leaders are increasingly focusing on delivering more value to customer to stay ahead of competition. Market complexity and turbulence can only be addressed through agile and resilient business practices [4]. Supply chain innovation is highlighted as one of the major priority areas as businesses continually seek true competitive advantage in today’s global markets. Like other business processes, new technologies and improved processes make supply chains stronger, more agile and resilient, and effectively supportive of other functions of an enterprise. In fact, driving sustained innovation in supply chains may result in improved profitability, faster cycle times, and customer satisfaction among other crucial benefits [1,5,6].

Supply chain innovation is a widely researched phenomenon. Earlier conceptualizations of supply chain innovation emphasize new ideas and practices aimed at providing new or enhanced services to customers. These conceptualizations, to a larger extent, treat supply chain innovation as a synonym for logistics innovation [2,4,5,7]. Today, supply chain innovation is conceptualized as a collection of enterprise-wide initiatives consisting of R&D and technological investments, process optimization, introduction of new products and services, building new models, knowledge acquisition and management (education and training), crossfunctional engagement, cross-border (global) and cross-sector partnerships, market intelligence, and other activities. The aim of these activities goes beyond facilitating the accomplishment of better supply chain efficiencies and effectiveness to improving the overall firm performance [3,7].

Existing literature focuses on both demand and supply side capabilities as important enablers of supply chain innovation. Mere adoption of emerging technologies cannot guarantee meaningful innovation. Rather, a series of improvements make the greatest impact on innovation. An organization-wide team effort and buyin is required to bring true innovation to supply chains [4,7].

Hypotheses Development

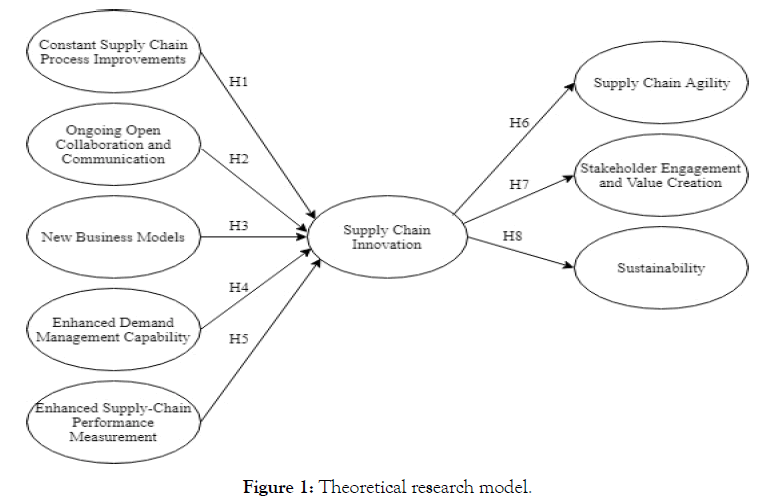

The following hypotheses were formulated to define the role of various capabilities or competencies in enabling supply chain innovation:

H1: Constant supply chain process improvements influence the successfulness of supply chain innovation.

H2: Ongoing open collaboration and communication across all stakeholders stimulate successful supply chain innovation.

H3: New business models influence the successfulness of supply chain innovation.

H4: Enhanced demand management capability contributes to successful supply chain innovation.

H5: Enhanced supply-chain performance measurement capability contributes to successful supply chain innovation.

Successful supply chain innovation may contribute to several positive outcomes. The core outcomes are directly defined by the following hypotheses:

H6: Superior supply chain innovation is linked to greater levels of supply chain agility.

H7: Superior supply chain innovation contributes to improved stakeholder engagement and value creation.

H8: Superior supply chain innovation is linked to greater sustainability potential.

Considering the nine proposed hypotheses, Figure 1 summarizes the theoretical research model.

Figure 1: Theoretical research model.

Research approach

A qualitative research methodological approach was employed to gain an in-depth understanding into the topic of interest. Typically, qualitative research generates a number of themes in form of exploratory words rather than numerical data. According to Smith [8], qualitative research is best suited for studies aimed at determining the facets of “what, how and why” regarding a specific topic. As such, the exploratory approach helped investigate the “what and how” aspects in relation to supply chain innovation’s capabilities and outcomes.

Data collection and analysis

Desk research was conducted to collect data. Findings were obtained from relevant literature searched from current secondary sources, including books, journal articles and conference proceedings. These sources were reviewed and synthesized to discover knowledge and patterns for the purposes of making concrete inferences and conclusions regarding the research topic. Data analysis entailed categorization of patterns/knowledge into major themes as guided by the defined research hypotheses.

Capabilities essential to supply chain innovation

Constant supply chain process improvements: Supply chain management (SCM) is a capability with a wide array of aims, including cost reduction, time savings, waste minimization, supplydemand balancing for perfect order cycles, and supply chain process standardization [4-6]. According to Mandal, new or improved SCM processes tend to evolve gradually rather than abruptly. The Internet of Things (IoT), autonomous vehicles, automated warehouses, and other technologies have a significant impact on supply chain innovation, but the underlying SCM processes must be fine-tuned to make maximum use of these technological solutions [3,9].

Ongoing open collaboration and communication: Integrated efforts and sharing of information among internal and external stakeholders play a critical role in identifying and meeting strategic organizational goals. When all stakeholder groups decide to willingly pool their human, knowledge, financial, time, and technical resources, there are greater chances of creating new and more efficient business models, processes, and products and services [3,6].

New business models: Every company should continuously rethink its business model to reshape customer expectations in the dimensions of how fast orders should be delivered, means of interacting with customers, and in-store inventory control [2].

Demand management capability: Demand management is mainly concerned with customer focus – ascertaining customer needs and meeting (or exceeding) those needs in order to ensure customer satisfaction [1,9]. It seeks to fulfill customer demands through strategies such as product and service differentiation, cost reduction, timely shipping, and reliable and tailored customer service. Moreover, demand management provides value addition [7].

Supply-chain performance measurement: The extent to which an organization evaluates its SCM operations determines the overall successfulness of supply chain innovation. Accurate and timely SCM evaluation findings facilitate informed and well-timed decisions regarding various SCM elements. Quantification of SCM elements facilitates innovation to meet certain performance targets Arlbjorn et al. [3,5,7].

Outcomes of supply chain innovation

Supply Chain Agility: Innovative supply chains facilitate flexible sourcing, manufacturing and distribution as a critical antecedent of fast response to dynamic customer requirements. Supply chain agility is a firm’s capability to work together with its suppliers, distributors and customers to rapidly respond, recover or adapt to market changes and disruptions. Supply chain innovation builds agility and resilience required to make supply chains function optimally at all times [1,2,5].

Stakeholder Engagement and Value Creation: Innovative supply chains enable streamlined interactions with diverse suppliers, distributors, manufacturers, and customers. With an efficient, agile and resilient supply chain, a business is better placed to meet the dynamic and complex needs and expectations of all stakeholders, especially the customers [3]. Supply chain innovation enables strategic partnerships with internal and external stakeholders [7]. Please refer to the article “how-to-achieve-six-figure-benefits-fromdigitizing- paper-based-supply-chain-operations” by Koul S in supply chain brief that explains how innovations like digitization helps to add value in the supply chain management [10].

Sustainability: Supply chain innovation promotes sustainability in cost savings, revenue generation, customer satisfaction, and strategic partnerships. Smooth supply chains contribute to the sustained competitive position of an organization, especially because of greater levels of customer satisfaction [6]. Moreover, quality and process enhancements reduce the incidence of product damages and waste, which lead to minimized customer complaints and environmental pollution [3].

Businesses pursue supply chain innovation to improve the efficiency, agility and resiliency of their supply chains. In addition, supply chain innovation is expected to drive greater levels of strategic partnerships, value creation and sustainability.

In the quest for true supply chain innovation, companies should focus on gradual supply-chain process improvements and new business models. Then, tested and proven improvements or model innovations should be implemented. Effective collaboration and communication tools and techniques should be implemented to facilitate stakeholder involvement in decision-making, and possible avoid misaligned strategies and action plans. Collaboration between multiple stakeholders will bring greater reward for supply chain innovation.

This research has made theoretical contributions to supply chain innovation, especially the arguments building in existing literature on the primary capabilities to and consequences of such innovation. Future studies should empirically test the five hypothesized capabilities (H1 to H5) and three outcomes (H6 to H8) included in the proposed theoretical research model.

Citation: Sunil K (2019) Supply Chain Innovation: The Core Capabilities Required and Expected Outcomes. J Inform Tech Softw Eng 9:256. doi: 10.35248/2165-7866.19.9.256

Received: 08-Feb-2019 Accepted: 06-May-2019 Published: 15-May-2019 , DOI: 10.35248/2165-7866.19.9.256

Copyright: © 2019 Sunil K. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.