Journal of Fundamentals of Renewable Energy and Applications

Open Access

ISSN: 2090-4541

ISSN: 2090-4541

Research Article - (2022)Volume 12, Issue 1

The present time, solar thermal technology has shown to be highly promising for providing process heat in a variety of industrial domains. By merging an unusual system, industries may minimize their usage by substituting solar energy for fossil fuels thermal energy and clean energy. The paper provides an in-depth analysis of eleven nations that have exhibited substantial usage of solar energy systems in their industrial sectors. This worldwide study was then compared to the existing Indian environment in order to forecast the future power of solar thermal integration in the Indian industrial sector. Selected nations are based on a database of possible industrial sectors as well as solar heating applications that take use of the present solar energy event. These are being evaluated in order to integrated into developing countries.

Solar energy; Thermal energy; Heating process; Industrial; Thermal power

Process heating is used in a wide range of applications, from the removal of unripe material through the final processing of completed items. Buildings, houses, and the usage of industrial process heat have all gotten a lot of attention in the last several decades. Natural oil and natural gas are utilized in the industrial business to provide warmth, resulting in the discharge of damaging greenhouse gases into a sustainable planet. Solar industrial process heat systems help to solve the sustainability challenge by reducing carbon emissions. Because solar thermal collectors are expensive, associated with these integrated systems, only a few projects will be completed. Solar thermal collectors have lately experienced substantial advancements due to the emergence of new tools for modelling solar collectors with solar processes.

Solar energy is heat created by solar radiation, making it a more environmentally friendly alternative to fuel sources. Thermal power conversion systems for commercial and industrial businesses often heat the process using a range of Solar collectors and concentrators that are powered by solar radiation. The kind of collector and installation location, effective solar fluid, system size, temperature changer, and load of specific applications are all essential design factors. Solar energy is extremely inefficient since it is not accessible 24 hours a day. Sunlight should be captured and stored in secondary heating systems. When accessible, the season's final system is not necessary.

The beams of the sun do not alter with the seasons. Seasonal variations occur in locations where there is a lot of snow.

Travel expenses account for 29% of overall costs [1]. A few studies have been undertaken to evaluate the proper industrial processes in which solar heat may be employed, worldwide or locally, in order to determine the feasibility of SHIP integration. Lauterbach et al. performed research to discover new industrial processes and assessed feasibility using the TRANSYS (transient system simulation tool). Simulations are used to examine regional data, solar collecting types, and solar irradiance rate data [2]. Weiss et al. study ten enterprises eligible for solar thermal integration and seek answers to the integration difficulties of the Solar Paces editor's nations and institutions [3].

Countries and governments are adopting their own energy plans in this age of industrialization in order to stabilize the planet, which will need to be driven towards carbon neutrality. The primary goal of this research is to identify Australia's solar energy, which is the world's biggest solar system. A detailed assessment and comparison of developed nations with several functioning SHIP plants yields strength. Nations having solar industry heating systems are recognized first based on the industrial sector, heat capacity, and collection area. The SHIP plant database is used to collect data sets, and nations are recognized based on the number of operational SHIP plants.

India and Pakistan are two potential candidates. This study report also discusses the key industrial sectors in these possible nations. SHIP plants in various nations are then classified based on crucial parameters such as installed thermal capacity, as well as the industrial sector As a result, considerable literary research is conducted at this stage in order to identify the country's subject matter and assemble its findings. A thorough analysis was afterwards undertaken to compare Australia, the world's largest solar country, with other countries based on solar energy availability, manufacturing sector performance, and renewable energy law. Following that, Australia's performance is compared to that of operational countries in the high-energy solar energy process.

The approach employed in this work is detailed in detail below.

1. The screening and categorization of industrial heating systems employing solar panels throughout the world identifies the top ten nations that may already have SHIP plants in operation.

2. SHIP industries are being researched in possible nations in order to identify major industry sectors in such countries.

3. Within the specified industrial sectors, the greatest active heat industry with its important features is supplied.

4. Thorough literature evaluations are undertaken in regard to the target nations and their major industrial sectors in order to determine the dominating elements that have the ability to heat up the solar industry process.

5. The thermal energy of the Indian solar system is tested using solar energy, industrial energy consumption, key industrial sectors, and other factors.

Process heating methods used in industry

Process heating systems usually contain heating equipment that creates and distributes heat, as well as a heat transfer mechanism (distribution system) that transports heat from the point of production to the point of usage. Heat is applied to the process in an indirect or indirect manner.

Heat is generated inside the material during direct process heating, whereas heat is delivered from another source to the material via one or more heat transfer devices during indirect process heating (convection, radiation, conduction). Metallurgical activities and the production of lime clinker in the cement manufacturing process are examples of direct mode process heating. Kilns are employed in the direct process heating technology.

Heating systems come in a variety of configurations

Electric fuel (fuel) based on electricity and electric fuel (fuel) based on electricity are the two most common forms of system heating systems.

Thermal processes based on heat: Heating is generated by the burning of solid, liquid, or gaseous fuels and transferred to be used in combustion processes or fuel-based heating systems [3]. The gases produced by gasoline combustion may interact directly with the product (direct heat) or aid in the production of steam or hot water in boilers. Steam boilers, furnaces, ovens, and other heatbased heating systems are examples.

Heating systems based on electricity: An electric current or an electromagnetic field causes heating in the heating systems of an electrical-based process, which is subsequently delivered to the item directly or indirectly. When electricity is used directly in a process to heat a substance, the material is heated by flowing current through it, creating current in it, or stirring the current in it. the amount of electrons contained in a given item Although one of the three processes stated above, an indirect procedure uses electricity instead of running it.

The importance of using solar energy for industrial process heating

As previously stated, the usage of fossil fuels dominates the industrial sector's fuel mix. As a consequence, while accomplishing the goal of lowering fossil fuel usage, expanding industrial energy demand offers the twin effect of reducing the demand for fossil fuels while also contributing to intergenerational equity (fossil fuel availability for future generations) and lowering greenhouse gas emissions. The industry may decrease its use of fossil fuels by improving the efficiency with which fuel and power are used in various processes and equipment ([i3i8] –su40b] situation of fossil fuels by incorporating renewable energy sources in applicable processes and end-uses. Energy efficiency improvements are vital and may produce major advantages in the short run.

Solar energy is one of the most ecologically friendly and sustainable energy sources, and it is widely regarded as one of the most promising energy sources for energy generation and heat usage in the home and industrial sectors. Converting solar energy into thermal energy would be far more efficient than generating electricity from solar energy (up to 70%). The efficiency of solar photovoltaic conversion, for example, is expected to be between 15-20%, whereas the efficiency of solar thermal energy generation is believed to be between 20%-25%. As a result, one of the most promising methods for oil importers to meet the rising need for energy businesses is to employ solar energy to heat up the industrial process in industrial usage.

Solar industrial process heating potential

Several research on measuring the thermal energy of the solar industry in various nations and areas while taking into account the needed temperatures for certain processes and applications have been published. This research recognized only Food processing, pulp and paper manufacturing, textile manufacturing, transportation, meat processing, plastic treatment, pharmaceutical and chemical manufacturing operations, and other industrial sectors. The sections that follow offer a brief study of some of the literature attempts to generate estimations that may be one of the study aims. In 1977, In order to enhance all solar panels, the International Energy Agency (IEA) created the Solar Heating and Cooling Program (SHC). Experts from International Energy Agency (IEA) member nations and the European Union are participating in the endeavor. Collaborate. According to a research undertaken as part of this Initiative's Task (IV) 33, the European Union's annual SIPH possibilities are estimated to be about 260 PJ, with a collection demand in the range of 143–180 million square meters.

Solar collectors are used for heating industrial processes

The following four parameters influence the choice of solar technology to satisfy the need to heat the industry process:

• Operating temperatures

• Solar collector efficiency

• Yearly power output, and

Other factors to consider are the availability of space and the ability to integrate the roof with the system size, since the present roof may not have enough room or a sturdy base to help the solar field The product's cost is also considered an essential aspect in its financial sustainability.

In particular the three types of solar collection technology used SIPH systems consist of a flat plate, a detachable tube, and screws. With soft solar panels, as heat transfer media, both water and air are used, and some designs vary the heat transfer fluid. Solar air collectors are widely used in the food processing industry to replace fossil-fuel-based drying or to reduce food waste losses caused by dry air drying [7]. Heat and hot water delivery to the boiler, flat plate, and systems based on the collection of spent tubes with low industrial process [8]. Commercially available designs for solar concentrators include a parabolic trough, a parabolic dish, and a linear Fresnel reflector.

SIPH system design and integration aspects

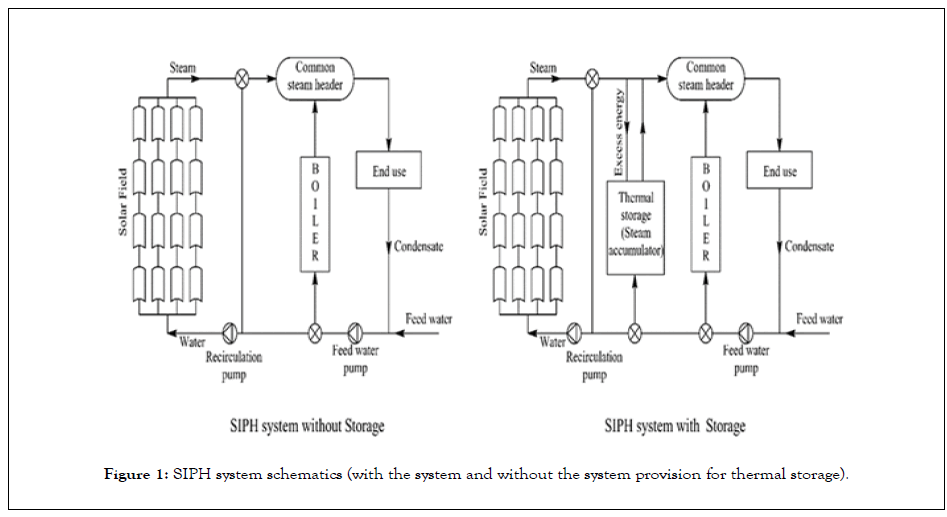

Common components of solar industrial heat systems include solar thermal collectors, heat transfer fluid, connecting pipes, pumps,heat exchangers, and optional thermal storage and/or backup. Industrial and thermal energy storage systems based on solar concentrators, including backup boiler schematics. The sun's rays are focused on the receiving pipe as they travel through the shaft of the solar concentrator, heating the liquid that flows through it. Depending on the application of a certain finish, the hot liquid (in this example, steam) is afterwards employed in various processes and in the manufacturing industry In 1976, the US Department of Energy financed 10 SIPH research projects to aid in the commercialization of solar thermal energy. After a few years of operation, a report was released with statistics on the performance of these projects, production, economic analysis, and application studies. It was discovered that, in addition to cost reduction, there was a requirement to minimize design and implementation flaws. Following that, a new handbook was created with detailed design information Collectors, storage, pipelines, inputs, pumps, valves, heat exchangers, and heat transfer fluids are examples of components, as well as a thorough step-by-step strategy to updating SIPH systems.

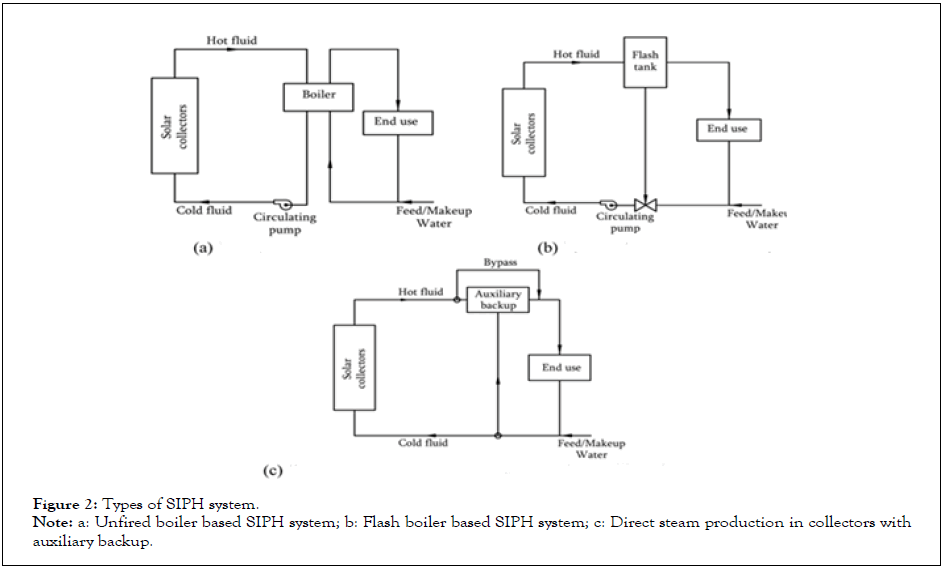

To generate indirect smoke: In this method, in a solar collecting loop, the heat transfer medium, such as hot oil or glycol, is heated and used to make steam indirectly via a temperature switch. Boiler systems that have been unblocked and flash-based boiler systems are two forms of indirect systems that create steam.

Direct smoke production: The water in the solar collector loop is boiled in this mode. When the water is somewhat warmer, it is routed via a steam tank, where the steam is extracted. The water level controller adjusts the quantity of water fed into the steam tank or coupled with recovered water.

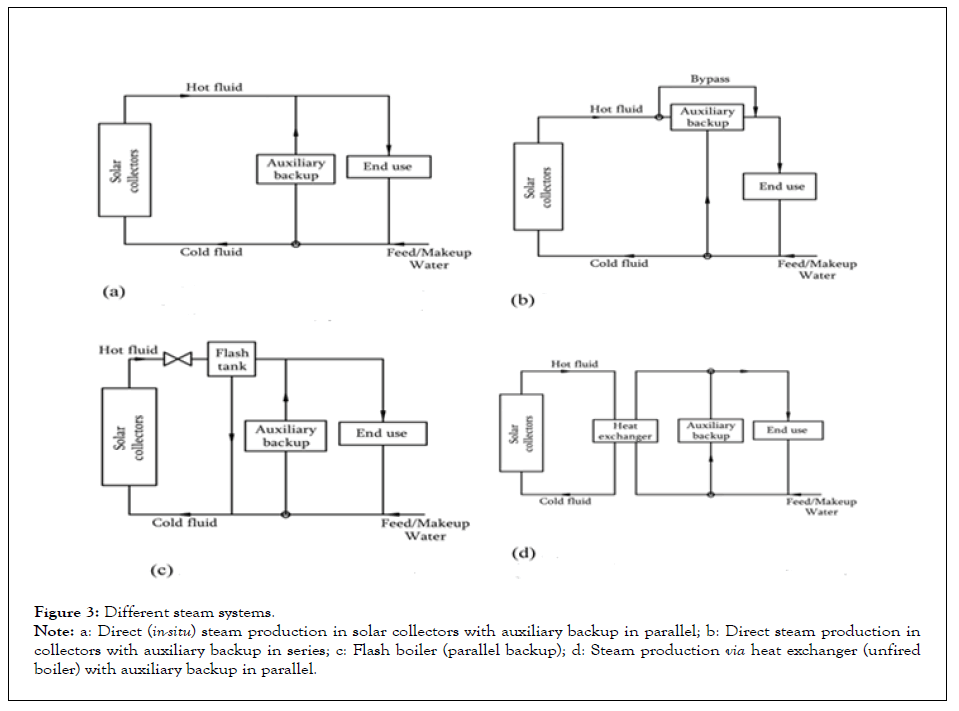

The above-mentioned SIPH systems can be established in series or compatible modes, according on the application, heating process, and other application requirements (Figures 1-3).

Figure 1: SIPH system schematics (with the system and without the system provision for thermal storage).

Figure 2: Types of SIPH system.

Note: a: Unfired boiler based SIPH system; b: Flash boiler based SIPH system; c: Direct steam production in collectors with auxiliary backup.

Figure 3: Different steam systems.

Note: a: Direct (in-situ) steam production in solar collectors with auxiliary backup in parallel; b: Direct steam production in collectors with auxiliary backup in series; c: Flash boiler (parallel backup); d: Steam production via heat exchanger (unfired boiler) with auxiliary backup in parallel.

SIPH system performance and case studies

The effectiveness of solar thermal systems on industrial operational systems influences their acceptance and diffusion, this has a direct bearing on their economic standard. The number of factors influence the functionality of the SIPH system, including available solar radiation, weather conditions in the application area, solar collection features, and the needed process temperature [9]. Conditions (delivery temperatures, pressures, and maximum flow rate, among others). The performance of the SIPH system is frequently measured in terms of usable energy and the percentage of total heat demand that can be met by solar energy (half solar).

To facilitate thorough and detailed testing, mathematical models and compact computer programmers can be used to include all necessary factors such as solar radiation, metrics representing the performance of solar collectors employed in the heating process, and operating pressure and temperature, and storage provision, among others.

Solar industrial process heating's economical and environmental effects

SIPH systems' economic feasibility adds to their adoption and spread among potential customers. One of the most appealing aspects of SIPH programme is their ability to minimize pollution. With the exception of a few studies that target exclusively the technoeconomics of SIPH systems, many research studies on design and performance testing tend to generate significant findings in one or more economic performance scores. The most generally reported processes for this economics testing/analysis to this systems application on various businesses are the payment period, current total amount, and internal refund rate. These measurements are typically evaluated based on the overall fuel savings that may be realized through SIPH equipment is being installed. A study of the possibilities of solar water system economics in the soft and oily vegetable sector in Khartoum (Sudan) was offered as an example. This Solar energy system, according to the research, has a lot of potential for industrial performance and may save a lot of over time. Several studies in Greece compared the economics of solar thermal power systems to standard fuel-based systems [8,9].

Energy to satisfy the demands of industrial process heating, the actual capacity employed to date is quite restricted. This has occurred for a variety of reasons. This includes the difficulty of integrating solar thermal systems into existing and well-prepared thermal systems, a small number of large power plants, while many industries are small, necessitating solution to all one industry, the price for S.I.P.H programmers of the mini/small and normal medium size businesses, and there is a scarcity of competent and professional designers, installers, and engineers.

Authors declare no conflict of interest.

Citation: Sharan GM, Jeevan BM, Aravinda P, Iman Khan, Prasad BR (2022) Solar Industrial Heating Practices in India. J Fundam Renewable Energy Appl. 12:282.

Received: 31-Jan-2022, Manuscript No. JFRA-22-15698; Editor assigned: 02-Feb-2022, Pre QC No. JFRA-22-15698 (PQ); Reviewed: 23-Feb-2022, QC No. JFRA-22-15698; Revised: 02-Mar-2022, Manuscript No. JFRA-22-15698(R); Published: 09-Mar-2022 , DOI: 10.35248/2090-4541-22.12.282

Copyright: © 2022 Sharan GM, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.