Journal of Fundamentals of Renewable Energy and Applications

Open Access

ISSN: 2090-4541

ISSN: 2090-4541

Short Communication - (2020)Volume 10, Issue 4

Concentrated solar power plants are a promising solution to limit the dependency of some countries to fossil fuels or nuclear energy. These plants, located in sunny regions, are exposed to extreme climatic conditions. Moreover, they are supposed to work during 25 years. So, it is necessary to ensure the durability of the different components. In particular, high solar absorptance receivers are a key element in a CSP plant project, because they receive the concentrated sun arrays, and are submitted to important thermal shocks. In this presentation, different receiver materials are studied: four alloy substrates combined with four new absorber coatings, operable in solar towers with molten salts or steam as heat transfer fluids, and a classic Pyromark paint considered as a reference. In order to test the durability of the coatings, 200 solar accelerated aging cycles were applied on the samples, using a concentrated solar facility (named SAAF). The cycles were defined so as to apply realistic high solar flux and temperature on the front side of the samples, with high cooling and heating rates reproducing the fast variation of solar irradiation due to cloudy weather and subsequent thermal shocks. The optical characteristics of the coatings were measured at the beginning and at regular intervals during the aging procedure. Different behaviors of the coatings were observed depending on the substrate, before any aging cycle. After this first aging campaign, some evolutions were observed on the solar absorptance or thermal emittance, depending on the substrate and the coating. Nevertheless, the degradations noticed are not significant enough to conclude about the durability of the coatings.

The increase in the share of renewable energy on the energy market needs the use of all the available sources (sun, wind, biomass, etc.) and the development of different kinds of devices to exploit them. Among them, the concentrating solar power (CSP) plants combine several advantages. The most noteworthy is the possibility to store the generated heat in order to produce electricity when the sun irradiance is not available (at night, or during cloudy days). Due to its big growth potential, there have been a lot of studies for the development of these plants and their performances during the past decades.

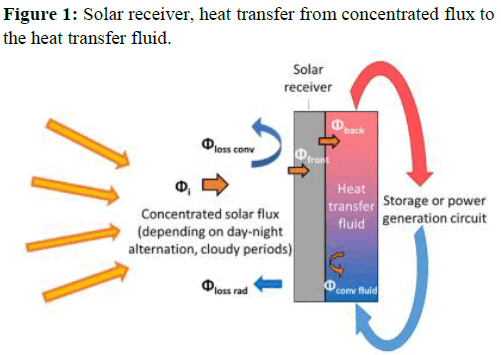

It is important to keep a high level of performance to maintain the cost-efficiency of the installation. This is the main purpose of the European project Raiselife started in 2016. A consortium of laboratories and industrial companies from Europe (France, Germany, Italy, Spain) and south of Mediterranean (Israel, Morocco) are working together to study the lifetime of the different components of a CSP plant, and to suggest new materials. In a solar tower, the receiver is one of the key elements to consider when looking at the lifetime of the plant: it is the intermediate component between the concentrated solar flux and the heat transfer fluid. It can receive a flux of about 850 kW/m2, and it can reach an outlet temperature higher than 600 °C for a liquid receiver and 700 °C for a gas receiver.

In this study, four alloy substrates and five coatings with high solar absorptance (four new coatings and a classic one) are investigated under aggressive aging cycles generated by concentrated solar irradiance.

Solar tower receivers collect the concentrated solar flux and transfer the heat to a fluid in order to produce electricity (Fig. 1). Depending on the fluid and the temperature conditions of the generator, different kinds of substrates are used. In this study, we consider four standard kinds of substrates used in the solar tower receivers: T22 (2% Cr), T91 (9% Cr) and VM12 (12% Cr) steel alloys and Inconel 617 super alloy (44% Ni – 20% Cr). T22, T91 and Inconel 617 can be used in solar receiver steam generators. T91 and Inconel 617 can be used for molten salt receivers. VM12 is considered to replace T91 in the future.

In order to improve the global efficiency of steam and molten salt tower receivers, the operating temperature of the coating, its initial solar efficiency and its durability have to be increased. To this end, new high temperature solar receiver coatings are being developed during the Raise life project by the consortium members:

1. A ceramic paint consisting of a primer and absorbing layer with black pigments, developed by BSII (referred to as Coating A);

2. A slurry deposited diffusion bond coating based on Al intermetallic, developed by INTA, with the ceramic absorbing coating A on top (referred to as Coating B). This protective layer is introduced to prevent the sample from hot oxidation;

3. A solar selective thin multi-layered coating deposited by magnetron sputtering, developed by Fraunhofer, applied on a polished substrate (Coating C);

4. A multi-metallic diffusion coating based on chromium and manganese applied with the powder pack cementation process, developed by Dechema (Coating D).

Coatings A, C and D are applied on the four substrates. Coating B is only applied on T22, T91 and VM12 substrates. The evolution of the new coatings after the aging tests is compared to the evolution of this one, considered as a reference.

•Aging criteria: focus on optical characteristics

•Measuring devices and method for the characterization

The accelerated aging tests have been carried out on a solar concentrating device, the SAAF. The flux is controlled by shutters which can be closed/opened depending on the flux instruction and the DNI (Direct Normal Irradiance, W m-2). The relationship between the DNI, the opening ratio of the shutters, and the flux on the outlet of the kaleidoscope was determined when the bench has been set up, thanks to a calorimetry device. The shutter can be fully opened in 0.7 s, so fast flux cycles can be applied on the samples. The temperature on the sample is measured by an Optris G5H CF4 pyrometer, considering the emissivity of the sample. The spectral sensitivity of the pyrometer is 5.2 μm, so it is considered solar blind. In order to control the temperature on the front surface of the sample exposed to the high solar flux, an air cooling device is used on the back of the sample. The air flow is adjusted to reach the set point temperature. Moreover, a thermocouple is put on the side of the sample in order to follow the temperature evolution on an additional point.

Determination of the cycles

The objective of an accelerated aging approach is to reproduce the evolution of the coating over the years in a much shorter period, from a few hours to a few weeks, in order to predict and anticipate the degradation of the performances. To this end, it is necessary to expose the coating to fast, but non unrealistic, degradation mechanisms. The main difficulty consists in determining a relevant aging procedure which could cause damage close to the real in situ damages. For example, according to the experience of CSP plant managers, it is conceivable to visually observe a slight discoloration of the coating, or a corrosion default, but a strong and fast delamination should warn of a nonplausible degradation mechanism.

The characteristics of the coatings before any aging cycle are different depending on the substrate on which they are deposited. The studies above show that the aging cycles chosen are realistic but the issue of the relevance of the protocol is discussed in the light of the results obtained. Furthermore, some additional aging strategies are considered.

After 200 cycles, no unreal or unexpected degradation has been observed so far, even with the classic Pyromark® coating. So the cycles applied are not to be considered as too aggressive, regarding the optical properties, despite their quick variation of flux and temperature. The global optical efficiency seems to remain stable, for all coatings, on all substrates. We even noticed an improvement in some cases: the T22 substrate with coating C, and the VM12 substrate with coating B. This could be due to a curing phenomenon emerging at these levels of flux and temperature. Nevertheless, a degradation of the characteristics was expected, since real receivers on solar tower show signs of deterioration after a few years.

Fast solar cycles under concentrated solar flux were applied to different coatings deposited on different substrates. The objective was to simulate quick changes of solar input on the receiver due to cloudy weather. The cycles were defined in order to maximize the thermal stress factors during the shortest period possible. The objective was to accelerate the aging, without causing any unexpected deterioration, in order to anticipate the degradation of the coating on the plant over time. After 200 aging cycles, no significant degradation has been observed. This can be due to an insufficient number of cycles. An additional round of aging is currently on going, until 300 cycles, on some samples. The application of more aggressive cycles is also planned (higher flux and higher temperature). Another reason can be the short duration of the tests. Increasing the time during which the coating is at the maximal temperature could be another strategy to test.

This work is partly presented at Joint Event on 13th International Congress on Biofuels & Bioenergy and Biofuels & Bioeconomy October 18-20, 2018 held at Ottawa, Canada

, DOI: 10.35248/2090-4541.20.10.276

Copyright: This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.