Journal of Physical Chemistry & Biophysics

Open Access

ISSN: 2161-0398

ISSN: 2161-0398

Review Article - (2021)Volume 11, Issue 5

This audit portrays the ongoing outcomes in aqueous liquefaction (HTL) of biomass in constant stream handling frameworks. Albeit much has been distributed about clump reactor trial of biomass HTL, there is just restricted data yet accessible on persistent stream tests, which can give an increasingly sensible premise to process plan and scale-up for commercialization. High-dampness biomass feed stocks are the well on the way to be utilized in HTL. These materials are portrayed and aftereffects of their preparing are talked about. Built frameworks for HTL are portrayed; in any case, they are of restricted estimate and don't yet move toward an exhibition size of activity. With the outcomes accessible, process models have been created, and mass and vitality adjusts decided. From these models, process costs have been determined and give some positive thinking with regards to the business probability of the innovation.

Hydrothermal; Liquefaction; Biomass; Algae; Lignocellulosic

Aqueous liquefaction of biomass is the thermochemical change of biomass into fluid energizes by preparing in a hot, pressurized water condition for adequate chance to separate the strong bio polymeric structure to principally fluid segments. Run of the mill aqueous handling conditions are 523-647 K of temperature and working weights from 4 to 22 MPa of weight. Firmly related handling in supercritical water conditions (>647 K and >22 MPa) won't be talked about in this audit, with the exception of with regards to fluid stage preparing. The procedure is intended to give a way to rewarding wet materials without drying and to get to ionic response conditions by keeping up a fluid water preparing medium. The temperature is adequate to start pyro lytic instruments in biopolymers while the weight is adequate to keep up a fluid water preparing stage.

Aqueous handling is partitioned into three separate procedures, contingent upon the seriousness of the working conditions. At temperatures under 520 K, it is known as aqueous carbonization. The fundamental item is a hydro char which has a comparative property to that of a low position coal. On account of microalgae, the hydro char is to a great extent delivered from the starch and protein divisions and the lipid portion is as yet perfect making it conceivable to remove the lipids before aqueous carbonization [1]. At middle of the road temperature ranges somewhere in the range of 520 and 647 K, the procedure is characterized as aqueous liquefaction bringing about the creation of a fluid fuel known as bio crude. Bio crude is like oil rough and can be moved up to the entire distillate scope of oil determined fuel items. At higher temperatures over 647 K gasification responses begin to overwhelm and the procedure is characterized as aqueous gasification, bringing about the creation of an engineered fuel gas. One of the upsides of aqueous gasification over liquefaction is the lower measure of natural carbon found in the water stage following gasification prompting high carbon efficiencies [2,3]. The general point for each situation is to create an item with a higher vitality thickness by evacuation of oxygen. The current audit will concentrate on the HTL pathway at middle of the road conditions to create bio crude utilizing consistent stream response frameworks.

Aqueous liquefaction (otherwise called direct liquefaction) is basically pyrolysis in hot fluid water. All things considered, it doesn't require an impetus, yet a lot of innovative work on reactant strategies in aqueous liquefaction has been embraced. The most ordinarily considered "impetus" has been the utilization of antacid to adjust the ionic medium to support certain base-catalyzed buildup responses, which can prompt fragrant oil development, in inclination to corrosive catalyzed polymerization responses, which lead to strong item arrangement. While HTL continues through pyro lytic instruments, its bio crude item is entirely different from quick pyrolysis bio-oil. It is more deoxygenated through, among other response pathways, buildup responses of the light parts produced from the biomass, bringing about a progressively hydrophobic stage with less broke up water. Truly, the bio crude is significantly thicker, however is in reality less thick than bio-oil [4].

Investigation of the HTL items from woody biomass show the bio crude item is obviously not oil simple. It is blend of oxygenated mixes stretching out over a wide scope of atomic weight. More subtleties of the examinations and the organization are portrayed in Elliott's audit [5]. The bio crude items included acids, alcohols, cyclic ketones, phenols, methoxyphenols (guaiacols from softwood lignin) and more consolidated structures, similar to naphthols and benzofurans. The measure of bio crude chromatographed mirrored the measure of distillate item. An enormous part of the chromatographed oil was excluded from the evaluated distinguished pinnacles, either in view of helpless goal and pinnacle cover or on the grounds that the complex, oxygenated isomers were not found in the standard mass spectrometry libraries. Endeavors to comprehend and compose the methods for arrangement of these blends have been assessed beforehand [6-9].

Direct biomass liquefaction was the phrasing utilized for aqueous liquefaction in the 1970-1980s. This early ceaseless stream process improvement work, including research center work at Lawrence Berkeley Laboratory [10] and the Albany Biomass Liquefaction Experimental Facility, both in the U.S., and the Hydrothermal Upgrading (HTU) plant in the Netherlands, was as of late depicted by Elliott [8]. Aqueous liquefaction has just been exhibited from a more minor perspective for brief timeframe periods. The biggest exhibit of a form of the innovation was the activity of the Albany Facility creating 52 barrels of item (around 8 m3) over the life of the office.

In spite of the fact that these pilot scale endeavors showed ceaseless stream activity of HTL, most by far of the writing depicts little clump reactor tests in the research center. This audit will focus on the ongoing exploration in persistent stream process advancement for biomass HTL and related subjects.

Most biomass can be handled in HTL on account of the hydrophilic idea of biomass and the sensible simplicity in shaping water slurries of biomass particles at pump able fixations, normally 5%-35% dry solids. In utilizing lingo cellulosic biomass, which is lower in dampness substance, recuperation and reuse of the water for slurry arrangement is basic. For high-dampness biomass, similar to green growth, some dewatering is required preceding preparing so as to reduce the handling expenses of over the top water. This presents some normal feedstock used in HTL handling, wet feed stocks are especially appropriate for HTL and particularly green growth biomass has gotten a ton of consideration in the examination field as of late. Woody biomass requires pounding before handling as is talked about in the resulting area, microalgae, a few strains of macro algae and certain composts and slimes are of reasonable little size for direct preparing. Additionally presents an outline of the HTL results distributed on the separate feedstock to date. It very well may be seen that the wet excrement and sewage muck feedstock have not been handled in nonstop frameworks, in spite of the fact that outcomes from clump frameworks are promising for their application in constant frameworks [11]. A further preferred position of utilizing aqueous preparing for slimes and excrements is the impact of sanitizing bioactive contaminants.

Algal biomass has been distinguished as a promising option as an asset for inexhaustible powers because of its higher photosynthetic effectiveness and zone explicit yields [1]. The advancement of third era biofuels from microalgae has seen expanding research endeavors in the course of the most recent decade. Microalgae are infinitesimal creatures that can develop in new, bitter or salt water. The benefit of microalgae contrasted with earthbound biomass is it’s a lot higher photosynthetic effectiveness which brings about higher development rates and improved CO2 relief. They are particularly appropriate for persistent aqueous liquefaction because of the little size (<100 um). Since they develop at fixations altogether under 0.1% they should be dewatered before HTL. In any case, through physical partition strategies, they are accessible as slurries with around 10%-20% water post development collect and dewatering. This implies the extra vitality spent to accomplish a dry feedstock required for most thermochemical biofuel pathways isn't required and nor is extra water included as required for a dry biomass feedstock for HTL. Their pump ability has been shown everywhere scale. The molecule size has been demonstrated to be in direct connection to pump ability and weight control in constant reactors.

Macro algae, otherwise called kelp, are a gathering of eukaryotic photosynthetic marine living beings. Differing and plentiful on the planet's seas and beach front water, they are normally involved a sharp edge or lamina, a stipe, and a holdfast (haptera) for mooring and backing in marine situations. They by and large have a low lipid content however are high in sugars, which are potential biofuel antecedents. Adams et al. examined the occasional variety in the synthetic structure of a macroalga, Laminaria digitata, for thermochemical transformation. They revealed that midyear harvests contained the most elevated extent of starch and least debris content creation them generally appropriate for change to biofuels. Macro algae are by and large of bigger size than microalgae and just certain species, for example, those of the variety Ulva don't require pre-handling; most of macro algae require crushing or maceration when wet before siphoning because of their enormous size.

Siphoning of wet biomass slurries is notable. For instance, the mash and paper industry moves slurries through their offices, however just at lower pressures. The utilization of higher weight frameworks at high temperatures leads into preparing an area with restricted business experience, and in this way stays a mechanical test. Significant modern scale siphoning frameworks have been distinguished, yet have not been exhibited for this application. While thinking about capital expenses for such frameworks, clearly increasingly focused feedstock slurries ought to require littler preparing frameworks for identical throughput and coming about lower capital expenses. Thus, higher temperature will prompt higher response rates likewise bringing about decreased reactor size and cost. Notwithstanding, higher temperature will require higher strain to keep up a fluid water stage for slurry transport in the aqueous framework. In this manner, the monetary drivers for capital cost decrease in aqueous procedures are higher slurry fixations and higher working weights the two of which lead to expanding troubles for siphoning.

These outcomes recommend that the taking care of wet biomass to aqueous handling frameworks is a hindrance to usage. The high-pressure taking care of biomass slurries ought to be all the more promptly accomplished at bigger stream rates wherein the sinewy idea of the biomass would not be required to scaffold and fitting the holes and valves. Though the previous system was to shape slurries with little molecule biomass takes care of, the size decrease costs (dry crushing) were high and successful drying of the biomass was additionally required, with a subsequent high vitality cost punishment. By utilizing wet biomass as the feed, size decrease can be cultivated in a lower cost wet pounding process step. Such outcomes have been accounted for wherein sorghum stalks were cleaved and prepared through a wet ball plant and sifted through a 18 work screen to deliver a slurry at 4%-6% evaporate solids was pump able at to 21 MPa. Pump able slurries of brewer's spent grain were likewise delivered by this technique wherein the last level of dry solids was 7.5%-9.2%. Therefore, tests were likewise performed with potato morsels from a "french fry" producing activity. These could be siphoned following the wet processing activity at 14% dry solids slurry content. Most as of late a high-pressure cylinder needle siphon (Isco) has been utilized to take care of biomass slurries. The siphon can take care of at up to 10 L/cap 21 MPa with a double cylinder game plan, which permits programmed topping off for continuous taking care of; be that as it may, the continuous feed rate is restricted to just 8 L/h in view of the fill rate. This siphon has been utilized to take care of wastewater treatment bio sludge at 1.5%-5% dry solids. The bio sludge was at first recouped as a 1.5% slurry or a dewatered slop with about 14% dry solids, which was remixed with the weaken slurry to shape the 5% dry solids material. Corn ethanol stillage (10.8% dry solids), which has been homogenized with an in-line sheer blender unit (Arde Barinco) has likewise been adequately siphoned with the needle siphon.

Lignocellulosic feed stocks

The National Advanced Biofuels Consortium (NABC) in the U.S. was built up with financing from the U.S. Division of Energy in 2010 to create biomass-based elective fills that can be "drop in" substitutes for gas and diesel fuel. NABC united 17 accomplices from the scholarly world, national research centers, and industry speaking to the whole fuel creation chain from biomass cultivators, to innovation engineers and treatment facility fuel makers. The consortium performed examination, improvement, and investigation over a three-year time frame that was finished in December 2013 on a scope of cutting edge biofuel creation advances including aqueous liquefaction.

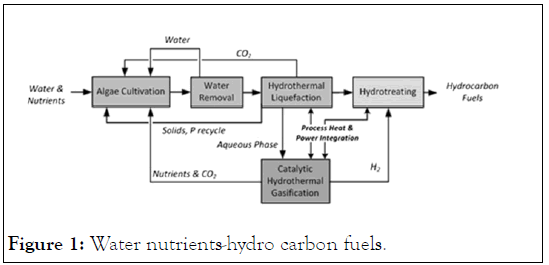

The HTL group, drove by Pacific Northwest National Laboratory (PNNL), exhibited a standard procedure with loblolly pine and corn stover. They analyzed the impact of procedure conditions (temperatures and living arrangement time) and the reuse of watery item to increment bio crude oil yields and lessening wastewater age. Hydro treating of the bio crude item was additionally tried to build material adjusts and to assess redesigned fuel quality. Research and development was done started in a 1-L persistent blended tank reactor working in full nonstop mode. To change the procedure towards an increasingly adaptable structure, a reactor arrangement that consolidated a little CSTR with plug stream segments was utilized for the last piece of the NABC test work. In this design, appeared in Figure 1, the CSTR was utilized to give great blending in the basic temperature extend from 160°C to 300°C.

Figure 1: Water nutrients-hydro carbon fuels.

The aftereffects of the NABC work (NABC, 2014) showed that:

• The main feed arrangement required was crushing for slurry readiness.

• Liquefaction didn't require a decreasing gas condition.

• Water reuse prompted improvement in bio crude quality, carbon yields, and decreased water utilization/wastewater removal.

• Bio crude was steady in a quickened maturing test (There was not exactly a 2% change in bio crude thickness over the span of the test (24 h@353 K)).

• Decreased response seriousness prompted lower quality bio crude.

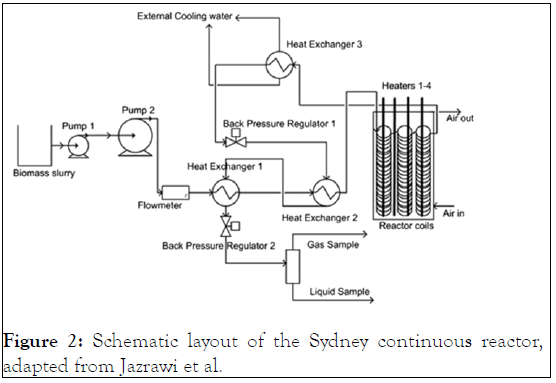

Generally speaking carbon yield, including hydro treatment of the bio crude item, was almost half, with the subsequent item displaying an enormous portion in the distillate run. The destiny of carbon in the general procedure is appeared in Figure 2. These outcomes depend on lingo cellulosic feedstock, and the outcomes could be fundamentally extraordinary for different biomasses, for example, green growth, with high nitrogen substance.

Figure 2: Schematic layout of the Sydney continuous reactor, adapted from Jazrawi et al.

In view of the Techno Economic evaluation (TEA), and comparative with other NABC methodologies, the total expense of creation on a gallon fuel equal premise was great.

To propel the specialized development of HTL, explicit difficulties were recognized including decreasing the danger of enormous scope pump ability, lessening capital expenses by moving endlessly from a consistent blended tank reactor arrangement to a versatile attachment stream reactor setup, and understanding fitting materials of development for process plan.

Overhauling gave the basic advance to decide the quality and monetary estimation of the bio crude created from HTL. Multiliter amounts of bio crude from seat scale HTL testing were given to direct screening tests to recognize impetuses and working conditions. Parametric tests were finished to decide the effect of procedure seriousness on updating item quality. Longerterm overhauling tests were directed to show suggested working boundaries and impetus preparing life (>100 h).

Bio crude from both the backwoods buildup and corn stover feed stocks were created for redesigning. The bio crude, hydrocarbon items, and results from the overhauling, including the fluid stream and the spent impetus, were broke down. A composite hydrocarbon item from the testing was given to the processing plant accomplices to increasingly point by point item assessment. In view of mass physical properties and displaying, potential treatment facility process areas (unit activities) for addition of the HTL materials were recognized.

Results of the work on HTL of lingo cellulosic feed stocks included [9-12]:

• Exhibited high return (>50% carbon effectiveness) and proficient HTL process on backwoods buildup and corn stover feed stocks requiring nothing other than size decrease (arranging).

• Exhibited the procedure in a fitting stream reactor (PFR) arrangement that kept up a little, ceaseless, blended tank reactor (CSTR) as a preheater.

• Working conditions that prompted connecting the PFR were recognized alongside methodologies for minimization of stopping. Consistency increments during heat up of the HTL feed stocks gave off an impression of being connected to lignin fixations and likely added to the stopping.

• A cross breed HTL reactor setup was exhibited that incorporated a preheater, CSTR, and PFRs. The design was viewed as strong and gave a noteworthy progression in reactor adaptability.

• Inside the restrictions of the erosion evaluation testing, the appropriateness of tempered steels for HTL applications was affirmed.

• Built up a solitary stage hydro treating convention to create distillate (57%) and naphtha (27%) and item fractionation and fuel properties were assessed.

• Arranged a full siphoning report surveying modern activity.

• Three sorts of positive relocation siphons, offered by five merchants, were discovered that meet the applied plant creation pace of 2000 DMTPD (2300 gallon for each moment), 15 wt %, 20.8 MPa.

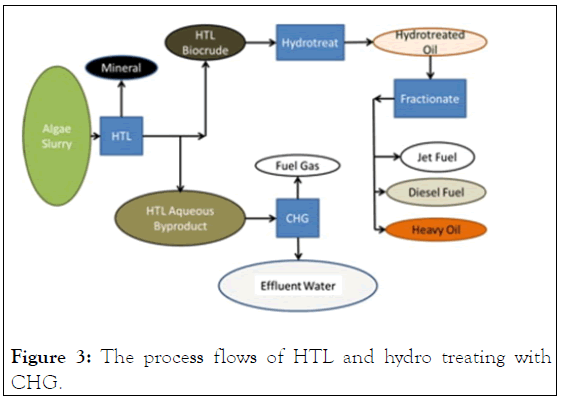

HTL gives an elective procedure course from green growth biomass to hydrocarbon fluid energizes. The immense majority of green growth process research has concentrated on the development of green growth with significant levels of lipid content with an eye toward dissolvable extraction of the triglycerides and transesterification to a biodiesel fluid fuel. HTL gives a pathway to a better return of a bio crude item dependent on change of the lipids as well as all the biomass material including the proteins and starches. Partition of the bio crude and updating the material is required before it very well may be utilized as a transportation fuel. Since HTL handling can be applied to a wide range of green growth, it considers expanding green growth creation without limitation to highlipid creation and with blended societies. Figure 3 shows the move through aqueous handling of green growth to hydrocarbon energizes with potential reuse streams for supplement reuse. A key component of HTL as applied to green growth is the potential for reusing of supplements through partition of solids (by precipitation at aqueous conditions) permitting recuperation of P and the change of N into ammonium in the process water, so it very well may be reused back for additional development. The reusing of supplements is viewed as basic for the achievement of algal determined biofuels. The solids partition step following HTL permits high debris containing feedstock to be handled into about solids-and without mineral bio crude. Tidy up of the natural material in the watery side-effect can be practiced by reactant aqueous gasification (CHG). Marine microalgae strains with high chloride substance can conceivably cause chloride stress consumption on tempered steel reactor parts. This angle is as of now under scrutiny and ought to be observed to guarantee the life span of reactor activities as Jazrawi et al. bring up (Figure 2).

Figure 3: The process flows of HTL and hydro treating with CHG.

With funds from the Australian National Collaborative Research Infrastructure Strategy (NCRIS) a continuous flow pilot-scale hydrothermal processing unit became operational at the University of Sydney in 2012. The design of the unit, as shown in Figure 1, has some noticeable differences compared to the PNNL set-up; it is unstirred and reactants flow through coiled stainless steel tubes submerged into a fluidized sand bath.

Utilizing high-pressure siphons and back-pressure controllers, nonstop sub-basic stream conditions could be gotten. A triplex cylinder siphon (GEA Niro Ariete NS3006P) fit for streams of 15-90 L/h, weights of 61 MPa and high thickness liquids could dependably siphon up to 10 wt % microalgae slurries. A progression of two warmth exchangers, recuperating a portion of the reasonable warmth of the reactor were utilized to pre-heat the slurry to 443 K before going to the reactor comprising of four 16 m 316 hardened steel loops (absolute volume of 2 liters). A nitty gritty portrayal and schematic of the reactor format can be found in Jazrawi et al. distribution. The stream rates examined in the investigation were in the locale of 15-30 L/h and brought about living arrangement times in the reactor of 3-5 min. The items are then gone right off the bat through backpressure controller and warmth exchanger diminishing the strain to 1.0 MPa and temperature to 443 K. As opposed to the constant aqueous treatment of microalgae in the PNNL contemplates, the exploration in Sydney utilized the utilization of a dissolvable for the recuperation of bio crude. This was at first performed to recuperate limited quantities of bio crude in the underlying dispatching runs with low solids convergences of just 1 wt% and later for consistency.

The two microalgae strains Spirulina and Chlorella were explored at a scope of temperatures (523-653 K) living arrangement times (180-300 s) and slurry fixations (1-10 wt %). A greatest bio crude yield of 42 wt % was accomplished at the most noteworthy temperature and 180 s living arrangement times.

Some recognizable results of the communitarian concentrate among Sydney and Leeds include:

Increasingly extreme response conditions prompted most significant returns; least oxygen however expanded nitrogen substance in the bio crude.

Extremely short habitation times produce yields like longer living arrangement time clump examines. This permits a lot higher throughput and diminished vitality necessities.

Higher strong loadings increment the bio crude yields, as appeared in PNNL contemplate, and diminish carbon misfortunes inside the framework.

The "converse scaling" impact of siphoning and weight control prompted the end that scaling up the Sydney configuration should bring about better controllability and decreased capability of arrangement of agglomerates and stores, which can prompt blockages.

The Savage gathering talk about in their ongoing distribution that lower living arrangement times can altogether lessen the capital expenses for constant aqueous liquefaction [6]. Their work on quick warming rate cluster frameworks prompted bio crude yields surpassing 60 wt % and vitality recuperations of around 90%. The bio crude yields utilizing Jazrawi et al. Sydney reactor setup was seen as >40 wt% for a 4 wt% lipid containing microalgae at the lower habitation time. Both the persistent stream work by Jazrawi et al. and the clump work by Faeth et al. recommend that higher warming rates and lower habitation times favor the creation of bio crude. This is probably going to improve the vitality parity and TEA of microalgae to fuel frameworks by nonstop HTL.

The National Alliance for Advanced Biofuels and Bio products (NAABB) (NAABB, 2014), an algal biofuels research consortium, was shaped to explicitly address the destinations set out by the U.S. Branch of Energy (DOE). DOE looked for a consortium that would "synergistically utilize their one of kind abilities to speed up the improvement of biomass based fuel creation pathways." Participants from industry, the scholarly world, and government or potentially non-government research facilities, all gave "top tier" specialized methodologies. NAABB explicitly tended to the accompanying pathways:

Feed stock Supply-Strain improvement and development.

Feed stock Logistics-Harvesting and extraction.

Transformation/Production of inter mediates and blend of powers and co products.

Direct transformation of the wet entire green growth biomass to bio crude was examined utilizing the thermochemical preparing strategy for aqueous liquefaction. What's more, a synergist aqueous gasification process was explored for the change of wet lipid-separated green growth (LEA) to methane and as friend wastewater treatment for HTL handling. The consolidated HTL-CHG handling course brought about the best bio crude yields, process financial matters, and life cycle evaluation. A disentangled procedure stream chart for the consolidated HTLCHG process with pictures of coming about procedure streams is appeared in.

The consortium concluded that the advantages of the HTLCHG processing pathway include:

• Catch of 85% of the carbon in green growth as fuel-grade parts (bio crude that can be moved up to diesel, stream, gas, and syngas).

• Creation of a bio crude that can be promptly changed over to meet diesel and Jet A fuel guidelines.

• Viable wastewater treatment to lessen the natural substance and give methane to process vitality.

• Reuse of water and supplements (nitrogen, phosphorous, and other minor elements for algal development.

• Critical diminishing in capital and working expenses contrasted with forms requiring high lipid-yielding algal biomass and extraction of the lipid from the biomass.

• NAABB inferred that one of the features of the three-year exertion was the high return extraction-transformation innovation, HTL, that joins extraction and change to give high bio crude yield without the requirement for extraction solvents, bringing about 86% cost decrease.

Wet green growth slurries were changed over into upgradeable bio crude by HTL in a seat scale constant stream framework at PNNL. Significant levels of carbon transformation to gravity-detachable bio crude item were cultivated at run of the mill HTL temperature (623 K) at a working weight of 20 MPa. Direct bio crude recuperation was accomplished without the utilization of a dissolvable and biomass follow segments were expelled by preparing steps so they didn't cause process challenges. The best return of bio crude (up to 82 wt % on a carbon premise) was gotten with high slurry convergences of up to 34 wt % of dry solids. With ensuing hydro treating of the bio crude and reactant aqueous gasification of the water-solvent natural sideeffects, a high change of green growth to fluid hydrocarbon and gas items was found with low degrees of natural tainting in the side-effect water. Each of the three procedure steps were cultivated in seat scale, consistent stream reactor frameworks with the end goal that plan information for process scale-up was produced.

Compound examination of the bio crude recommended the aqueous transformation of the full supplement of green growth parts including lipid, starch, and protein. The bio crude was made out of carbon, hydrogen and oxygen, yet in addition nitrogen and sulfur. The Explicit parts are recognized by the Gas Chromatography-Mass Spectrometry (GC-MS) included fragrant hydrocarbons and phenolics, notwithstanding nitrogen heterocycles, and long chain unsaturated fats and amides. Nitty gritty examination of the bio crude was embraced utilizing Fourier Transform Ion Cyclotron Resonance Mass Spectrometry (FT-ICR MS) appearing specifically the heavier parts containing oxygen in blend with nitrogen. The investigation inferred that the parts found in the bio crude were fundamentally the same as those likewise found in the watery result in that sweet-smelling nitrogen mixes and free unsaturated fats are dominating species. The segments in the fluid stage are marginally lower in atomic weight.

Ensuing work included HTL of Chlorella green growth and the subtleties of the procedure results are accounted for as a component of a plan contextual investigation [12]. A key end identifies with the appropriation of natural item between the bio crude stage and the watery result stage. The yield of stage divisible bio crude is plainly an element of dry solids fixation in the feedstock slurry. Also, comparable bio crude is delivered from the various species and they can be hydro treated with comparative outcomes.

Macro algal slurries have been changed over into bio crude by HTL in a seat scale, ceaseless stream reactor framework. Carbon transformation to gravity-distinct bio crude item was lower than for microalgae at 57.6% when utilizing feedstock slurries with a 21.7% grouping of dry solids. What's more, CHG was adequately applied for HTL side-effect water cleanup and fuel gas creation from water solvent organics. Accordingly, high transformation of macro algae to fluid and gas fuel items was found with low degrees of lingering natural pollution in the side-effect water. A key end was the relationship of the algal dry solids in the slurry to the yield of gravity distinguishable bio crude. The bio crude yield dropped to just 17.1% (on a carbon premise) when the feedstock fixation was just 5.3 wt% dry solids. The bio crude organization was a lot of like the microalgae bio crude, at any rate on a natural premise.

Different reports demonstrate that yields of bio crude from macro algae are low and contain a lot of high sub-atomic weight material and nitrogen. The higher warming worth (HHV) of the bio crude was high contrasted with the first feedstock and the oxygen content was fundamentally brought down. The mineral issue was for the most part circulated between the watery stage and the strong buildup. The sugars were passed into the watery stage making further use conceivable, for example, maturation. Macro algae will in general have higher sugar content which has been appeared to deliver lower bio crude yields during HTL, microalgae then again for the most part contain higher lipid content which brings about increment bio crude yields.

Resulting handling of HTL item streams

While HTL of wet biomass gives a suitable course to fluid powers from biomass, ensuing overhauling of the HTL bio crude item is required all together for the item to be valuable in the current fuel markets. What's more, treatment of the result fluid is a key segment for delivering an economical, inexhaustible fuel by means of HTL.

Summing up the distributed papers on HTL of green growth, it has been indicated that a high bio crude yield (40-60 wt.%) is gotten in constant stream reactor frameworks. The bio crude is a profoundly thick oil with moderately high nitrogen (~5 wt %) and oxygen substance (~ 5%) with HHV of around 35 MJ/kg. Apparently the ideal working conditions for most extreme bio crude yield are ~ 623 K with a space time of 3-14 min. In any case, the working conditions are profoundly strain and framework explicit. On the off chance that a bio crude of lower nitrogen content is wanted with higher lipid content, lower working conditions ought to be utilized or the protein division ought to be expelled before HTL. On the other hand, esteem included mixes, for example, lipids can be removed as shown by Zhu et al. (2013) and Vardon et al. (2012) and bio crude delivered in this way. As of late Prof. Chen's exploration bunch at the Washington State University has built up a novel twoadvance consecutive HTL innovation (SEQHTL) for the extraction of significant worth included polysaccharides followed by bio crude creation. This is a fascinating methodology as the extraction of high-esteem mixes from algal biomass is an angle that could well recognize it from earthbound biomass. The initial step included gentle aqueous handling (433 K) and evacuation of the polysaccharide rich water separate by precipitation with ethanol. This was introduced in bunch reactors, yet the application to consistent frameworks could be practical. Another option proposed to improve the bio crude yields and creation includes microwave pre-treatment of the green growth with ensuing aqueous liquefaction. This was tried in clump tests bringing about expanded yields and lower heteromolecule content in the bio crudes [2]. To date just lipid extraction preceding nonstop aqueous preparing has been shown while the other pre-treatment and extraction approaches are still in the creating cluster reactor stages.

Evaporator terminating tests were embraced with HTL bio crude items delivered from Douglas fir wood. The bio crude dealt with and terminated like a #6 leftover fuel oil, requiring preheating to 410 K to perform acceptably. Fuel oil consume test information contrasted with HTL bio crude proposed that with less abundance air, the NO and SO2 were lower overall (likely due to bring down nitrogen and sulfur substance in the fuel) while the CO was higher because of a few huge spikes in fixation level. The higher normal CO was gotten from spikes in the pro fluent and it has been estimated that the spikes were because of particulate in the bio crude, bringing about various consuming properties.

As a component of NABC, a techno-monetary investigation for HTL of woody biomass was readied based test results and contribution from consortium mechanical accomplices. An original copy of the TEA was arranged and has been distributed. Affectability assessments were performed to assess joining of a CSTR pretreatment step and a HTL reactor reuse circle.

As a major aspect of NAABB, a techno-financial investigation for HTL of algal biomass was readied based exploratory outcomes. An original copy of the TEA was arranged and has been distributed [9]. The essential cost driver was resolved to be the green growth feedstock cost.

Resulting work included plan investigations of HTL of Chlorella green growth. Key ends identify with the dissemination of natural item between the bio crude stage and the fluid result stage and the requirement for increasingly effective bio crude recuperation. More procedure results at a more extensive scope of working conditions with a more extensive scope of green growth species is expected to help characterize the working wrap for HTL. Proceeded with improvement of fitting stream reactor tasks are additionally required. More data on consumption is expected to educate the materials regarding development choices. The examination inferred that for the anticipated objective case, a $ 4.49/gallon of gas equal (gge) was the base fuel selling cost thinking about the accepted expenses ($ 430/ton DAF green growth including the development, reap and dewatering to 20 w% dry solids) and money related structure. This adds up to a change just cost (barring all feedstock related expenses) of $1.18/gge. Improvement to a $ 3/gge least fuel selling cost would require a blend of enhancements, for example, updating at a focal (bigger scope) site, co processing with other accessible biomass types, and diminishing the expense of the CHG water treatment.

As of late a real existence cycle investigation (LCA) has been distributed dependent on microalgae to green diesel utilizing information from a persistent pilot-scale plant. Three situations are dissected, in particular, lab scale, pilot-scale and full scale frameworks. The vitality quantifiable profit, just as the ozone harming substance discharges, were determined and contrasted with lipid separated algal bio-diesel, oil fills, corn-ethanol and soy biodiesel. The examination depended on information and mastery from Sapphire Energy Inc. (USA), for the creation of green diesel utilizing HTL. It was indicated that pilot scale offices have life cycle troubles comparable to traditional biofuels. Be that as it may, the outcomes from extrapolating to full scale offices were increasingly great; ozone harming substance outflows were lower contrasted with oil powers and corn ethanol. The vitality quantifiable profit (EROI) was seen as somewhere in the range of 1 and 3 with full scale creation offices having an EROI of around 2.7. These EROI results are good contrasted with all customary biofuels however not as high as oil determined fills. An affectability investigation uncovered the zones where upgrades could have a huge effect to be the yields of bio crude and productive supplement reusing.

The current survey on ceaseless HTL of biomass prompts the end that there is huge potential for commercialization of the innovation. A few feed stocks have effectively been handled at high feed fixations bringing about high vitality recuperations and carbon efficiencies. There are as yet various difficulties which should be tended to before the innovation is showcase prepared. The current size of non-stop frameworks isn't sufficient for show size of activity. TEA counts by the by feature the capability of the innovation particularly for wet waste and green growth feedstock.

Citation: Jones SB, Biller P, Elliott DC (2021) Aqueous Liquefaction of Biomass: Developments from Clump to Constant Procedure. J Phys Chem Biophys. 11:306.

Received: 03-Aug-2020 Accepted: 17-Aug-2021 Published: 24-Sep-2021 , DOI: 10.35248/2161-0398.21.11.306

Copyright: © 2021 Jones SB, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Sources of funding : PhD-project on ethical challenges and decision-making in nursing homes has been financially supported by the Norwegian Extra Foundation for Health and Rehabilitation through EXTRA funds (grant no. 2008/2/0208).