Journal of Geology & Geophysics

Open Access

ISSN: 2381-8719

ISSN: 2381-8719

Research Article - (2025)Volume 14, Issue 1

The study is significant as there are currently numerous oil rim deposits and gas cap layers all over the world with high gas content. These deposits hold a considerable portion of reserves. Utilizing simplistic methods like relying on a rigid water pressure regime for developing those deposits can be extremely challenging. The sharp decrease in reservoir pressure makes it impossible to restore it through these mechanisms, making exploring alternative approaches crucial. Therefore, alternative methods must be considered to access hard-to-recover hydrocarbon reserves for development. For areas with a significant decline in reservoir pressure, water-gas stimulation combined with associated petroleum gas will be investigated and proposed. The article presents a powerful new technique that combines water-gas stimulation with associated petroleum gas, enabling the effective influence of deposits with high gas content. Compressing gas and mixing it with liquid to maintain reservoir pressure eliminates the need for utilizing associated petroleum gas in technological processes. An increase in production of 10%-20% can be achieved using this process, resulting in oil rims that are more economically viable for development. This approach is a gamechanger for the industry and represents a significant step forward in producing more efficient and cost-effective gas extraction methods. Additionally, a software-based approach for utilizing water-gas stimulation has been examined, showing great potential for improving the process.

Water-gas stimulation; Oil rim; Gas cap; Enhanced oil recovery; Low-pressure associated gas

In oil and gas extraction areas, it is common for the reservoir pressure to decrease over time. However, the traditional compensation method that uses water pressure mode may not always yield the desired results [1-4]. This has led to the exploration of alternative methods for maintaining reservoir pressure and optimizing oil and gas production. Alternative methods of influencing the reservoir must be considered to create a piston effect to displace hydrocarbons and increase reservoir pressure. One of these methods is water-gas impact [5-8]. In the field of production practice, there are numerous techniques utilized for water-gas stimulation of the formation. These methods include injecting dry or wet gas, nitrogen or carbon dioxide into the formation, as well as injecting a watergas mixture that is prepared directly at the pump under reservoir conditions [9-12]. Each of these methods has its own set of advantages and limitations, which are evaluated based on the formation's specific geological and reservoir characteristics. Effective water-gas stimulation is crucial for optimizing oil and gas production from reservoirs. Each of these methods is effective under various geological and technological conditions of development sites [13-15]. The article discusses the technology of water-gas stimulation by injection of a water-gas mixture in surface conditions. This technique is most effective for developing hard-to-recover reserves in fields characterized by the presence of a gas cap or oil rim [16-18]. The development of such facilities is necessary to address the issue of low oil recovery rates caused by gas and water breakthroughs during operation.

Injection of a Water-Gas Mixture (WGM) as a displacement agent is already used in Russia in oil-rim fields and shows quite good results [19,20].

The article discusses the modernization of the use of this technology for injecting hydrocarbon gases to increase the oil recovery factor when developing sub-gas zones of oil and condensate fields.

Application of water-gas impact (stimulation)

The use of WGM injection technology is an effective method for increasing oil recovery in formations or areas of deposits in the sub-gas zone (presence of a gas cap) and oil rims. The technology under consideration has several advantages in contrast to other water-gas technologies:

Increases reservoir oil recovery by achieving the following:

When preparing WGM, there are no restrictions on the composition of the mixed gas. Therefore you can mix dry, enriched and wet gas, up to a wide fraction of light hydrocarbons (NGL), which is very important for increasing oil recovery. This approach can alter the liquid's rheology and increase the efficiency of the process. In addition, this fact is crucial for the utilization of gas from nearby facilities that produce hydrocarbons.

When the Pressure of the reservoir (Pr) falls below the Saturation pressure (Ps), the process of gas separation from the oil begins. This leads to the degassing of the liquid and the occurrence of two-phase flow in the formation-gas plus oil. The dissolved gas regime is characterized by a high rate of decline in reservoir pressure and an increase in the gas-oil ratio. In certain circumstances, gas present in a formation can be released from the liquid that is injected into RPM wells. This can replenish the energy of the formation. However, it is important to observe the appropriate injection mode to ensure that the resulting formation pressure does not exceed the saturation pressure. This will ensure that the reservoir operates according to the nature of the gas repression displacement process as intended.

During the period of the well operation in the Pr=Ps mode at the bottom of the well, gas breaks through to the perforation holes of the production wells. Two cones are formed: Gas on top, oil plus water below, the product becomes gassed and watered. The water-gas stimulation technology under consideration is focused on operating the deposit at a pressure below the saturation pressure and preventing gas breakthrough, as well as preventing the pull-up of a cone of water.

The technology can be combined with unsteady impact to Redistribute Fluid Flows (RFF) and involve poorly drained zones in the development.

By carefully choosing the right wells and calculating the method, it may be possible to significantly reduce the volume of gas that needs to be disposed of, potentially by 95 to 100%.

Effective implementation of WGM injection depends on the availability of:

Regarding geological properties, the technology is more applicable to homogeneous formations. Still, it also applies to deposits characterized by lateral and vertical heterogeneity, mostly oil rims. The main condition is the presence of free gas. The technology is most effective when the reservoir pressure is below the saturation pressure for operation in gas repression mode. Since at a reservoir pressure above the saturation pressure, the incoming gas from the outside will dissolve in the oil and degas at the bottom, which has a detrimental effect on the operation of the pumping equipment.

Proposed scheme for using water-gas stimulation

As mentioned above, the WGM injection technology is successfully used in the fields of Eastern Siberia. The preparation process for WGM involves an injection line that connects the compressor to a high-pressure water pipeline. This pipeline typically runs from a Cluster Pumping Station (CPS) to well clusters and feeds directly into injection wells. Alternatively, following the standard scheme, it may connect to a water pipeline at a well cluster as part of a Block Cluster Pumping Station (BCPS). To make this setup work, it necessitates a highpressure compressor that can efficiently pump flammable liquids and gases. Low-pressure associated petroleum gas is supplied to the compressor inlet. The compression ratio is about 15-20. Field experience shows that this scheme is ineffective because of the following:

Thus, it is imperative to consider an alternative approach for efficient and effective injection. Therefore, the work proposes to explore another scheme for injecting hydrocarbons into the reservoir. This scheme differs in that the increase in gas pressure (for dissolution in liquids) occurs in stages and the energy of injected water is used to mix in the ejectors and separate in the separators.

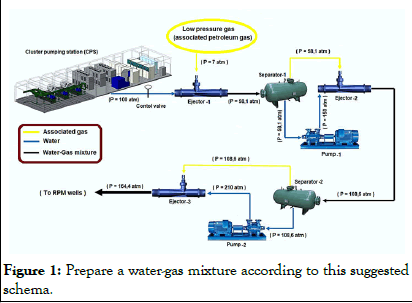

Figure 1 shows one of the software calculations for mixing lowpressure gas with liquid from a cluster pumping station for injection into a reservoir with a final pressure of 164.4 atm. The pressure increase ratio of the first-stage pumps is 2,5. The pressure increase ratio of the second-stage pumps is 2.

Figure 1: Prepare a water-gas mixture according to this suggested schema.

Water is supplied from the high-pressure line from the CPS (there is no need to regulate the pressure on the SPS pumps) with the required pressure, which is maintained by the control valve-according to the setting value of the pressure sensor. Water flows next to ejector-1 (High-Pressure (HP) flow), where associated gas (Low-Pressure (LP) flow) is introduced. The mixture is mixed and supplied to separator-1, separated into water and gas, but with a higher gas pressure. Next, the gas flows to the ejector-2, the water first to the high-pressure pump-1 and then to the ejector-2 input (HP flow).

After mixing, the mixture goes to the second stage separator-2. Next, the mixture is separated and the gas leaves the separator with even higher pressure and enters the ejector-3 (LP flow) and the water first goes to the high-pressure pump-2, then to the ejector inlet-3 (HP flow). At the exit from the ejector, a readymade water-gas mixture is obtained, which is pumped with a certain pressure through RPM wells into the formation.

To evaluate the effectiveness of the proposed WGM injection scheme, additional oil production was calculated in the TNavigator hydrodynamic simulator. A compositional model of the XX cluster of wells at the field was built for more accurate calculations. In contrast to the "volatile oil" model, a more detailed picture of the distribution of reserves was obtained when creating a compositional model, where the component composition for each phase was specified. This method allowed for studying the peculiarities of mass transfer processes inside the formation.

When calculating the effect of production growth, three development options were considered for comparison:

Figure 2: Oil production levels during Reservoir Pressure Maintenance (RPM) system modernization.

The calculation was carried out over 50 years of development. The increase in the oil recovery factor was 7.7%.

Cost-effectiveness assessment

Based on the results of calculations of the technological efficiency of using WGM, the economic efficiency of modernizing the RPM technology using water-gas stimulation on the deposit was calculated.

Table 1 discusses the costs of setting up a system for preparing WGM and injection into the reservoir.

| Product description | Number | Cost, × 106 rubbles (RUB) |

| Capital costs | 52 | |

| Ejector | 3 | 1 |

| High-pressure pump type KM80-50-200 | 2 | 0.5 |

| Developing a system for preparing water-gas mixtures | 2 | 10 |

| High-pressure pipeline DN 80, Length=10 km (Before insertion into the main RPM system and arrangement of the preparation system) | 1 | 35 |

| Valve assemblies, flow meters, operation algorithms, application software | 1 | 5 |

| Emergency and drainage tank V=64 m3 | 1 | 0.5 |

| Operating cost | ||

| Installation-specific fluids | 200 l/year | 2 |

| Total | 54 | |

Table 1: Setup costs for preparing RPMs and injecting them into reservoirs.

It is worth taking a closer look at the economic indicators observed during the profitable period of the project implementation. These indicators are listed in Table 2 and can provide valuable insights into the project's financial performance. Additional capital costs for implementing EOR under option no. 3 amounted to 52 million rubbles.

| Indicator | Unit | Amount |

| Brent oil price average | $/barrel | 53.6 |

| Taxes on mineral extraction | × 106 (RUB) | 1 557 |

| Capital investments | 52 | |

| Internal Rate of Return (IRR) | % | 46.66 |

| Discounted Payback Period (DPB) | year | 5 |

| Discounted Profitability Index (PI) | fraction | |

| Net Present Value (NPV) | × 106 (RUB) | 472 |

Table 2: Economic indicators during project implementation.

Net Present Value (NPV) with an increase in oil recovery factor by 7,7% amounted to 472 million rubbles (Figure 3).

Figure 3: A dynamic analysis of discounted cash flows, in billions of rubbles (RUB).

Analytical calculations were conducted to study a water-gas stimulation method, which involves using associated petroleum gas to prepare the mixture. Additionally, a technology for mixing low-pressure gas with water from a reservoir pressure maintenance system was proposed for injection into the reservoir. An effective method has been developed to improve oil extraction from gas-rich deposits. This method involves injecting water into the formation to increase the coverage of the productive formation and suppress the gas. The result is an increase in oil recovery.

The addition of technology to inject a mixture of water and gas can significantly increase the production of reserves while developing sub-gas zones in oil and gas condensate fields. This process may increase the production by 10%-20%, resulting in a more economically feasible development of oil rims. The proposed scheme for preparing and injecting a water-gas mixture has a low installation cost, making it cost-effective.

For automated calculation of gas and liquid mixing, including assessment of the final reservoir pressure, specialized software has been developed and registered in the C shell programming language. The program enables analysis of reservoir pressure, operating mode of the mixture preparation unit and calculation of required reagent consumption. Any similarities with actual production values are purely coincidental. The data presented are not predictive but are indicators of the effectiveness of using this technology.

Citation: Al-Obaidi SH, Chang WJ (2025) Utilizing Water-Gas Technology to Recycle Low-Pressure Associated Gas in Gas-Cap Formations and Enhance Oil Recovery. J Geol Geophys. 14:1210.

Received: 24-Mar-2024, Manuscript No. JGG-24-30438; Editor assigned: 27-Mar-2024, Pre QC No. JGG-24-30438 (PQ); Reviewed: 10-Apr-2024, QC No. JGG-24-30438; Revised: 04-Mar-2025, Manuscript No. JGG-24-30438 (R); Published: 11-Mar-2025 , DOI: 10.35841/2381-8719.25.14.1210

Copyright: © 2025 Al-Obaidi SH, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.