Journal of Geology & Geophysics

Open Access

ISSN: 2381-8719

ISSN: 2381-8719

Research Article - (2025)Volume 14, Issue 1

Increasing oil recovery in the oil industry requires a better understanding of the mechanism of behaviour of silica gel in porous media. Several technologies have been developed for redistributing fluid flows of injected or produced water in this work. These technologies were developed based on a proposed mechanism of the silica gel creation in a porous medium. The technologies presented here have been developed in order to increase oil recovery, and their implementation at various oil field sites has been evaluated. As a result of the implementation of these technologies in 519 well operations across different oil fields, an additional 797,734 tons of oil were produced, or 1,537 tons more per well.

Silica gels; Technologies; Porous media; Oil recovery; Behaviour mechanism

Many oil and gas fields around the world have developed technologies for redistributing fluid flows with gel-forming compositions based on sodium silicate (liquid glass) [1-5]. These systems have several advantages, including the technology to prepare and inject the reagents conveniently, the ability to handle large pressure gradients, the possibility of destruction by alkali agents and the environmental safety of the reagents [6-9].

The mechanism of formation of an alkaline silica gel has been sufficiently studied [10], but there is debate about the mechanism of behavior of a silica gel in a porous medium.

Silica gels are formed as a result of the interaction of sodium silicate with mineral or organic acids according to the following scheme:

Where x is the module of liquid glass.

As a result of the reaction, a silicic acid sol is formed, which over time turns into a gel according to the following scheme:

As a result of the reaction, polysilicic acids of various structures are formed (linear, branched, cyclic and mixed). This polycondensation process is called gelation. Up to a certain point, the viscosity changes slightly and after that it increases sharply. This moment is called the onset of gelation.

Since the formation of the gel occurs over time, exposure is required to achieve maximum gel strength. It was experimentally established that the holding time should exceed the time of onset of gelation by approximately three times. The process of forming a silica gel from a low-viscosity solution is the basis for the following technologies for redistributing the flow of injected or produced water in oil wells:

For the successful application of the above technologies, it is necessary not only to study the physicochemical laws of the formation of silica gel, but also to know the mechanism of behavior of silica gel in a porous medium. It is this concept that represents the main focus of this study.

Study design and setting

A laboratory installation from core laboratories was used to study the flow characteristics of silica gel. This installation is designed to study the oil-displacing and flow properties of compositions of various chemical reagents under conditions close to reservoir conditions. Experiments were carried out on core samples of different permeability.

The following methodology was used in the experiments:

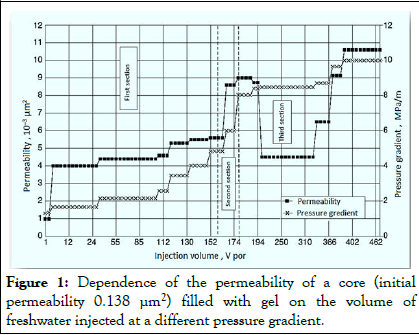

The flow studies were carried out on core samples with permeability of 0.138 and 0.079 μm2. Figure 1 represents the flow results for a core with a permeability of 0.138 μm2 (a similar dependence was obtained for a core with a permeability of 0.079 μm2).

Figure 1: Dependence of the permeability of a core (initial permeability 0.138 μm2) filled with gel on the volume of freshwater injected at a different pressure gradient.

This figure shows the dependence of the permeability of a core saturated with a gel-forming composition followed by exposure until a silica gel forms and the pressure gradient on the injected volume. This dependence can be divided into three sections: The first section is the region of elastic deformation of the silica gel in a porous medium up to a pressure gradient of 4.8 MPa/m, the second section is the region of partial destruction of the silica gel up to a pressure gradient of 8.0 MPa/m, the third section is the region of behavior in a porous medium of a compacted partially destroyed silica gel up to a gradient of 10 MPa/m.

Further increases in liquid flow could eventually increase pressure to the point where completely destroying the compacted silica gel would be possible. However, due to instrument limitations, it was unable to obtain the maximum destruction pressure for silica gel in an experimental study involving cores filled with silica gel.

As confirmation that the 1st section in Figure 1 is the region of elastic deformations in a porous medium, ceasing water flow in this section and resuming water flow at the final flow parameters do not change the permeability of the core sample.

In the second section of the graph, permeability begins to increase sharply with increasing pressure gradients, which indicates partial collapse of the silica gel, as well as an increase in permeability to 9 × 10–3 μm2.

The third section represents the behavior of the partially destroyed compacted silicate gel. With compaction and partial destruction of the silicate gel, first, the permeability of the core sample filled with silicate gel decreases to approximately 4.5 × 10–3 μm2 at a pressure gradient of 8.5 MPa/m and then, with an increase in the pressure gradient, cracks in the silicate gel open and the permeability of the core sample increases.

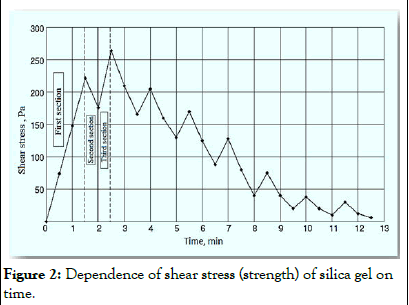

Physical and chemical studies of silica gels confirm the findings of flow studies. The dependence of shear stress (strength) on time is presented in Figure 2. Three sections can also be distinguished from the obtained dependence: The first is an elastic deformation region of the silica gel for up to 1.5 minutes; the second is a region related to the partial destruction of the silica gel and the formation of cracks for up to 2 minutes; the third is related to the behavior of compacted partially destroyed gel for up to 2.5 minutes. Since the cell of the Reomat-30 device is of an open type, the readings of the device and the changes occurring in the silica gel can be observed visually.

Figure 2: Dependence of shear stress (strength) of silica gel on time.

As far as calculating the volume of silica gel injection is concerned, the focus should be on the final pressure of the first section, i.e., 4.8 MPa (insulation coefficient 25) and attempts to prevent partial gel destruction.

Based on Figure 1, the core sample filled with silica gel until partial destruction can withstand a pressure gradient of about 4.8 MPa/m and has a permeability of about 0.0056 μm2. The permeability reduction factor was about 25. This means that if an annular zone of silica gel is created in a highly permeable layer of an injection or production well, its injectivity will decrease by 25 times. This led to the suggestion of using silica gel in technologies for redistributing fluid flows of injected or produced water. The technologies have been successfully tested in oil fields in various regions of Russia and Kazakhstan.

The technological effectiveness of using the above technologies in oil fields in various regions of Russia and Kazakhstan has been reported in various publications and is presented in Table 1. This table shows the results of applying the technologies proposed in the study to 519 well operations in different oil fields. The average success of applying the technologies was 93%, resulting in an additional 797,734 tons of oil production, or 1,537 tons of more oil production per well.

| Oil field | Number of operations | Success, % | Additional oil production, t | Specific additional oil production, t/well-oper |

| A | 16 | 100 | 39500 | 2469 |

| B | 19 | 100 | 75254 | 3961 |

| C | 35 | 100 | 198174 | 5662 |

| D | 11 | 100 | 99300 | 9027 |

| E | 40 | 93 | 34630 | 866 |

| F | 30 | 100 | 42171 | 1406 |

| G | 24 | 73 | 17787 | 741 |

| H | 31 | 94 | 31000 | 1000 |

| I | 13 | 100 | 12612 | 970 |

| J | 113 | 86 | 92844 | 822 |

| K | 187 | 95 | 154462 | 826 |

| Total | 519 | 797734 | 1537 |

Table 1: Various companies' results of implementing the technologies for redistribution of injected or produced water flows in oil wells.

As a result of understanding how silicate gel behaves in porous media, treatment technologies for both injection and production oil wells can be designed more objectively. Several technologies developed for redistributing fluid flows of injected or produced water based on the proposed mechanism of silica gel in a porous medium. It is preferable to work in the elastic deformation region of silicate gel when designing an injection well treatment.

The technologies proposed in the study were applied to 519 well operations, resulting in an additional 797,734 tons of oil production or 1,537 tons of more oil production per well.

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

Citation: Al-Obaidi SH, Khalaf FH (2025) New Technologies to Investigate the Behaviour of Silica Gels in Porous Media. J Geol Geophys. 14:1209.

Received: 01-Feb-2024, Manuscript No. JGG-24-29455; Editor assigned: 06-Feb-2024, Pre QC No. JGG-24-29455 (PQ); Reviewed: 20-Feb-2024, QC No. JGG-24-29455; Revised: 17-Jan-2025, Manuscript No. JGG-24-29455 (R); Published: 24-Jan-2025 , DOI: 10.35841/2381-8719.25.14.1209

Copyright: © 2025 Al-Obaidi SH, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.