Journal of Biomedical Engineering and Medical Devices

Open Access

ISSN: 2475-7586

ISSN: 2475-7586

Research Article - (2017) Volume 2, Issue 1

Diagnostic medical equipment are medical equipment that aid in the observation of various aspects of a patient’s health condition. These devices help to form the basis for diagnosis and is therefore critical for this equipment to be efficiently maintained to ensure accurate and reliable output. In this study, we investigated the maintenance culture of diagnostic medical equipment and relate the findings to indices to find the exact causes of equipment failures. In the case study the sphygmomanometer was used. Our results have shown the following: (i) that most failures are due to preventable causes (ii) inadequate medical equipment technicians and engineers, (iii) Data deficiencies and (iv) lack of predictive maintenance.

Keywords: Sphygmomanometer; Ultrasound machines; Predictive maintenance; Electrocardiographs

The role of diagnostic medical devices is crucial for efficient healthcare delivery in any country. Devices are highly important in personnel’s health and to improve patient’s treatment [1,2]. In addition to physical examinations or patients’ descriptions of their symptoms, physicians rely on diagnostic instruments to check for signs of diseases. Therefore, the availability and optimal utilization of medical equipment is important in improving the quality of health services. Studies have been carried out around the globe to assess the maintenance management of medical equipment in general [3-9]. In developing countries such as Ghana, significant investments are made for the purchase of these equipment but enough attention is not given to the maintenance and repairs of these equipment. As a result, a lot of these equipment are out of service due to high break down rate.

Equipment failures occur due to various causes which include the following [3]; Improper storage and transportation, Initial failure, Inappropriate handling, Inadequate maintenance, Environmental stress, Random failure, Inappropriate repair technique and Wear-out failure [10]. The World Health Organisation (WHO) estimates that 50% to 80% of such equipment remains non-functional and the most commonly cited reasons are, poor maintenance culture and lack of highly trained technicians [11,12]. According to statistics on medical equipment failures from WHO about 80% of all medical equipment failure cases are caused by preventable factors and failures due to inadequate maintenance alone account for about 60% of all the medical equipment performance cases [2]. In addition to this, failures due to inappropriate handling, environmental stress and wear-out account for about 20% of all the failure cases [2]. There are several types of maintenance practices that are carried out on medical equipment. These include Inspection, Predictive Maintenance, Preventive Maintenance, Repair/Corrective Maintenance.

Investigating causes of equipment failure involves logical troubleshooting using wide-range knowledge of operating principles of the equipment, structure of the equipment, and understanding of the electronic circuits of the equipment.

The broad objectives of this project are to:

1. Find out the maintenance culture in Ghanaian hospitals,

2. Identify the major causes of equipment failure and their link to maintenance practices carried out on this equipment using the fault tree analysis (FTA).

3. Inform stakeholders in planning interventions on equipment failures.

Data for this study was collected in some selected hospitals in the Greater Accra Region of Ghana through visits at maintenance departments, clinical engineering departments, administrative departments and equipment supply stores of the hospitals by administering questionnaires, conducting interviews and observations. The hospitals selected are: 37 Military Hospital, Ridge Hospital, University of Ghana Hospital, FOCOS Orthopedic Hospital. The main reasons for selection of these hospitals are they are referral hospitals, proximity and accessibility. The following application softwares were used to analyze the data and plot the graphs, Microsoft Office 2013, Edraw Max 7.9, diagrams, statechats. The following diagnostic medical equipment were studied: Sphygmomanometers, Stethoscopes, Electrocardiographs (ECG), Thermometers, Ultrasound machines, X-ray machines, CT Scanners.

Theory

The Fault Tree Analysis (FTA)

FTA is a top down, deductive failure analysis in which an undesired state of a system is analyzed using Boolean logic to combine a series of lower level events [13,14]. This analysis identifies and records systematically the logical fault paths from a specific effect to the prime causes or simply to understand how system can fail. It identifies all relevant events and conditions leading to undesired event or a failure and determine parallel and sequential event combinations leading to the failure. It is based on AND and OR gates which define the major characteristics of the fault tree. The probability of a gate’s output event depends on the input event probabilities. An AND gate represents a combination of independent events. In set theoretic terms, this is equivalent to the intersection of the input event sets, and the probability of the AND gate output is given by assuming that A and B are the input events as;

P(A AND B)=P(A ∩ B)=P(A)P(B) (1)

An OR gate, on the other hand, corresponds to set union:

P (A OR B)=P (A U B)=P (A)+P (B)-P (A ∩ B) (2)

P (A OR B)=P (A)+P (B)-P (A) P(B) (3)

Since failure probabilities are usually very small, P (A ∩ B) becomes a very small error term hence P (A OR B)=(P(A)+P (B)) (4)

Weibull analysis equations

The Weibull analysis provides a simple and useful graphical plot of the failure data which is very important to the engineer because it is very informative and very useful. The scope of Weibull analysis include failure forecasting and prediction, maintenance planning and cost effective replacement strategies. is a typical Weibull plot for sphygmomanometers. The horizontal scale is a measure of life or aging, in our case the operating time. The vertical scale is the Cumulative Distribution Function f(t), describing the percentage that will fail at any age. The complement of the scale (100-f(t)) is the reliability. The two defining parameters of the Weibull plot are the slope (β) and the characteristics life (η). The slope is particularly significant because it tells the analyst whether or not scheduled inspections or overhauls are needed. For example if

β<1.0 indicates infant mortality

β=1.0 means random failures (independent of age)

β>1.0 indicates wear out failures.

Where the characteristic life is the typical time to failure.

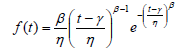

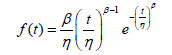

The three parameter probability density function f (t) of the Weibull function is given as;

(5)

(5)

Where f(t) ≥ 0, t ≥ 0 or γ, β>0, η>0, -∞<γ+∞

γ-location parameter (or failure free life).

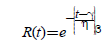

The reliability function for the 3-parameter Weibull distribution is then given by:

(6)

(6)

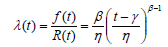

and the Weibull failure rate function, λ(t), is given by:

(7)

(7)

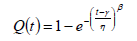

The unreliability Q(t) is

(8)

(8)

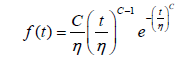

The 2-parameter Weibull pdf is obtained by setting, and is given by:

(9)

(9)

The 1-parameter Weibull pdf is obtained by again setting γ=0 and assuming β=C=Constant assumed value or:

(10)

(10)

Maintenance practice

Personnel: The below shows the distribution of medical equipment maintenance personnel at the various hospitals visited. Graph of medical equipment maintenance personnel.

Equipment inventory

All hospitals contacted have records of medical equipment available at their institutions.

In-house equipment repairs: The University Hospital performs no in-house repairs; rather they do contract companies to help in equipment maintenance, whereas Ridge Hospital, 37 Military Hospital and FOCOS Orthopaedic Hospital perform majority of in-house repairs on basic and some complex equipment.

Medical equipment outsourcing: University Hospital practices mainly outsourcing of maintenance services, that is, relying on external sources for equipment maintenance. The company contracted to perform these services usually engages in equipment maintenance once every four (4) months.

Ridge Hospital and FOCOS Orthopaedic Hospital also practice some level of outsourcing of maintenance services. They do so when they are unable to perform the required maintenance in-house. 37 Military Hospital however, does not practice outsourcing of maintenance services. These results are presented in Table 1.

| Hospital | Equipment Inventory | In-house | Out-sourcing |

|---|---|---|---|

| University | Adequate | Nil | Fully |

| Ridge | Not adequate | Partial | Partial |

| 37 Military | Adequate | Fully | Nil |

| Focos autopedic | Adequate | Partial | Partial |

Table 1: Outsourcing of maintenance services.

Types of maintenance practice: Table 2 illustrates the types of maintenance carried out at each hospital visited. The below shows the construction of FTA diagrams for manual and digital sphygmomanometers respectively.

| Hospital | Predictive | Preventive | Repair | Inspection |

|---|---|---|---|---|

| University Hospital | No | No | Yes | Yes |

| Ridge Hospital | No | Yes | Yes | Yes |

| 37 Military Hospital | No | Yes | Yes | Yes |

| FOCOS | No | Yes | Yes | Yes |

Table 2: Types of maintenance practice.

The below shows the construction of FTA diagrams for manual and digital sphygmomanometers respectively. The results as illustrated in the FTA diagrams show that the major causes of the sphygmomanometer failure are: Power failure and. Poor handling which are preventable causes.

Risk assesment

Reliability and hazard rate plots for manual sphygmomanometer: A one-parameter Weibull probability, reliability and hazard rate plots for manual sphygmomanometer are shown in the below. These plots show the probability of equipment failure, the reliability of the equipment as well as the hazard rate of the equipment.

The Weibull probability plot for manual sphygmomanometer is shown below:

At 584 hours of usage, the reliability of the equipment was found to be 36.8%.

The reliability plot of the manual sphygmomanometer is shown below:

The hazard rate of the manual sphygmomanometer is shown below:

At 584 hours, the hazard rate of the equipment was found to be 0.00392. This indicates that the equipment has good reliability over the period of time.

Poor staffing in the hospitals result in extreme workload on few personnel at post hence delaying equipment maintenance. Poor equipment inventory and records prevents effective equipment tracking. Lack of preventive maintenance causes frequent breakdown of some of these medical equipment. Preventive maintenance carried out ensure that medical equipment do not break down frequently. These results are summarized in Table 3.

| Hospital | Effects |

|---|---|

| University | Delay in equipment maintenance Equipment under utilised Extra cost in equipment repairs Frequent breakdown of equipment |

| Ridge | Delay in equipment maintenance Inadequate equipment inventory and records prevent equipment tracking |

| Focos | Delay in equipment maintenance |

| 37 Millitary | Effective equipment maintenance |

Table 3: Effects of types of maintenance practice on the various hospitals.

Our study has revealed that there is inadequate maintenance records at the hospitals; the data deficiencies include failure records, inspection data, unknown ages of some of the equipment. As a result quantitative analysis which includes predictive maintenance, risk assessment of the equipment could not be done. The types of maintenance practice done are preventive, corrective/repairs and inspection. The FTA diagrams from the case study showed that most failures are due to preventable causes. Inadequate medical equipment technicians and engineers has caused the delay in maintenance and poor records on equipment failures making most of these equipment under utilized.

The way forward to addressing these limitations is developing an effective maintenance records suite to keep track of all maintenance activities carried out within the hospitals.