Journal of Geology & Geophysics

Open Access

ISSN: 2381-8719

ISSN: 2381-8719

Research Article - (2025)Volume 14, Issue 2

Gulu ironstones deposits well-endowed with hematite, holds significant economic importance due to its diverse properties and applications. It possesses great potential to contributes significantly to industries, aesthetics and technological advancements, making it a valuable and versatile compound in our daily lives. Integrated Geophysical investigations using Vertical Electrical Sounding (VES) technique, geological field mapping and geochemical analysis were employed to investigate the subsurface resource, by mapping the Ironstone occurrences, estimated the volume and quality of the Iron ore present. This assessment informs mining companies and other stakeholders about the economic viability of exploitations as well as guiding the exploration efforts, minimizing costs and maximizing efficiency for responsible resource utilization wisdom. Five VES points data were acquired using ABEM SAS 4000. The data sets were processed using computer processing techniques. The area (Gulu) was geologically mapped and the sample taken was geochemically analyzed using Genius IF-Xenemetrix XRF equipment to affirm the 18 different chemical components of the investigated Ironstone. The varying concentrations of the 18 chemical components were discovered across the profile with picks indicated by Iron III oxide. Developing traces of silicon di-oxide and aluminium oxide were also established within the investigated area. The VES data processed using the IPI2WIN software programme plotted as modelled plots correlated well with the chemical analysis results. The VES results indicated that the Ironstone average thickness deposit was 67.84 m at Gulu, with resistivity values ranging between 1063 ohm/m and 631125 Ω-m. The study in addition, reveals a thick Ironstone occurrence with deposit reserve estimate of about 1.6 × 109 tons. The observed outcrops from the geological field mappings, analytic signal peaks and thickness levels from the geophysical 2-D source parameter images and discoveries from the geochemical analysis results are the basis for the produced Ironstones prospectivity map for the area studied.

Ironstones, Hematite; Subsurface resource; VES, Iron III oxide, Silicon di-oxide

Nigeria as a nation well blessed with mineral resources in abundance, fairly distributed across all the states of the federation is still suffering from serious minerals underexploitation which have been fuelling revenue deficit. However, with tumbling global oil prices and downturn in the Nigerian economy, the ministry of mines and steel development has developed strategies through a roadmap that can take advantage of the opportunities available for the development of the nation’s solid mineral resources within the context of a diversified economy where mining (including petroleum), industrial agriculture and manufacturing will be the key players [1].

Ironstone, being a sedimentary rock which contains a substantial proportion of an iron ore compound from which Iron (Fe) can be smelted commercially can serve as a great alternative resource. It is usually derived from weathering of iron-rich rocks or precipitation of iron-oxides in water. Ironstone deposit of economic magnitude has a great potential for industrial and agricultural applications, such as cement production, fertilizer and soil amendment. It is essential for producing steel, which is used in construction, manufacturing and other Industries. Although, it may not be suitable for ceramics due to its oxide impurities. It can be used as a building material in construction. However, despite these huge economic importance, the preliminary discovery by of its deposit in the Bida Basin have not yet received any significant follow-up using geoscientific techniques to evaluate the ironstone and other economic minerals allies. Thus, considering its revenue driving potential, it is crucial to account for their occurrences, distribution and the geoscientific context in terms of the economic value.

In resource assessment, characterizing the mineralogy, texture and structure of the ironstone deposits, aids in resource evaluation. Thus, by mapping the Ironstone occurrences, geoscientists can estimate the volume and quality of the iron ore present. This assessment informs mining companies and other stakeholders about the economic viability of exploiting these deposits.

Furthermore, from the geological context of the geoscientific approach, understanding the geological setting of the ironstone helps determine its origin and formation processes. It provides insights into the tectonic history and environmental conditions during the ironstone deposition. In an ironstone exploration, geo-scientists do employ various methods, including geophysical surveys, geological mappings, geochemical analysis and remote sensing, to locate the ironstone and other possible minerals deposits in a given area. These techniques guide exploration efforts, minimizing costs and maximizing efficiency. Thus the exploration approach via geo-scientific techniques is essential for understanding the ironstone or other minerals deposits, evaluating their economic potentials and ensuring responsible resource utilization.

Although, for more accuracy and more reliability, it is always better when embarking on any detailed geophysical exploration for minerals, to integrate various geophysical methods, such as magnetometry along with the resistivity measurements. This integrated approach is expected to enhanced the detection and characterization of the Gulu ironstone and siltstone deposits. However, due to the financial constraint and convincing ironstone outcrops, the research was limited to electrical resistivity survey which is further integrated with the geological field mapping and geochemical analysis.

The study areas and the geology

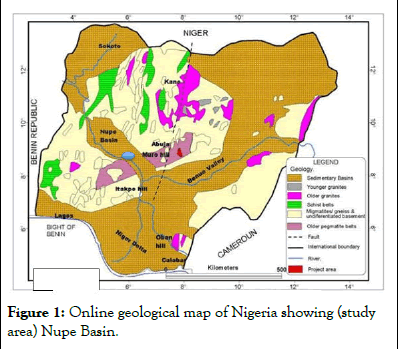

Figure 1 showed the Nupe Basin in which the study area (Gulu) is located. The Gulu prospective area is located between 8°39'0" and 8°40'3" N, 6°34'59" and 6°35'49" E. it is 45 km to the west of Lapai town. The population of Gulu (Census 2006) is 3,163 with land mass area of 923.00 km2. The lithology of the area is quite eroded after uplifting, outcrops and sequence of faulting . Gulu areas has many hills the lower part of which are characterized by areas with thick soil, ironstones, shale/claystones and siltstones outcrops. It is in these valleys that blast soil sediments which have high iron and other minerals rich has accumulated.

The Nupe Basin also known as Bida Basin, (Figure 1) is a NWSE trending intracratonic sedimentary basin located in the central part of Nigeria. It is filled with mainly continental sediments of cretaceous to paleogene age, with minor occurrences of marginal/shallow marine to freshwater floodplain deposits. The basin which have been poorly understood and has not been extensively explored according to the researchers was discovered to possesses a very great potential for hydrocarbon exploration, as it has source rocks, reservoirs, seals and traps. The basin has been identified to be bounded by faults and it merges with the Anambra and Sokoto basins. The basin is divided into three formations: The Lokoja formation, the Patti formation and the Agbaja formation, which represent different depositional environments. The geology of the Bida Basin is influenced by the Santonian orogenic movements and the rifting of the Benue Trough.

Previous research revealed the presence of ironstone deposit within the Bida Basin mainly in the Agbaja plateau, for which one of the three major ironstone plateaus is in the southern Bida Basin, while the other two are located in Kotonkarfe and Basange areas. It was opined also that the ironstone deposit belongs to the Agbaja/Sakpe ironstone formation, which is part of the upper cretaceous sequence of the Bida basin. The ironstone formation was identified to overlies the Lokoja/Bida sandstone formation and is overlain by the Patti/Enagi formation [2] discovered the contents of ironstone to included clay, quartz, feldspar and organic matter with a low iron content of the range between 20% and 40%. The deposit was thus classified as a low-grade iron ore, the inference which according to them was also supported by the observed high levels of phosphorus content within the deposit which usually is attributed to the reduction in the quality and economic value of the ironstone deposit.

Figure 1: Online geological map of Nigeria showing (study area) Nupe Basin.

Issues on the most attractively observed outcropped massive ironstone deposit around Gulu area includes; lack of the accurate figure on the deposit reserve estimate, the specific locations of the deposit of economic significance, quality status and any other possible associated mineral play within the Bida Basin. All these, informed the need for a geoscientific research on the areas. This was aimed to unveil the deposit reserve estimate, the specific viable locations, quantity and quality status of the ironstone deposit and any other possible mineral play within the study areas [3].

Such an integrated geoscientific investigation of such area will provide the certainties on the economic location, quantity and quality status of the ironstones deposits within the two areas. It will also unveil the possibility of discovering any other mineral resources of great economic potentials, since the basin have not been fully explored for full exploitation aside the petroleum exploitation efforts [4]. The under-exploration of the basin could probably be due to the diverted government attention to the already identified petroleum resources potential of the basin or lack of adequate geoscientific basinal database, infrastructure, technology and investment interest [5]. All these put together therefore, kick-started this study to determine the viable locations, quantity and quality status around the observed already outcropped ironstone at Gulu area. The outcome is expected to induce venturing into the further exploration efforts for maximum exploitation of the ironstone and any other additional possible mineral play within the basin alongside with petroleum exploitation for full basinal exploitation [6].

The study therefore adopted a combined geophysical exploration method, geological prospecting and geochemical analysis which involved the preliminary visitation to the investigated site-Gulu ironstone deposit field for geophysical survey, geological mapping, aerial photography, sample collection, geochemistry and data modelling using the acquired electrical resistivity and other acquired data.

The choice of these exploration methods was based on the mineralogical and geological characteristics of the ironstone deposit, the large size area involved and the targeted economic deposit areas. The physical and chemical characteristics of the ironstone deposit site will for sure have a considerable bearing on its deposit, ownership, exploitation and marketing especially, as it relates to the Niger state government and the individual revenue boost.

The Gulu iron fields exploration which have revealed some deposits to the tune of economic viability is capable of capturing the government attention or of any interested stakeholder’s attraction to the development of the major economic deposits areas and thus, investment opportunities, implying a boost in both the government and individual revenues.

This work thus presents results of a pilot study to discover the magnitude of the ironstone commonly found in Gulu area of Niger state in Nigeria [7]. The study used geophysical, geological and geochemical methods to discover the potentials in the localized ironstone deposits in the hilly parts of the area and in addition, search for any possible mineral play within the investigated area.

The methodological approach involved the use of geophysical exploration using the electrical resistivity technique, geological field mapping and sample collection and geochemical analysis as briefly described below.

Geophysical exploration

This involves the geophysical exploration for ironstone using the electrical resistivity method. This is a non-invasive technique that measures the resistance of subsurface materials to the flow of electrical current using Schulumberger electrode configuration. This method is particularly useful for detecting the variations in the subsurface that is capable of indicating the presence of the investigated ironstone deposits.

Data acquisition, processing and interpretation

The first step was to designed the survey targeted towards accuracy; Schulumberger electrode array was selected with the maximum electrode spacing of AB/2 120 m. this was based on the expected geology and the depth of investigation. Data were then acquired after setting up all the four electrodes into the ground and closing the circuit on IBM SAS 4000 Terrameter, thereby introducing into the subsurface varying electrical current through the two current electrodes and measuring the resulting potential differences via the two potential electrodes arranged in accordance with Schulumberger electrode configuration [8]. This was followed by data processing which involved converting into apparent resistivity the measured field resistances which were earlier treated for both the noise removal and the geometric factors related corrections to the electrode array used.

The processed data were used to create the 2-D models (pseudo cross-section and resistivity cross-section) of the subsurface resistivity using IP2WIN software. The model then helped to interpret the resistivity measurements in terms of the geological structures present (ironstones, siltstone, claystones and sandstones). This was achieved by analysing the resistivity model and the anomalies indicating the presence of such deposits and in correlation with the geological and geochemical results for the area. The resistivity of the ironstone was influenced by its composition, including the amount of iron and other minerals. This advanced modelling technique took into account the topography and other relevant geological features and so provided the more accurate representation of the subsurface of the two investigated areas.

The efficacy of this method is clear when the model visualized the subsurface structure and the potential ironstone and further delineated other mineral deposits (siltstones) of economic play within the investigated area (Gulu). The model was used to predict how the electrical current travelled through the various deposits in order to guide any ironstone or siltstone exploration and exploitation efforts.

Ironstone Reserve Estimation (IRE)

The ironstone deposit reserve estimation for the probed locations in Gulu area of Lapai local government of Niger state for which the representative dimensions and area were used to determine the deposit reserve estimate for the representative area using equation (1). The IRE for the area was determined using the values of the average thickness of the ironstone deposits and ironstone density.

Geological field mapping

Field investigation was undertaken at the study location (Gulu in Enagi formation in Batati formation) to map the occurrences, distribution and characterise exposures across the location. Each of the exposure was log to understand the stratigraphic positions of the ironstone in relation to other existing lithology and were documented. The coordinates and samples were collected for laboratory geochemical analysis. The fieldwork was well planned by the provision of adequate fieldwork logistics, including topographic map, equipment, safety measures and team coordination (Figure 2).

Figure 2: Research team from right; Endurance G, Obaje NG, Yusuf TU and Bissala just before departure to the field (Gulu area).

The mapping technique adopted was the traverse technique which was achieved using topographic map as a guide. The Ironstone deposit was studied in the field with the view to understand its colour, thickness, texture, grain size, structure and vertical as well as lateral extents. The Gulu ironstone was logged in relation to the overlying Batati formation and underlying Enagi formation.

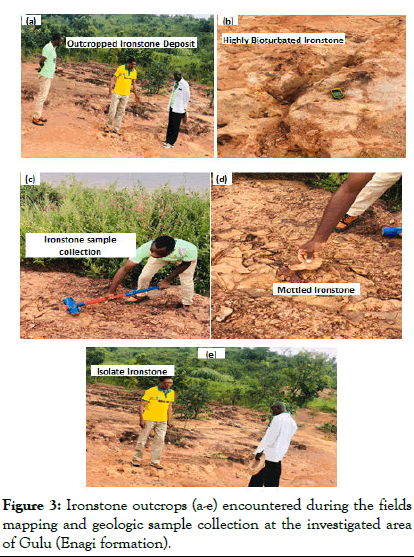

Detailed field observations, examination of ironstone outcrops, sedimentary layers, fossils, structures (such as faults) and other features in the investigated fields were conducted (Figure 3).

Figure 3: Ironstone outcrops (a-e) encountered during the fields mapping and geologic sample collection at the investigated area of Gulu (Enagi formation).

Sample collection for geochemical analysis

From the field, sample was collected as a representative sample of the ironstone formation visited for laboratory geochemical analysis. The rock sample was labelled as G-IL1 for the analysis. The G-IL1 sample was taken from the outcropped Ironstone deposit from the weathered Enagi formation to determine the mineral composition (quality status).

Geochemical analysis

This was the final and confirmatory method in this research. It was achieved via the XRF analysis. The pulverized aliquot was analysed using Genius IF-Xenemetrix XRF equipment. Duplicate analyses were performed to unveil the various chemical components of the samples taken from the field during the geological field mapping.

Sample preparations: The samples were crushed and pulverized to -75 μm and then submitted for XRF analyses at national steel raw materials exploration agency, Kaduna Nigeria) (Figure 4). A duplicate analysis was performed on the pulverized aliquot using Genius IF-Xenemetrix XRF equipment to obtain the average values.

Figure 4: Samples preparation involving crushing and pulverization for XRF analysis.

The models from the processed field data are presented in Figures 5-10 in the form of pseudo and resistivity cross-sections and the VES curve and log-log tables of the resistivity (Ωm) against electrode separation (m). The models were interpreted, the anomalies indicating ironstone and other deposits were identified as well as other delineated geologic features.

Electrical resistivity method

Profile 1 Gulu location in Enagi formation: Figures 5-10 represent the pseudo cross-section and the corresponding resistivity cross-section, VES curves and the log-log table of the profile 1 at Gulu ironstone deposit site. The model revealed three geo-electric sections which revealed a very highly resistive anomaly interpreted as the ironstone deposit (coloured ranged yellow to brown) around VES points 2, 3, 4 and 5. This extends from the topmost layer down to the third layer with resistivity values ranging between 1063 and 631125 Ω-m. The thickness varied from 3.46 to 71.30 m, while the depth varied between 3.46 and 79.30 m [9]. The total estimated probable ironstone deposit thickness in this profile is 67.84 m with overburden thickness of just 3.46 m.

This observed very highly resistive anomaly correlated well with both the ironstone outcropped viewed during the geological field mapping and the geochemical results implied the anomaly is interpreted as the iron III oxide. This is supported by the usual high resistivity values attributive to (Fe2O3) as a results of its unique crystal structure, electron exchange and antiferromagnetic behaviours. However, despite its deficiency (of not a good conductor) like pure iron, its properties still make it economically valuable for various applications; including pigments, magnetic materials, etc.

Figure 5: Pseudo cross-section for Gulu location 1 at VES points 1.

Figure 6: Resistivity curve and log-log table for Gulu location 1 in Enagi formation at VES points 1.

Figure 7: Resistive curve and log-log table for Gulu location 1 in Enagi formation at VES points 2.

Figure 8: Resistivity curve and log-log table for Gulu location 1 in Enagi formation at VES points 3.

Figure 9: Resistivity curve and log-log table for Gulu location 1 in Enagi formation at VES points 4.

Figure 10: Resistivity curve and log-log table for Gulu location 1 in Enagi formation at VES points 5.

Mineralogy estimation at Gulu area

Summarily, from Tables 1 and 2 it is deducible that the average thickness of the ironstone deposits across the investigated area (Gulu) is to the magnitude of 67.84 m. This is economically lucrative, especially when compared with the geochemical results (Table 2) for which the highest iron content (80.17%) was confirmed with a deposit thickness of 67.84 m (Figure 11).

| Location and coordinate | Modelled parameters | Ave. ironstone thickness (m) | First layer | Second layer | Third layer | |||

| Min | Max | Min | Max | Min | Max | |||

| Gulu 1 | Resistivity variation (Ω-m) | 67.84 | 6888 | 20580 | 1063 | 10919 | 14111 | 631125 |

| Thickness variation (m) | 3.46 | 29.7 | 3.64 | 22.8 | 10.8 | 71.3 | ||

| Depth variation (m) | 3.46 | 29.7 | 7.1 | 51.1 | 17.9 | 79.3 | ||

Table 1: Estimated possible ironstone deposits at Gulu area of Lapai LGA, Niger state, Nigeria.

Figure 11: Ironstone Reserve Estimation (IRE).

IRE=Area × Average thickness × Density (1)

=2,742,616.60 m2 × 112.18 m × 5.24 g/m3

= 1.6 × 109 tons

Geological field mapping

In the geological field mapping, the combined field observations together with sample data points, and base maps were used to create the geologic map that represents the different rock units, structures and lithology/staking pattern (Figure 12). This very vital map revealed the geologic information of the displayed visible outcropped ironstones of Batati formation at Gulu area. It will attract the relevant stakeholders, decision-makers and the public [10]. In addition, this geological mapping is definitely capable of contributing to any informed decision-making, uncertainty reduction and will also supports sustainable land management and resource utilization as well as enriching the Bida Basin exploration efforts.

Figure 12: Lithology/Stacking pattern of the Bida Basin from Doma to Gulu showing the stratigraphic location of the targeted outcropped ironstone deposits at weathered Batati formation (2023).

Geochemical analysis results

The results from geochemical analysis are presented in Table 2. It reveals that the study area (Gulu) contained eighteen (18) different chemical compounds (SiO2, Al2O3, Fe2O3, V2O5, K2O, CaO, TiO2, ZrO2, SO3, Co3O4, MgO, MnO, ZnO, CuO, WO3, Ta2O5, Cl and Nb2O3). These different compounds exist in different percentage by mass compositions at the location as detailed in Table 2. The result further revealed that Gulu area in Enagi formation does not contain ZrO2 and Nb2O3, interestingly, the investigated sample from the formation contained the targeted iron compound in the form of Iron III oxide (Fe2O3,).

Iron III oxide (Fe2O3) and Silicon II oxide (SO2) were identified in the analysed sample along traces of other sixteen. Fe2O3, is the major and dominant mineral in the analysed sample from Gulu, accounting for up to 80.17%.

Regards to the quality of the ironstones being a sedimentary rock, the quality classification demands that it must contain at least 15% iron by weight. This is applicable to using the general classification based on the iron content by percentages within the source rocks. The quality of the iron III oxide contained in the analysed sampled ironstone deposits was outstanding compared to the other minerals present and is in the increasing order of Fe2O3>SiO2>Al2O3>Cl>TiO2>Co3O4>MgO>CuO>V2O5>WO3>K2O>SO3>CaO>MnO>Ta2O5. This implied Gulu area have great potential for qualitative ironstone deposit based on the general industrial usage classification [11]. This also means that the formation have a bright prospect for exploitable quality iron potential.

This Iron (III) oxide is one of the main oxides of iron which is commonly found in nature as the mineral hematite (Iron (III) oxide), also known as ferric oxide. It is an inorganic compound with the chemical formula Fe2O3. It forms a key ingredient in the steel-making process being the primary source of iron for the steel industry. It’s also used as a pigment and in various other industrial applications due to its magnetic properties in certain forms. Other several uses across different industries include; thermite welding, catalysis, medicine, Magnetic Resonance Imaging (MRI), jewellery, as a pigment to colour concrete and give it an aesthetically pleasing finish. The quality and diverse uses highlight the versatility of iron (III) oxide in both industrial and commercial applications worth of exploration for maximum exploitations capable of boosting the national economy.

| Samples | SiO2 | Al2O3 | Fe2O3 | V2O5 | K2O | CaO | TiO2 | ZrO2 | SO3 | Co3O4 | MgO | MnO | ZnO | CuO | WO3 | Ta2O5 | Cl | Nb2O3 |

| G-IL1 | 12.35 | 4.24 | 80.17 | 0.15 | 0.12 | 0.19 | 0.66 | - | 0.11 | 0.33 | 0.06 | 0.24 | 0.07 | 0.09 | 0.14 | 0.04 | 0.72 | - |

Table 2: XRF results of samples (%).

The trends of the ironstone chemical compositions of Gulu area in Batati formation

The trends of the minerals compositions of the investigated Gulu area was visualized from the modelled geochemical results using Excel software and presented in Figures 13 and 14. The model showing the combined location trends of the various chemical components across investigated location for which the iron III oxide top the rest identified compounds are presented in Figure 14.

Figure 13 revealed Gulu area showing the iron III oxide displaying the highest trend. It further revealed higher trends of silicon di-oxide and aluminium di-oxide. The model further revealed the patterns of the trends of other identified chemical compounds with low trends within the analysed sample. It is thus predictable here that the Enagi formation is also developing gradual potential for quality silicon di-oxide and aluminium di-oxide, in addition to the highly portentous iron III oxide for future exploitation viability wisdom.

Figure 13: The trends of the various chemical components of Gulu 1 location showing iron III oxide with highest trend based on the geochemical analysis result.

Figure 14: The combined location trends of the various chemical components across investigated locations for which the iron III oxide top the rest compounds.

Ironstone grading

The iron (III) oxide discovered as one of the key components of the delineated Gulu ironstone deposits (Table 2) are of higher grade (80.17%) based on the general classification by iron ore composition (i.e., percent per mass composition) [1]. Although, the grades may also vary based on other parameters such as; its purity, particle size and other characteristics such as; catalyst grade used in various chemical reactions, nanopowder grade (a fine powder with particle sizes less than 50 nanometres) used in research and nano-technological applications, general grade also commonly used in various industrial processes, including pigments, ceramics and as a raw material for iron production (i.e., by iron mass composition for which at least the rock must contain about 70% of ferric iron (III) oxide). However, the specific grade and properties of the ferric iron (III) oxide can vary based on its intended use and manufacturing process.

Geomodeling of resistivity and geochemistry data were integrated with geological field mapping to evaluate the occurrence of the iron ore deposits in the study area. The locations of inflection points where thickness and depths to the source of electrical resistivity anomaly were delineated and corresponded to the observations from the geological field mappings and the geochemical analysis. The study indicates that these deposits are part of a potentially extensive resource [12]. These areas are interpreted as intrusion of iron oxide deposits. They are recognized by their high resistivities from the adjacent layers which also corresponds to their low resistive values from their host rocks. The results from the investigations has successfully characterized the presence of high quality ironstones deposit of economic potential and a developing siltstones and aluminium oxide deposits for a future play in the study area. Conclusively, since the ironstone deposits are of economic magnitude government and relevant stakeholders should spring into exploration and exploitation action so as to fully exploit the basin.

The technical competence of the geophysical method in accurately delineating the electrical resistivity anomalies as equally observed in the field during the geological field mapping showcase its efficacy in ironstone exploration. The visible widespread of the outcropped ironstones deposits across the Gulu area is indicative of high potential for large scale iron III oxide accumulation and a developing gradual potential for silicon di-oxide and aluminium oxide found in the iron bearing hill of Gulu. Further geological and geophysical studies will need to be under taken to establish whether the Gulu iron extends beyond the investigated area or its localized resource.

The researchers are in all humbleness and gratefulness to acknowledge the fact that this study was undertaken under the full sponsorship of the Tertiary Education Trust Fund (TETFund). This financial support from the TETFund have helped the researchers to actualise the Ironstone prospecting which is of great importance to the national economy if fully exploited. In addition, any attempt at any level can’t be satisfactorily completed without mentioning the support, guidance and administrative enabling environment provided by the Vice Chancellor, IBB University and his management team. We are particularly very grateful for their efforts and contributions to knowledge and exploration of the national economy potentials.

Citation: Yusuf TU, Obaje NG, Yusuf I (2025) Integrated Geophysical, Geological and Geochemical Assessment of Ironstone Deposits in the Bida Basin: A Case Study from Gulu Area, North-Central, Nigeria. J Geol Geophy. 14:1219.

Received: 13-Apr-2024, Manuscript No. JGG-24-30772; Editor assigned: 18-Apr-2024, Pre QC No. JGG-24-30772 (PQ); Reviewed: 02-May-2024, QC No. JGG-24-30772; Revised: 10-Apr-2025, Manuscript No. JGG-24-30772 (R); Published: 17-Apr-2025 , DOI: 10.35248/2381-8719.25.14.1219

Copyright: © 2025 Yusuf TU, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.