Journal of Ergonomics

Open Access

ISSN: 2165-7556

ISSN: 2165-7556

Research Article - (2021)Volume 11, Issue 6

The small-scale sheet metal industry involves repetitive processes such as blanking, bending, punching, drilling, welding, and tapping. Workers in the profession are continually exposed to work-related stresses and injuries while working for long hours. Occupational health is concerned with risk factors that can have harmful consequences on workers and, in some cases, render them permanently disabled. Ergonomics is an inherent study of the design and assessment of equipm

ent, machinery, workers, and workplace conditions for safe, pleasant, and effective human functioning to enhance the working lives of industrial employees. This study conducts an ergonomic evaluation of working postures, workstation design, and working conditions in the sheet metal industry. The primary goal is to identify Occupational Health Hazard (OHH) for the workers and suggest better changes to reduce OHH in the long run.

The ergonomic risk factors are quantified using a detailed pre-assessment questionnaire, Rapid Entire Body Assessment (REBA), and Rapid Upper Limb Assessment (RULA). The ultimate score of both REBA and RULA is compared to standards once data is collected utilizing monitoring processes. Posture-related stressors are detected as a result of this assessment. The current health state, morbidities (if any), health exposure at work, and other associated data were gathered based on the questionnaire filled out by each worker. The assigned OHH rating ranges from 0 to 100, with 0 indicating an exceptionally joyful work environment and 100 indicating extremely overworked working circumstances. The most prevalent ergonomic problem is musculoskeletal problems caused by poor work posture, extended work hours, a lack of brief breaks, and a lack of relaxing activities for physically demanding occupations.

At the conclusion of the study, various recommendations are suggested to both employees and industry management in order to achieve an ideal work environment and lower the risk of OHH affecting workers' lives. Scheduled rest intervals, exercises to drain the tension exerted on the body, material handling training, shifts in different job activities within the same industry, and improvements in the workspace and organizational setup are only a few of the recommendations to decrease workplace risks.

Ergonomics; Small scale sheet metal industry; Occupational health hazard; Human functioning

Ergonomics plays a significant role in the design and layout of products, jobs, tools, machines, and workplaces. Performance and quality of life can be increased with a critical understanding of workers' efficiency at work while considering their skills and constraints, which are determinants accessed using OHH and earnings. Ergonomics research aids in the development of a comfortable rhythm of work that synchronizes physical, physiological, and psychological factors. These factors influence human behavior and productivity and are critical aspects in determining a worker's effectiveness. Musculoskeletal and psychological strength are significant factors in completing daily tasks.

It is vital to consider risk-minimizing measures in the work environment of the sheet metal industry where workers are often at high risk. When designing a workstation, arranging activities and rest breaks, regulating job-related pressures, and offering better modifications to industrial workers for a longer and stress-free work-life, ergonomics must be taken into account. The different operations followed in the industry are blanking,bending, punching, tapping, welding, and drilling, which are all monotonous labor that demand full attention from the workers. Any form of distraction at work may lead to deadly situations and cause multiple injuries. Workers develop fatigue in their muscles as a result of repetitive actions, and they frequently modify their working posture to a more comfortable but ergonomically incorrect posture, resulting in musculoskeletal diseases in most cases. Longterm exposure to a high volume of sound can cause hearing loss, and long-term focus on a machine tool can create eye strain, which can harm eyesight. In cases where work ergonomics are not followed correctly, a worker may experience several other negative repercussions in his or her working life.

Occupational health hazards must be addressed as a priority but addressing such dangers for workers in the industry is a difficult undertaking. The workers want to meet the targets to maximize their earnings, and monotonous labor often exposes them to significant work dangers. Factors such as extended working hours, type of labor, lack of sufficient rest breaks, and others harm worker's health, resulting in serious health problems. Industries and human factors engineering researchers are constantly striving to strengthen workplace ergonomics to improve worker's well-being and productivity.

According to human psychological nature research, when physical and mental situations are not good, a person's performance suffers. The International Ergonomics Association (IEA) describes ergonomics as the science of human interaction and other structural factors, as well as the profession that applies theories, concepts, data, and design approaches to improve human wellbeing and overall system performance [1].

Many studies have found that organizational management methods in small and medium-sized businesses are not as effective as they are in big industries [2]. Studies by Ruchi, et al. claimed that ergonomics benefit both workers and employees since healthy workers boost output nearly three times more than workers in bad health. At present, the major problems for workers at their workplace are Musculoskeletal Disorders (MSDs) [3,4]. Repetitive Stress Injury (RSI), Cumulative Trauma Disorder (CTD), Carpal Tunnel Syndrome (CTS), and Upper Limb Disorder (ULD) may lead to permanent disability if not treated in time [5]. Researchers have identified many variables that contribute to musculoskeletal disorders, including a lack of ergonomic elements in workstations and office buildings and inappropriate posture [6] as well as increased level of psychological stress [7]. Adaptability and information are two factors that improve worker effectiveness and welfare [8].

REBA and RULA are two extensively used techniques for analyzing workplace postures and determining risk levels. These two assessment methodologies have been compared in several publications [9]. When examining postural risk factors on pediatric populations of various ages, Dockrell reported that RULA was more trustworthy to assess the older age group of children. When evaluating younger children, RULA's dependability was poor [10]. According to Mahendra, et al. ergonomic professional education programs will need to be updated on a regular basis in order to teach the requisite information, methodologies, and skills to meet the ergonomic challenges [11]. Long working hours have been linked to lower subjective health, more injuries, unhealthy behavior, and higher morbidity and fatality over time [12]. Research by Senthanar, et al. claimed that musculoskeletal problems afflicted truck drivers the most, accounting for roughly half of all work-related ailments. Loss of time due to the disorder is also a problem besides adverse health impacts [13]. It has been stated that the exposed work environment has a significant impact on a worker's efficiency [14]. A participatory ergonomics strategy is an interactive and successful means of comprehending and applying ergonomic concepts to subjects, with the goal of reducing MSDs [15].

• Visit the sheet metal industry to explore the current circumstances of the industry.

• Pre-assessment questionnaire development: Develop a questionnaire querying the subjects about their working experience, Present health condition, health condition background, emotional health, health risk questions from employer side and working Condition questionnaire.

• Sample: A total of 25 subjects involved in the sheet metal were targeted in the survey.

• Analyzing the postures of workers and filling in the REBA and RULA assessment tools.

Feedback from workers in ‘Divye Precise Engineering’ was taken through questionnaire regarding:

• Health condition they are in.

• Any sort of tardiness due to work.

• Working condition.

• Working body postures of workers.

Analyzing the working conditions in ‘Divye Precise Engineering’ with working area assessment:

• Total working hours

• Rest Breaks

• Temperature in work area

• Light and sound exposure

• Repetitive work durat ion

Data analysis: Data from assessments were studied on MATLAB using Neural Network Tool (NN Tool) for better assessment.

Finding the optimal working parameters to reduce occupational health hazards and maximize productivity.

Tools used

MATLAB is a high-performance programming language that allows users to execute mathematical operations such as matrix manipulations, function and data visualization, algorithm construction, generic algorithm execution, and a range of other operations.

The generic algorithm is a data training methodology regularly used by current data analysts to construct an intelligent algorithm to forecast future events or trends.

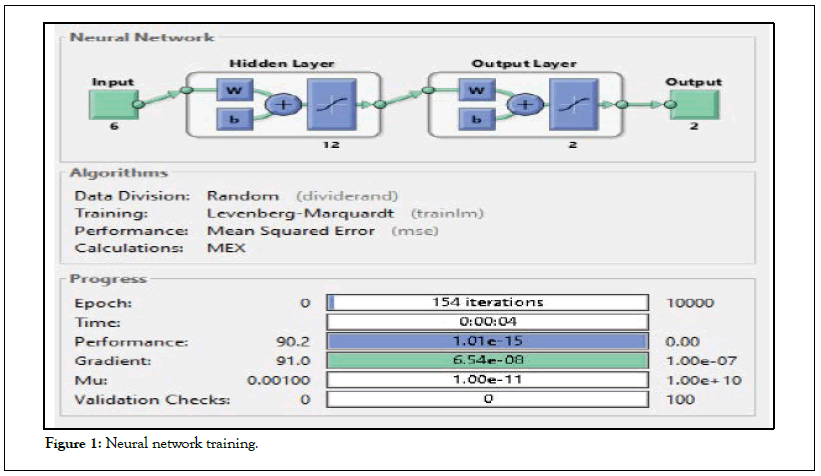

The neural network tool is a unique MATLAB tool that creates a feed forward perceptron neural network with a hidden layer. The function of a neural network depends on the input and target data. The neural network training can be tested on MATALB2018A following the below steps:

• Create an input and target table in the workspace.

• Execute command (>nntool) in the command window.

• Enter input and target data in neural network/data manager

• Create and train the network (Figure 1).

Figure 1: Neural network training.

Problem formulation

Workers in sheet metal industry face a few problems which can be divided into following parts:

• Repetitive task (Punching, Blanking, Tapping, etc.)

• Posture (siting and working)

• Working condition (Poor light and loud noise)

In this work, the aim is to reduce the OHH of workers in Divye precise engineering. The parameters to be taken into consideration for the purpose are as follows:

• RB (Rest Break): Time interval between continuous works. It is taken to avoid tiredness in the work.

• WH (Working Hours): The total time spent by the worker at work.

• SOAJ (Switching Over to Alternate Jobs): Switching to alternating jobs to avoid monotonous repeating of jobs.

• WHBTCB (Working Hours Between Two Consecutive Breaks): This is to determine the maximum time of work before a break is provided.

The goal is to minimize health hazards and maximize productivity using some optimization technique to find optimal working condition.

Data analysis

The work in the sheet metal industry can be divided into following jobs:

• Power Press Operator (PPO)

• Punching Machine Operator (PMO)

• Welder (W)

• Drill Machine Operator(D)

• Packager (P)

• Helper (H)

Power press operators and punching machine operators, among the listed activities, need lengthy hours of sitting, as well as higher and longer focus. As a result, these occupations will face greater psychological problems than other occupations.

Working parameters

To prevent a repetitive schedule, we shall assume in this study that a worker does two types of jobs every day. One of these two occupations is a power press operator, while the other can be any of the remaining five.

• Rest breaks vary between=0 to 30 minutes for each type of job.

• Working hours between two rest breaks in hours=0 to 3 hours

• Working hours in a day=10 hours

• Earning of a ‘Power Press Operator’=48 Rs/hr.

• Earning of a ‘Punching Machine Operator’=40 Rs/hr.

• Earning of a ‘Welder’=36 Rs/hr.

• Earning of a ‘Drill machine operator’=32 Rs/hr.

• Earning of a ‘Packager’=30 Rs/hr.

• Earning of a ‘Helper’=28 Rs/hr.

Working conditions

• Maximum temperature at work=46°C

• Exposure time to max. Temperature=9 hrs.

• Any type of vibration while working=Mechanical vibration

• Exposure time to vibration=9 hrs.

• Any repetitive work=tapping, punching, drilling, packaging

• Time duration of repetitive work=10 hrs.

• Available rest break time=1 hr.

Analysis of RULA and REBA score

The workers' average REBA and RULA scores are listed below. The average RULA value was identified to be 5, whereas the average REBA value was found to be 7. Both evaluations suggest that the average population is in moderate danger and that changes should be studied in detail (Tables 1-5).

| WH1(hr.) | RB1(min) | WHBTCRB1(hr.) | WH2(hr.) | RB2(min) | WHBTCRB2(hr.) | OHH | Earning |

|---|---|---|---|---|---|---|---|

| 7 | 30 | 3 | 2 | 0 | 0 | 95 | 456 |

| 6 | 20 | 3 | 3 | 20 | 3 | 75 | 448 |

| 5 | 20 | 2 | 4 | 20 | 1 | 65 | 440 |

| 4 | 15 | 2 | 5 | 15 | 2 | 60 | 432 |

| 3 | 10 | 3 | 6 | 25 | 3 | 65 | 424 |

Abbrevations: WH: Working Hours; RB: Rest Break; WHBTCB: Working Hours Between Two Consecutive Breaks; OHH: Occupational Health Hazard

Table 1: Data set for Power Press Operator (PPO)+Punching Machine Operator (PMO).

| WH1(hr.) | RB1(min) | WHBTCRB1(hr.) | WH2(hr.) | RB2(min) | WHBTCRB2(hr.) | OHH | Earning |

|---|---|---|---|---|---|---|---|

| 7 | 30 | 3 | 2 | 0 | 0 | 100 | 444 |

| 6 | 25 | 3 | 3 | 10 | 3 | 85 | 432 |

| 5 | 20 | 2 | 4 | 10 | 1 | 80 | 420 |

| 4 | 20 | 2 | 5 | 10 | 2 | 70 | 408 |

| 3 | 10 | 3 | 6 | 25 | 3 | 75 | 396 |

Abbrevations: WH: Working Hours; RB: Rest Break; WHBTCB: Working Hours Between Two Consecutive Breaks; OHH: Occupational Health Hazard

Table 2: Data set for Power Press Operator (PPO)+Welder (W).

| WH1(hr.) | RB1(min) | WHBTCRB1(hr.) | WH2(hr.) | RB2(min) | WHBTCRB2(hr.) | OHH | Earning | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 7 | 30 | 3 | 2 | 0 | 0 | 95 | 432 | ||||||||

| 6 | 20 | 3 | 3 | 20 | 3 | 85 | 416 | ||||||||

| 5 | 25 | 3 | 4 | 10 | 3 | 80 | 400 | ||||||||

| 4 | 10 | 2 | 5 | 20 | 2 | 70 | 384 | ||||||||

| 3 | 20 | 3 | 6 | 20 | 3 | 80 | 368 |

Abbrevations: WH: Working Hours; RB: Rest Break; WHBTCB: Working Hours Between Two Consecutive Breaks; OHH: Occupational Health Hazard

Table 3: Data set for Power Press Operator (PPO)+Drill Machine Operator (DMO).

| WH1(hr.) | RB1(min) | WHBTCRB1(hr.) | WH2(hr.) | RB2(min) | WHBTCRB2(hr.) | OHH | Earning | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 7 | 20 | 3 | 2 | 10 | 1.5 | 85 | 426 | ||||||||

| 6 | 30 | 3 | 3 | 0 | 0 | 80 | 408 | ||||||||

| 5 | 20 | 2.5 | 4 | 10 | 2 | 70 | 390 | ||||||||

| 4 | 20 | 3 | 5 | 20 | 3 | 65 | 372 | ||||||||

| 3 | 30 | 3 | 6 | 10 | 2 | 50 | 354 |

Abbrevations: WH: Working Hours; RB: Rest Break; WHBTCB: Working Hours Between Two Consecutive Breaks; OHH: Occupational Health Hazard

Table 4: Data set for Power Press Operator (PPO)+Packager (P).

| WH1(hr.) | RB1(min) | WHBTCRB1(hr.) | WH2(hr.) | RB2(min) | WHBTCRB2(hr.) | OHH | Earning |

|---|---|---|---|---|---|---|---|

| 7 | 25 | 3 | 2 | 10 | 3 | 80 | 420 |

| 6 | 20 | 3 | 3 | 20 | 3 | 70 | 400 |

| 5 | 20 | 2 | 4 | 10 | 3 | 65 | 380 |

| 4 | 20 | 2 | 5 | 10 | 1.5 | 60 | 360 |

| 3 | 30 | 3 | 6 | 10 | 2 | 50 | 340 |

Abbrevations: WH: Working Hours; RB: Rest Break; WHBTCB: Working Hours Between Two Consecutive Breaks; OHH: Occupational Health Hazard

Table 5: Data set for Power Press Operator (PPO)+Helper (H).

• Average REBA score for Power Press Operator (PPO)=6

• Average RULA score for Power Press Operator (PPO)=5

• Average REBA score for Punching Machine Operator (PMO)=7

• Average RULA score for Punching Machine Operator (PMO)=4

• Average REBA score for Welder(W)=8

• Average RULA score for Welder(W)=6

• Average REBA score for Drill Machine Operator (D)=8.5

• Average RULA score for Drill Machine Operator (D)=5

• Average REBA score for Packager (P)=6

• Average RULA score for Packager (P)=3.5

• Average REBA score for Helper (H)=7

• Average RULA score for Helper(H)=5

Occupational health hazard scale

• Negligible=00

• Very Low=20

• Low=40

• Medium=60

• High=80

• Extremely High=100

Results analysis

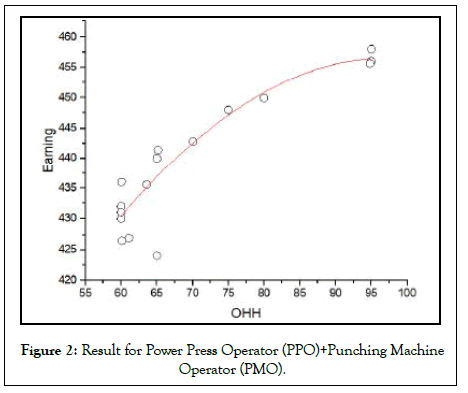

The scatter plot depicts the association between OHH (x-axis,independent variable) and total daily earnings (y-axis, dependent variable). The above graph combines two occupations in a day's schedule (Figure 2): Power Press Operator (PPO) and Punching Machine Operator (PMO). The OHH varies between 60 and 95, and an employee in the industry earns between Rs. 430 and Rs. 455 per day as PPO and PMO in shifts. The figure depicts that low daily earning corresponds to lower OHH levels. Whereas higher daily wage corresponds to a considerably greater OHH. Because OHH rises with income, the optimal daily earning with low risk of OHH is approximately Rs. 445 for a combination of PPO and PMO activities with an OHH of 75.

Figure 2: Result for Power Press Operator (PPO)+Punching Machine Operator (PMO).

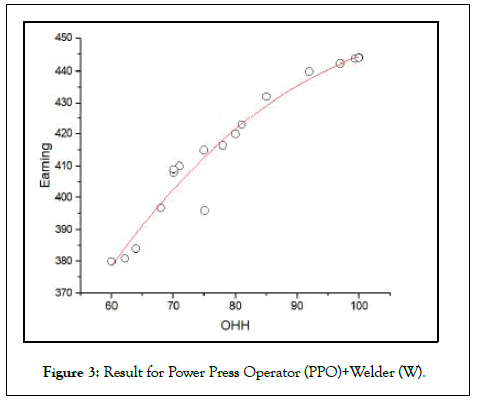

The scatter plot depicts the association between OHH (x-axis, independent variable) and total daily earnings (y-axis, dependent variable). The above graph combines two occupations in a day's schedule (Figure 3) Power Press Operator (PPO) and Welder (W). The OHH varies between 60 and 100, and an employee in the industry earns between Rs. 380 and Rs. 445 per day as PPO and Welder in shifts. The figure depicts that low daily earning corresponds to lower OHH levels. Whereas higher daily wage corresponds to a considerably greater OHH. Because OHH rises with income, the optimal daily earning with low risk of OHH is approximately Rs. 410 for a combination of PPO and Welder activities with an OHH of 70.

Figure 3: Result for Power Press Operator (PPO)+Welder (W).

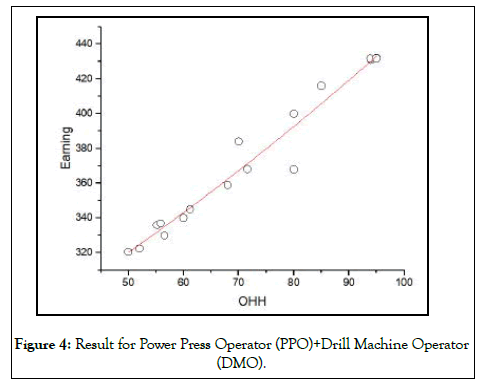

The scatter plot depicts the association between OHH (x-axis, independent variable) and total daily earnings (y-axis, dependent variable). The above graph combines two occupations in a day's schedule (Figure 4): Power Press Operator (PPO) and Drill Machine Operator (D). The OHH varies between 50 and 95, and an employee in the industry earns between Rs. 320 and Rs. 430 per day as PPO and DMO in shifts. The figure depicts that low daily earning corresponds to lower OHH levels. Whereas higher daily wage corresponds to a considerably greater OHH. Because OHH rises with income, the optimal daily earning with the low risk of OHH is approximately Rs. 380 for a combination of PPO and DMO activities with an OHH of 75.

Figure 4: Result for Power Press Operator (PPO)+Drill Machine Operator (DMO).

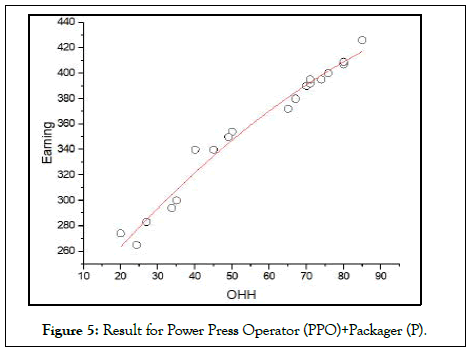

The scatter plot depicts the association between OHH (x-axis, independent variable) and total daily earnings (y-axis, dependent variable). The above graph combines two occupations in a day's schedule (Figure 5) Power Press Operator (PPO) and Packager (P). The OHH varies between 20 and 85, and an employee in the industry earns between Rs. 260 and Rs. 430 per day as PPO and Packager in shifts. The figure depicts that low daily earning corresponds to lower OHH levels whereas higher daily wage corresponds to a considerably greater OHH. Because OHH rises with income, the optimal daily earning with the low risk of OHH is approximately Rs. 360 for a combination of PPO and Packager activities with an OHH of 50.

Figure 5: Result for Power Press Operator (PPO)+Packager (P).

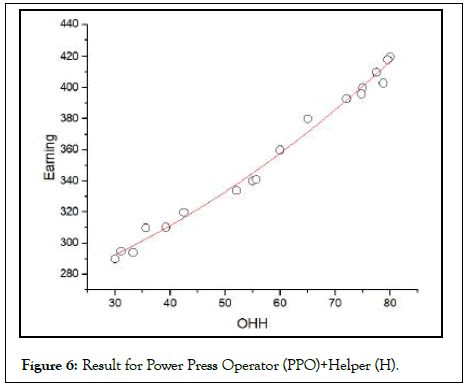

The scatter plot depicts the association between OHH (x-axis, independent variable) and total daily earnings (y-axis, dependent variable). The above graph combines two occupations in a day's schedule (Figure 6) Power Press Operator (PPO) and Helper (H). The OHH varies between 30 and 80, and an employee in the industry earns between Rs. 290 and Rs. 420 per day as PPO and Helper in shifts. The figure depicts that low daily earning corresponds to lower OHH levels. Whereas higher daily wage corresponds to a considerably greater OHH. Because OHH rises with income, the optimal daily earning with the low risk of OHH is approximately Rs. 360 for a combination of PPO and Helper activities with an OHH of 60.

Figure 6: Result for Power Press Operator (PPO)+Helper (H).

The graphs above illustrate that a worker can avoid musculoskeletal pain by performing a mixture of two jobs with proper rest breaks rather than working for a lengthy period. Workers can have high daily earnings with stressful jobs, but their health is at high risk. It is necessary to find a favorable condition in which they earn maximum without compromising health. By switching activities and having adequate rest breaks during working hours, the research suggests that workers can achieve a similar or greater wage while minimizing OHH.

A punching machine operator's daily wage is Rs. 400 for ten hours of labor, with a high OHH of 100; however, while rotating between the power press and the punching machine, the same worker can earn the higher pay of Rs. 440 at a lower OHH of 60. The result noticed higher work pay with controlled OHH while executing mixed jobs of various levels. However, it is a foremost priority to study other determining factors to improve worker's quality of life.

According to human psychological nature research, when physical and mental situations are not good, a person's performance suffers. The compensation to workers in the industry is comparatively low. This research suggested increasing the pay and benefits provided to the workers while strengthening their skills. To avoid accidents and support a safe and healthy working environment, a collection of safety advice and ergonomics recommendations, as well as workspace instructions, were given. Suggestions made postexamination on how to improve their work posture will lessen the risk of musculoskeletal problems. Illustrations displaying health and safety information will detail health and safety advice to employees and visitors. Provision of aprons following the examination will protect workers from small metal fragments strewn around by the operating equipment. Sudden distractions due to mobile phones placed next to the worktable are potential threats to worker's safety. The research suggested lockers to store mobiles along with other belongings of the workers.

Regular rest intervals, in general, can be an efficient way to sustain performance, manage stress, and prevent weariness from building up during work. The frequency of rest breaks throughout work hours was increased, which resulted in workers experiencing lower discomfort and exhaustion. Those who work in the industry might develop a variety of health issues due to poor posture. Poor posture can cause undue stress on joints, muscles, and ligaments throughout the body. Being more aware during the workday can help workers improve their posture. The research advised jobholders to keep their joints in a neutral position, avoid bending forward and keep the task closer to their body to reduce back pain. Poor hand tool choices lead to work injuries, varying quality of work, and lower efficiency in production. Work-related Musculoskeletal Diseases (WMSDs) can be caused by using the wrong tool. Several risk factors linked with the usage of hand tools, such as awkward wrist and hand postures, static muscle loading, mechanical stress, vibration, noise, torque, temperature, and pinch points, all enhance the risk of WMSDs. The research advised the availability of the appropriate and user-friendly tools for the work at hand. The study suggested innovative curved instruments with extra friction, compressible rubber handles, and counterweight for large handheld equipment to execute work with big weights. The workspace also encountered vibration due to machines at the worktable. Long-term exposure to vibration can harm employees' joints, muscles, circulation, and sensory nerves, leading to discomforts, time off, and even disabilities. Well-conditioned machines have lower vibrations. Workers are less prone to suffer from vibration-related illnesses or diseases when machine movement is at sufficiently low levels. The research suggested that ample light must be available at workstations ranging between 200-750 lux. The workers should have earplugs because of the high machine noise in the workspace. Workers have also been suggested some basic exercises before beginning their work to keep them relaxed and avoid musculoskeletal pains.

Thus, suggested improvements to worker's working posture and work ethics will improve their performance and quality of life and yield higher production to the company.

We are grateful to Mr. Chander Kant Ahuja and workers at Divye Precise Engineering for coordinating with us in data collection. We are thankful to Mr. Divyansh Ahuja for helping us in implementing the changes in the industry. This research was conducted under the aegis of the Mechanical Engineering Department, Manav Rachna University. The contents of this work are solely the responsibility of the authors.

Citation: Das M (2021) Identification of Occupational Health Hazards in Sheet Metal Industry through REBA and RULA Method. J Ergonomics. 11:290.

Received: 05-Oct-2021 Accepted: 19-Oct-2021 Published: 26-Oct-2021

Copyright: © 2021 Das M. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.