Journal of Geology & Geophysics

Open Access

ISSN: 2381-8719

ISSN: 2381-8719

Research Article - (2016) Volume 5, Issue 3

Blasting is widely used in quarries and mining production processes. It is the beneficial industrial technology which provides achievement of expected results in a short period of time with relatively low cost. Never one less, blasts produce undesirable vibrations and sounds. This current investigation reports the ground motion and airblast over pressure measurements around the open pit mine nearby Metlaoui village (south-western Tunisia). An empirical relation proposed by USBM was utilized to calculate K (site constant) and n (slope of the PPV vs scaled distance) and verifies whether the recorded shots overcame the thresholds indicated by DIN and USBM. The site parameters obtained provide us with the propagation equation of the blast induced seismic waves in the study site. Also, an overview of frequency for the study area revealed the dominance of low frequencies (>40 Hz). Such values can cause damage to the nearby structures when a specific PPV value is reached by blasting. Moreover, it has been demonstrated in this study that all over pressure magnitudes are less than 134 dB, which is the safe limit of air blast level.

Keywords: Rock blasting, Peak particle velocity, Open pit mine, Ground vibration: Air blast

On surface mining, blasting technique may be considered as the most economical method used for fragmenting rocks masses. Nonetheless, only 20-30% of the used energy is served for rocks fragmenting and displacing, while the rest is wasted in the form of ground vibration, air blast, noise and fly-rocks [1]. Both ground vibration and air blast are matter of great concern as they would result in damage to the existing surface structures and nuisances to the inhabitants in the vicinity of mines, which are exceedingly approaching near populated areas. In order to analyze the vibration-related problems, the combined effect of several factors such as site characteristics, propagation of surface, the body waves in the ground, and response of structures should be taken into consideration. The best approach for estimating the charge weight, that at given distance produces vibrations below the limit of safety, is using instrumentation on blasts to determine the constants of the actual blasting conditions. Furthermore, the effective control of problems related to vibration requires the development of a reliable vibration monitoring system and an assessment of attenuation characteristics of different vibrations [2].

Ground motion, which represents the major important effect of blasting, requires some regulations in relation with its structural damage. These regulations are mainly based on peak particle velocity (PPV) due to blasting operations [3]. Many scientists have investigated the PPV [4-7]. The United States Bureau of Mines (USBM) proposed the first significant PPV predictor equation.

There are regulatory limitations on blasting vibrations in relation to the maximum charge and the distance to a concerned location. Several established criteria of damage (USBM, DIN 4150) associated to the potential damage of blasting, can be used to confirm the design. Moreover, the relatively small charge per delay shall not result in potential damage.

In this work, the recorded measurements of ground vibration in Metlaoui open pit mine of phosphate were analyzed according to several established criteria of damage in order to study the ground vibrations characteristics resulting from production blasts and to evaluate the vibrations impact on the nearby structures.

Study area

The study site is an opencast mine of phosphate located in southwestern Tunisia, about 5 Km north of Metlaoui (Figure 1). The phosphate deposit of Metlaoui, belonging to dissymmetrical synclinal with layers dips not exceeding 10 degrees [8]. It has been exploited using opencast method since 1999. It contains considerable reserves of phosphate that are covered by the Eocene limestone deposits of the Kef Eddour Formation. This Eocene deposits constitute hard materials and, thus, its fragmentation must be carried out using explosive in order to facilitate the extraction of phosphates by opencast.

The sedimentary record of the Metlaoui phosphatic deposit is composed of various lithostratigraphic successions. The sedimentary rocks outcropping are composed by phosphatic Chouabine formation (Ypresian) and the studied limestone of the Kef Eddour formation (Early Lutetian), which is fragmented by explosive. The Chouabine Formation containing a significant amount of phosphates is overlain by limestone of the Kef Eddour formation [9,10].

Peak particle velocity (PPV)

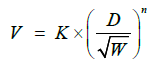

The ground vibration intensity was measured in terms of peak particle velocity (PPV) to evaluate its potential damage. Peak particle velocity, which corresponds to an indicator of a structural damage, largely depending on the maximum charge, the distance between the blast and measuring point and the characteristics of the medium [11]. At areas with unknown transmission characteristics, seismic constants low of sites are determined by monitoring the ground vibrations at variable distances for identifying the blasting parameters [12-16]. The PPV is related to the charge weight and distance by the prediction equation (1) proposed by the USBM:

(1)

(1)

Where:

V: is the peak particle velocity (mm/s)

D: is the distance between the center of blasting site and measuring unit (m)

W: is the charge per delay (kg)

: is the scaled distance SD (m/kg1/2)

: is the scaled distance SD (m/kg1/2)

K and n are site constants which vary from site to another; K represents the line intercept at SD=1 on the log-log graph. It is the initial energy transferred from the explosive to the surrounding rocks. Finally, n is a slope factor that induces the attenuation rate of the PPV caused by the geometric spreading and the influence of rocks characteristics. The variation in site constants can be attributed to different rock-mass properties at different sites.

Air blast over pressure

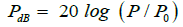

Air blast represents an undesirable and unavoidable output of blasting technique. The air blast damage and annoyance may be influenced by numerous factors such as blast design, weather, field characteristics, and human response. Air blast disturbances propagate as compression wave in air. Under specific weather conditions and poor blast designs, air blast can travel for long distances [11]. The over pressure may be expressed in Pascal (Pa) or with decibels (dB). The dB is calculated by the following formula (2):

(2)

(2)

Where P is the measured pressure. P0 is the reference pressure of 2 10-5 Pa.

Air blast is an atmospheric pressure waves emanating from explosion in air. This wave comprises (Figure 2):

• The audible part of the airblast (acoustic). It is characterized by higher frequency from 20 to 20,000 Hz.

• The sub-audible part of the airblast (infrasound) having a low frequency content below 20 Hz.

Unlike the audible air blast (Acoustic), which is classified as noise, the air blast at frequencies below 20 Hz is called concussion. These are classified as an “over pressure” when air blast pressure exceeds atmospheric pressure. Airblast overpressure exerts a force on structures and in turn causes a secondary and audible rattle within a structure. It is very often confused with vibrations transmitted by the ground [17].

Blast vibration regulatory limits

Ground vibrations related to rock blasting result in several deleterious problems for mining, construction, quarry, and pipelines. Worldwide, numerous researches were established for providing the damage criteria such as the energy, the energy ratio, the displacement, the velocity or the acceleration. It has been demonstrated that the particle velocity of ground motion near structures is an effective criterion of damage evaluation. The United States Bureau of Mine (USBM) RI 8507 reveals that peak particle velocity corresponds to the best description of the single ground vibration [18]. The safe maximum velocity of particles around 2 in/sec (50 mm/s) is recommended for all buildings [19,20]. During the last two decades, the PPV and frequency have been used as a damage criteria; and some standards from USBM and DIN (Deutsches Institut für Normung) were developed (Table 1). Most modern blasting seismographs must express the vibration data according to the USBM limiting criterion. In general, at lower frequencies, the ground vibration should not exceed 12.7 mm/s, but at higher frequencies, the limit can increase to 50 mm/s [21].

| US Bureau of Mines RI 8507 | DIN 4150-3 | |||||

|---|---|---|---|---|---|---|

| Structure | PPV (mm/s) | Structure | PPV (mm/s) | |||

| <40 Hz | ≥40 Hz | 10 Hz | 10-50 Hz | 50-100 Hz | ||

| Modern homes dry- | 18,75 | 50 | Industrial buildings | 20 | 20-40 | 40-50 |

| wall interiors | Residential buildings | 5 | 5-15 | 15-20 | ||

| Older homes | 12,50 | 50 | More sensitive buildings than above | 3 | 3-8 | 8-10 |

Table 1: Safe level blasting criteria: thresholds of PPV values at different frequencies (USBM and DIN 4150) [18,22,25].

Another blasting level set of smooth criteria was recommended by the USBM – RI 8507 (Table 1). For each blast, it requires a frequency analysis of blast-generated ground vibration wave as well as the measurements of the particle velocity. This method would be the best means to evaluate the potential damage to residential structures as well as human annoyance. Any seismic record for any component (longitudinal, transverse, vertical) for the particle velocity at a particular predominant frequency below any part of the solid line graph of Figure 3 may be considered safe. On the other hand, any value above any part of the solid line graph increases the possibility of human annoyance and residential damage.

Figure 3 shows the German Standard DIN 4150 [22] criteria. DIN 4150 suggests three lines of time-dependent vibration limits for different types of structures [11,12]. The first line is utilized for buildings used for commercial and industrial purposes. The second line is applied for dwellings and buildings of similar design and/or use. The third line is used for structures, which are not included in those listed in lines 1 and 2, due to their particular sensitivity to vibration; and are of great intrinsic values, e.g., building that are under a preservation order. Line 1 is close to the upper boundary of vibration limits in the 4-100 Hz frequency range [23]. The low-frequency portion of the seismic waves thereby plays an important role. Furthermore, the potential damage of blast-induced vibrations on structures is conditioned by the particle velocity and the low-frequency portion of seismic waves. The low frequency range (<40 Hz) potential damage is considerably higher than that of the high- frequency range (>40 Hz). This is due to the resonance effects at the natural frequency range (5-16 Hz).

Air blast regulatory limits

The Bureau of Mines Report of Investigations 8485 (1980), “Structure Response and Damage Produced by Air blast From Surface Mining” generally recommends a maximum safe overpressure of 0.014 psi (134 dB) for air blast recorded at residential structures [24]. This set of criteria was based on the major superficial type of damage affecting residential-type structures. Any criterion of the sets represents the safe maximum air blast levels although the best is recommended to be the 134 dB at 20 Hz high pass system. These recommended levels provide 95-99% of a non-damage probability and 95-90% of annoyance acceptability (Table 2).

| Overpressure unit | Description | |

|---|---|---|

| Db | Pa | |

| 180 | 206842,71 | ?Structural damage |

| 170 | 6550,01 | ?Most windows break |

| 160 | 2068,42 | |

| 150 | 655 | ?Some windows break |

| 140 | 206,84 | ?OSHA* maximum for impulsive sound |

| 130 | 65,50 | ?USBM TPR 78 maximum |

| ?USBM TPR 78 safe level | ||

| 120 | 20,68 | ?Threshold of pain for continuous sound |

| 110 | 6,55 | ?Complaints likely |

| 100 | 20,684 | ?OSHA maximum for 15 minutes |

| 90 | 0,65 | |

| 80 | 0,20 | ?OSHA maximum for 8 hours |

*Occupational Safety and Health Administration.

Table 2: Overpressure unit conversion (dB and psi) and effects on human annoyance and structural damage [18].

Air blast can be affected considerably by surface winds and climatic conditions such as temperature inversions (increase of temperature with altitude). Under these conditions, the peak over pressure can increase by a factor of 5-10, requiring therefore the adoption of certain precautions. Indeed, high air blast over pressure could cause structural damage, while, those produced by routine blasting operations under normal atmospheric conditions are not likely to do so [25-27].

Measurements and methods

During the present study, the blasting parameters of three shots with nonel initiation systems were carefully recorded in Metlaoui quarry. Blasting was performed within the Eocene limestone. We have used five seismographs; three of them are Deltaseis model and the two other are Instantel model. The seismographs have also attached microphones which can measure sound and airblast overpressure (Figure 4).

In order to monitor the ground vibration and air blast over pressure generated from blast, seismographs were installed at predetermined distances from the blast site to the town of Metlaoui (Figure 5). The threshold of release of each seismograph is selected according to its location.

Each seismograph consists of 3-axis velocity transducer, an air over-pressure transducer, and a data acquisition and storage device. Figure 6 displays a typical printout of seismograph obtained for each blast. It contains information about the graph such as the duration, the acoustic scale, the seismic scale and the interval between the two lines of time. Also, it gives details about amplitudes, frequencies and Fourier analysis.

The records of the seismographs were printed including full waveforms, summary of peak values of ground motion as well as air blast over pressure. Table 3 shows the data for each blast, including geophone, SD, PPV (mm/s) for longitudinal (L), transverse (T), and Vertical (V) components of ground vibration along with their frequencies (Hz), and their vector sum resultant (PPVR), air blast (sound) over pressure in Decibels (dB).

| N Blast NO | Seismograph | PPVMAX | Particle velocity (mm/s) | Ground vibration Frequency ( Hz) | Charge per delay W (kg) | Distance D (m) | Scaled distance SD (m/kg 0.5) | Air blast (dB) | Air blast frequency( Hz) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Longitudinal Peak(PVL) | Vertical peak (PVV) | Transverse peak(PVT) | |||||||||

| B1 | S1 | 14,2 | 11,1 | 7 | 14,2 | 5 | 390 | 434 | 22 | 117 | 2,25 |

| S2 | 1,7 | 0,7 | 1,6 | 1,7 | 2,25 | 390 | 610 | 57,8 | 108 | 10,63 | |

| S3 | - | - | - | - | - | - | 1141 | - | - | - | |

| S4 | - | - | - | - | - | - | 1429 | - | - | - | |

| S5 | - | - | - | - | - | - | 4867 | - | - | - | |

| B2 | S1 | 7,6 | 7,6 | 4,3 | 7,2 | 3,13 | 275 | 391 | 23,6 | 118 | 1,88 |

| S2 | 2,1 | 2,1 | 1,7 | 1,3 | 2,5 | 275 | 592 | 35,7 | 111 | 1,5 | |

| S3 | 1,1 | 0,8 | 1 | 1,1 | 2,5 | 275 | 1144 | 69 | 108 | 2,4 | |

| S4 | 1 | 0,6 | 0,6 | 1 | 2 | 275 | 1452 | 87,6 | 100 | 8,1 | |

| S5 | - | - | - | - | - | 275 | 4898 | - | - | - | |

| B3 | S1 | 13,6 | 9,5 | 5,5 | 13,6 | 5,63 | 300 | 280 | 16,2 | 110 | 1,38 |

| S2 | 1,7 | 1,7 | 0,9 | 1,7 | 2 | 300 | 503 | 29,1 | 106 | 6 | |

| S3 | 0,9 | 0,6 | 0,6 | 0,9 | 2 | 300 | 1069 | 61,7 | 108 | 5 | |

| S4 | 0,6 | 0,5 | 0,5 | 0,6 | 1,63 | 300 | 1404 | 81,1 | 115 | 3,88 | |

| S5 | - | - | - | - | - | 300 | 4850 | - | - | - | |

Table 3: Results of ground vibration and air blast measurements.

Vibration predictor equation

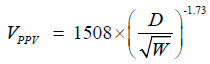

In order to establish a relationship between PPV and scaled distance for this site, regression analysis was carried out by using all data pairs. The determined equation for this site can be used to determine the permissible explosive charge at any distance for a specific scaled distance value. Also, this equation can be used to determine a compliant or safe value of the distance for a given charge weight of explosive as well as a specified scaled distance. The determined equation for this site study is given below.

The ground vibration data including PPV and scaled distance for various blasts was analyzed to understand the effect of ground vibrations induced by blasting in the open pit mine of phosphate in Metlaoui. The following predictor equation in terms of scaled distance and PPV is:

(3)

(3)

R2=0.847

The empirical factors k and n were determined by regression analysis as 1508 and -1.73, respectively.

In order to develop a statistically reliable curve, relationship between blast-induced vibrations scaled distance were established on a log-log diagram (Figure 7).

The relationship shows that the PPV decreases when maximum charges per delay in the holes are decreased or else if the distance is increased. In order to find maximum charge per hole with respect to the structures at fixed distances, the stipulated PPV as per the requirements of the status is to be maintained. This case analysis is site specific and cannot be adopted for general use in other mines.

Evaluation of damage risk

The measured magnitudes of PPV and frequency of the shots were evaluated taking into account several established damage criteria (USBM and DIM 4150) used in mining and geotechnical/structure engineering. According to USBM damage criteria (Table 1 and Figure 8) for the recorded ground vibration frequencies data, which are less than 40 Hz in all blast PPV are below the safe limits for moderns homes (PPV=18.5 mm/s) but, some of them exceeded the safe limits for older homes (PPV=12.50 mm/s). Moreover, according to DIN damage criteria (Table 1), PPV and frequency measurements are in the class of Residential and More sensitive buildings (PPV=5 mm/s and F=10 Hz). It was observed that in the plot of PPV versus frequency (Figure 9), the majority of the shots were below permissible limits described in the damage criteria corresponding for residential and more sensitive buildings.Nevertheless, some of measured PPV exceed the safe limits, which may have a damage risk.

Based on USBM and DIN 4150 criteria, PPV and frequency measurements are in the class of modern homes and residential buildings, respectively. It was observed that in the plot of PPV versus frequency, somerecorded ground vibration datawere above permissible limits described in both of the damage criteria,thereforeit may be increase the probability of structural damage.

Air blast results

The over pressure values, which range from 100 and 118 dB (Table 3), decrease with increasing scaled distance. This over pressure level is characterized by rattling windows and banging sound causing fear and annoyance but not damaging structures. However, considering the air blast over pressure levels, the building and the instrumentation are marginally safe, which is within the USBM limits (Table 2). Hence, some changes in the current blasting practice have to be made to make sure that the over-pressure is below the safety margin by greater magnitude. This will provide additional security against unpredictable atmospheric adverse conditions. In addition, it is recommended to measure the wind speed and direction before blasting to avoid blasting if the wind direction is towards the town of Metlaoui.

Frequency analysis

Ground vibration frequency: It was observed that the majority of blast frequencies were less than 5 Hz (Table 3). Below 5 Hz, the structures are generally solicited indirectly by the vibrations. The foundation soil may be mobilized especially if unconsolidated, heterogeneous, sloping and / or the foundations do not redistribute properly the stresses. In fact, it is the case of soil that characterizes the Metlaoui area which consists of sandy clays and conglomerates (lower Mio-Plio-Pleistocene) also silt and gypseous clays (lower Holocene, higher Pleistocene) [8].

The measured event frequencies of blast induced ground vibrations represent high-potential damage risk due to resonance effects. However, the frequency interval of 1-5 Hz that has higher damage risk constitutes the majority of all shots. These low frequencies are very critical to residential structures because they are in the range of their natural frequencies. The measured values frequency are near the natural frequency of residential structures (<20 Hz) is the most dangerous because it causes amplification of ground vibration.

Among the potential causes that can explain the records of lower frequencies, we mention the fracturating that characterizes the study area. Generally, the frequencies are higher in the non-fractured hard rocks. They decrease when the rock becomes increasingly fractured. The soil acts as a filter, imposes its own frequency and absorbs rapidly the high frequencies.

The distribution of recorded frequency values is given in Table 3.

Air blast frequency: All frequencies of induced air blast monitoring recorded were less than 20 Hz (Table 3), which increases risk of damage. In fact, air blast is considered as an ever annoying phenomenon in Metlaoui Mine and mostly propagates in low frequencies (<20 Hz), and causes perceptible rattling of windows easily in the building.

To better understand the ground vibration it is required to get the optimum blast result. The present study corresponds to the application of regression technique in blasting operation considering two variables (the distance and the maximum charge per delay), to find out the maximum PPV representing safe limit with minimum spoil to environment.

As a result of the particle velocity measurements in certain number of explosions by means of seismic devices and according to the ground vibration propagation equations, the site parameters obtained provide us with the propagation equation of the blast induced seismic waves in that area. The propagation equation, then, is used to keep the particle velocity within certain limits through alterations to the explosive parameters. The site parameters were determined based on the particle velocity data measured in the site; and in accordance with the equation given by USBM, which has been the most widely used one among international propagation equations. Frequency values of ground vibrations were below 40 Hz, which are considered as low frequency according to the international standards. Such values can cause damage to the nearby structures when a specific PPV value is reached by blasting. In addition, it was thought that such low frequencies could lead to human response at this site.

The Control of blasting done by recording airblast clearly shows that the quality of blasts taken can affect buildings, airblast over pressure frequencies are usually less than 20 Hz. On the other hand, it has been demonstrated that all over pressure magnitudes are less than 134 dB, which is the safe limit of air blast level.