Journal of Ergonomics

Open Access

ISSN: 2165-7556

ISSN: 2165-7556

Research Article - (2023)Volume 13, Issue 3

Hypothermia is a major hazard during long exposure in cold water and can lead to unconsciousness, organ damage, and eventually death. Cold water divers typically wear bubbled neoprene wetsuits to protect themselves from these harsh conditions. However, wetsuits have their limitations. Air bubbles within the neoprene shrink with depth under the increasing ambient pressure, which degrades the suit’s thermal protection. Thicker neoprene is warmer but is less flexible and fatigues the diver faster. To solve this problem, we developed and reported on the K1 suit. K1 featured composite plates fitted to non-bending areas of the body. The composite was made of hollow glass microspheres embedded in thermally cured silicone cast in 3D-printed molds designed from 3D scans of the diver’s body. The K1 combined the ergonomics of a 3 mm suit with thermal protection superior to a 7 mm suit. Next, adding a further layer of composite (made of ceramic microspheres embedded in silicone) produced the K2 suit. The K2 featured even better thermal protection with the same high flexibility and contributed neutral buoyancy. However, both K1 and K2 were based on individually shaped molds, which made fabrication difficult and expensive. Herein, we report on a new suit (K3), which solves this problem by the Chocobar technique – standardized flexible composite pads that can be trimmed to fit any diver. This significantly simplifies fabrication and lowers cost. Field tests of K3 vs commercial neoprene suits demonstrated thermal protection that was 4.5°C better than a 7/6 mm suit and on par with a top-of-the-line 8 mm suit, while featuring superior flexibility and ergonomics. The K3 is an important development in diving suit technology and should be of strong interest to commercial, recreational, and military divers.

Ergonomics; Microspheres; Buoyancy; Diving; cold; Hypothermia; Microparticles; Glass; Ceramics; Manufacturability

Sea water has 4 times the heat capacity and 24 times the thermal conductivity of air [1]. As a result, even evolutionarily adapted sea mammals lose heat 4.5 times faster in water than in air [2]. That heat loss [3] leads to hypothermia [4] even more rapidly with human divers [5]. After 1 hr in 10°C water, or ¼ hr in 5°C water, a diver’s core temperature would fall below 35.5°C and the diver would enter hypothermia [6], leading to loss of consciousness, organ damage, and eventually death. While physical conditioning can buy extra time underwater, it cannot fully compensate for the heat loss [7]. Thermal protection extends the operability during long dives in cold waters. Thermal protection is typically provided by a wetsuit. The wetsuit is stitched and/or glued together from tailored pieces of a 3-8 mm bubbled neoprene layer sandwiched between two 0.2 mm layers of cloth. The microscopic air bubbles in the neoprene make it flexible and thermally resistive, as air is a good thermal insulator. In 5°C water, a 3 mm neoprene suit would extend the time to hypothermia from 15 min to 1 hr, while a 5 mm suit would extend it to 1.5 hr [6]. Thicker suits offer more thermal protection but are less flexible. That makes movement more difficult and fatigues the diver faster. As a result, the thickest single suit on the market is 8 mm, while US Navy divers typically use 7/6 mm neoprene suits (7 mm chest, 6 mm limbs) as a compromise between protection and ergonomics. Thicker neoprene is also more positively buoyant, which requires divers to add more ballast to compensate for it. This also means larger differences between the ballast needed at the surface and at depth. To illustrate, a 3 mm wetsuit needs 2 kg ballast at the surface and 1 kg at depth, while a 7 mm wetsuit needs 6 kg ballast at the surface and 2 kg at depth. This difference is typically dealt with using a BCD (buoyancy control device). However, the BCD taxes the attention of the diver to adjust manually and continually through the dive, thus distracting him from his primary tasks. The BCD also requires some expenditure in breathing gas, which shortens the available diving time. Overall, thicker neoprene suits incur significant loss of ergonomics compared to thinner suits.

A further problem of the neoprene suits is that the air bubbles providing the thermal protection shrink with depth as the ambient pressure increases, thereby degrading [8] the thermal protection offered by the neoprene suit. Lab tests [9] have shown that 8 mm neoprene from a top-of-the-line commercial suit loses ~50% thermal insulance at 30 msw, compared to sea level. To solve this problem, we produced a thermally insulative composite material [9] made of hollow glass microspheres embedded in thermally cured silicone polymer. Lab tests [9] showed that the material maintained its thermal insulance with applied pressure and was more insulative than neoprene of the same starting thickness.

Next, we used the composite to build the K1 suit [10] by casting the material in 3D printed polycarbonate molds fashioned from the digital segments of 3D scans of the body of the diver. The cast composite segments were attached to a 3 mm neoprene undersuit by encapsulating them within matching tailored external pockets glued to the undersuit. The segments were designed to cover the non-bending parts of the body, while the bending parts were only covered with the 3 mm undersuit. The result [10] was that K1 had the flexibility and ergonomics of a 3 mm suit, but its thermal protection exceeded the one of a commercial 7 mm suit, thereby offering the best of both worlds.

Next, we improved upon the K1 by adding a second layer of composite in each respective pocket. This second composite was made of solid ceramic microspheres embedded in silicone. The result was the K2 suit, which featured even better thermal protection with the same flexibility, while also approaching neutral buoyancy. Neutral buoyancy further improved the ergonomics as it decreased the needed ballast, improved weight distribution, and thus decreased the straightening torque that divers experience in water [11].

While highly successful for their intended purposes, both the K1 and K2 suits suffer from poor manufacturability. The custom body scans and matching 3D-printed molds maximize the quality of the suit’s fit to the diver’s body. However, on the flip side, this method means that scans and molds must be made for each diver individually, because of the wide ranges of human body types, proportions, and sizes. This would make mass production of such suits difficult and expensive, ultimately limiting the general use and accessibility of the technology. Our proposed solution is to build suits from a universal composite segment, which can be mass produced by casting from standardized molds, and then trimmed to fit each diver appropriately during the tailoring process. To provide the necessary flexibility and variable curvature, the segment geometry was based on identical truncated square pyramids arranged in a rectangular array. Due to an obvious visual analogy to the striations on a chocolate bar, this approach was called the “Chocobar”. The result is a segment that can be easily bent to fit the body and follow its curvature.

Measurements of the radius of human body curvatures showed that Chocobar designs based on just two values of that radius are sufficient to cover most of the human body. Respective molds were designed, 3D-printed, and used to cast prototypes. The prototypes were characterized for thermal insulance under pressure and then used to construct a new suit, the K3, by the same external-pocketing approach [10,11]. The K3 suit was field- tested against three commercial neoprene suits by diving in pairs and recording temperature difference and ambient pressure. The results showed that K3 is superior in thermal protection and ergonomics to a 7/6 mm neoprene suit, on par with an 8 mm neoprene suit in thermal protection but superior in ergonomics, and less thermally protective but more ergonomic compared to a 15/7.5 mm neoprene Long-Johns suit. K3 offers a huge gain in manufacturability, a substantial gain in thermal protection, and same flexibility but degraded buoyancy ergonomics, compared to the K2. Overall, K3 is a major development in suit technology, which should be of great interest to military, commercial, and recreational divers.

IRB approval

Field test plans for the project were reviewed and approved by the Institutional Review Board (IRB) at the Naval Postgraduate School (NPS).

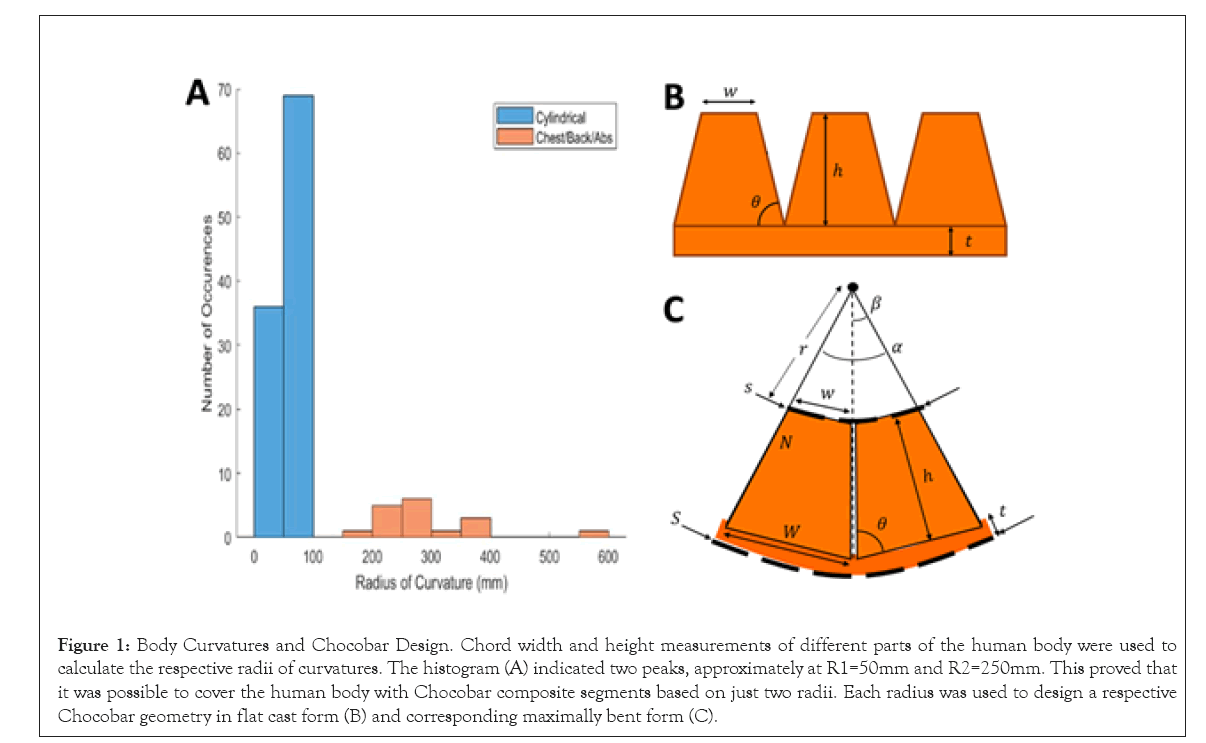

Body curvature

Measurements of the width and height of the chord of different parts of the body were collected and used to calculate corresponding radii of curvature. The results were organized in a histogram, which showed two peaks centered approximately at R1=50 mm and R2=250 mm, respectively (Figure 1).

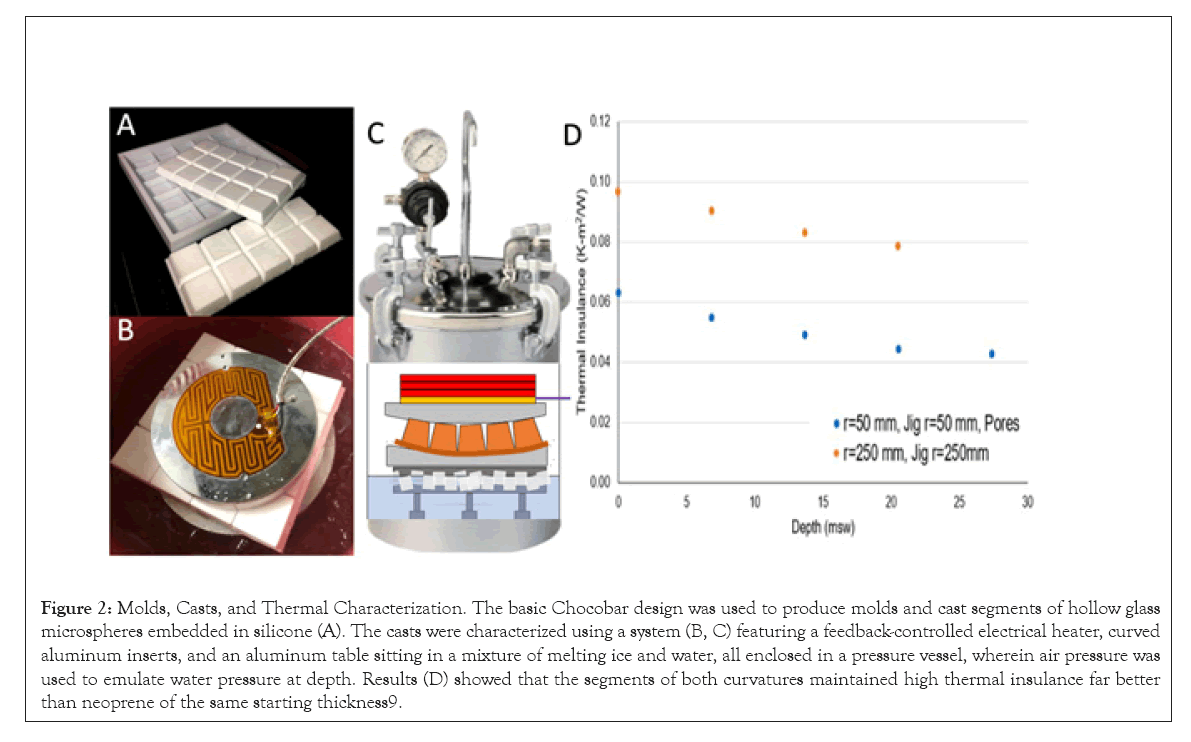

Molds and casts

Molds were designed for two types of Chocobar arrays (R1=50 mm and R2=250 mm). The designs were 3D printed in polycarbonate (Figure 2A) using a Fortus 400 mc 3D printer (Stratasys, Eden Prairie, MN, USA). Sylgard 184 (Dow Corning, Midland, MI, USA) prepolymer was mixed with K1 hollow glass microspheres (3M Corp.) in a planetary mixer (ARE310, THINKY, Japan) for 4 min at 1500 rpm, degassed in a large dessicator vessel attached to a mechanical vacuum pump, poured into the molds, and cured in the molds in a Forced Air Oven (VWR) at 80°C for 2 hours. The Chocobar casts were extracted from the molds and deflashed. Thermal characterization of Chocobar segments

Matching pairs of cylindrical aluminum inserts were machined to have one side flat and the other to have a cylindrical surface matching one of the two set curvatures (R1=50 mm and R2=250 mm). Each of the matching pairs was assembled with a corresponding Chocobar segment (Figure 2B) and sandwiched between a heater element and an aluminum table inside a pressure vessel (Figure 2C). The aluminum table stood in a mixture of melting ice and water, while the heater element was set to be maintained at 37°C by an external electronic controller, which displayed the applied DC voltage and the electrical DC current supplied to the heater. Applying air pressure to the pressurized vessel simulated saltwater pressure at depth. Additional flat composite circular pads were added on top of the heater (Figure 2C) to minimize heat loss to the surrounding air. In steady state, the voltage and current were used to calculate the thermal insulance of the sample (Figure 2D), using the previously established procedure [9] (Figure 2).

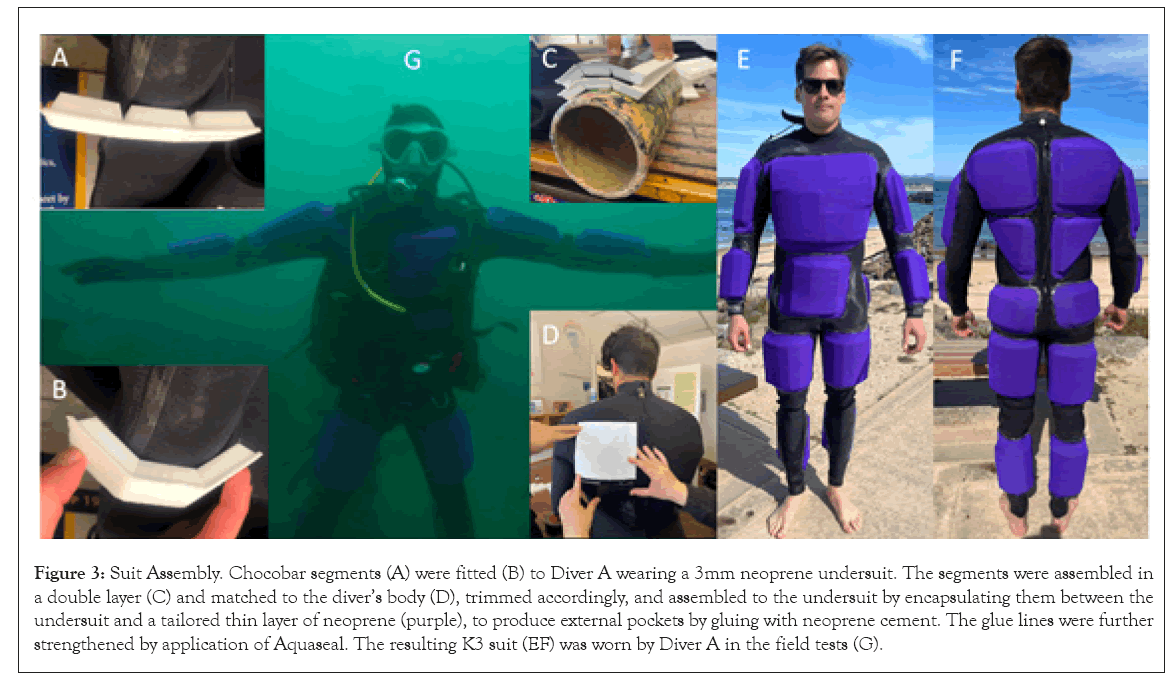

Suit assembly

The Chocobar composite segments were fitted onto a 3 mm neoprene undersuit worn by Diver A, trimmed appropriately in matching pairs forming a double layer (Figures 3A-3D). The pairs were then attached to the undersuit by encapsulating them inside external pockets made by gluing tailored thin neoprene (purple) to the undersuit (black), using neoprene cement. Aquaseal was then applied to the glue lines to strengthen them. This completed the suit (Figures 3E and 3F) and made it ready for field trials (Figure 3G)

Biometric data

For each diver participating in the field tests, biometric data was collected using ES-26M-W Smart Body Analyzer (FITINDEX, fit-index.com). The results were anonymized in compliance with (HIPAA) Health Insurance Portability and Accountability Act regulations. The anonymized biometrics is presented in Table 1.

Field testing

The field test dives were conducted in Monterey Bay, California.

In each dive, Diver A wore the K3 suit, while Diver B wore a commercial dive suit. In each dive, the two divers maintained the same depth and close proximity (<0.9m), including swimming hand-in-hand in poor visibility and swift currents. Different dives tested against different arrangements of commercial systems. OM- CP-PRTEMP1000 dataloggers (Omega Engineering, Norwalk, CT) were used to record the pressure and temperature digitally and automatically. Each diver wore a logger under his suit at the breastbone. Diver A also wore an additional logger inside his BCD (Buoyancy Control Device) mesh, to record the ambient water temperature.

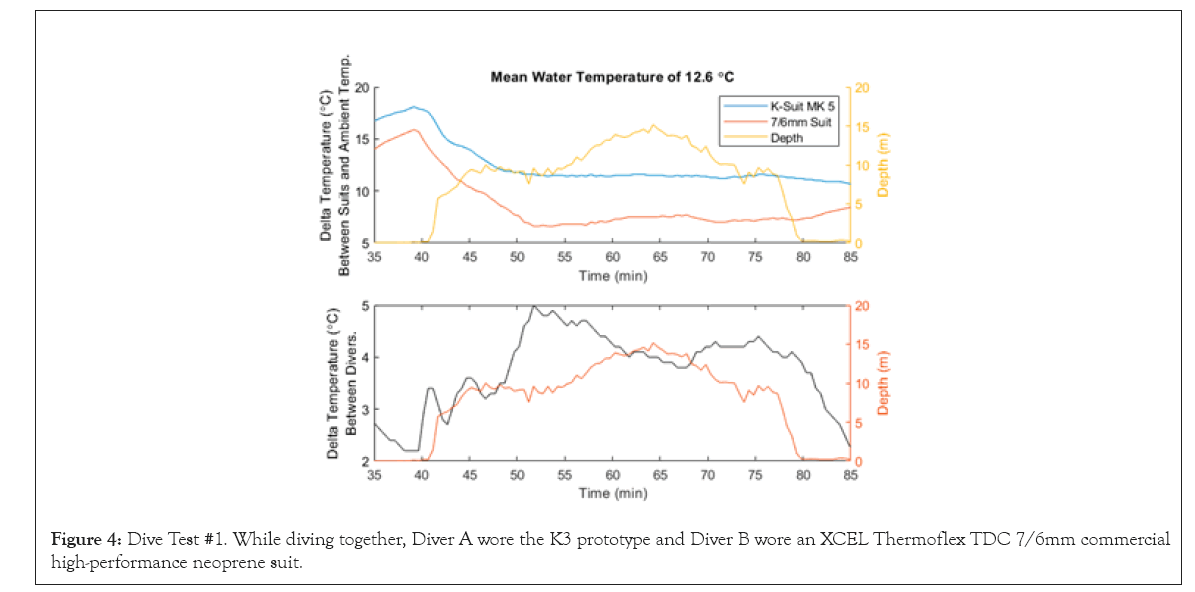

Dive Test #1, was conducted at Whaler’s Cove in Point Lobos State National Reserve. Diver A wore the K3, while Diver B wore an XCEL Thermoflex TDC 7/6 mm high-performance dive suit. The average water temperature was 12.6°C and maximal depth was 15m. Diver A noted a small leak through the wrist cuff during the dive. The results are shown in Figure 4.

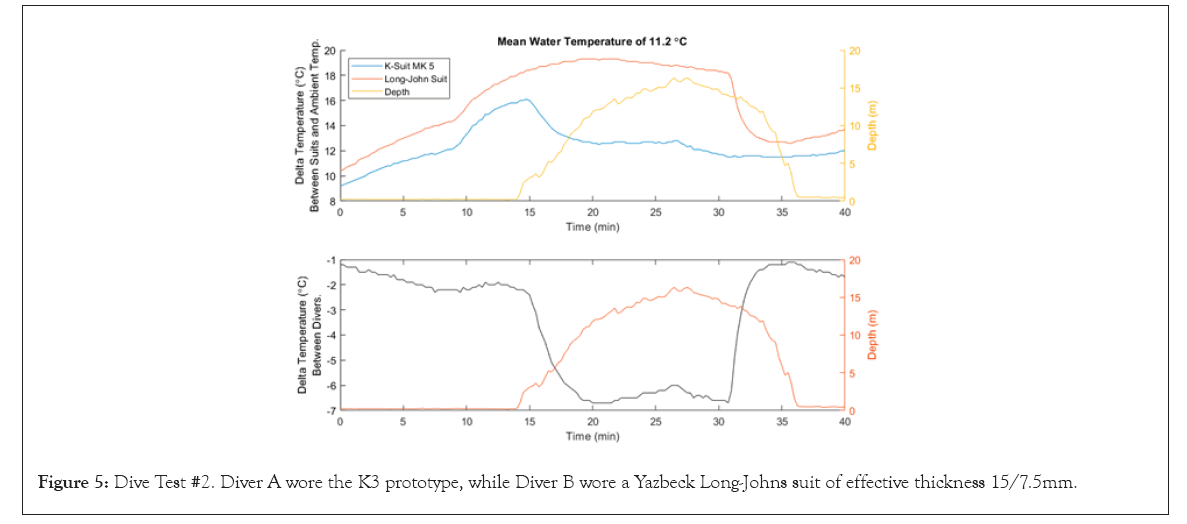

Dive Test #2, was conducted at San Carlos Beach in Monterey, California. Diver A wore the K3, while Diver B wore a Yazbeck Long-John suit, featuring two pieces of 7.5 mm thickness each. As they overlapped at the torso, the resulting effective protection was 15/7.5 mm neoprene. The average water temperature was 12.6°C and maximal depth was 15m. The visibility was 3-4.5m and the maximal depth achieved was 15m. The results are shown in Figure 5.

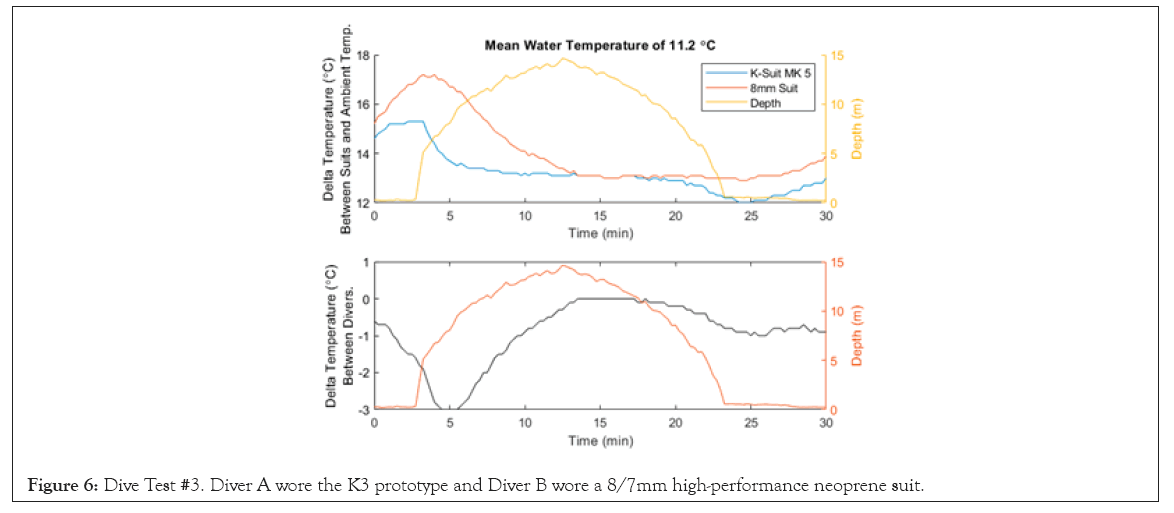

Dive Test #3, was conducted at San Carlos Beach in Monterey, California. Diver A wore the K3, while Diver B wore an Aqualung SOLAFLEX 8/7 mm top-of-the-line neoprene suit. The SOLAFLEX boasted additional features, such as a neck dam and integrated hood, fleece lining, across-the-chest zipper with double lining, and semi-dry cuffs on the wrists and ankles. The SOLAFLEX is the highest-thermal-performance wetsuit produced by Aqualung.

The first version (K1) of the K-suit offered improved thermal protection coupled with superior flexibility, when compared with commercial 7 mm neoprene suits [10]. However, it also had significant positive buoyancy as the composite effective density was ~500kg/m3. The positive buoyancy meant the diver needed to compensate for it by increasing the carried load of ballast [9]. That increased the overall inertial mass, slowing the diver down, while the ballast carried around the waist also worsened the weight distribution of the diver. These issues led us to the idea of improving the K-suit by changing the content of the composite in such a way that its effective density approaches neutral density. In addition, further improvement of thermal protection was also desirable. These features were combined in the K2 suit [11]. The K2 utilized the same approach of composite casts from molds designed off body scans of the diver, but the individual segments were reinforced with an additional thin layer of solid ceramic microspheres embedded in silicone [10]. This extra layer in the same pocket provided the additional thermal protection, as well as raised the effective density to near neutral buoyancy [11], improving the suit’s weight-distribution ergonomics for the diver. While highly successful as suits, both K1 and K2 were difficult to manufacture due to the segments being molded to specific body scans. To improve manufacturability, lower cost, and improve accessibility of this suit technology, we herein present the Chocobar approach. The basic idea is to have universal segments that can be fitted to any diver. This would avoid the need for individual body scans and customized molds. To achieve this mechanically, the composite segments must be bendable. However, the composite material itself is less flexible than bubbled neoprene at the same thickness. So, the approach taken was to minimize the thickness in terms of bending, while maximize the thickness in terms of thermal protection. To achieve both at the same time, the universal segment was designed as a 2D array of truncated square pyramids (Figure 1). As a result, the composite segment is easy to bend along the striations, as the flexibility is largely determined by the thickness t of the shared base (Figures 1B and 1C), while the thermal protection is governed by the combined thickness (h+t). Different values of the geometric parameters of the truncated pyramid would key into different radius of curvature at maximal bending. This raised the question which values of that radius would be needed for maximized coverage of a human body. That brought the need to measure the radius of curvature of different body parts, which was done by measuring the corresponding chords’ thicknesses and heights. The results were organized in a histogram (Figure 1A), which showed two peaks, approximately at R1=50 mm and R2=250 mm. This proved that just two types of universal molds would be sufficient to cast all pieces needed for a diver suit. Essentially, the larger radius produces a flatter segment useful to cover the pectoral, abdominal, and dorsal areas, while the smaller radius produces a far more curved segment useful to cover the limbs.

Figure 1: Body Curvatures and Chocobar Design. Chord width and height measurements of different parts of the human body were used to calculate the respective radii of curvatures. The histogram (A) indicated two peaks, approximately at R1=50mm and R2=250mm. This proved that it was possible to cover the human body with Chocobar composite segments based on just two radii. Each radius was used to design a respective Chocobar geometry in flat cast form (B) and corresponding maximally bent form (C).

Accordingly, molds were designed, 3D printed, and used to cast universal composite segments (Figure 2A). It made sense to characterize these segments in terms of thermal insulance versus applied pressure, as it was previously done with flat round samples of the composite [9]. The test station had to be modified to accommodate the new geometry. Sandwiching the Chocobar segment between two flat surfaces would not be fair, since the Chocobar is meant to be deployed in a bent state in a diver suit.

Figure 2: Molds, Casts, and Thermal Characterization. The basic Chocobar design was used to produce molds and cast segments of hollow glass microspheres embedded in silicone (A). The casts were characterized using a system (B, C) featuring a feedback-controlled electrical heater, curved aluminum inserts, and an aluminum table sitting in a mixture of melting ice and water, all enclosed in a pressure vessel, wherein air pressure was used to emulate water pressure at depth. Results (D) showed that the segments of both curvatures maintained high thermal insulance far better than neoprene of the same starting thickness.

Accordingly, aluminum cylinders were designed and machined in pairs, wherein the outer two surfaces were made flat to interface with the rest of the testing system (heater on top and thermal sink on the bottom (Figures 2B and 2C)), while the inner two surfaces were made to follow a cylindrical surface of radius of curvature corresponding to the one of maximal bending of the particular Chocobar (R1=50 mm and R2=250 mm). The testing system (Figure 2C) was then used as before [9], to measure the thermal insulance of the sample.

The results (Figure 2D) show loss of thermal insulance at 30 msw of ~11% for the R2=250 mm and ~30% for the R1=50 mm Chocobars. These are significantly better than the ~50% loss for 8 mm neoprene of similar thickness, but worse than the loss (<4%) noted for the flat segments [9]. The explanation is that the Chocobars are bent only in one of the two directions, and so the “teeth” are closed in only one of the directions. In the other direction, there are significant air gaps between the “teeth” rows, which make the overall material more susceptible to compression, essentially approximating collapsible air cavities within the overall structure. This explains the quantitative results rather well, as the gaps are larger for the smaller-curvature design. It also demonstrates a general limitation to the Chocobar approach. Nevertheless, the thermal performance of Chocobar segments is still superior to the one of neoprene of the same starting thickness, when exposed to the pressure of typical working depths.

It should also be noted that the current designs are meant to be bendable equally in both directions. If bending in just one direction is sufficient, the Chocobar can be redesigned accordingly (e.g. with striations in only one direction) to eliminate this shortcoming. Alternatively, the Chocobar can also be redesigned to match different radii in the two directions. This could be a further significant improvement in manufacturability, as only one type of mold would be sufficient for both basic curvatures. Essentially, one direction will be used for bending along flatter body areas, e.g. pectoral and abdominal, while the other direction on the same type of segment can be used for the limbs. However, this further improvement would come at some expense in thermal performance, as outlined in the above discussion.

The two types of segments were fitted to the body of Diver A and arranged in double layers (Figures 3A-3D), then encapsulated in external pockets to make the suit (Figures 3E and 3F). The pockets were made by gluing a thin layer of neoprene (purple) to the neoprene of the 3 mm undersuit (black). The resulting K3 suit was field-tested by diving (Figure 3G) in the cold waters of Monterey Bay. In the field tests, Diver A always wore the K3, while Diver B wore three different commercial suits. The performance of the K3 suit was measured by recording the internal suit temperatures for both divers, and the temperature of the ambient water, using automated dataloggers. The dataloggers also recorded ambient pressure, which was converted into depth in meters of salt water. The anonymized diver biometrics are listed in Table 1.

Figure 3: Suit Assembly. Chocobar segments (A) were fitted (B) to Diver A wearing a 3mm neoprene undersuit. The segments were assembled in a double layer (C) and matched to the diver’s body (D), trimmed accordingly, and assembled to the undersuit by encapsulating them between the undersuit and a tailored thin layer of neoprene (purple), to produce external pockets by gluing with neoprene cement. The glue lines were further strengthened by application of Aquaseal. The resulting K3 suit (EF) was worn by Diver A in the field tests (G).

| Diver A | Diver B | |

|---|---|---|

| gender | male | male |

| Height, cm | 180 | 180 |

| Weight, kg | 75.05 | 86.95 |

| Age, yr | 31 | 29 |

| BMI, kg/m^2 | 22.9 | 26.8 |

| Body Fat, wt% | 11.9 | 20.9 |

| Fat-free Body Weight, kg | 66.08 | 68.8 |

| Subcutaneous Fat, wt% | 10.2 | 18 |

| Visceral Fat | 6 | 10 |

| Body Water, wt% | 63.6 | 57.1 |

| Skeletal Muscle, wt% | 56.9 | 51.1 |

| Muscle Mass, kg | 62.8 | 65.3 |

| Bone Mass, kg | 3.3 | 3.44 |

| Protein, wt% | 20.1 | 18 |

| BMR, Kcal | 1797 | 1855 |

Table 1: Biometric Data for Divers.

In Dive Test #1, Diver B wore a commercial high-performance 7/6 mm neoprene suit. This means 7 mm thickness on the chest and 6 mm thickness on the limbs. The results (Figure 4) show that the K3 suit outperformed the 7/6 mm suit in thermal protection by ~4.5°C, while also offering the ergonomics of flexibility of a 3 mm suit. This is a major improvement of important practical consequences, as a 7/6 mm suit is a standard suit for US Navy divers performing long dives of ship maintenance, as well as a standard thick suit for recreational divers. A significantly warmer, less obstructive suit should make a huge practical difference. The shown advantage (~4.5°C) also compares favorably to the K2 suit’s advantage (~1°C) [11] over a 7 mm suit. Hence, K3 improves upon K2 by ~3.5°C in thermal protection. Diver A also reported a small water leak in the wrist cuff, which must have somewhat degraded the K3 suit’s performance, as measured in that dive.

Figure 4: Dive Test #1. While diving together, Diver A wore the K3 prototype and Diver B wore an XCEL Thermoflex TDC 7/6mm commercial high-performance neoprene suit.

In Dive Test #2, Diver B wore a commercial Yazbeck Long-Johns neoprene suit. This is a suit made of two 7.5 mm parts that overlap at the torso, providing a double layer. So, the equivalent is a 15/7.5 mm in standard nomenclature. The results (Figure 5) show that at depth, the Long-Johns outperformed the K3 by ~6°C at depth. This is a large improvement compared to the same suit outperforming the K2 by ~11°C in similar conditions. So, this indirect comparison shows that K3 outperformed the K2 by ~5°C. In addition, the K3 absolute performance was about the same in both Dive #1 and Dive #2, namely a drop of ~4°C in temperature difference when moving from the surface down to 15m of depth. This confirmation shows that the K3 performs consistently.

Figure 5: Dive Test #2. Diver A wore the K3 prototype, while Diver B wore a Yazbeck Long-Johns suit of effective thickness 15/7.5mm.

In Dive Test #3, Diver B wore an Aqualung SOLAFLEX 8/7 mm top-of-the-line neoprene suit. The SOLAFLEX boasted additional features, such as a neck dam and integrated hood, fleece lining, across-the-chest zipper with double lining, and semi-dry cuffs on the wrists and ankles. The SOLAFLEX is the highest-thermal- performance wetsuit produced by Aqualung. This performance is achieved using the above features but also at the cost of highest thickness and worsened ergonomics. The results show that the 8/7 mm suit rapidly lost its advantage during the move from the surface to operational depth, where the K3 achieved parity in thermal protection while maintaining significant superiority in ergonomics of flexibility. These results establish the K3 as the better solution at depth (Figure 6).

Figure 6: Dive Test #3. Diver A wore the K3 prototype and Diver B wore a 8/7mm high-performance neoprene suit.

In future work, the SOLAFLEX extra features should be incorporated into the design of the undersuit as much as possible. For example, starting from a well-built well-fitted 3 mm commercial suit as the undersuit, would ultimately offer additional improvements to the overall performance of Chocobar suits. If even more protection is needed at some tradeoff with ergonomics, the undersuit thickness can be increased to 4 or 5 mm. A separate line of advance would be to replace the second Chocobar glass layer inside the pockets with a Chocobar layer incorporating solid ceramic microspheres. This change should lead to near-neutral buoyancy, regaining K2’s ergonomics advantage in weight distribution [11]. Diver A reported that ~13 kg of ballast was necessary to compensate for K3’s large positive buoyancy. Switching to a glass/ceramic combination of Chocobars would thus significantly decrease the ballast needed, as well as rebalance the weight distribution more advantageously. During the field tests, Diver A wore a commercial 3 mm neoprene hood. A better option would be the design of an open-face helmet using a 3 mm hood as the undersuit, and then adding Chocobar protection in external pocket by the now established approach. Such a change should contribute significantly to the suit’s overall thermal performance.

The K3 prototype diver suit is presented herein. Built by the new universal Chocobar technique, the K3 is far easier to manufacture than its predecessors the K1 and the K2 suits. The field test results showed the K3 outperformed a standard heavy-duty XCEL Thermoflex 7/6 mm suit by +4.5°C at depth. K3 was not as thermally protective as a Long-Johns 15/7.5 mm suit but achieved thermal parity at depth with a top-of-the- line SOLAFLEX 8/7 mm suit. K3 also outperformed all three commercial suits in ergonomics of flexibility but required extra ballast to compensate for high positive buoyancy. Overall, the K3 is a combination of high manufacturability, improved thermal protection, and superior ergonomics of flexibility. Hence, the K3 is an outstanding new option available to commercial, military, and recreational divers.

The authors thank Dan Sakoda and Alex Savattone at NPS for their help with the 3D printing of molds.

Funding for the work was provided from the Office of Naval Research through the NEPTUNE center grant at NPS and through ONR grant N0001418GTC62271.

The authors have no conflicts of interest to declare regarding this manuscript and the work it describes.

The data that support the findings of this study are available from the corresponding author upon reasonable request.

[Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

Citation: Clark C, Waldron A, Sabesky G, Catterlin J, Kartalov EP (2023) Ergonomic Segmented Composite Diving Suit with Superior Thermal Protection and Enhanced Manufacturability through Chocobar Technique. J Ergonomics.13:350

Received: 11-Apr-2023, Manuscript No. JER-23-23404; Editor assigned: 04-May-2023, Pre QC No. JER-23-23404(PQ); Reviewed: 18-May-2023, QC No. JER-23-23404; Revised: 26-May-2023, Manuscript No. JER-23-23404(R); Published: 19-May-2023 , DOI: 10.35248/2165-7556.23.13.350

Copyright: © 2023 Kartalov EP, et al. This is an open-access article distributed under the terms of the Creative Co mmons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.