Journal of Chemical Engineering & Process Technology

Open Access

ISSN: 2157-7048

ISSN: 2157-7048

Short Communication - (2021)Volume 12, Issue 7

The mathematical framework of the principles of holistic systems interactions is demonstrated by facilitating experiential learning with specific industrial case study examples. Two industrial case study examples are introduced as potential interactive teaching tools. Industrial case studies play an increasingly important role in the teaching of systems engineering and sustainability within an industrial ecological framework utilizing metacognitive and experiential learning principles. Each individual case study example makes use of the “closed loop” optimization of material and energy inflows and outflows to minimize waste and harmful environmental emissions. The attainment of the “closed loop” is achieved by facilitating successive progressive stages of materials and energy recovery and re-processing coupled with the re-utilization and regeneration of intermediate byproducts and waste from each successive processing stage. The options that can be exercised to minimize harmful environmental impacts are explored by progressive sampling within the possibility envelope. The learner is expected to demonstrate the systematic process of “narrowing down” of the options and choices through a decision making process starting off with the lead activity lifecycle which defines the outermost boundary of the possibility envelope. The scope of all possible actions and consequences is explored and reduced successively by the introduction and consideration of all other life cycles; progressing along a decision pathway that updates and integrates the considerations made under each of the materials and energy life cycles

Sustainability; Circular economy; Holistic systems; Metacognitive learning

There is increasing support for the principles and applications of circular economy as the primary means for sustainable development. The science for circular economy is not yet fully developed but currently rides on the concepts of avoiding in-process and postconsumption waste of materials and energy whilst at the same time minimizing CO2 and other greenhouse gas emissions that are now proven scientifically to cause catastrophic effects on the world’s climate Erickson and Brase, 2019 [1]; Pauliuk and Heeren, 2021 [2] and biodiversity Attenborough and Hughes, 2020 [3].

To comply with the demands of circular economy and meet the challenges of climate change and biodiversity depletion, the chemical and process industries are placed under increasing pressure to adapt to change. This is implemented with the development of novel technologies and plants, whilst also retrofitting existing plants and modifying the existing materials and energy supply chain infrastructure, to reduce significantly, in the short term, and eliminate completely, in the medium to longer term, the industry and urban society dependence on carbon rich fossil fuels.

All of the above required changes, for successful implementation, rely also on the education of the public at large to the real positive benefits of change as well as introducing new teaching and learning methods for systems engineering and sustainability to engineering disciplines in both academic degree courses and in industrial training programmes. In this second of the short communication titles for Chemical and Biological Engineers Tuzun, 2021 [4], further metacognitive teaching and learning methodologies are introduced and their potential is demonstrated with industrial case studies.

The case studies are focused on the wood and pulp industry sector that pose great challenges to sustainability with their high levels of process energy demand coupled with production of solid and liquid waste as well as air borne emissions. Paper products constitute the largest single fraction of municipal solid waste. The production and use of paper is a giant industry sector; fifth largest consumer of energy that accounts for 4%-5% of total global energy use. The sector also creates solid and liquid waste on a very large scale and thus in order to achieve sustainability, the industry needs to monitor, control and reduce emissions and waste; Cheremisinoff and Rosenfeld, 2010 [5] who provide and extensive guide to cleaner production and green energy practices in the sector.

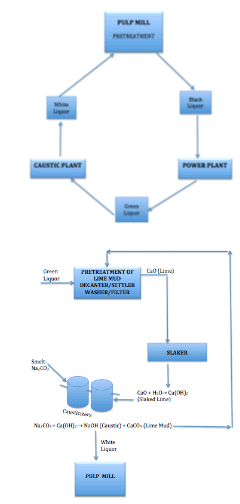

Case study 1 considers the main steps in pulp and paper manufacturing that include raw material pre-treatment (comprising of cellulose fibres, general wood, recycled paper and other agricultural residues), wood debarking and chip making, pulp manufacturing and cellulosic fibre recycling. Kraft process uses cooking at elevated temperatures (150°C-180°C) of the chipped wood in alkaline sulphate followed by a bleaching step; see Figure 1. Gasification of the black liquor and production of bio-fuels (for primary use in the sector) in an integrated plant complex are currently considered for commercial viability as possible alternatives to the Kraft Process Cycle comprising of pulp mill, power plant, and caustic plant in Figure 1; Bashkar and Pandey, 2018 [6], and Cheremisinoff and Rosenfeld, 2010 [5].

Case Study Example 1Microstructural process plant unit operation stages

Chemical/Bio-Chemical Synthesis

Intermediate Product Structuring

Selective Separations

End-Product Recovery

Byproducts and Waste Products

Regeneration and Re-Use

Kraft pulp mill & chemical recovery process plant

1. Identify the raw materials, intermediate products, byproducts and waste product streams and suggest alternative ways the process plant unit operations could be integrated to maximize heat and materials recovery and re-use.

2. Identify the role of the power plant in processing the “black” to “green” liquor as feed to the caustic plant. Discuss the environmental merits of processing pretreatment waste liquor in a power plant relative to other alternatives that can be considered.

Kraft process caustic plant

1. Discuss the possible specialty products that can be manufactured with further processing from Calcium and Sodium compounds at the Kraft Caustic Plant as alternative to producing the “white liquor” for the pulp mill as seen above.

Recommended further reading

Handbook of Pollution Prevention and Cleaner Production: Best Practices in the Wood and Paper Industries, N.P. Cheremisinoff and P.E. Rosenfeld, 2010, Elsevier, ISBN: 978-0-08-096446-1.

Figure 1: Closed-loop processing of intermediate products and selective separations for specialty products and re-use of residual products in pre-treatment of raw materials.

In addition to the fixed point sources of emissions such as vents, boilers and stacks depicted in Figure 2, the Kraft process also gives rise to large scale fugitive emissions from vapours emitted during wood treating, kiln emissions, tank breathing, vapours from surface ponds, drainage ditches, and dust emissions from on-site heavy machinery traffic in addition to boiler emissions. Prevention and abatement of environmental emissions are taken on board in case study 2 (Figure 2) where the student centred learning focus is expanded from considering just solid and liquid waste treatment to also include environmental emissions and thus broadening the scope of the systems engineering for sustainability; Tuzun, 2020 [7].

In contrast to the large scale processing of bulk chemicals, the specialty components produced with microstructural processing are often milled, mixed and blended, embedded and encapsulated with other materials when produced at large scale, Cussler and Moggridge, 2011 [8], Cadman et al., 2013 [9] for more product details. Quite clearly, the systems for process unit operations are inherently not only parallel but also vertically integrated to provide the complex “value added” functionality that comes with the specialty applications as seen in Figure 1 above.

Life cycle stages of unit operations in a microstructural process plant involves (i) Chemical/Bio-Chemical Synthesis, followed by (ii) intermediate product structuring and shaping which in turn yields (iii) end product functionality through selective separations and product recovery for targeted applications. Byproducts and waste products can be processed through similar stages of unit operations to provide regeneration and re-use.

Life cycle stages of value added microstructural products involve (i) selective thinning and aeration of liquids and pulverization and/ or deposition of particulate solids followed by (ii) selective and successive additions of solid and mixing of liquid components. Selections of commercial consumer products accessible at each life cycle stage are also dictated by branding and market demand.

After familiarization with the environmental impacts and systems engineering issues for sustainability of the Kraft Process Cycle, the student is encouraged to engage with evaluative mapping of the processes and products in Figures 1 and 2 to the generic process and product life cycle steps and phases provided of microstructural product and hybrid energy processing plant configurations. For the implementation of systems evaluation using this holistic systems mapping approach Tuzun, 2020 [10]. This application constitutes the transition from normative (descriptive) to cognitive (evaluative) learning Bloom, 1956 [11] by the student through application of self-evaluative skills of analysis and synthesis based on the descriptive factual information gained from the Kraft Process applications studied.

Case Study Example 2Hybrid energy process plant unit operation stages

Chemical/Bio-Chemical Synthesis

Selective Separations and Alternatives to Evaporation

Green Liquid Recovery

Solid and Liquid Waste Products

Atmospheric Emissions

Kraft process power plant

1. Suggest a partitioned plant configuration that can share integrated energy flows to enable large-scale parallel processing of multiple product brands as described in Figure 1.

2. Identify the hybrid system of energy sources, energy recovery and pathways for possible energy generation for electricity grid supply network and possible routes for bio-fuels production from black liquor.

3. Comment on the significance of the recovery boiler operation on environmental emissions of CO2 and other greenhouse gases. Is greenhouse gas emissions abatement possible with an alternative route for “black liquor” treatment process used in the power plant? Consider both fixed point and fugitive emissions in the power plant.

Recommended further reading

Waste Biorefinery: Potential and Perspectives Edts. Bhaskar T, Pandey A et al, 2018, Elsevier, ISBN 978-0-444-63992-9 DOI:/10.1016/ C2016-0-02259-3.

Figure 2: Hybrid energy process plant (hepp) for power generation whilst converting pulp mill effluent stream into raw material feed to caustic plant.

To introduce the student to the final stage of the progression of normative (descriptive) cognitive (evaluative) metacognitive (reflective) learning exercise, it is possible to divide the student project groups into exploring the possibilities of further process and product development and use with (i) Kraft Process Lignin (black liquor in Figure 1 and (ii) Kraft Caustic Plant byproducts (green liquor) and caustic plant waste (white liquor).

Here, it would also be helpful to introduce the student to the concept of organised reflection and encourage independent exploration of initiatives by formal consideration of the topological psychology framework now known as the Force Field Theory of Lewin,1966 [12]. This guiding approach makes use of the principles of judgement and choice and decisions and consequences. Lewin’s Force Field Analysis splits the possible thought provoking scenarios into four groups: (i) Forces for Change, (ii) Driving Forces, (iii) Restraining Forces and (iv) reisting Forces.

When placed into the context of the student assignments (1-3) of the case studies 1 and 2 respectively, it is possible to prioritise Forces for Change as (i) circular economy requirements, (ii) worsening climate change and biodiversity effects whilst Driving Forces could be stated as reduction/abatement/elimination of greenhouse gas emissions and recycling and re-use of solid and liquid process waste and further use of Kraft Process byproducts.

Restraining Forces could include considerations of (i) closeness, proximity and connectedness of possible material and energy supply chains necessary for secondary and tertiary processing of primary Kraft process intermediates and products, and (ii) ligninrich biofuel use for steam and heat generation and recovery boiler operation (Figure 2).

Resisting Forces could be classified (i) low calorific value coupled with higher emissions of Kraft lignin as bio-fuel compared to cheap fossil fuels such as coal, (ii) the additional capital and operating costs associated with lowering the pH of the black liquor to generate less CO2 and other flue gas emissions, (iii) inexpensive use of recycled white liquor from the caustic plant (Figure 1) for provision of cooking and bleaching agents during the biomass pretreatment in the pulp mill.

The above listing is deliberately not exhaustive to allow the student to engage with and explore the other progressive possibilities and/ or limitations that may exist to either broaden or reduce the initial possibility envelope constructed by the use of Lewin’s,1966 [12] force field analysis. The holistic analysis pathway for informed decisionmaking and exercising of judgement and choice is established once again with this further mapping exercise, following the initial mapping of the Kraft Process plants and product life cycles as microstructural processing of specialty products.

Kraft Lignin is the only natural source of aromatic compounds; it can serve as a renewable and sustainable source for specialty liquid fuels and chemicals Luo and Abu-Omar, 2017 [13] and Wei and Yingting, 2017 [14]. Paone et al., 2019 [15] review the possible reductive catalytic fractionation of lignocellulosics and conversion of lignin to aromatic feedstock for further valorisation. Catalytic extraction and depolymerisation are used to stabilize monolignols and phenolic compounds that can be further used in value-added chemicals, polymeric materials and in pharmaceutical active ingredients. The selective separation of Kraft Lignin from the black liquor (Figures 1 and 2) therefore merits further evaluative and reflective study by the student project groups.

Caustic Soda (NaOH) is commonly used in soaps, detergents, and cleaning fluids. Washing soda (Na2CO3) is used for water softening and in detergents. Bicarbonate of soda is used in food and pharmaceutical additives. Limestone (CaCO3) is used in the manufacture of cement and glass and in purification of iron in blast furnaces. Soda lime (CaHNaO2) is a mixture of Calcium hydroxide and sodium (or potassium) hydroxide. Soda lime has a unique ability to absorb moisture from air. It also absorbs carbon dioxide from air. Hence it is used in manufacture of gas masks but could also be used in carbon capture and storage (CCS) during solid/liquid fuel gasification. Hence, these marketing possibilities could be evaluated against the use of the white liquor from the caustic plant as feed to the pulp mill; refer to Figure 1.

The use of the holistic cradle-to-cradle systems analysis is demonstrated with the use of two industrial case studies corresponding to the closed-loop unit operation stages of the Kraft process. Circular economics generated is made possible by (i) in-process recycle and re-use of materials and energy as well as (ii) further use and re-processing of Kraft process intermediates to manufacture value-added products which, in turn, can be precursor materials in a wide range of consumer products industry applications. The application of holistic systems engineering using the successive normative (descriptive)-cognitive (evaluative)- metacognitive (reflective) thought processes are illustrated, with the use of industrial case study assignments, designed for experiential and interactive group learning by chemical and biological engineering students.

Earlier conversations and observations (2018/19) regarding the multi-phase processing of paper and pulp suspensions with researchers at the University of Coimbra, Portugal and the consultations with Perlmutter Idea Development LLC in USA are gratefully acknowledged.

Received: 28-Jul-2021 Accepted: 24-Aug-2021 Published: 31-Aug-2021 , DOI: 10.35248/2157-7048.21.12.421

Copyright: This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.