Journal of Pharmaceutical Care & Health Systems

Open Access

ISSN: 2376-0419

ISSN: 2376-0419

Research Article - (2023)Volume 10, Issue 3

The cold chain refers to the storage and transportation of vaccines within the optimally required temperature starting from the time the vaccines leave the manufacturing plant until they reach the end-users. The objective of the study was to assess the status of the cold chain management of Ethiopian Pharmaceutical Supply Agency (EPSA), Hawassa cluster. A facility-based cross-sectional study was employed in EPSA, Hawassa cluster to assess its cold chain management practice. Data were collected from both primary and secondary sources to complete the assessment. Due to the binary nature of the variables (Yes or No) data was compiled and analyzed using count and percentage. In summary, the floor of the cold chain warehouse is not in a good condition. It has holes and breaks affecting warehouse operation. Dedicated room and space are available for vaccine and dry products, respectively. One person is assigned to monitor and manage cold chain warehouse operations. Based on the baseline findings, the authors concluded that EPSA Hawassa cluster is constrained majorly by a lack of effective warehouse operations and infrastructures, lack of manual documentation of inventories and transactions, and lack of proper stocking of commodities.

Measles; Measles mumps rubella; Rubella; Measles rubella

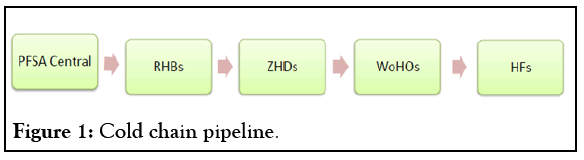

The cold chain refers to the storage and transportation of vaccines within the optimally required temperature starting from the time the vaccines leave the manufacturing plant until they reach the end-users. A successful immunization program depends on an ample supply of vaccines, skilled health care providers, and a well-functioning cold chain system. In Ethiopia, vaccines are transported and stored at various points before they reach clients. The chain begins at the Federal Ministry of Health, followed by regional health bureaus, Zonal health desks, Woreda health offices, health centers, and health posts. Each vaccine requires a prescribed temperature level and the utmost care during transportation and storage to maintain its efficacy. Thus facilities and health offices that handle the vaccines are equipped with refrigerators specifically designed for storing vaccines along with accessories such as iceboxes and ice packs (Figure 1) [1].

Figure 1: Cold chain pipeline.

The integrity of the cold chain depends on three essential elements that underpin the standards:

• The people managing vaccine manufacture, storage, and distribution, and those managing the cold chain at the provider level.

• The systems and processes providers use to ensure they monitor the vaccine storage conditions and actions taken if the vaccines are exposed to temperatures outside the required range.

• The equipment is used for storing, transporting, and monitoring vaccines from the time the vaccine is delivered to an immunization provider to when the vaccine is administered to an individual [2].

The Expanded Program on Immunization (EPI) was established by the World Health Organization (WHO) in 1974 to control vaccine-preventable diseases. The EPI was designed 40 years ago for two types of vaccines:

• Those that are heat stable but freeze sensitive

• Those that is stable to freezing but heat-labile [3].

In Ethiopia, the EPI program was launched in 1980 to achieve 100% immunization coverage for all children under two years old by 1990. In 1986, the coverage target was reset to 75%, and the target age group was changed to less than one year old but progress in increasing coverage has been slow. With the introduction of new approaches known as Reaching Every District (RED) and Sustainable Outreach Services (SOS) for immunization in 2003, improvement has been documented [4]. WHO recommends that ensuring access to medicine with the right quality, quantity, time, and place and with the least possible cost is an expected service from a certain pharmaceutical supply chain. In this regard, the Ethiopian Pharmaceutical Supply Agency (EPSA) has several problems including non-availability, poor storage, lack of stock management, shortage of expertise, and a weak distribution system including weak fleet management [5]. The assessment of the EPSA Hawassa cluster was done using the Effective Vaccine Management Assessment (EVMA) tool. EVMA is a diagnostic tool and identifies issues in Cold Chain Logistics (CCL) system that needs to be fixed and to be sustained.

In 2013, the Federal Ministry of Health (FMOH) agreed to begin the formal transfer of responsibility for the management of vaccines and cold chains to the Pharmaceutical Fund and Supply Agency (PFSA) which is currently renamed EPSA. Key aspects of the transition program include:

Vaccines are fragile and must be stored properly from the time they are manufactured until they are administered. The purpose of the vaccine “cold chain” is to maintain product quality from the time of manufacture until the point of administration by ensuring that vaccines are stored and transported within WHOrecommended temperature ranges. Storage and handling errors might lead to:

• Reduced potency and effectiveness

• Cost thousands of dollars in wasted vaccine and revaccination

• Loss of patient confidence

Temperature requirements for vaccines

Regular temperature monitoring is vital to proper cold chain management. Temperatures in both the freezer and refrigerator units should be read twice each day, once in the morning and once before leaving at the end of the workday. A temperature log should be posted on the door of the storage unit where the twicedaily temperature readings are recorded. Center for Disease Control (CDC) and prevention recommends keeping these temperature logs for at least 3 years unless state statutes or rules require a longer period (Table 1) [6].

| Parameter | Recommended temperatures |

|---|---|

| Freezer | Between -58°F and +5°F (-50°C to 8°C) |

| Refrigerator | Between 35°F and 46°F (2°C to 8°C) |

| Average | 40°F (5°C) |

Table 1: Recommended temperature for vaccines.

Vaccines are grouped into six categories. Within each of these six categories, the vaccines are arranged in alphabetical order, not in order of sensitivity to heat within the group. The most heatsensitive vaccines are in Group A and the least heat-sensitive vaccines are in Group F. Some vaccines are very sensitive to light and lose potency when exposed to it. Such vaccines should always be protected against sunlight or any strong artificial light, and exposure should be minimized. Vaccines that are as sensitive to light as they are to heat include BCG, measles, measlesrubella, measles-mumps-rubella, and rubella. These vaccines are often supplied in dark glass vials that give them some protection from light damage.

• Detailed planning and organizing for the oversight and management of vaccines and the cold chain by EPSA.

• Operational system and network design improvements and capacity building with EPSA.

• Addressing needs within EPSA’s information systems, including an EPI dashboard.

• Developing and utilizing monitoring mechanisms for vaccine availability and cold chain effectiveness.

• Network and transport modeling and costing analysis to provide EPSA with efficient and cost-effective approaches to vaccine distribution

Study design

A facility-based cross-sectional study was employed in EPSA Hawassa cluster to assess its cold chain management practice. The assessment was conducted from December 07 to 15, 2022.

Source and type of data

Data were collected from both primary and secondary sources to complete the assessment. Direct observation was employed to inspect the cold chain infrastructure and equipment as per the data collection tool. Professionals working in the area (vaccine management focal person and warehouse managers) were approached to gather the required data. Secondary data was collected from reviewing relevant documents and reports (temperature logbook, contingency plan, vaccine requisition form, Health Commodities Management Information System (HCMIS) software).

Data analysis

The collected data were summarized and analyzed to result in baseline information about cold chain practice. Due to the binary nature of the variables (Yes or No) data was compiled and analyzed using count and percentage. During interpretation of the data, scoring 1(100%) to a specific parameter means the facility has full filled that specific criterion. Whereas scoring 0(0%) refers to the facility doesn’t fulfill that specific parameter (unless and otherwise it is indicated in the remark section).

The procedure of data collection

The first step was visiting and inspecting the cold chain warehouse per the assessment tool. The following parameters were inspected: Number and the functional status of cold rooms, freeze rooms, and CCEs (DFs and ILRs); the cold chain infrastructure; vaccine store building; vaccine storage and handling and stock status of vaccine (availability or stock out).

The second step was reviewing the presence of relevant documents and records related to the assessment. The following document and formats were included in the review: The presence of Standard Operating Procedures (SOPs), contingency plan, a temperature logbook for each cold room, freeze room and CCEs and stock register; temperature recording practice (twice daily, on holidays, Sundays); documentation of damaged and expired vaccines; vaccine wastage rate calculation for each vaccine; the presence of planned preventive maintenance plan.

The third step was interviewing the warehouse manager to assess his/her knowledge of handling vaccines. In addition to oral inquiry, he/she was asked to demonstrate how to read Vaccine Vial Monitoring (VVM) and to perform a shake test. Information that could not be collected by direct observation and document review was also collected from the warehouse manager (information related to supportive supervision, whether temperature monitoring and mapping study has been conducted or not).

The baseline assessment of the cold chain system of the Hawassa cluster was completed using a prepared assessment tool comprising ten requirements (Tables 2-12). The ultimate goal of this study is to improve lower performances and to achieve the targets score. The target score for each parameter is 100%.

| Parameter | Yes/No |

|---|---|

| What type of cold chain equipment is used in the store? (Select one or more options): | |

| Freezer room and/or cold room are used for storing vaccine. | Y |

| Freezers and/or refrigerators are used for storing vaccine. | N |

| Freezer room, cold room, freezers or refrigerators are used for freezing icepacks or cooling cool water packs. | Y |

Table 2: Type of equipment.

| Parameter | Yes (%) | No (%) |

|---|---|---|

| Dedicated space/room available for cold chain at the facility | 1 (100) | 0 |

| Dedicated room/space for dry storage at facility | 1 (100) | 0 |

| Dedicated table for conditioning of ice packs | 0 | 1 (100) |

| Dedicated clean clothes for wiping of icepacks after conditioning | 0 | 1 (100) |

| Power backup available/stand by generator available | 1 (100) | 0 |

| One person assigned to monitor cold chain | 1 (100) | 0 |

| Guideline they utilize (WHO, EPI, MOH) | 1 (100) | 0 |

Table 3: Cold chain infrastructure.

| Parameter | Yes (%) | No (%) | Remark |

|---|---|---|---|

| How many refrigeration units are there? | 5 | 4 cold room and 1 freeze room | |

| How many were fully operational at the time of inspection? | 5 (100) | 0 | |

| Are all cold room and freezer room enclosures in good condition at time of inspection? | 1 (100) | 0 | |

| Do all rooms have continuous temperature recorders? | 4 (80) | 0 | One of the cold rooms does not have |

| Are all cold rooms and all freezer rooms fitted with dual refrigeration units? | 0 | 1 (100) | |

| Can doors be locked from the outside but freely opened from the inside? | 1 (100) | 0 | |

| Are all rooms fitted with sufficient good quality shelving? | 0 | 1 (100) |

Table 4: Cold rooms and freezer rooms.

| Parameter | Yes (%) | No (%) |

|---|---|---|

| Is the vaccine store building suitable for the climate? | 1 (100) | 0 |

| Is the roof free of leaks? | 19 (100) | 0 |

| Are the external walls free of severe cracks or other major damage? | 1 (100) | 0 |

| Are windows and external doors in good condition and secure (grilles and/or locks)? | 1 (100) | 0 |

| Are floors dry and reasonably level? | 0 | 1(100) |

| Are there any fire extinguishers and have they been tested in the past 12 months? | 1(100) | 0 |

| Is the air-conditioning system working? Score 'n/a' in climates where a/c is not required. | 0 | 1(100) |

| Does it have a functioning alarm system | 0 | 1(100) |

| Can delivery vehicles easily reach the store(s)? | 0 | 1(100) |

Table 5: Vaccine store building.

| ILRs and DFs | Yes (%) | No (%) | Remark |

|---|---|---|---|

| Separate functional thermometer inside every functional equipment | 0 | 1 (100) | |

| Cold chain equipment (ILRS and DFs) placed on wooden blocks | 0 | 1 (100) | |

| Cold chain equipment (ILRs and DFs) at least 10 cm away | 1 (100) | 0 | |

| Each equipment is connected through functional Voltage Stabilizer | 0 | 1 (100) | |

| Functional thermometer placed correctly | 0 | 1 (100) | |

| Temperature log book | |||

| Each CCE is having separate temperature log book | 1 (100) | 0 | |

| Temperature is recorded twice daily | 1 (100) | 0 | |

| Temperature is recorded on Sundays and holiday | 1 (100) | 0 | |

| Record of power failure maintained in temp. log book | 1 (100) | 0 | |

| Records of defrosting/cleaning maintained in Temp.log book | 0 | 1 (100) | |

| Temp. Log book reviewed by DIO in last three months | 0 | 1 (100) | |

| Temp. Log book reviewed periodically by facility in charge | 0 | 1 (100) | |

| ILRs | |||

| Functional ILR within the temperature range (+2°C to + 8°C) | 1 (100) | 0 | |

| Correct placement of vaccine from top to bottom inside ILRs | N/A | ILRs are used only for freezing icepacks | |

| Diluents placed in ILR, at least 24 hours before distribution | N/A | ||

| DFs | |||

| Deep freezer within the normal temperature range (-15 to -25) | 1(100) | 0 | |

| Correct placement of ice packs inside DFs (crisscross) | 0 | 1(100) | |

| Ice pack are filled up to the mark and capped | 0 | 1(100) | |

| Vaccines | |||

| Nil stock of any vaccine found during the visit | 0 | 1 (1000 | No vaccine was stock out |

| All vaccine vials have proper readable label | 1 (100) | 0 | Sample taken |

| All vaccine found within expiry dates | 1 (100) | 0 | |

| All the vaccines with usable VVM (I and II) | 1 (100) | 0 | |

| Any vaccine found in frozen condition | 0 | 1 (100) | |

| Any open vaccine vial stored inside ILRs | N/A | - | |

| Open vaccine vial are stored in separate box/zipper bag | N/A | - | |

| Date and time of opening is written on the vial | N/A | - | |

| All open vaccine vial are of <28 days duration | N/A | - |

Table 6: Vaccine storage and handling.

| Parameter | Know/not |

|---|---|

| VVM | Y |

| Shake test | Y |

| Cold chain prayer | Y |

| Time of use of reconstituted vaccine | N/A |

| Timing of placement of diluents inside ILRs | N/A |

| Vaccine requiring diluents | Y |

| Open vial policy | Y |

| Freeze sensitive vaccines | Y |

Table 7: Knowledge and cold chain handlers.

In summary, the floor of the cold chain warehouse is not in a good condition. It has holes and breaks affecting warehouse operation. The cold chain warehouse does not have an air conditioning system. The cold chain warehouse does not have a functioning temperature excursion alarm system. There is no prepared space/table for conditioning ice packs. The cold chain warehouse (receiving and dispatch areas) is not easily accessible by vehicle. Thermometers are not placed in Deep Freezers (DFs) and Ice Lined Refrigerators (ILRs). Poor arrangement of icepacks in DFs and ILRs (didn’t follow the standard procedure) DFs and ILRs are not connected to voltage stabilizers which put them in danger during power fluctuation. Supervisors don’t check the temperature log book periodically. No scheduled deforesting and records of deforesting in previous periods. Health and pharmaceutical supply chain managers are being trained at the national level (Jimma and Addis Ababa University). There is a development of new software and applications and implementation of the Kaizen principle in the cluster. In many low-income countries, vaccine delivery systems have remained largely unchanged due to challenging contextual factors that have limited their ability to meet immunization program requirements. The major challenges include:

| Parameter | Yes (%) | No (%) | Remark |

|---|---|---|---|

| Is stock register in use for vaccine and logistics as per norm? | 0 | 1 (100) | HCMIS do this function |

| All parameters for vaccines, logistics and diluents are recorded? | 0 | 1 (100) | No record for diluents |

| Returned vials from the field are entered in the stock register? | N/A | ||

| Is distribution register in use for vaccine and logistics as per norm? | 1 (100) | 0 | |

| Expired and wasted vaccines are documented in Stock register | 1 (100) | 0 | Posted on the wall |

| Physical counting of vaccine stock is done at least once in last 3 months? | 1 (100) | 0 | |

| Physical stock of (BCG/measles) is matching the stock register for that day? | 0 | 1 (100) | Done for measles |

| Vaccine and Logistics stock management updated till last transaction | 1 (100) | 0 | |

| Chart/SOP on ILR/DF/vaccine/ice pack arrangements available | 1 (100) | 0 | SOP available |

Table 8: Management information system and supporting system at cold chain points.

| Parameter | Yes (%) | No (%) | Remark |

|---|---|---|---|

| Has a temperature monitoring study has been carried out in the past five years | 0 | 1 (100) | |

| Has the recommendation of this study been implemented | 0 | 1 (100) | |

| How many vaccines freezer rooms and cold rooms are there? | 1 and 4 | ||

| How many of the rooms have a fully documented temperature mapping study? | 0 | 1 (100) | None of them |

Table 9: Temperature monitoring and mapping study.

| Parameter | Yes (%) | No (%) | Remark |

|---|---|---|---|

| Is there a satisfactory SOP which sets out a contingency plan in the event of equipment failure or another emergency? | 1(100) | 0 | |

| Are emergency contact details posted in the vaccine store? | 1(100) | 0 | |

| Do staffs know what to do in the event of an emergency? | 1(100) | 0 | Sample |

Table 10: Vaccine store contingency planning.

| Parameter | Yes (%) | No (%) | Remark |

|---|---|---|---|

| Is there a written multi-year Planned Preventive Maintenance (PPM) program? | 1 (100) | 0 | But not multiyear plan |

| Is there documentary evidence that the program is being followed? | 0 | 1 (100) | Posted PPM was for the year 2010 |

| Is there visual evidence that maintenance is taking place? | 0 | 1 (100) | |

| Is somebody assigned to carry out routine maintenance? | 1 (100) | 0 | |

| Is there evidence that cold rooms/refrigerators/freezers have recently been cleaned and defrosted? | 0 | 1 (100) | Evidence of frosting was seen |

Table 11: Planned preventive maintenance.

| Parameter | Yes (%) | No (%) | Remark |

|---|---|---|---|

| Do you calculate wastage rates for each vaccine? | 1 (100) | 0 | |

| Is there a standard form used to record wastage? | 1 (100) | 0 | |

| Is there a complete set of wastage records for the review period? | 1 (100) | 0 | |

| Are these data used to monitor vaccine management performance? | 1 (100) | 0 | According to vaccine focal person |

Table 12: Wastage rate calculation.

Insufficient cold chain capacity

When the required capacity is absent new vaccine introductions can be delayed and can disrupt service delivery.

Causes of insufficient capacity: Poor understanding of current cold chain equipment status: most cold chain inventories do not have systems for routine data collection, which limits the existence of accountability structures and inhibits accurate and regular inventory updates. Insufficient forecasting of future capacity requirements: anticipating future needs is essential, particularly given the lead times for procurement. Inadequate implementation systems: even when sufficiency gaps are identified, immunization programs often lack the systems and resources to fill them.

Lack of latest technology or optimal equipment

The performance of cold chains has been hampered by large quantities of outdated equipment, which fails to provide the protective benefit of more recent designs.

Causes for weak adoption of better technologies: Insufficient awareness and recognition of the benefits of these new features: Lack of awareness regarding the relevance of new features and benefits of upgrading equipment in individual countries is among the most significant barriers to the adoption of new technology.

Switching costs: concerns about the performance and reliability of latest generation units can also inhibit the uptake of newer technology.

Expensive product offerings: countries have favored older technologies as optimal units are initially more expensive.

Inadequate temperature monitoring and maintenance systems

Malfunctions are common at the facility level: temperature monitoring studies have found that active Cold Chain Equipment (CCE) is often not functioning properly, with significant temperature control problems.

Causes of poor temperature regulation: Awareness and monitoring of functionality status: acute CCE breakdowns are evident to health workers on-site but freeze and heat exposures are harder to detect.

Availability of services and resources: while awareness of functionality is critical, alarms must be tied to corrective actions by a trained and equipped cold chain officer and technician [7-9]. As countries address immediate gaps in their cold chain, stakeholders must look beyond the initial challenges to securing long-term safety, sufficiency and efficiency. Achieving this will require a significant investment of resources, effort and political will both in-country as well as at the global levels [10].

As one of the Millennium development goals is to minimize neonatal and infant mortality, the vaccine cold chain has gained the attention of the government. Due to this, multiple NGOs and international organizations support it. Based on the baseline findings, the authors concluded that EPSA Hawassa cluster is constrained majorly by a lack of effective warehouse operations and infrastructures, lack of manual documentation of inventories and transactions, and lack of proper stocking of commodities. While reading the present study two things shall be considered. The first one is even though the tools used to prepare the assessment tool are standardized and validated; the assessment tool prepared for this assessment is not checked for validity. Important parameters were selected from the two tools and merged to make the tool as comprehensive as possible. Secondly, it was difficult to determine the cost of installing air conditioning and temperature excursion alarm system. Few experts in the area were asked and they replied as it is difficult for them to estimate unless they visit the actual place (which was not possible). Regardless of the limitation, this study would be an important document input to fill actual gaps observed in EPSA Hawassa cluster.

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

The authors have no conflicts of interest to declare.

[CrossRef] [Google Scholar] [PubMed]

[CrossRef] [Google Scholar] [PubMed]

[CrossRef] [Google Scholar] [PubMed]

[CrossRef] [Google Scholar] [PubMed]

[CrossRef] [Google Scholar] [PubMed]

Citation: Mengistu HS, Haile KT (2023) Cold Chain Management in Ethiopian Pharmaceutical Supply Agency: Study of Hawassa Cluster. J Pharma Care Health Sys. 10:277.

Received: 04-May-2023, Manuscript No. JPCHS-23-23874 ; Editor assigned: 08-May-2023, Pre QC No. JPCHS-23-23874 (PQ); Reviewed: 25-May-2023, QC No. JPCHS-23-23874 ; Revised: 05-Jun-2023, Manuscript No. JPCHS-23-23874 (R); Published: 13-Jun-2023 , DOI: 10.35248/2376-0419.23.10.277

Copyright: © 2023 Mengistu HS, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.