Journal of Ergonomics

Open Access

ISSN: 2165-7556

ISSN: 2165-7556

Research Article - (2017) Volume 0, Issue 0

Objective: The compatibility of human capabilities and limitations, in conjunction with operations and work environment, with the ways of designing machines is dealt within ergonomics. The placement of controls is a complex task for the designer who must take into account the anthropometric characteristics of his target population. The efficiency and comfort of the operator is improved with properly designed tractor workplace.

Design: Study was conducted in which the tractor operator workplace configurations of 5 different tractor models were measured using different measuring scales. The location of different tractor seat and control locations were calculated considering the biomechanical and anthropometric measurements. These values were given as design values for tractor operator’s workplace design. The ergonomic evaluation of workplaces of 5 different tractor models was carried out in laboratory as well as in the field.

Results: Studies on evaluation of the most efficient location of controls resulted in steering column angle of 65° with horizontal, foot pedals (clutch and brake) distance of 87.50 cm and the draft control lever distance of 28.68 cm from Seat Reference Point (SRP).

Conclusion: It was concluded that the values obtained from the different tractor workplace configurations under study should be nearer to design values so that the operator can operate it with efficiently and comfortably.

Keywords: Ergonomics; Workplace; Anthropometrics; Tractor; Drivers

The increasing awareness on the potential benefits of good ergonomic design has resulted in a steady improvement of the operator’s workplace [1-3]. At the same time, though tractorization has reduced the drudgery involved in the farm operations, but it was evident those tractors had ergonomic shortcomings [4-6]. Tractor driver’s comfort and safety needs serious thought as far as his overall performance is concerned. The major factors affecting efficiency of the operator on performance of machinery are workplace layout, noise, vibration, etc. An important factor influencing efficiency in the operation of vehicles is the extent to which the automotive equipment has been designed to meet the human capabilities and limitations [7]. Tractor operator’s safety and comfort, have received considerable attention abroad, particularly, noise and vibration control and operator seating space. All Indian tractor designs are based on foreign designs, with a view of anthropometric data of 95% of the driver population of those countries only. In India however, no substantial effort has been done on this aspect [8].

The placement of controls is a complex task for the designer who must take into account the anthropometric characteristics of his target population. Anthropometric data alone are not adequate for predicting which man can get into and out of the spaces. Additional studies in a representative task are necessary to provide an estimate of the adequate space. If the operator’s controls are not properly adapted to his anatomy, the performance demanded of him may quickly reach and even exceed the limits of tolerance. As a result of excessive stress, premature fatigue and impaired health, the possibility of accidents will increase. Better design of seat and controls resulted reduction in tractor operator effort and stress [4]. Therefore, great emphasis is required to be placed on adopting the operating controls to physical needs of the human operator.

The efficiency and comfort of the operator is improved with properly designed tractor workplace [9-12]. Moreover, there should be uniformity in placement of these controls on various tractors to accommodate the Indian operator population leading to an efficient and comfortable operation. Keeping in view the above aspects of tractoroperator interface an investigation was undertaken with objectives to measure the workplace configurations and to compute most efficient configuration of tractor workplace for Indian tractor drivers by using anthropometric data as well as physiological and subjective aspects.

Study of tractor workplace configurations of different tractor models

The tractor models, which are under production and widely used in India were considered. Different dimensions of existing tractor operator workplace configuration designated as T1, T2, T3, T4, and T5 from tractor model TM1, TM2, TM3, TM4 and TM5 respectively are measured.

Biomechanical model of seated tractor operator

The seated tractor operator modeled as biomechanical model consisting of a relatively small number of straight-line links (representing bones) and joints (representing major articulations). Figure 1 shows such a typical link-joint biomechanical model. The details of different angles notations are as follows.

Anthropometric data of Indian operator

The anthropometric data of randomly selected seven hundred thirty four male tractor operators of Gujarat were collected and used [12]. The locations of controls were determined considering the biomechanical and anthropometric measurements. The comfort angle between links (Table 1), link length (Table 2) and anthropometric data were used to calculate the design values by making use of equations 2.1 to 2.7.

| Body angle | Range, deg | Angle used in design | Comments |

|---|---|---|---|

| Back(θb) | 20-30 | 10 | - |

| Hips(θh) | 95-120 | 95 | - |

| Knee(θk) | 95-136 | 95 | Foot resting on foot rest |

| (фk) | 115 | Foot pedal operation | |

| Ankle(θa) | 90-110 | 90 | - |

| (фa) | 90 | - | |

| Upper arm(θu) | 10-45 | 45 | For steering control |

| (фu) | 10 | For hydraulic control | |

| Elbow(θe) | 80-120 | 120 | For steering control |

| (фe) | 165 | For hydraulic control | |

| Wrist(θw) | 170-190 | 170 | For steering control |

| (фw) | 170 | For hydraulic control | |

| (θsp ) | NA | 3 | - |

| (θls) | NA | 25 | - |

| (θn) | NA | 180 | - |

Table 1: Range of comfort and angle used in design of tractor operator workplace.

| Link | Link length in terms of anthropometric measurement (cm) |

|---|---|

| Forearm link | (Forearm hand length, Lfa-Hand length, Lh) |

| Upper arm link | (Shoulder elbow length, Le) |

| Hand link | (Hand length, Lh x 0.5) |

| Thigh link | (Buttock-popliteal length, Lp x 0.8) |

| Shank link | (Popliteal height, Hp x 0.8) |

| Spine link | (Sitting shoulder height, Hs) |

| Neck link | (Sitting eye height, Heh-Sitting shoulder height, Hs)x 0.5 |

| Foot link | (Foot length, Lf x 0.5) |

Table 2: Length of links in terms of anthropometric measurements.

Design of configuration using different equations and anthropometric data

Design configuration is made based on some equations and anthropometric data of target population including range of comfort angles used in the design of tractor workplace design. It is based on typical link joint biomechanical model of seated tractor operator (Figure 1) which is helpful for hand operated controls, steering wheel and foot operated controls.

Hand operated control: The location of hydraulic control w.r.t. Seat Reference Point is expressed by following expressions:

Horizontal distance from Seat Reference Point (SRP)=(Lfa-0.5 Lh) Sin(фe-фu)+Le Sin(фu)-Hs Sin(θb)+(Lh/2) Sin(фw+фe-фu-π)+0.07Hst (2.1)

Vertical distance from SRP=Hs Cos(θb)-Le Cos(фu)+(Lfa-0.5 Lh) Cos(фe-фu )+(Lh/2) Cos (фw+фe-фu-π)+0.043Hst (2.2)

Where,

Lfa=Forearm hand length, cm;

Hs=Shoulder height (sitting), cm;

Lh=Hand length, cm;

Hst=Stature, cm;

Le=Shoulder elbow length, cm.

Steering wheel: From the geometry of bio-mechanical model given in Figure 1 and considering palm remains parallel to the plane passing through the steering wheel surface. Steering column angle in degrees with the horizontal can be given as:

θsc=θw+180+θe-θu (2.3)

The location of the steering wheel center is expressed by equations:

Horizontal distance from SRP=(Lfa-0.5 Lh) Sin(θe-θu)+Le Sin(θu)-Hs Sin(θb)+(Lh/2) Sin(θw+θe-θu-π)+0.07Hst (2.4)

Vertical distance from SRP=Hs Cos(θb)-Le Cos(θu)+(Lfa-0.5 Lh) Cos(θe-θu)+(Lh/2) Cos(θw+θe-θu-π) +0.043Hst (2.5)

Foot controls: The position angle of the fulcrum (if pedal is hinged) and the maximum force required to operate the pedal are important parameters. An optimum angle between 25º to 35º produces the highest forces. Horizontal location of foot control (brake or clutch) from SRP may be given below as per Figure 1.

Horizontal distance of foot control from SRP=Lp Cos(θsp)+Hp Sin((фk+θsp–π/2)+(Lf/2) Cos(фk+θsp–фa)+0.07 Hst (2.6)

Vertical distance of foot control from SRP=-Lp Sin(θsp)+Hp Cos(фk+θsp–π/2)-(Lf/2) Sin(фk+θsp–фa)+0.043 Hst (2.7)

Where,

Lp=Buttock popliteal length, cm;

Hp=Popliteal height, cm;

Lf=Foot length, cm.

Comparison of existing tractor workplace configurations with design values

A comparison was made between the existing tractor workplace configurations and design values to evaluate the most efficient tractor workplace among the different tractors in India. The values obtained from the different tractor workplace configurations under study should be nearer to design values for higher efficiency and comfort.

Selection of subjects

Three male subjects were randomly selected for the study. The subject should be medically fit to undergo the trails and these should be true representative of the user population. Anthropometric data of selected subject were measured and depicted in Table 3.

| Subjects | Age (Year) | Height (cm) | Weight (kg) |

|---|---|---|---|

| S1 | 51 | 175 | 73 |

| S2 | 56 | 173.5 | 62 |

| S3 | 29 | 174.5 | 58 |

Table 3: Anthropometric dimensions of subjects.

Ergonomic evaluation

Five models of tractor workplace configurations viz. T1, T2, T3, T4 and T5 were studied. An optimum workplace configuration would be one in which the location of the essential tractor controls such as clutch, brake, draft control lever & steering wheel are so located that minimum energy is spent in operation as well as the operator would feel comfortable. For the ergonomic evaluation of workplaces of different tractor workplace configuration, subjects were allowed to drive the different tractor models in field and asked to operate all of the controls for a predetermined period and physiological evaluation was made in terms of heart rate measurement. Three replications were taken and average values were reported here.

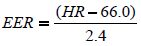

Physiological evaluation: The experiment was carried out with the randomly selected subjects. Each subject was allowed to sit on different tractors and operate the clutch, brake, draft control lever and steering task for 20 min. The initial HR of the subjects S1, S2 and S3 were measured by stethoscope. The heart rate measurements of selected subjects were taken at time t1, t2, t3, t4 and t5 which represent time before tractor operation, after 5, 10, 15 min duration while operating on different tractors and after 5 min rest, respectively. The measurements were replicated thrice for accuracy. Relationship (equation 2.8) between Energy Expenditure Rate (EER) and Heart Rate (HR) was used in this study [13].

(2.8)

(2.8)

Subjective evaluation

The subjective evaluation of the operator’s feelings was also carried out using Borg [14,15] scale and this scale (Figure 1) were presented in front of the operators while they were performing the tasks. They were asked to indicate their scores on the basis of their feeling in a given configuration. The tractor operators were allotted sufficient rest between consecutive tasks. This procedure was followed for each of the tractor workplace configurations under study.

All the measurements and ergonomic evaluation of different tractor workplaces were carried out in the laboratory as well as in the field of Junagadh Agricultural University.

Measurement of tractor workplace configurations

The comparison of dimensions and their mean and coefficient of variation are shown in Table 4. Wide variations are found in the case of dimensions such as steering column angle, position of hydraulic control lever, and horizontal and vertical distance of clutch and brake pedal from seat reference point. The reason of variation is that different company’s manufactures different tractor model of the tractor.

| Sr | Parameters | T1 | T2 | T3 | T4 | T5 | Mean | Cv |

|---|---|---|---|---|---|---|---|---|

| 1 | Steering Wheel | |||||||

| i) Steering column angle from horizontal, deg. | 50.0 | 65.0 | 68.0 | 65.0 | 65.0 | 62.6 | 11.44 | |

| ii) Horizontal distance of steering wheel center from SRP, cm | 60.0 | 69.0 | 68.0 | 45.0 | 74.5 | 63.3 | 18.11 | |

| iii) Vertical clearance of steering wheel center from SRP, cm | 24.5 | 20.0 | 23.0 | 26.5 | 14.5 | 21.7 | 21.52 | |

| 2 | Foot control | |||||||

| a) Clutch | ||||||||

| i) Horizontal distance from SRP, cm | 72.0 | 75.5 | 57.0 | 57.0 | 74.0 | 67.1 | 13.86 | |

| ii) Vertical clearance from SRP, cm | -36.0 | -32.0 | -36.0 | -32.0 | -46.0 | -36.4 | 15.73 | |

| b) Brake | ||||||||

| i) Horizontal distance from SRP, cm | 70.0 | 70.0 | 60.0 | 57.0 | 70.0 | 65.4 | 9.76 | |

| ii) Vertical clearance from SRP, cm | -35.0 | -37.0 | -40.0 | -34.0 | -46.0 | -38.4 | 12.57 | |

| 3 | Foot rest height from SRP, cm | -55.0 | -54.0 | -58.0 | -50.0 | -60.0 | -55.4 | 6.94 |

| 4 | Hydraulic control lever | |||||||

| i) Horizontal clearance from SRP,cm | 33.0 | 28.0 | 28.0 | 31.5 | 28.0 | 29.7 | 8.03 | |

| ii) Vertical clearance from SRP, cm | -21.0 | -22.0 | -18.0 | 7.0 | -23.0 | -15.4 | 82.21 |

Table 4: Placement of tractor operator controls in existing Indian tractors.

Anthropometric data of Indian operator

The anthropometric data were measured and analyzed for 5th, 50th and 95th percentile values (Anon., 2005) and are shown in Table 5.

| S. No. | Dimension | 5th | 50th | 95th | SD |

|---|---|---|---|---|---|

| 1 | Stature | 152.44 | 163.12 | 173.79 | 6.46 |

| 2 | Weight, kg | 39.24 | 55.25 | 71.26 | 9.73 |

| 3 | Grip diameter(inside) | 4.24 | 5.07 | 5.91 | 0.51 |

| 4 | Shoulder breadth | 38.27 | 43.12 | 47.97 | 2.95 |

| 5 | Arm reach from the wall | 76.02 | 83.32 | 90.62 | 4.44 |

| 6 | Shoulder grip length | 63.90 | 77.48 | 70.69 | 4.13 |

| 7 | Foot length | 22.55 | 24.74 | 26.93 | 1.33 |

| 8 | Sitting height | 73.71 | 80.83 | 87.95 | 4.33 |

| 9 | Sitting eye height | 64.39 | 71.24 | 78.08 | 4.16 |

| 10 | Sitting shoulder height | 50.23 | 55.68 | 61.14 | 3.32 |

| 11 | Elbow rest height | 16.18 | 19.61 | 23.05 | 2.09 |

| 12 | Knee height sitting | 44.99 | 50.41 | 55.84 | 3.30 |

| 13 | Sitting popliteal height | 39.49 | 44.11 | 48.73 | 2.81 |

| 14 | Buttock popliteal length | 40.01 | 44.67 | 49.33 | 2.83 |

| 15 | Buttock knee length | 45.59 | 52.82 | 60.04 | 4.39 |

| 16 | Functional leg length | 87.08 | 93.02 | 98.96 | 3.61 |

| 17 | Thigh clearance height sitting | 10.81 | 13.25 | 15.70 | 1.48 |

| 18 | Hip breadth sitting | 27.47 | 32.01 | 36.54 | 2.76 |

| 19 | Shoulder elbow length | 34.05 | 36.07 | 38.09 | 2.33 |

| 20 | Forearm hand length | 41.81 | 45.61 | 49.40 | 2.31 |

| 21 | Hand length | 15.58 | 17.68 | 19.78 | 1.28 |

Table 5: Anthropometric data of male agricultural workers of Gujarat (N=734).

Configuration design using different equations and anthropometric data

Placement of tractor operator controls and seat is presented in Table 6.

| Sl. | Parameters | Design value ( percentile) | Range | ||

|---|---|---|---|---|---|

| 5th | 50th | 95th | |||

| 1 | Steering wheel | ||||

| i) Horizontal distance of steering wheel centre from SRP, cm | 65.94 | 72.33 | 73.21 | 7.27 | |

| ii) Vertical clearance of steering wheel centre from SRP, cm | 44.03 | 48.79 | 55.15 | 11.12 | |

| 2 | Foot control | ||||

| a) Clutch | |||||

| i) Horizontal distance from SRP, cm | 79.10 | 87.65 | 96.17 | 17.00 | |

| ii) Vertical clearance from SRP, cm | -34.03 | -37.82 | -41.59 | 7.56 | |

| b) Brake | |||||

| i) Horizontal distance from SRP, cm | 79.10 | 87.65 | 96.17 | 17.00 | |

| ii) Vertical clearance from SRP, cm | -34.03 | -37.82 | -41.59 | 7.56 | |

| 3 | Foot rest height from SRP, cm | -57.90 | -55.40 | -52.90 | 5 .00 |

| 4 | Hydraulic control lever | ||||

| i) Horizontal clearance from SRP, cm | 26.91 | 28.62 | 30.52 | 3.61 | |

| ii) Vertical clearance from SRP, cm | -14.73 | -14.24 | -15.18 | 0.45 | |

Table 6: Placement of tractor operator controls and seat.

Table shows that the difference in vertical distance of controls for the 5th to 95th percentile tractor operators’ stature varies from a minimum of 0.45 cm (for hydraulic control) to a maximum of 11.12 cm (for steering wheel). Therefore, in order to accommodate the 5th to 95th percentile tractor operator stature, provision of 11.12 (=12) cm vertical and 17 cm horizontal adjustment in seat is desirable. The designed value of steering column angle, 65º is obtained using anthropometric data (Table 7).

| (6) | |

| (7) | VERY, VERY LIGHT |

| (8) | |

| (9) | VERY LIGHT |

| (10) | |

| (11) | FAIRLY LIGHT |

| (12) | |

| (13) | SOMEWHAT HARD |

| (14) | |

| (15) | HARD |

| (16) | |

| (17) | VERY HARD |

| (18) | |

| (19) | VERY, VERY HARD |

| (20) |

Table 7: Subjective scale.

Ergonomic evaluation

Physiological response of the subjects: The Heart rate variations of selected subjects on different tractor models are compared in form of graphs (Figures 2-6). The EER was calculated from equation 2.8 using heart rate and the values are presented in Table 8. It is seen from the data that the mean heart rate values of the subject S1 were 94.00, 79.00, 91.00, 86.00 and 80.00 beats min-1 as the mean in configurations T1, T2, T3, T4 and T5 respectively while for subjects S2 and S3 HR values were 99.33, 94.00, 96.67, 96.67 & 95.00 and 94.67, 91.33, 93.33, 92.67 and 92.00 beats min-1, respectively. These values were used for graphical presentation and shown in Figures 3-7. It may be concluded that the physiological behaviour appears quite similar for subjects S2 and S3 during operating different tractor models, indicating the fact that the subjects experienced identical load conditions. However, subject S1 appeared to have been stressed less than others possibly because his initial resting heart rate was lower.

| S. No. | T1 | T2 | T3 | T4 | T5 |

|---|---|---|---|---|---|

| S1 | 11.67 | 5.42 | 10.41 | 8.33 | 5.83 |

| S2 | 13.88 | 11.67 | 12.78 | 12.78 | 12.50 |

| S3 | 11.94 | 10.54 | 11.38 | 11.11 | 11.11 |

Table 8: EER of subjects on different tractor workplace configurations in kJ min-1.

From the comparison, it is seen that for tractor model T2, all subjects had lower heart rate variation. This result shows that the steering wheel and other controls location in workplace of tractor model T2 are more comfortable and appropriate than that of other models.

Physiological responses of all the three subjects during evaluation of workplace configuration are presented in form of histograms in Figure 7. It is evident that configuration T2 requires minimum energy. It is also apparent that configuration T1 shows maximum physiological effects on the operators and may be due to inefficient location of the controls with respect to SRP.

Subjective response of the subjects: The RPE scores are obtained for location of different controls viz. steering wheel, foot operated controls and hand operated controls on different tractor workplace configurations. Subjective rating of steering wheel of different tractor workplace configurations is shown in Figure 8. It is clear from the figure that the lowest RPE score (very, very light) was obtained for T2 workplace configuration from all the selected subjects. Therefore T2 workplace configuration is most comfortable for steering wheel operation among other tractors studied. The results show that the subjective rating is quite similar for all the subjects for different tractor workplace configurations. It can also be said that the T1 configuration is the most difficult due the highest RPE score (hard) was obtained.

Figure 9 shows subjective rating of foot operated controls of different tractor workplace configurations studied. Shows subjective rating of foot operated controls of different tractor workplace configurations under study. From figure, it is observed that the lowest RPE score (very, very light) was obtained for T2 workplace configuration from all the selected subjects. Therefore T2 workplace configuration is most comfortable for foot operated controls operation among other tractors under study.

Subjective rating of hand operated controls of different tractor workplace configurations is shown in Figure 10. From figure, it is observed that the lowest RPE score (very light) was obtained for T3 workplace configuration from all the selected subjects. Therefore T3 workplace configuration is most comfortable for hand operated control operations among other tractors under study.

The average subjective rating was computed from RPE scores of steering wheel, foot operated controls and hand operated controls for all the tractor workplace configurations under study. It can be concluded that on an average T2 tractor workplace configuration is most comfortable among all the tractors (Figure 11).

Comparison of existing workplace configurations with the design values

The comparison of existing tractor workplace configurations with the most efficient workplace configuration was made and presented in Table 9. Table indicates that the steering column location of the existing tractor models needs to be shifted by -15.0°, 0.0°, +3.0°, 0.0°, and 0.0° with respect to the configurations T1, T2, T3, T4, and T5, respectively. Further, foot pedal and draft control lever locations need to be shifted; the clutch pedal by -15.5, -12.5, -30.5. -30.5, -13.5 cm; the brake pedal by -17.5, -17.5, -27.5, -30.5, -17.5 cm; and the draft control lever by +4.32, -0.68, -0.68, -2.82, and -0.68 cm, respectively for the tractor configurations T1, T2, T3, T4 and T5. Figure 12 shows the most efficient workplace configuration based on this study.

| Sr. No. | Control Locations | Tractor workplace Location a | |||||

|---|---|---|---|---|---|---|---|

| T | T1 | T2 | T3 | T4 | T5 | ||

| 1 | Steering column angle, degree | 65 | 50.0 (-15.0) | 65.0 (0.0) | 68.0 (+3.0) | 65.0 (0.0) | 65.0 (0.0) |

| 2 | Clutch pedal location, cm | 87.5 | 72.0 (-15.5) | 75.5 (-12.5) | 57.0 (-30.5) | 57.0 (-30.5) | 74.0 (-13.5) |

| 3 | Brake pedal location, cm | 87.5 | 70.0 (-17.5) | 70.0 (-17.5) | 60.0 (-27.5) | 57.0 (-30.5) | 70.0 (-17.5) |

| 4 | Draft control lever location, cm | 28.68 | 33.0 (+4.32) | 28.0 (-0.68) | 28.0 (-0.68) | 31.5 (+2.82) | 28.0 (-0.68) |

Table 9: Comparison of existing tractor workplace configurations vs design values.

The tractor workplace configurations vary widely in the case of dimensions such as steering column angle, position of hydraulic control lever, and horizontal & vertical distance of clutch and brake pedal from Seat Reference Point. The reason of variation is that different companies manufacture their own models and there is no consideration of anthropometric data of Indian population. Studies on evaluation of the most efficient location of controls resulted in steering column angle of 65º with horizontal, foot pedals (clutch and brake) distance of 87.5 cm from SRP and the draft control lever distance of 28.68 cm from SRP for Indian operators based on anthropometric data and biomechanical model. The values obtained from the different tractor workplace configurations under study should be nearer to design values so that the operator can operate it with efficiency and comfort. From the comparison, made between existing workplace configurations and most efficient configuration (design values), T2 is concluded as superior to other configurations studied. This result is in match with the ergonomic evaluation, in which the minimum Energy Expenditure Rate and minimum Rated Perceived Exertion score were obtained for T2 configuration.

θa: Ankle angle for foot resting on foot rest, degree.

фa: Ankle angle for foot resting on undepressed clutch/brake, degree.

θb: Back angle from vertical, degree.

θc: Elbow angle for operation of steering wheel, degree.

фc: Elbow angle for operation of draft control lever in lowest position, degree.

θk: Knee angle for foot resting on foot rest, degree.

фk: Knee angle for foot resting on undepressed clutch/brake pedal, degree.

θu: Upper arm angle from vertical for steering wheel operation, degree.

фu: Upper arm angle from vertical for draft control lever in lowest position, degree.

θsp: Seat pan angle from horizontal, degree.

θw: Wrist angle for steering wheel operation, degree.

фw: Wrist angle for draft control lever operation in lowest position, degree.

θn: Angle between neck and spine links, degree.