Journal of Ergonomics

Open Access

ISSN: 2165-7556

ISSN: 2165-7556

Research Article - (2023)Volume 13, Issue 3

The limited scope of geological exploration of offshore fields is the reason for the high structural uncertainty in any traps. The lack of a complete set of initial information for well construction requires an innovative approach to planning, drilling and well support. Geosteering can significantly improve the quality of the horizontal section borehole drilling and is an opportunity to obtain actual data from the bottomhole. Drilling support allows to quickly make adjustments to the well trajectory due to changes in the geological conditions. Based on the geological drilling support experience at the analyzed offshore field, in general the reasons classification for operational adjustments taken during drilling was created. The most common reasons for changing the planned trajectory and the results of decisions are noted. The analyzed field is complicated by faults, has lateral variability of both reservoir properties and lithological composition. This is the reason for the high percentage of possible risks and uncertainties limiting the quality of well placement. Based on this, the specialists of the geological drilling support issue erroneous corrections. This article analyzes the cases of erroneous changes in the well trajectory; the logic of the decisions made based on the interpretation of data from the bottomhole and considers their consequences.

Geological exploration; operational adjustments; geosteering

Well geosteering in the offshore fields

The structure of the offshore field has conditions of high uncertainty due to the limited scope of geological work, and, as a result, insufficient knowledge of the developed geological object. This requires an innovative approach for planning, drilling and well tracking [1]. Geosteering of horizontal wells allows the positioning of the horizontal wellbore in accordance with the technological, operational and geological constraints associated with the entire construction cycle of the well [2].

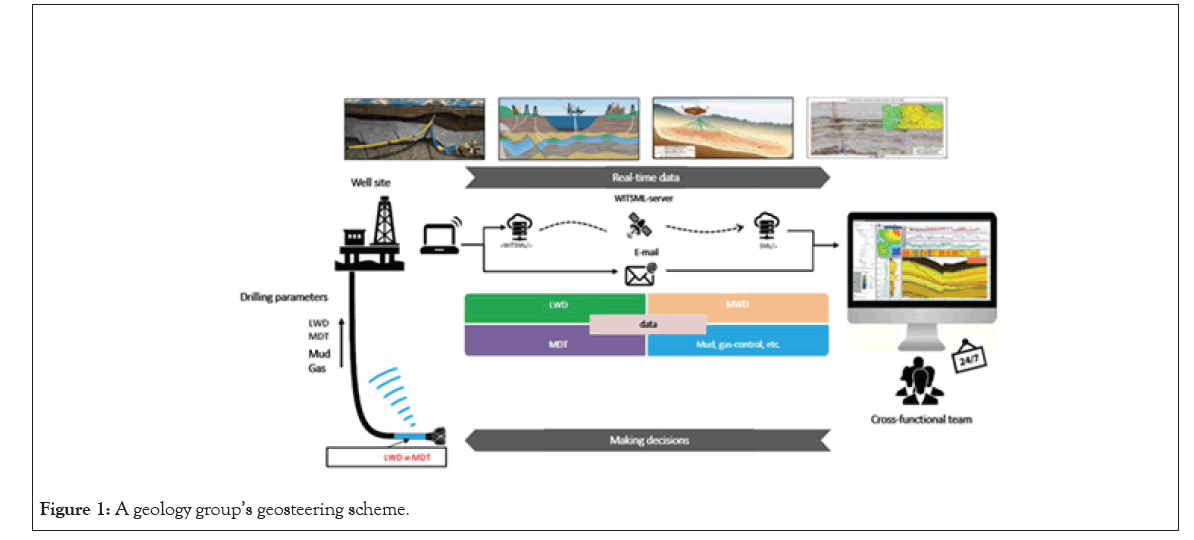

The drilled deposit is located on the territory of the Caspian Sea. A total of 3 reference wells were drilled during the exploration work. Drilling planning and well design was carried out with limited direct information. 3D seismic exploration and geological models were built on the basis of the obtained data. Drilling at the field is provided by using special devices in the bottom hole assembly that transmit information from the bottom hole during drilling and allow solving the set tasks. The study and analysis of the data of the reporting information on the geological support of drilling allows us to identify the reasons and the number of adjustments made during drilling of wells (Figure 1).

Figure 1: A geology group’s geosteering scheme.

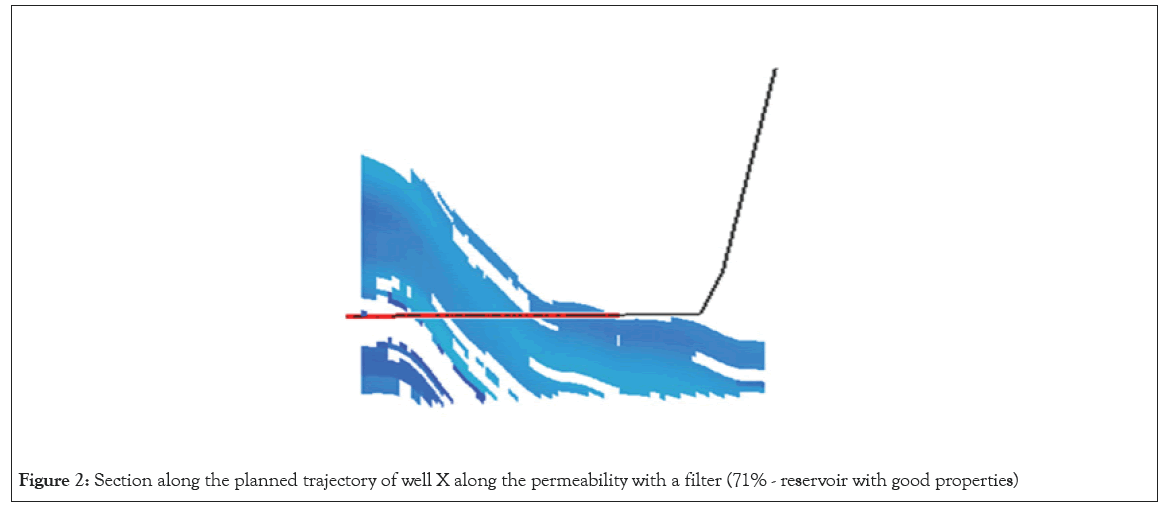

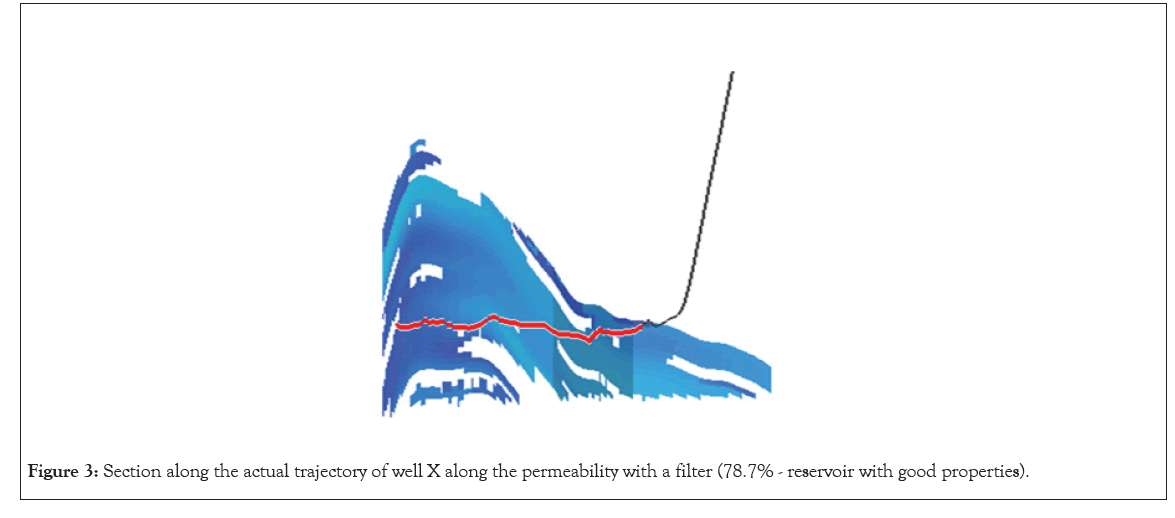

In order to analyze the development indicators, the planned and actual trajectory of the well X was compared in a hydrodynamic simulator. In the process of drilling the well, the preliminary structures, formation dip angles of the formation were not confirmed, and complications appeared that became the reason for changing the planned trajectory. According to the loaded trajectories, it can be seen that there are differences in the planned and actual trajectories, but they are not so colossal. However, it was these changes that made it possible to increase the penetration through the reservoir, and as a result, oil and gas production, without opening the oil-water zone, reduced water production. The results of comparing the actual and planned trajectory penetration along the reservoir are shown in Figures 2 and 3.

Figure 2: Section along the planned trajectory of well X along the permeability with a filter (71% - reservoir with good properties)

Figure 3: Section along the actual trajectory of well X along the permeability with a filter (78.7% - reservoir with good properties).

Figures 2 and 3 shows the range of permeability values above 100 mD. Filter the values from 0.01 to 100 mD and calculate the percentage of the reservoir. When analyzing real production data, drilling with geological support of the well made it possible to increase the penetration through the reservoir, avoid emerging complications and achieve drilling goals. Thus, geological support geosteering allows making operational decisions in order to increase the efficiency of well drilling in conditions complicated by geological uncertainties, as well as to understand the position of the wellbore relative to geological boundaries.

Recommendations for trajectory changes, changes of the azimuthal, inclination angle are based on information obtained from the bottom hole. The ability to obtain data from gamma logging, resistivity logging, variable density logging, neutron logging, and density image from the bottom hole in real time is provided using devices included in the bottomhole assembly [3,4].

Modern equipment for ultra-deep mapping, which is part of the (BHA) Beta Hydroxy Acids, also allows us to determine the position of the stratigraphic horizons. The principle of operation of the device is to provide a wide range of directional electromagnetic measurements. The bottomhole assembly contains a source and two receivers of the electromagnetic field. The ultra-deep radius of the study is provided by a significant distance between the source and the receivers, as well as the use of low operating frequencies. When processing data, the inverse two-dimensional problem is solved by inverting electromagnetic measurements [5, 6].

Decisions aimed at correcting the well trajectory and understanding the occurrence of the reservoir structure are based on the analysis and interpretation of the density image data. To assess the quality of filtration and reservoir properties logging data is used. Decisions regarding the operational section are made based on the correlation of gamma logging and resistivity logging with neighboring wells. When creating a basic version for the trajectory of a horizontal wellbore, artificial logging is calculated, on the basis of which assumptions about the structural occurrence of productive layers are made, markers are identified, and the approximate lithological composition is determined. [7- 9]. Based on the results of the analysis of the reporting data on the support of drilling of 20 horizontal wells of 6 sidetracks at the offshore field X, the reasons that became the basis for changing the planned trajectory were determined. Table 1 shows the reasons for the adjustments and their total number for the stock of analyzed wells (Table 1).

| Reasons of well trajectory adjustments | Quantity |

|---|---|

| Retention of the reservoir interval with improved of filtration and reservoir properties | 83 |

| Changing the angle of the structure (flattening of the structure, growth or fall of the structure) | 37 |

| Holding the drilling trajectory in a certain part of the reservoir | 34 |

| Minimization of penetration through shale barrier and compaction interlayers/rocks | 22 |

| Increase in penetration through the productive reservoir | 17 |

| Revised structure of the productive reservoir, opening of the full geological section | 11 |

| Prevention of the risk of a tectonic fault or the intersection of a disjunctive dislocation | 6 |

| Prevention of the exit to a low permeability interval | 6 |

| Opening of the OWC or opening of the oil-saturated zone above the OWC, bypassing the gas cap | 6 |

| The discrepancy between the expected and actual of filtration and reservoir properties of the reservoir, the search for the reservoir | 3 |

| Intersection of the unstable interval | 1 |

Table 1: Reasons and number of well trajectory adjustments. This table shows the reasons for the adjustments and their total number for the stock of analyzed wells.

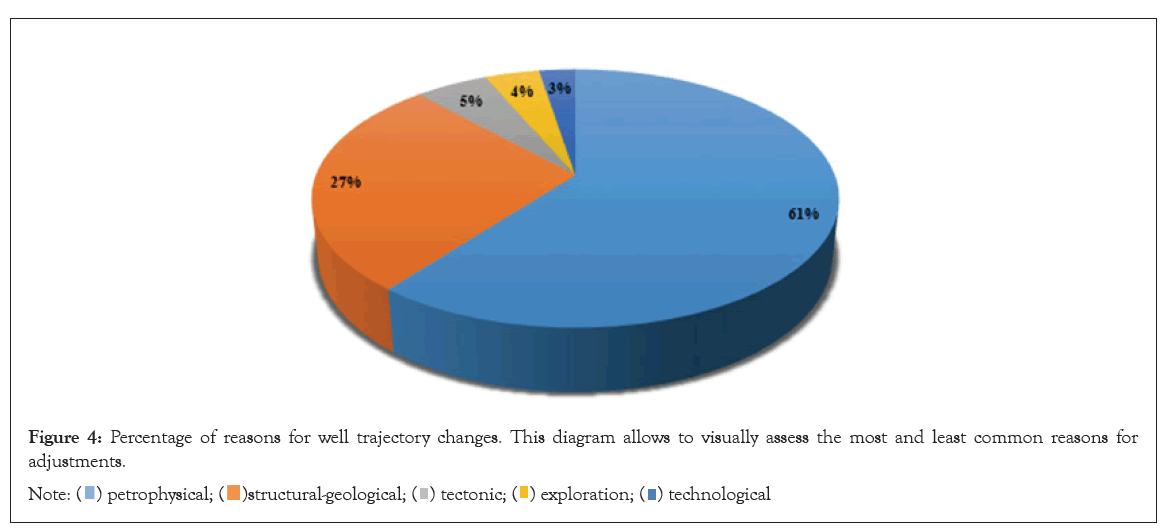

The obtained data are the basis for creating a general classification of the accepted adjustments. Arrange them in descending order depending on the frequency of manifestation. Thus, petro physical, structural-geological, tectonic, exploration and technological adjustments can be distinguished. According to the statistical analysis of the geological support of drilling of field X, the main reason for the change of the planned trajectory is the placement and retention of the trajectory in the reservoir interval with improved filtration and reservoir properties, as well as a decrease in penetration through clay and compaction interlayers. These changes are aimed at increasing the penetration through the reservoir (Figure 4).

Figure 4: Percentage of reasons for well trajectory changes. This diagram allows to visually assess the most and least common reasons for

adjustments.

Logging methods during drilling do not allow predicting the approach to nonuniformity zones in advance. Any change in the geological situation can be registered, and as a result, interpreted only after its direct intersection. The uncertainties that occur during the construction of wells at this field are constant changes in the angles of occurrence of the structure, lateral changes in both the lithological composition of rocks and filtration and reservoir properties. It should also be noted that the field is complicated by the presence of disjunctive dislocation, which are not distinguished according to seismic data. In addition, in the process of drilling a well, there are situations when drilling takes place in the interval of interbedding of the reservoir with compacted layers, then determining the angle of the structure by the density image becomes difficult. The absence or poor-quality data of any logging as a result of malfunctions becomes the cause of poor-quality petrophysical interpretation of data. This causes erroneous adjustments to be issued by drilling support specialists. Thus, the resulting general classification of decisions made to change the trajectory of the well should be divided into two categories. Solutions that allowed to increase the penetration through the reservoir, to fulfill the set targets before drilling and erroneous decisions that require subsequent changes.

Analysis of cases of making erroneous decisions

According to the fund of drilled wells and sidetracks at the offshore field, it was statistically revealed that the total number of agreed and accepted adjustments is 226, of which 18 adjustments were erroneous, which is 7.9 %.

Before proceeding to the consideration of the logic of decisions made when introducing erroneous adjustments in the drilling process, it is worth noting that the wells in question are introduced for the purpose of developing hydrocarbons, as well as for the purpose of additional exploration of parts of the field. Which initially implies an increased percentage of possible uncertainties related to the structure’s occurrence, lithological composition and reservoir properties.

Before drilling a well, the basis for engineering a planned trajectory is a structural model of the target interval, which is constantly updated based on the results of already drilled wells. When planning of well, the distance to the (OWC) Oscillating water column is calculated, the estimated angles of occurrence of the structure are noted, synthetic logging is issued based on the correlation of reference and neighboring wells.

In order to introduce into development of the hydrocarbon reservoir of the western part of the field into development, with the subsequent transfer of the well to the injection fund, a well was drilled X. When drilling the horizontal section, one of the erroneous adjustments was issued in order to evenly open the Neocomian stage at full capacity, it was agreed to continue drilling at an angle of 87-87.5°. However, drilling continues in the upper siltstone pack with density readings up to 2.4-2.5 g / cm3. The angle of the structure in this interval was estimated at 1.8° of incidence in the azimuth of drilling. During drilling, it was found that the structural angle reaches 2-2.3° of incidence. At this depth, it was decided to continue drilling at an angle of 86-86.5° in order to quickly enter the interval of a good collector of the first bundle of the Neocomian stage.

In order to introduce into development of the hydrocarbon reservoir, as well as to clarify the geological structure of the eastern part of the field, the main borehole of a horizontal well was drilled X. In order to return to the improved poro-perm properties range as soon as possible during the construction of the horizontal section, it was recommended and decided to continue drilling with a zenith angle of 92°. According to the logging data, the best reservoir properties interval is located in the preroofed part of the surface of the second formation member. The structural angle of the formation member was estimated at 0.5-1°. Therefore, drilling continued with a set of angles, which led to an exit into the top of the formation, the structural angles were not confirmed.

In order to introduce into development of the hydrocarbon reservoir, as well as to clarify the geological structure of the northern slope of the eastern part of the field, a horizontal sidetrack was drilled X. Drilling of the initial borehole interval took place according to the initial trajectory plan with a zenith angle of 91°. Further, an increase in the density along the upper quadrant was noted, which indicated the presence of a dense interlayer on top of the BHA. In order to drill parallel to the stratification and not intersect this layer from bottom to top, a recommendation was agreed to continue drilling with a zenith angle of 89. During further drilling, a decrease in the rate of bit penetration was observed, which indicated a deepening into compact rocks. In order to escape from compact rocks, it was decided to continue drilling with a reset of the zenith angle to 87°.

The main purpose of geosteering during drilling of sidetrack X at the field was the well targeting of the horizontal section of the hole within the Neocomian stage. In the process of supporting the construction of the well, the roof of the second formation member was opened ~3 m deeper than expected. In this regard, a recommendation was agreed to hold up the scored inclination angle of 85°. The recommendation to set the zenith angle to the design values was planned to be issued after confirming the bottom of the second formation member according to LWD operation. The bottom of the second formation member of the Neocomian stage was confirmed by LWD at a depth that is ~0.5 m lower than expected according to the initial structural model. Accordingly, a recommendation was agreed on the set of the zenith angle for the purpose of flattening of the structure within the third target formation member of the Neocomian stage. The borehole crossed the roof of the third formation member. There was a significant reduction in the capacity (by more than 3 meters) of the shale barrier between the second and third formation member. In this regard, drilling continued according to the planned trajectory until the correction.

The basis for the uncertainty analysis is a geological model built on the basis of structural surfaces, in which the model is prepared on the basis of reference and neighboring wells. As a rule, before drilling, a list of possible uncertainties is determined based on the level of drilling of the site, the quality of the correlational relationship and the data obtained. The most common reason for issuing an erroneous correction is precisely the errors of the angles of the structural occurrence of the formation. After the intersection, recommendations are issued for changing the zenith angle/azimuth based on the density image data, when characteristic structures appear, which are markers that drilling is taking place up/down the section, and also provide an opportunity to determine the actual occurrence of the structure.

The result of an incorrect assessment of the data on the occurrence of the structure, as a rule, is the well targeting of the hole trajectory along shale sections of the reservoir, cap rock or intervals with degraded reservoir properties.

The main purpose of geosteering during drilling of the sidetrack X at the field was the well targeting of the horizontal section of the borehole within the Neocomian stage. From a further depth along the borehole, a gradual exit into the roof part of the reservoir is observed. The angle of incidence of the structure was estimated to be up to 1.5°. In order to move away from the roof of the third formation member, an adjustment was agreed on the reset and retention of the inclination angle of 87°. After moving away from the roof of the first formation member, the borehole crossed a number of compacted interlayers with unconformable occurrence. In order to gradually approach the bottom of third formation member, an adjustment was agreed to set the zenith angle to 88°. During the drilling process, the borehole entered the shale barrier between the third and fourth formation member. According to the correlation and the density image, the angle of incidence of the formation is estimated at 0.5°. In order to reduce the penetration of unproductive shales, an adjustment was made to reset and hold the zenith angle to 86° before crossing the roof of the fourth formation member. In the next interval along the wellbore, the lower sector of the density image is determined by a shale layer, interpreted as the bottom of preroofed part of the fourth formation member. The recommendation is to continue drilling with a zenith angle of 90.5° and then with a zenith angle of 91° in order to return the wellbore to the improved reservoir interval. However, siltstones and further shale were opened by the sidetrack, which is interpreted as the lower part of the shale barrier between the fourth and third formation member. A recommendation was issued to set the zenith angle to 92° in order to return the sidetrack to the interval of the reservoir of the third and then the second formation member.

In order to introduce into development of the hydrocarbon reservoir, maintain reservoir pressure, as well as clarify the geological structure of the eastern part of the field, a well was drilled X. During well targeting of the horizontal section, the structural angle flattens. According to the initial model, up to 0.5° of fall was expected at these depths, it was decided to continue drilling with a set and retention of the zenith angle of 90°. During further drilling, according to the density image data, drilling was noted subparallel to the stratification, since the lower sensor recorded drilling parallel to the compacted layer. In order to detect an improved poroperm properties reservoir, it was decided to continue drilling at an angle of 89°. However, drilling still continued in the rocks represented by the interlayering of sand and compacted rocks. The structural angle according to the inversion and density image data is estimated at 0.5-1° of incidence. In order to search for an improved reservoir, it was agreed to continue drilling with a zenith angle of 87°. When passing through the borehole, the BHA was repelled from the compacted interlayer, the zenith angle increased from 87 to 89.5. Due to the growth of the zenith angle, it was decided to establish a trough downwards in order to cross the compacted interlayer and enter the underlying high-resistance zone. The establishing a trough allowed to reset the zenith angle from 89.55 to 89.42.

The peculiarity of the geological structure of this deposit is that, according to seismic analysis, it is complicated by a system of tectonic dislocation. In the process of drilling planning, discontinuous faults are taken into account on the existing geological model, but the field also includes the presence of fracture zones and discontinuous faults, which are difficult to recognize according to seismic data.

In order to introduce hydrocarbon reserves into development, as well as to clarify the geological structure of the eastern part of the field, a horizontal well was drilled X. Drilling of the horizontal section was complicated by the expectation of crossing a disjunctive dislocation. During further drilling after 700 m, the opening of the fault was interpreted by a sharp change in the well-logging curves and the characteristic structure on the density image. Two versions were put forward in which the block offset is 3 m or 13 m. It was decided to continue drilling according to version 1 in order to further assess the situation. During further penetration, an increase in resistances was not noted, but relatively low density values, average gamma ray values were detecting. Gas indications increased, which could mean drilling in the first formation member. In order to avoid a quick reservoir penetrating of the productive layer of the presumptive first formation member, a set of the zenith angle to 91° was agreed. As the logging was received, stable readings were noted, but such values were not observed in any reference well in the first formation surface, but were observed under Marker 1. In this regard, the adjustment has been canceled and further drilling is recommended to continue according to version 2.

In order to introduce into development of the hydrocarbon reservoir in the eastern part of the field, a horizontal borehole was drilled X. When drilling the borehole according to the density image and geophysical exploration data, there is an intersection of a disjunctive dislocation with a fault throw of ~63 m, which was estimated based on the intersection of the roof of the first formation member and the angle of occurrence of the structure. According to the characteristic behavior of gamma ray, density and neutron porosity, the roof of the first formation member of the Neocomian stage was taken down. The angle of occurrence of the structure was estimated to 4-5° of growth in the direction of drilling. Drilling continued with the retention of the zenith angle of 89-89. 5°. In order to quickly cross the first formation member and the location of the borehole in the reservoir of second formation member, an adjustment was agreed on the discharge and stabilization of the zenith angle of 87°. However, during this adjustment, a disjunctive dislocation was crossed, with amplitude of ~10 m vertically. And there is an intersection of shale barrier, characteristic of the roofing part of the third formation member. In order to locate the well in the reservoir of the second formation member, an adjustment was agreed on the azimuth reversal with an intensity of 2°/30 m for 200 m.

In order to introduce the axial part of the field into the development of hydrocarbon reserves, a sidetrack of the well was drilled X. Drilling continued in the interval of a relatively homogeneous reservoir of the first formation member with better filtration and reservoir properties. The trajectory with the agreed adjustment is accepted for the work. Drilling continued down the section, in the reservoir of the second formation member of the Neocomian stage with the retention of the zenith angle of 85.5°. After sinking by well 100 m along the borehole, there was an abrupt change in the gamma ray, density and resistances curves, which was interpreted as the intersection of a disjunctive dislocation. Intensive drilling mud losses was noted. The lifting of the BHA was carried out to prevent an accident, but this did not lead to a positive result, as a result of which it was decided to install a cement plug and drill the second sidetrack.

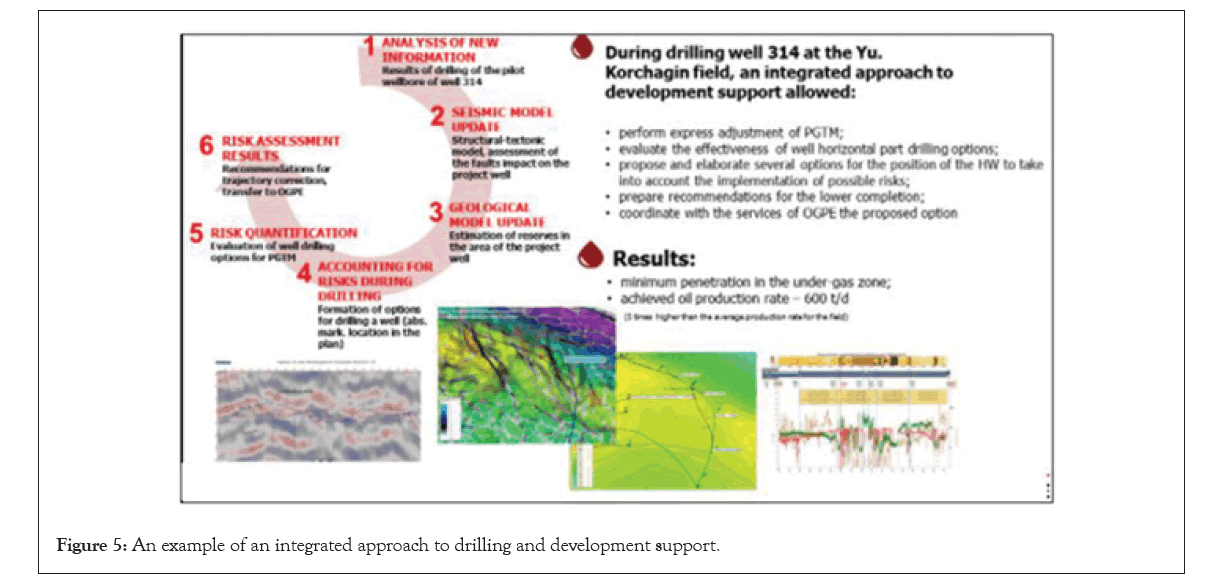

Thus, the presence of faults that are not determined by the seismic survey data, due to its low resolution, complicate drilling. [2] When designing the trajectory, it is necessary to most accurately assess possible risks and uncertainties, as well as have alternative ways to solve them and ways to improve the well position in the reservoir and avoid complications during drilling. It is worth noting that erroneous adjustments when accompanying drilling help to clarify the structural occurrence of formations, the location of faults and their amplitudes. The actual data obtained during drilling allows to update the geological model and take this information into account for the design of new wells (Figure 5).

Figure 5: An example of an integrated approach to drilling and development support.

The consequence of poor communication is a decrease in the effectiveness of the project:

Sub-optimal decision-making at individual stages of implementation; Untimely decision making; Lack of integration of work performed by different services; High variability of technical and economic parameters. Application of cross- functional integration everywhere from geological support of drilling to issuing operational recommendations on operating modes to increase involved reserves and rational development of resources divers.

The authors have no conflicts of interest to declare regarding this manuscript and the work it describes.

[Google Scholar] [PubMed]

Citation: Polyakov D, Diana A (2023) Analysis of the Experience of Geosteering and Making Erroneous Decisions at Offshore Field. J Ergonomics.13:351

Received: 01-May-2023, Manuscript No. JER-23-22384; Editor assigned: 04-May-2023, Pre QC No. JER-22-22384(PQ); Reviewed: 18-May-2023, QC No. JER-23-22384; Revised: 26-May-2023, Manuscript No. JER-23-22384 (R); Published: 02-Jun-2023 , DOI: 10.35248/2165-7556.23.13.351

Copyright: © 2023 Polyakov D, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.