Research Article - (2025)Volume 14, Issue 1

Revolutionizing Wheelchair Cum Bed Functionality: A Novel Design Integrating Mechanical and Electrical Features for Enhanced Mobility and Multifunctionality

Safaa Najah Saud Al-Humairi*Abstract

This project aims to enhance the functionality of wheelchairs beyond their conventional purpose of facilitating mobility for individuals with disabilities. While wheelchairs serve as crucial aids in moving people from one location to another, their utility has been traditionally limited to this aspect. In response, this study proposes a novel wheelchair design incorporating mechanical and electrical features to broaden its scope. The integration of a rotation motor and a 5-pin switch forms the core of this innovative system, enabling a transformative mechanism that seamlessly converts the wheelchair into a multifunctional bed. The proposed design offers a swift transition, requiring only a few seconds to convert the wheelchair into a bed. By introducing this adaptive feature, the wheelchair can serve dual purposes, functioning not only as a means of transportation but also as a bed, thereby enhancing the overall versatility and utility of wheelchairs in supporting individuals with disabilities

Keywords

Wheelchair; Cum bed; Disability; SDLC

Introduction

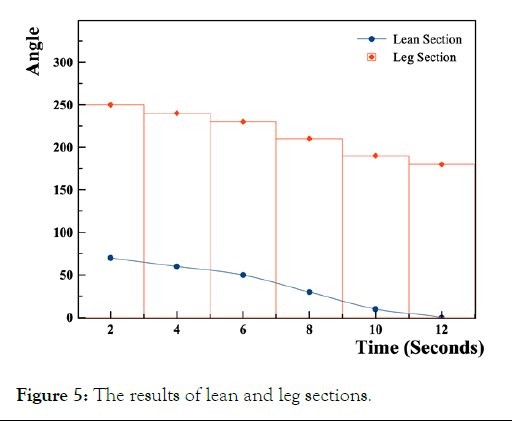

Globally, an estimated 75 million individuals with disabilities necessitate wheelchairs, yet only 5–15 percent possess one. To address this gap, the International Society of Wheelchair Professionals (ISWP) strives to integrate wheelchair service education into rehabilitation programs worldwide. This study examines the global landscape of wheelchair service provision education within academic rehabilitation services, investigating integration processes, associated facilitators and obstacles. The aim is to inform the development of strategies enhancing integration [1]. The World Health Organization (WHO) predicts a one percent wheelchair need within a population or ten percent for individuals with disabilities. In Tajikistan, this suggests around 80,000 people require wheelchairs among a population of eight million. Discrepancies exist in reported numbers, highlighting a lack of reliable data on future mobility device users. Assistive technologies encompass wheelchairs, exoskeletons and walking devices, addressing the pressing need for improved autonomy and reduced caregiver dependency among older adults [2-5]. As an indispensable aid for mobility impaired individuals, the wheelchair has evolved to meet diverse patient needs. Recent advancements in robotics, artificial intelligence, and sensor technology have paved the way for the development of an automatic wheelchair cum bed, offering enhanced independence for bedridden patients [6-8]. Motorized wheelchairs, driven by electric motors, have significantly improved the quality of life for those with mobility impairments, with recent innovations focusing on user-friendly controls and enhanced vehicle aptitude[9,10]. In the pursuit of advancing assistive technologies, the creation of the smart wheeler-a smart robotic wheelchair equipped with cameras, on-board computing, Wi-Fi and autonomous navigation features-aims to empower individuals with mobility disabilities in various environments. However, studies reveal user dissatisfaction with both direct operation and complete autonomy due to various physical and cognitive challenges [11,12]. Conventional fixed-frame manual wheelchairs may pose a risk of tipping when traveling on sloped and uneven surfaces, especially for inexperienced users. The risk is higher for wheelchair users with higher wheeling speeds and when encountering larger obstacles. The top three self-reported causes of wheelchair-related accidents are inexperience, uneven surfaces, and obstacles. To reduce the risk of tipping, it is recommended to lower the seat as far as possible, if thewheelchair includes this function, for downhill wheeling. Additionally, training wheelchair users to effectively navigate obstacles during downhill wheeling, including by adjusting their wheeling speed for different obstacles, is crucial. For controlled wheeling over higher obstacles, users may be required to slow down. User movements, such as balancing in a wheelie, could also be used in addition to configuration changes and speed to further improve downhill stability over bumps. The primary objective of this project is to expand the functionality of wheelchairs beyond conventional mobility assistance for individuals with disabilities. This goal is achieved by designing a new form of wheelchair that incorporates additional mechanical and electrical features. The central components of this innovative system include a rotation motor and a 5-pin switch, facilitating a transformative mechanism capable of converting the wheelchair into a bed cum. Remarkably, this design boasts a swift transition, requiring only a few seconds to seamlessly change the wheelchair into a bed. Consequently, the wheelchair serves a dual purpose, functioning not only as a means of transportation but also as a bed, aligning with the modern demand for multitasking and time efficiency. Notably, the production of this prototype emphasizes the significance of time utilization. Graphically depicted, both the leg section and the lean section exhibit uniform time intervals, ensuring a quick transition to a complete bed with a 180-degree angle in just 12 seconds.

Materials and Methods

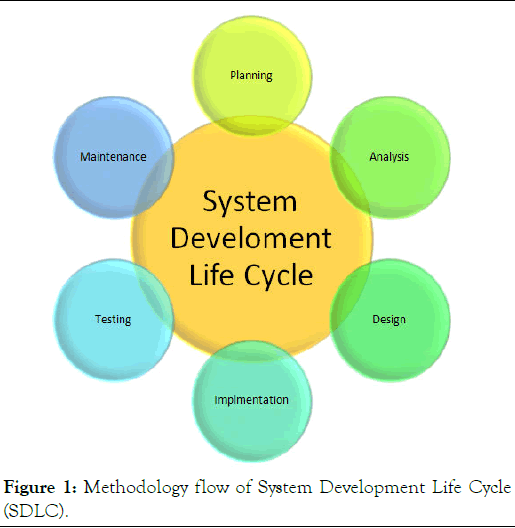

The project adhered to the disciplined approach of the System Development Life Cycle (SDLC) methodology, as depicted in Figure 1. SDLC is a systematic process for planning, developing, implementing and supporting new systems or modifying existing ones. It involves the creation of modules and methodologies to enhance or initiate information systems. This structured methodology ensures that each phase of the development process is executed sequentially, devoid of overlaps or iterative phases. The use of SDLC not only provides a framework for systematic progression but also ensures the efficient and organized creation or modification of information systems, contributing to the project's overall success.

Figure 1: Methodology flow of System Development Life Cycle (SDLC).

Planning

The first stage of the project is to focus on wheelchairs that can accommodate beds. So the main purpose of this stage is to identify the causes of problems that will emerge when the project is run. So that if a problem occurs during the project, it can be resolved immediately because the plan to overcome each problem has been planned. The implementation is to study the background of the project and apply some improvements to improve the weaknesses in the study conducted previously. In this case, it is to enhance the functionality of wheelchairs by incorporating mechanical and electrical features.

Analysis

The second step of this project is the analysis stage. At this stage, the analysis will be narrowed down only to more accurate studies or those pertaining to the project to be implemented later. This includes studying and collecting information from the research obtained so that it can further strengthen the planning before the project is developed. Collect detailed requirements for the new wheelchair design, focusing on the integration of a rotation motor and a 5-pin switch for the transformative mechanism.

Design

In the third step, the design process is carried out, taking into account some form of project from previous studies. This includes the development of mechanisms that contribute to a more robust design and are able to withstand sufficient loads. Develop a detailed design for the new wheelchair system, outlining how the rotation motor and 5-pin switch will be integrated into the wheelchair to facilitate the transformation into a bed.

Testing and implementation

In this phase, the project development was carried out by focusing on the mechanism so that the wheelchair is parallel when turning into a bed and when the project is fully completed, the data collection process of the weight of the load that can be accommodated and the time for the wheelchair to turn cum bed is recorded. Test individual components, such as the rotation motor and 5-pin switch, to ensure they function as intended.

Development methodology

The development process of the wheelchair cum bed involves a systematic approach, beginning with the evaluation of load carrying capacity to ensure optimal design. Following this, meticulous consideration is given to the selection of metal material and the type of steel, aligning with the specific load requirements for the wheelchair cum bed. The subsequent phase encompasses the initiation of fabrication, where the identified design is translated into a robust framework capable of withstanding the intended load. Upon the successful completion of fabrication, the focus shifts towards the selection of appropriate electrical and electronic materials. The emphasis is placed on the capabilities of electrical devices, ensuring compatibility with the envisioned functionality. Rigorous evaluation and finalization of the chosen electrical materials follow. With the requisite materials secured, the wiring phase commences, adhering to the original project design to enable the seamless functioning of the planned mechanism. Once the wiring is successfully implemented and aligns with the project specifications, the measurement and fabrication of the mechanism are undertaken in accordance with established guidelines.

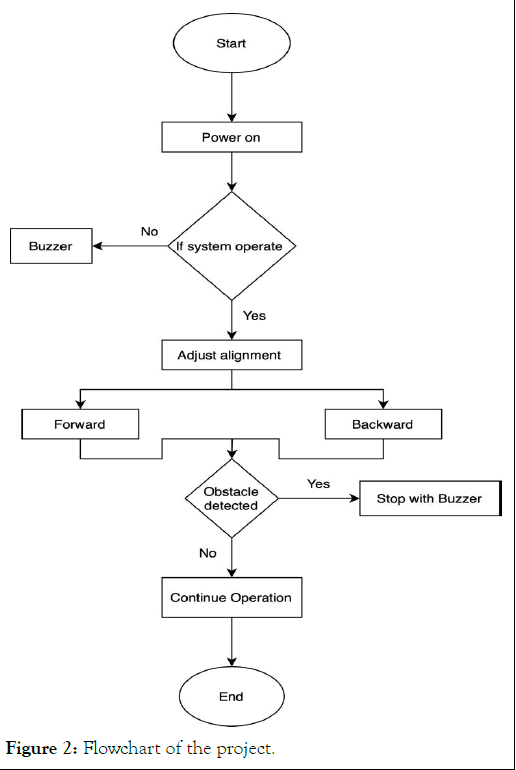

Subsequently, the installation of electrical components and key mechanisms, pivotal to the project, is finalized. The concluding phase involves meticulous finishing work to ensure the project is executed with precision. The culmination of these steps results in a fully functional wheelchair cum bed, depicted in the project flow chart illustrated in Figure 2. This comprehensive process underscores our commitment to delivering a reliable and efficient product.

Figure 2: Flowchart of the project.

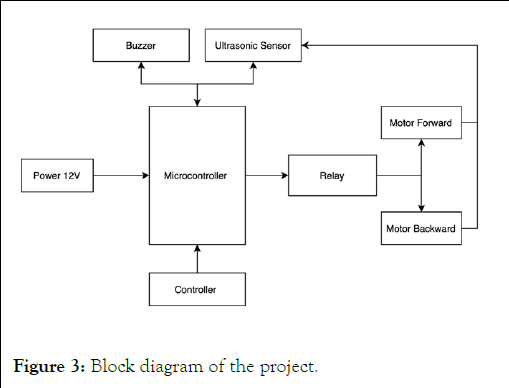

Figure 3 shows the block diagram of the designed system, which consisted of a 12V battery used as a source of power for the 5 pin switch. The switch then supplies the power to the rotation motor and will also command the rotation motor to rotate either counterclockwise or clockwise of the mechanism. A buzzer is a component that is used to provide feedback if an obstacle is interfaced with or triggered by the ultrasonic sensor. A microcontroller of an Arduino UNO was used to control all the other components including processing inputs from sensors and sending commands to actuators. The controller allows the device to be controlled remotely, providing flexibility and convenience. The microcontroller processes the sensor data and sends commands to the motors to move the device in the appropriate direction.

Figure 3: Block diagram of the project.

Results and Discussion

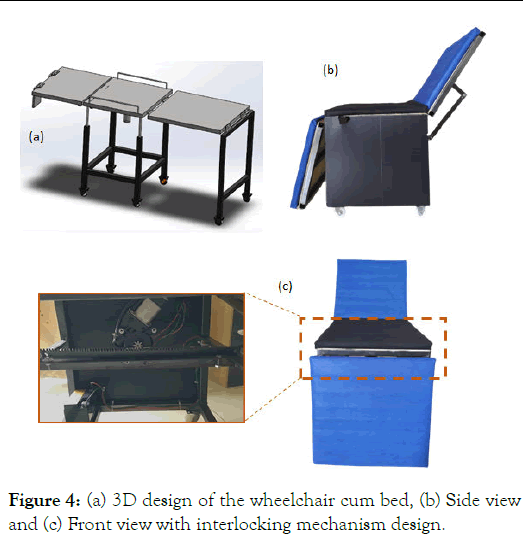

The structural integrity, frame construction and judicious selection of wheelchair materials contribute to the remarkable load-bearing capacity of up to 100 kg and potentially more, contingent upon the structural and rotational strength of the designated motor. In-depth consideration of welding strength played a pivotal role in determining the weight threshold that the project could effectively accommodate. Rigorous dye penetrant tests were conducted on all weld joints, yielding positive results and ensuring the robustness of the design. A comprehensive 3D design (Figure 4a) has been meticulously crafted to scrutinize the efficacy and visual representation of the project's functionality. Serving as a guide, this design not only exemplifies the meticulous execution of the project but also vividly illustrates the seamless transformation of the wheelchair into a versatile wheelchair cum bed. This visual representation is instrumental in conveying the project's efficacy in aiding individuals with disabilities in their daily activities, fostering confidence in its ability to significantly enhance their quality of life. The synthesis of structural soundness, welding integrity and innovative design positions this project as a symbol of excellence in the realm of assistive technology for individuals with disabilities. Moreover, meticulous adherence to the project plan is observed during the construction of the prototype to ensure flawless functionality. Simultaneously, an emphasis is placed on enhancing user comfort by incorporating additional features. Specifically, plush cushions are strategically installed on the wheelchair, prioritizing the well-being and comfort of its users. Furthermore, the safety aspect of the prototype (Figures 4b and c) is a paramount consideration. Even in the event of an unforeseen failure in the motor rotation system, a robust interlocking mechanism has been incorporated into the design. This innovative safety feature ensures that the wheelchair structure remains steadfast and will not collapse. This structural reinforcement is aptly illustrated in Figure 5, exemplifying the commitment to not only functional excellence but also the safety and durability of the wheelchair cum bed prototype. This comprehensive approach reflects our dedication to delivering a product that excels in both performance and user satisfaction.

Figure 4: (a) 3D design of the wheelchair cum bed, (b) Side view and (c) Front view with interlocking mechanism design.

Following the physical test, it was determined that the automatic wheelchair cum bed exhibited a load capacity of up to half the intended 50 kg. Despite this, the project remains viable as it effectively accommodates loads of up to 50 kg, which is deemed acceptable considering the overall weight of the project is only 17 kg. This outcome attests to the efficiency and lightweight design of the wheelchair cum bed. In Figure 5, the graph depicts the time required for both the leg and lean sections to transition into a complete bed at a 180° angle. Notably, the recorded times encompass scenarios with and without additional load on the wheelchair. The graph illustrates that, regardless of the load, both the leg and lean sections consistently achieve the transformation within a swift 12 seconds. This uniformity underscores the precision and accuracy of the meticulously planned and analyzed mechanisms integrated into the design during the project's conceptual phase. The robust performance in the physical test, coupled with the consistency depicted in the time graph, reinforces the project's success in achieving its objectives. This underscores the meticulous planning and analytical efforts undertaken before the initiation of the project, ensuring the development of a reliable and efficient automatic wheelchair cum bed.

Figure 5: The results of lean and leg sections.

Conclusion

In the dynamic landscape of scientific and technological progress, an unprecedented opportunity emerges to revolutionize the production of wheelchair cum beds. Synthesizing insights from previous studies, this project seeks to streamline the conversion process from a wheelchair to a bed, significantly enhancing time efficiency. The innovative design not only facilitates rapid transitions but also optimizes space utilization through its compact structure. Building upon the collective knowledge amassed from prior research endeavors, this project aspires to deliver a ground-breaking solution, offering substantial time and space savings for individuals with disabilities. The overarching objective is to empower those facing mobility challenges to lead more independent lives. Anticipating a profound impact, this innovation aims to instill enthusiasm and positivity among individuals with disabilities, alleviating their burdens and fostering greater confidence in managing their daily lives autonomously. As we navigate the intersection of science and compassion, the fusion of technology with thoughtful design materializes in a product transcending mere functionality, striving to enhance the overall well-being and autonomy of its users. Notably, with a 12 V battery power supply, it boasts an impressive six-month lifespan, alleviating concerns about power supply disruptions. This is attributed to the energy-efficient DC rotating motor, which minimizes operational costs. The wheelchair cum bed's transformative process, taking only 12 minutes, coupled with its straightforward operation, underscores the precision of the meticulously planned mechanisms. These features, validated during the planning phase, showcase the commitment to delivering an efficient, user-friendly and technologically advanced solution, thereby bridging the gap between innovation and compassion in assisting individuals with mobility challenges.

Acknowledgement

The author gratefully acknowledges the supported facilities and funds provided by Management and Science University (MSU).

References

- Fung K, Miller T, Rushton PW, Goldberg M, Toro ML, Seymour N, et al. Integration of wheelchair service provision education: Current situation, facilitators and barriers for academic rehabilitation programs worldwide. Disabil Rehabil Assist Technol. 2020.

[Crossref] [Google Scholar] [PubMed]

- Dubowsky S, Genot F, Godding S, Kozono H, Skwersky A, Yu H, et al. PAMM-a robotic aid to the elderly for mobility assistance and monitoring: A "helping-hand" for the elderly. InProceedings 2000 ICRA. Millennium Conference. IEEE International Conference on Robotics and Automation. Symposia Proceedings. 2000;1:570-576.

- Bostelman R, Albus J. A multipurpose robotic wheelchair and rehabilitation device for the home. In2007 IEEE/RSJ International Conference on Intelligent Robots and Systems). 2007:3348-3353.

- Guo-Zheng X, Ai-Guo S, Hui-Jun L. System design and control technique of robot-aided rehabilitation. J Tissue Eng. 2009;13:717–720.

- Borges B, Chandra A, Kalantri R, Gupta S, Dsilva G, Rajguru S. Android controlled wheelchair. In2018 First International Conference on Secure Cyber Computing and Communication (ICSCCC). 2018:1-7.

- Gowran RJ, Clifford A, Gallagher A, McKee J, O’Regan B, McKay EA. Wheelchair and seating assistive technology provision: A gateway to freedom. Disabil Rehabil. 2022;44(3):370-381.

[Crossref] [Google Scholar] [PubMed]

- Khan E. Synthesis of trolley cum wheelchair for patient handling. Int J Eng Sci Technol. 2011;3:6311-6316.

- Liu HY. Evaluation of titanium ultra-light manual wheelchairs using ANSI/RESNA standards. J Rehabil Res Dev. 2008;45(9):1251-1267.

[Google Scholar] [PubMed]

- Mantlana KB, Maoela MA. Mapping the interlinkages between sustainable development goal 9 and other sustainable development goals: A preliminary exploration. Bus Strategy Dev. 2020;3(3):344-355.

- Mercuri E, Finkel RS, Muntoni F, Wirth B, Montes J, Main M, et al. Diagnosis and management of spinal muscular atrophy: Part 1: Recommendations for diagnosis, rehabilitation, orthopedic and nutritional care. Neuromuscul Dis. 2018;28(2):103-115.

[Crossref] [Google Scholar] [PubMed]

- Thomas I, John MI, Lal R, Lukose J, Sanjog J. Design and fabrication of low-cost detachable power unit for a wheelchair. InAdvances in Electromechanical Technologies: Select Proceedings of TEMT 2019. 2020;25:755-764.

- Naeem M. The role of social media to generate social proof as engaged society for stockpiling behaviour of customers during COVID-19 pandemic. Qual Mark Res. 2021;24(3):281-301.

Author Info

Safaa Najah Saud Al-Humairi*Citation: Al-Humairi SNS (2025) Revolutionizing Wheelchair Cum Bed Functionality: A Novel Design Integrating Mechanical and Electrical Features for Enhanced Mobility and Multi functionality. Global J Eng Des Technol. 14:245.

Received: 13-Jan-2024, Manuscript No. GJEDT-24-29172; Editor assigned: 16-Jan-2024, Pre QC No. GJEDT-24-29172 (PQ); Reviewed: 30-Jan-2024, QC No. GJEDT-24-29172; Revised: 15-Mar-2025, Manuscript No. GJEDT-24-29172 (R); Accepted: 22-Mar-2025 Published: 22-Mar-2025 , DOI: 10.35248/2319-7293.25.14.245

Copyright: © 2025 Al-Humairi SNS. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.