Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- RefSeek

- Hamdard University

- EBSCO A-Z

- SWB online catalog

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

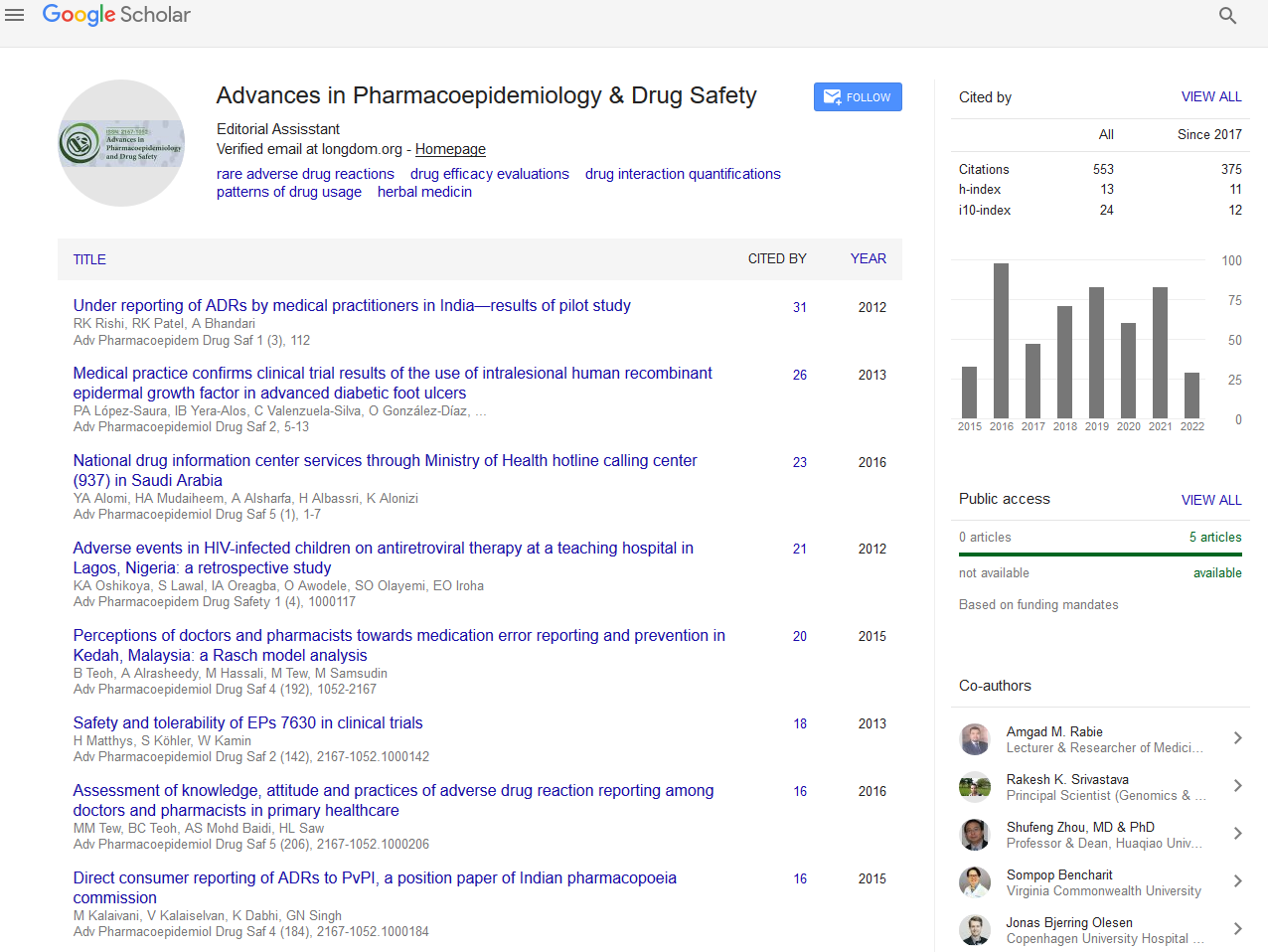

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Short Communication - (2020) Volume 9, Issue 2

Phama Sci Preparation, In Vitro and In Vivo Studies of Vitamin B12 Loaded Implants Al-Rasheed University College, Iraq

Jabar A Faraj1, Shaimaa M. Mohammed1, Ihab I. Al-Khalifa2*, Sabah Nema Al- Thamer1, Kadum A. Al Shareffi1 and Pattric P Deluca32Al-Rasheed University College, Baghdad, Iraq

3University of Kentucky, Lexington Kentucky, USA

, DOI: 10.35248/2167-1052.20.9.224

Introduction

Vitamin B12 is an important water-soluble vitamin which is found in a variety of food such as fish, shellfish, meat, and dairy products. It helps maintain healthy nerve cells and red blood cells, as well as aid in rapid DNA production during cell division. The daily requirement of vitamin B12 for the human body is approximately 1-25 μg . In 1960 introduced long- acting depot antipsychotic drug as the first long acting medications. Depot formulations providing further reductions in morbidity and mortality. Because they bypass the gastrointestinal tract, Depot treatments decrease the amount of medication needed and reduce certain peripheral side effects. Understanding the clinical and compliance of patients from the use of single dose with multiple and consecutive treatment of B12, we have developed long-term implantable medication delivery loaded with vitamin B12. The proposed method of controlled drug delivery uses sterile implants processed with a Poly (lactic-co- glycolic acid) (PLGA) polymer with a delivery interval of up to one month depending on polymer composition, and drug loading. In this study, 3 goals were addressed:

1: To formulate six different batches of biodegradable polymer implants loaded with vitamin 12 and target profile shown in Tables 1.

2: To characterize the formulated implants and establish an in vitro release for the B12 as a function of time. 3: Perform in vivo study and measure the serum concentration of B12 released from implants subcutaneously inserted into rats.

Accomplishment of these three goals could provide the feasibility of controlled release vitamin B12 implants for human treatment for vitamin deficiency.

Materials and Methods

In Vitro Studies:

Formulation of Implants Six different batches of implants were formulated from a 75: 25 PLGA (Poly Lactic-Glycolic acid) polymer (Lakeshore Biomaterials, Birmingham, AL) and vitamin B12 (supplied by the Sigma Aldrich). Each batch was prepared with different process parameters. The vitamin B12 was added to the polymer in a ratio of 75:25 and mixed very well in a common solvent to make a homogenous mixture at ratio of 25 wt. % drug load and solvent was removed by evaporation at temperature not more than 42°C in a vacuum oven with very light airflow until no traces of solvent remained. The resulting product was molded with compression into small rods using DACA Instruments, Goleta, CA and dried at 40°C for 4 hours. Unloaded control rods were formulated in the same manner.

Experiment 1: Implant Characterization

The loaded implants were tested after sterilization process to ensure that vitamin B12 stable throughout formulation process. A set of control and vitamin B12 loaded implants from a single batch were sterilized by ethylene. The sterilized implants were analyzed for polymer degradation using HPLC. Additionally, The stability of vitamin B12 was also evaluated in a pH range of 2.0 to 7.4 in order to ensure that the vitamin is stable under the acidic media due to polymer degradation. A 10 mg of drug was dissolved in 1,000 ml of phosphate buffered saline (PBS) at pH 7.0 to prepare a standard solution. One ml samples were taken weekly and analyzed by HPLC. HPLC was performed using a Column C18, 250 2.1 mm, 3.6 μm column, a gradient method (Mobile Phase: 0.1% TFA in water: 0.1% TFA in acetonitrile), column temperature of 60°C, auto-sampler temperature of 5°C, 214 nm wavelength, and 20 μL injection volume. The flow rate was set at 1ml/min with a run time of 30 min for each sample.

Experiment 2: In Vitro Release Studies

The loading of vitamin was set at 25 wt. % to evaluate a possible delivery interval as a function of polymer degradation. A polymer and drug were mixed in a ratio of 75:25 as described in the formulation of implants.

To evaluate the in vitro release profiles for each batch, three replicates of each implant type for the six batches were placed in separate bottles of the USP dissolution apparatus filled with 500 ml of phosphate-buffered saline at 37°C and stirred at 40 rpm.. One ml aliquots were taken from each bottle once a week and analyzed by HPLC [14]. The correlation coefficient for the standard solution was 0.99. After each aliquot was removed, 1 ml of buffer was added to maintain constant volume and the cumulative release percentage profile of the vitamin B12 is shown in Figure1. Figure 1: In vitro release profile of vitamin B12 release from implants containing 75:25 PLGA, 25 wt. %.

In Vivo Studies: Experimental Animals

Male and female Sprague Dawley rats (Harlan Inc., Indianapolis, IN) weighing approximately 300 gm were used as animal models for testing four selected formulations (4 batches) based on the in vitro release profiles. The Institutional Animal Care and Use Committee (IACUC) at MPI laboratory of Michigan US approved all protocols. Four groups of 7 animals each (3 male and 3 females for testing and one animal untreated for control) were used. The dosing strategy and the results are summarized in Table 2. Figure 2 shows the average results for the four formulations with their standard deviations. A total of 24 rats were treated with loaded vitamin B12 implants and 4 animals for control placed in the subcutaneous space on the dorsal surface under isoflurane anesthesia.

Experiment 3: Pharmacokinetic study

A 0.5 ml blood samples were sampled from the rat tail vein at predetermined intervals, after which the samples were centrifuged in Microtainer tubes (Becton Dickinson & Co., Franklin Lakes, NJ) and serum was collected. Serum samples for each of Group (A, B, C, and D) were frozen and stored at −20°C until analysis. The retention time for vitamin B12 was approximately 30 min. The in vivo blood serum concentration profile for each rat was determined by plotting serum concentration against time for all animals for the four groups. Observations of the rats were made every day for 7 days immediately after implantation to investigate any signs of high initial drug release.

Results and Discussion

In Vitro Studies

Vitamin B12 was found to be stable under physiological conditions. The concentration of B12 remained constant with an overall change of almost 0.0% over 30 days. In addition, results showed that the molecular weight of the polymer is not substantially changed by sterilization procedure with the use of ethylene oxide (EO). Thus, sterilization process had no significant effect neither on polymer nor vitamin B12 content in implants. Also vitamin B12 was completely stable at low pH levels that simulate the internal microenvironments during polymer degradation throughout the study time (pH 7.4, pH 6.4, pH 5.4, pH 4.4, pH 3.0, and pH 2.0). In vitro vitamin B12 release varies according to the process parameters utilized. Implants reach full release at 40-45 days as shown in Figure 1. These results suggest that B12 in vitro release from the six batches were almost similar even with different process of formulation. In Vivo Studies: Pharmacokinetic Studies In vivo onset was rapid and serum concentration was within the target range of 2- 28 ng/ml for a substantial portion of the release interval. Serum levels were approximately 2-28 ng/ml at 10 days and decreased to about 2-5 ng/ml at 10 and 20 days (Figure 2). Then after, serum concentration was increased up to ~28. Implants were removed at 40 days; there was no B12 detected in serum. Thus, implants delivered vitamin B12 for at least 30 days. Figure 2 uses the average plasma level of B12 (ng/mL) for each animal (takes the mean value of all six treated animals with standard error of the mean, for the indicated batch) at each time. Analyses of drug content in the removed implants showed that the percent of vitamin decreases over time, indicating that the rate of release was faster than the rate of polymer degradation. No tissue reaction at the site of implantation and fibrosis found suggesting good local compatibility throughout the delivery interval at all-time points. Tables 3 and 4 show some of the statistical and pharmacokinetic data from the analysis performed at MPI Research Laboratories, Michigan, and USA for male and female rats. It shows that female animals had a higher maximum blood level concentration (Cmax) than that for male. At the meantime, Tmax, AUC (0- 720hr), and AUC Ratio were very similar

Conclusion

This study demonstrates the stability of vitamin B12 against pH environment of the polymer degradation during the release study. The Polymer (PLGA) was also stable during the sterilization process with EO. Results showed that in vitro and in vivo release can be controlled based on process parameters. Current results suggest that implants containing B12 could achieve appropriate release of medication within approximately one week and last for at least 45 days. This study is fundamentally a feasible method of drug delivery that could be applied across many medications. We strongly believe that implants represent a potentially beneficial approach addressing vitamin deficiency and acceptable drug delivery system.

Acknowledgements

The Profounda Inc. FL USA drug company funded this research. All experiments comply with “Principles of laboratory animal care” and conform to University of Alabama and MPI animal care center IACUC standards.

Conflicts of Interest

The authors declare that there exist no conflicts of interest regarding the publication of this paper.

REFERENCES

- Andrès, E., Fothergill, H., & Mecili, M. (2010). Efficacy of oral cobalamin (vitamin B12) therapy. Expert opinion on pharmacotherapy, 11(2), 249-256. https://doi.org/10.1517/14656560903456053

- Ball, G. F. (2013). Bioavailability and analysis of vitamins in foods.

- Chen, Z. P., Liu, W., Liu, D., Xiao, Y. Y., Chen, H. X., Chen, J., ... & Pan, J. (2012). Development of brucine-loaded microsphere/thermally responsive hydrogel combination system for intra-articular administration. Journal of controlled release, 162(3), 628-635. https://doi.org/10.1016/j.jconrel.2012.07.037

- Gould, T. J., Bizily, S. P., Tokarczyk, J., Kelly, M. P., Siegel, S. J., Kanes, S. J., & Abel, T. (2004). Sensorimotor gating deficits in transgenic mice expressing a constitutively active form of G s α. Neuropsychopharmacology, 29(3), 494-501. https://doi.org/10.1038/sj.npp.1300309

- Hyon, S. H. (2000). Biodegradable poly (lactic acid) microspheres for drug delivery systems. Yonsei medical journal, 41(6), 720-734. https://doi.org/10.3349/ymj.2000.41.6.720

- Kane, J. M., Eerdekens, M., Lindenmayer, J. P., Keith, S. J., Lesem, M., & Karcher, K. (2003). Long-acting injectable risperidone: efficacy and safety of the first long-acting atypical antipsychotic. American Journal of Psychiatry, 160(6), 1125-1132. https://doi.org/10.1176/appi.ajp.160.6.1125

- Kane, J. M. (2006). Review of treatments that can ameliorate nonadherence in patients with schizophrenia. The Journal of clinical psychiatry, 67, 9.

- Kapur, S., VanderSpek, S. C., Brownlee, B. A., & Nobrega, J. N. (2003). Antipsychotic dosing in preclinical models is often unrepresentative of the clinical condition: a suggested solution based on in vivo occupancy. Journal of Pharmacology and Experimental Therapeutics, 305(2), 625-631. https://doi.org/10.1124/jpet.102.046987

- Kitchell, J. P., & Wise, D. L. (1985). [32] Poly (lactic/glycolic acid) biodegradable drug—polymer matrix systems. Methods in Enzymology, 112, 436- 448. https://doi.org/10.1016/S0076- 6879(85)12034-3

- Knox, E. D., & Stimmel, G. L. (2004). Clinical review of a long-acting, injectable formulation of risperidone. Clinical Therapeutics, 26(12), 1994-2002. https://doi.org/10.1016/j.clinthera.2004.12.009

- Lambert, D., Benhayoun, S., Adjalla, C., Gélot, M. A., Renkes, P., Felden, F., ... & Nicolas, J. P. (1996). Crohn's disease and vitamin B 12 metabolism. Digestive diseases and sciences, 41(7), 1417-1422. https://doi.org/10.1007/BF02088567

- Metzger, K. L., Shoemaker, J. M., Kahn, J. B., Maxwell, C. R., Liang, Y., Tokarczyk, J., ... & Winey, K. I. (2007). Pharmacokinetic and behavioral characterization of a long-term antipsychotic delivery system in rodents and rabbits. Psychopharmacology, 190(2), 201-211. https://doi.org/10.1007/s00213- 006-0616-8

- Mundargi, R. C., Babu, V. R., Rangaswamy, V., Patel, P., & Aminabhavi, T. M. (2008). Nano/micro technologies for delivering macromolecular therapeutics using poly (D, L-lactide-co-glycolide) and its derivatives. Journal of Controlled Release, 125(3), 193-209. https://doi.org/10.1016/j.jconrel.2007.09.013

- Naiker, D. V., Catts, S. V., Catts, V. S., Bedi, K. S., & BryanLluka, L. J. (2006). Dose determination of haloperidol, risperidone and olanzapine using an in vivo dopamine D2-receptor occupancy method in the rat. European journal of pharmacology, 540(1-3), 87- 90. https://doi.org/10.1016/j.ejphar.2006.04.048

- Pavot, V., Berthet, M., Rességuier, J., Legaz, S., Handké, N., Gilbert, S. C., ... & Verrier, B. (2014). Poly (lactic acid) and poly (lactic-co-glycolic acid) particles as versatile carrier platforms for vaccine delivery. Nanomedicine, 9(17), 2703-2718. https://doi.org/10.2217/nnm.14.156

- Ramteke, K. H., Dhole, S. N., & Patil, S. V. (2012). Transdermal drug delivery system: a review. Journal of Advanced Scientific Research, 3(1), 22-35.

- Wu, P., & Grainger, D. W. (2006). Drug/device combinations for local drug therapies and infection prophylaxis. Biomaterials, 27(11), 2450-2467. https://doi.org/10.1016/j.biomaterials.2005.11.0 31

- Yamada, K. (2013). Cobalt: its role in health and disease. Interrelations between essential metal ions and human diseases, 295-320. https://doi.org/10.1007/978-94-007-7500-8_9