PMC/PubMed Indexed Articles

Indexed In

- Online Access to Research in the Environment (OARE)

- Open J Gate

- Genamics JournalSeek

- JournalTOCs

- Scimago

- Ulrich's Periodicals Directory

- Access to Global Online Research in Agriculture (AGORA)

- Electronic Journals Library

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Virtual Library of Biology (vifabio)

- Publons

- MIAR

- University Grants Commission

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2021) Volume 12, Issue 6

Performance of Aquaponics Technologies in the Albertine Region, Western Uganda

Kiweewa Bernard*Received: 05-May-2021 Published: 26-May-2021, DOI: 10.35248/2155-9546.21.12.636

Abstract

Overfishing is a challenge that has caused the extinction of endemic fish species and decreasing fish stocks in Lake Albert. This study focuses on the performance of aquaponics technology as a farming alternative in Hoima region to address the challenges faced by aquaponics farmers. This technology is known to provide fish resources and agricultural products for both commercial and domestic consumption. The objectives of this study included; comparing the performance of fish, small and large leaf plants in an aquaponics system, determining the efficiency of plant beds in filtering water, and identifying the challenges faced by aquaponics farmers in Hoima district. The KYUBDAS investigation helped this study identify the performance of fish and plants in a Recirculating fish Aquaculture System (RAS). The fish species were, (1) Nile tilapia (Oreochromis niloticus) (2) African catfish (Clarius gariepinus) and vegetable plants included: (1) Coriander (Coriandrum sativa) (2) Sukuma wiki (Brassica oleracea), (3) Spinach (Spinacia oleracea), and (4) Lettuce (Lectuca sativa).

Keywords

Nile tilapia (Oreochromis niloticus); African catfish (Clarius gariepinus); Coriander (Coriandrum sativa); Sukuma wiki (Brassica oleracea); Spinach (Spinacia oleracea); Lettuce (Lectuca sativa)

Introduction

Data collection methods and materials involved use of the Hydro lab apparatus, taking records of fish mortality, and a foot ruler for measuring midrib lengths and counting number of plant leaves. Due to differences in nutrient demands, tests were run on samples of Sukuma wiki (big leaf plants) and Coriander (small leaf plants) for presence of Carbohydrates, proteins, and moisture nutrients. Hoima aquaponics farmers were questioned and interviewed to obtain knowledge of challenges in aquaponics. Data analysis was done using Minitab 17 for quantitative data analysis and QGIS to generate maps for the data collected. The results for plant nutrient intake indicated that plants (both planted in a hydroponic setting and in the soil) performed better with aquaculture effluent compared to those using water. The study found out that plants with small and simple leaves like coriander and lettuce take a smaller number of days and effluent content to obtain maximum fresh and dry matter compared to the big leaf plants. The fresh weight, moisture and protein contents of plants with small leaves and big leaves did not show any significant difference with p values, 0.077, 0.352 and 0.176 respectively. However, dry weight showed a significant difference (p=0.01) between the two plant varieties. The study revealed that Small leaf plant varieties can grow well in shallow media beds compared to the big leaf plants like Sukuma wiki and Spinach which may need supplemental N.P.K if the nitrate absorbed from the fish effluent is lacking sufficient nutrients. Shallow (6-8) and clogged media beds affect performance of big leaf plants as they grow. Over 80% of aquaponics farmers face water availability problems and poor record keeping deprives their realization of over Ushs 37,000,000 for large scale and over Ushs 2,900,000 for small scale farmers per year in aquaponics business. The study recommends the culture of Nile tilapia for aquaponics to supplement catfish in aquaponics farming. It is also recommended that major challenges in Hoima District aquaponics management need Government and private sector participation to provide sensitization, functional regional hatcheries and community involvement for sustainable fish resources yield [1].

Fish is preferably the most desired nutritious and available natural resource in the great lakes’ region of Uganda, Democratic Republic of Congo, South Sudan, Rwanda, Burundi, Kenya and Tanzania. The growing population and markets in the region have mounted pressure on fish resources in the lakes of Victoria, Kyoga, Tanganyika, Edward, Kivu, and Albert. Hoima district on the eastern side of Lake Albert has 68 percent of its total population engaging in crop growing or livestock farming. The Water Governance Institute (WGI) empowered 20 farmers in Hoima with starter kits and information to engage in aquaponics as a move to reduce over dependence on the dwindling capture fisheries from Lake Albert.

Aquaponics is defined as, “the integration of hydroponic plant production into Recirculating fish Aquaculture Systems (RAS)”. Aqua a Latin word for water and Ponics a Greek word meaning to work or labor; also refers to roots growing in water without soil. The aquaponics nitrogen cycle enables symbiotic fertility towards the plants and cleans the water for the fish in an aquaponics system. The left over fish food and the fish waste produce ammonia which is digested by nitrosomonas bacteria to become nitrite. The nitrite will further be decomposed by nitrobacter to become ammonium nitrate. The nitrates fertilise the soilless hydroponic plant gardens.

The over dependence on fish in lake Albert in particular, culminates from its being the sole source of food to the villages around the lake. Numerous research and articles have asserted the need for sustainable ways of fish farming in the said regions to address the pragmatic and future uncertainties of fish availability in Lake Albert. Stagnating wild catches and a 25% import duty on imported fish to the EAC have triggered a strong increase in fish demand. The current discovery of oil and gas resources and their expected impacts on littoral zones, uncontrolled fishing methods, climatic changes and ‘Common resource’ conflicts will require remedy to sustain the desperate populations and markets that depend on L. Albert’s fish resources.

Marine and land fish farming by use of aquaculture technologies like cages, ponds, and aquaponics have contributed greatly to the sustainability of fish markets in Uganda. This study focuses on the challenges farmers face in managing aquaponics and takes an intricate look into fish and crop performance in aquaponics as an alternative fish and crop farming method that ensures sustainability of the fish natural resources and supplement to food alternatives for the population in the Hoima region and Uganda as a whole.

Lake Albert is one of the Great Lakes in the western arm of the East African Rift Valley. Its shallow nature has allowed a speciation rise in fish to an extent that during Uganda’s colonial times, John Stoneman a Uganda Fisheries Department officer led a stocking expedition of transferring 47 Nile Perch from Butiaba Lake Albert to Lake Victoria and 100 more to Lake Kyoga. The socioeconomic aspects of the artisanal fisheries at Lake Albert show that the problem of overfishing is a result of a complex set of economical, socio-cultural and political factors. Marine fish cage aquaculture, ponds and aquaponics technology are some of the modern ways of breeding fish to increase fish stocks for human consumption as well as enable conservation of fish resources in the L. Albert and substitute artisanal fishing practices.

Uganda had 461,200 tonnes of fish from capture fisheries in 2014 but they decreased by 14 percent in 2015 as a result of over fishing. Hoima district by Lake Albert is faced with a population growth rate of 3.2 per annum, climate change, soil degradation, water scarcity and food security challenges. Aquaponics, as a closed loop system consisting of hydroponics and aquaculture elements, could contribute to addressing these problems. However, there is a lack of quantitative research to support the development of economically feasible aquaponics systems.

The Water Governance Institute (WGI), an Innovator for Securing Water for Food (SWIFF) stated the problems of Poverty, and lack of economic alternatives or the high cost of appropriate fishing technologies lead to an overexploitation of the open access fisheries in Hoima district. Community management of aquaculture technologies failed and the WGI invested aquaponics kits to a total of 20 aquaponics farmers in the Hoima region and 100 farmers in Uganda as whole to produce 11.2 tons of aquaculture and horticultural products.

Aquaponics will probably allow use of organic ammonia from fish water in a combined system that will produce healthy plants and fish for both domestic and commercial use. The need of integrated development (Government, private sector, community and individual levels) to conservation and sustainable use of the fisheries resources is long overdue.

WGI statistics show over 8.5 tons of fish got from Uganda’s aquaculture. There is however a gap of documentation regarding aquaponics plant performance, reliable aquaponics management practices which has limited the participation of farmers in the aquaponics especially in Hoima region [2].

Adopting Sace and Fitzsimmons concept on vegetable production in a recirculating aquaponics using Nile tilapia (Oreochromis niloticus), two recirculating aquaponics systems were installed in a greenhouse as a controlled environment to study the growth of lettuce (Leutica sativa), Chinese cabbage (Brassica rapa pekinensis) and Pac Choi (Brassica rapa) using Nile tilapia and with or without prunes.

The illustrate the study problem of lack of quantitative research to support the development of good manageable aquaponics systems. This study looked at plant performance by analyzing the effluent intake needed by small and large leaf plants, and the grow beds that can be recommendable to facilitate their growth. The study also analyses on the other hand, the socio economic viability of aquaponics and looks at the challenges faced by aquaponics farmers in Hoima district as well as the management systems used. This theoretical approach will enable the determination of quantifiable benefits of aquaponics to rural and urban individuals and communities as well as address the challenges faced by farmers.

In order to address the various challenges of aquaponics, the following general and specific objectives were formulated. The objectives will enable focus on the major factors that cause inquiry into this research.

To assess the performance of aquaponics as a viable alternative technology to provide fish and nutritious vegetables population Hoima district compared to dependence on Lake Albert capture fisheries.

• To identify the challenges faced by aquaponics farmers in Hoima district.

• To determine the efficiency of plant beds and aquaponics management systems used in Hoima.

• To compare the performance of fish species as well as small and large leaf plant species in an aquaponics system.

The scope of the study

This involved laboratory tests for growth performance of plant species, water testing, and culture of fish and plants in the aquaponics investigation and focus group of farmers dealing with aquaponics in Hoima.

The study took place in the Sample area of aquaponics farmers in Hoima municipality for preliminary and imperial data. A domestic research investigation in Kyambogo University was made to provide data on plant bed efficiency and crop performance with fish effluent in a combined system.

Uganda’s aquaculture fish production has steadily increased from 15,000 tons in 2005 to over 120,000 tons of fish in 2015. The growing government concern and appeal to foreign investors into the aquaculture sector has been triggered by increasing prices and demand for fish products for commercial markets, consumption and industrial use in Uganda, Congo, Rwanda, Kenya, Tanzania and South Sudan respectively.

Knowledge of the socio-economic potential of aquaponics, and the right management practices of aquaponics will enable farmers and policy makers to prioritize aquaponics for the increasing population and enable conservation of the fish populations in the overfished water bodies.

Amidst the challenges of growing populations, oil industry development and over fishing as well as global warming, it is necessary to focus on less environmentally damaging ways of aquaculture that can sustainably be depended on by commercial fisheries and enhance growth of fish populations in the Lake.

Fish stocks

Sub populations of a particular species of fish for which intrinsic parameters (growth, recruitment, mortality and fishing mortality) are traditionally regarded as significant factors in determining the population stocks dynamics and intrinsic factors (migration) are traditionally ignored.

Aquaculture

The farming of fish, crustaceans, molasses, aquatic plants, algae and other organisms in excavated ponds, fish tanks, and marine or fresh water cages.

Aquaponics

A system of aquaculture in which the waste produced by farmed fish or other aquatic creatures supplies the nutrients for plants grown hydroponically, which in turn purify the water that is later pumped back into the fish tank or ponds.

Ammonia (NH3)

This is a chemical reaction that converts to ammonium due to fertilizers, pollution increase and increase in water temperature and pH.

Brown blood disease

There caused by abrupt water change and high concentration that weakens the immune system of the fish and causes blindness, fin damages and fatal stress to the fish. It can be managed by addition of non-iodized salt (potassium) to the water to fix fin damages or neutralize acidic water pH.

Challenges of aquaponics management

Fisheries contributed 12% of Uganda’s GDP second to coffee in the agricultural sector and over 50% animal protein. USD 574,000 was budgeted for the Capacity Building for adaptive research technology generation and dissemination strategy for the L. Albert fisheries to be implemented by National Fisheries Research Resources Institute (NaFIRRI). An annual Work plan Budget of Shs 43,600,000 for Bulindi Zonal research development institute was to be used for evaluation of fish cage farming for increased fish productivity in the L. Albert Cresent Zone focusing on catfish cage assessment. This leaves the gap of information on breeding research for other technologies like aquaponics which improves domestic livelihood.

The Parker Swift Weatherman site for world weather forecast indicates that Hoima has an advantage of over 93% chances of torrential rains. With a changing climate in Uganda, rainfall distribution patterns have become more irregular. Currently, there are little or no well explained technologies like rain water management system approaches to enhance crop yields and livestock production including aquaponics in times of water shortage.

A readiness to invest in these systems has outpaced the availability of information needed to make sound decisions concerning system design, construction, management and economics, data on capital and operating costs needed for financial projections has seldom been obtained. This shows that there are few publications on the financial research covering the topics of capitalization cost, profitability, and cash flow of aquaponics systems. Along with the University of the Virgin Islands, two other prominent aquaponics operations that conduct short courses on aquaponics workshops: Growing Power, Inc. and Aquaculture International in North Carolina. Diver also mentions that another company called Nelson and Pade conducts courses, though he does not identify Nelson and Pade as one of the prominent organizations offering short courses.

In 2007, Tim and Susanne's Hawaiian farm were the first aquaponics operation in the United States to be organically certified to provide courses on aquaponics. Their students started commercial operations, many of them had become organically certified to educate farmers about the Rakocy system which included adding freshwater prawns to the deep-water troughs used for hydroponic vegetable production. They later improvised bio digesters to further reduce dependence on fossil fuels as a source of energy for their aquaponics systems that many farmers and institutions have adopted over the past several years.

In Uganda, only the Water Governance Institute (WGI) a nongovernmental organization started educating, experimenting and providing facilitation equipment to individual farmers, numerous knowledge gaps about the potential of aquaponics in the uplifting of livelihood standards and management of aquaponics systems have limited the practice of aquaponics to only 5 districts of Uganda among which is Hoima products [3].

Community and environmental management potential

Aquaponics is implemented for its many community benefits including reducing aqua cultural wastewater runoff, lowering irrigation requirements to grow crops, producing a source of fish that does not depend on open lake capture fisheries, and providing a means to grow food on polluted land or in areas with poor soil quality. Other socio-economic values of aquaponics to communities are that it provides a hands-on teaching tool in classrooms, teaches ecological literacy, and incorporates well into school curricula. Aquaponics operation serves as a community source of livelihood, creating innovation and industrialism as well as providing employment opportunities. Despite these community and economic benefits, the literature is not yet clear on whether aquaponics can be a profitable venture. Love and Genello with 257 respondents showed that 188 respondents sold aquaponics grown fish and plants, on a commercial scale and 162 sold aquaponics related materials including supplies and equipment, consulting fees for design or construction of aquaponics facilities and fees associated with workshops, classes, public speaking and agrotourism. This study endeavors to determine the economic significance of aquaponics to a region if embraced (Table 1).

| Milestone | 2015/16 | 2016/17 | 2017-February |

|---|---|---|---|

| Number of Beneficiaries | 13 | 39 | 11 |

| Crop Yield (Kg) | 39 | 1665 | 101 |

| Monetary Value of crop produce (Ugx) | 116250 | 7956200 | 298000 |

| Fish Yield (Kg) | 0 | 1984 | 20 |

| Monetary Value of Fish Produce (Ugx) | 0 | 20305000 | 100000 |

| Number of Partnerships | 2 | 5 | 6 |

Table 1: Aquaponics progress in Uganda.

Facilitated by international donors, WGI embarked on a campaign to sensitize farmers in Hoima region about the increasing demand for fisheries resources in the region. The study found out that in the initial year of 2015, WGI would provide 100% farmer requirements of an aquaponics system kit, advice, catfish fry from Entebbe and feed from Kampala stores. In 2016 as farmers started to positively respond to the aquaponics approach, the WGI reduced starter aquaponics kit facilitation to 75% as the new farmers would source 25% of the requirements that included feed and the plants as well as the fish fry. In 2017 the WGI realized the failure of groups and institutions in managing aquaponics systems as the projects were abandoned by communities due to less personal attachment to the farms. Hence the supervision of the feeding and crop management was left to the leaders of the schools and small community organisations with the “it is not mine, it belongs to the community” attitude. Focus was turned to only interested individual farmers who would vie for fish feed and provide special attention to the crops, water harvesting, and manual change of water from the fish containers to the hydroponic gardens. In 2017, WGI only availed 50% of the starter kit and then attach prices to the some items as farmers who started well were realizing the benefits of the system. WGI never extended services to the populations in Tonya and Kaiso fishing communities villages because they were predominantly cattle keepers who showed no interest in subsistence farming and especially fish culture but farmers in Hoima municipality cooperated well.

Over 60 aquaponics projects had been adopted in five districts of Uganda by 2017. Amidst challenges of community mismanagement eventually shifting capacity to individuals who own the farms, a crop yield value of over shs 8,000,000 and catfish fish yield of over shs 20,000,000 was benefited by the few farmers who engaged in only aquaponics projects by 2017.

It shows the benefit over cost potential of aquaponics to transform nitration. And livelihoods of communities as well as inculcate the sustainable conservational shift from open lake capture fisheries to domesticated aquaponics among the numerous aquaculture technologies.

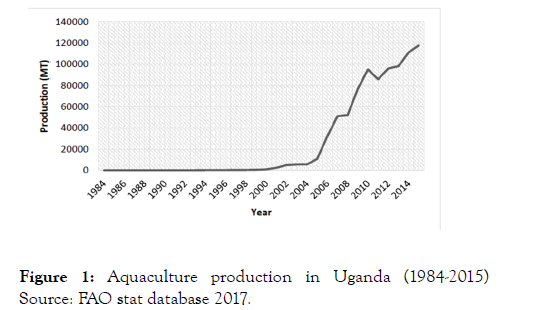

Uganda had 14,000 aquaculture operators in the country with 30,000 ponds, and 2,135 cages in Lake Victoria. A 50% of production volume of Catfish (Clarias gariepinus), 48% Nile Tilapia (Oreochromis niloticus), and 1% Common carp (Cyprinus carpio). Aquaculture production was reported to contribute 20% of fisheries yield and increased have increased from 31 MT to 117,590 MT between 1984 and 2015 (Figure 1).

Figure 1: Aquaculture production in Uganda (1984-2015)

Source: FAO stat database 2017.

It shows the growing demand for fish and this growth could be triggered by the demand for the by products such as glue, nutritional feeds, buoyancy swim bladders, fish omega 3 among other medicinal values has hiked the market demand for fish.

Aquaculture has a tremendous potential to stir FAO the growth of the fishery industry, hence providing a practical solution or complement to address the fish production gap plagued by supply side constraints. The evidence demonstrates that it is possible for the fishery sub-sector to predominantly place a reliance on aquaculture for fish production rather than too much dependence on unpredictable and struggling capture fisheries. Uganda can draw key lessons from successful and leading aquaculture producing countries to boost its aquaculture sub-sector. Nile tilapia (Oreochromis niloticus) and African catfish (Clarias gariepinus) being the most commonly cultured fish species in Uganda, Nile tilapia culture is however, challenged by uncontrolled reproduction of mixed tilapia in culture systems. This has resulted into stunting that affects final sizes harvested. The need of analyzing the profitability of Uganda’s aquaculture enterprises has arisen due to increased use of commercial quality feeds and less of natural organic feed. Lack of empirical economics data about a given the aquaculture sector in Uganda has not only negatively affected direct investment into the sector but also limited credit access from banks and microfinance institutions. The key lessons include, among others, the development and provision of quality fish seed and feed, introduction of new fish species through research and development, technology including experimental demonstrations for the transfer of techniques or skills for new culture to small rural aquaculture farmers, and the provision of low-cost financial resources for aquaculture.

Encouraging Nile tilapia culture

An article by James in Farmer’s weekly magazine, South Africa stated that the Nile Tilapia (Oreochromis niloticus) is the fastest growing fish species at a rate of 400-500 grams in just nine months if cultured in warm temperatures between 25° C-30° C and good feeding following guidelines like those recommended by the Bureau of Fisheries and Aquatic Resources National Freshwater Fisheries Technology Center. These temperatures are relative to Uganda’s climate and specifically Hoima.

As Uganda struggles to attain the United Nations Development Program (UNDP) Sustainable Development Goal (SDG) of the need for better nutrition that aims to end hunger, achieve food security and improve nutrition and promote sustainable agriculture, the streamlining of aquaponics technology will enable the sustainable attention to nutrition requirements of the populations since Uganda was among the first countries to develop its national development plan in line with the SDGs.

The efficiency of plant beds and management practices in aquaponics

Aquaponics can be considered a sustainable agricultural production system. Sustainable agriculture is a process that does not deplete any non-renewable resources that are essential to agriculture in order to sustain the agricultural practices. Sustainable agricultural production can be achieved by resembling natural ecosystems and “designing systems that close nutrient cycles”, which is one of the main characteristics of aquaponics. Hydroponic plant beds are sand and stone or gravel that help the plant roots to be firm in the beds, filter effluent and are home to nitrobacter and nitrobacteria that turn effluent from ammonia to nitrate. The majority of media-based aquaponic growers recommend about 12 (300 mm) of media leaving the top 1–2 dry to control algae and fungal growth. This can be done depending on the sizes of the gravel to be used. Deeper beds are an extra expense to many farmers and the cost of constructing a stand that can support the weight of the media becomes dependable. The use of a flood tank would be a better option if a standard of 4–6 gravel media depth is used for the hydroponic plant beds. The flood tank or drain tank helps to save the excess water that is got from the fish containers and allows the completion of the nitrogen cycle as the grow beds filter and prepare for another watering flood and drain trays which are widely available.

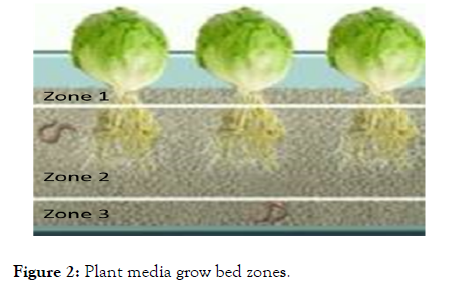

The porousness, and depth of the grow bed media is a determinant of the types of plants to be grown in the hydroponic component of the aquaponics system. Grow bed depths influence the types of plants with shallow rooted plants such as Lettuce (L. sativa) and Coriander (C. sativa) performing best in shallow depths while plants like tomatoes, cucumbers, corn, melons that need a longer growth period with deep roots need deeper grow beds. The shallow media grow beds may not provide the base of nutrients, bacteria and space for large root zones required for the relatively long life of deep rooted plants. The standard of grow bed media for better plant yield is 12 (Figure 2).

Figure 2: Plant media grow bed zones.

The top 2 (50 mm) is the dry zone (Zone 1) where light can penetrate and allow controlled evaporation of moisture from the bed. This zone protects the plants from rotting at the base (collar rot) and algal blooms are controlled. The moisture that makes plants dump is reduced. Root zone (Zone 2), 6–8 (150–200 mm) allows plant root activity as the water is being filtered through the grow bed, the roots get oxygen and nitrogen fixing bacteria, soil microbes, and the resident earth/composting worms form as the water drains downwards. During the flood part of the cycle, the incoming water distributes moisture, nutrients and incoming solid fish waste particles throughout the growing zone. The worm population does most of its very important work in this zone, breaking down and reducing solid matter and thereby releasing nutrients and minerals to the system. ‘Worm Tea’, as it is commonly known, will be evenly mixed and distributed during each flood and drain cycle. The Mineralization Zone (Zone 3) lies at the bottom 2 (50 mm) of the grow bed. In this zone fish waste solids and worm castings are finally collected. The solid material has been reduced by up to 60% by volume, by the action of the resident garden/composting worms, and microbial action. During each flood and drain cycle, what is left of the solid’s percolates down into this zone. Further and final mineralization occurs in this area via bacterial and earth worm activity. Due to the excellent action of the flood and drain cycle, this bottom area is kept fresh as the filtered water is released to return to the fish containers filled with oxygen and minerals.

It was observed that in Africa there is a lot of maize and cassava plantation but not much of greens or protein. Doing aquaponics in a developing country would require reliability, simplicity and freedom from the need for grid power as well as the need to control flood and drain parameters of the aquaponics system and this is why there is need for a good piping system that controls inflow and outflow of water from the system. Hughley designed demonstration systems of aquaponics for orphanages and schools and invented the Flood valve system to control the flow of water in aquaponic systems that do not rely on electricity. The flood valve can utilize any kind of pump whether electric, gas or wind driven, or any kind of energy chosen by the subsistence farmer. After the water has been pumped from the fish tank to the flood tank, the flood valve which has an extension of a standard toilet valve extended on the overflow pipe will draw back as waster fills the flood tank through the flood pipe, the valve will keep rising with the water level and weight of the water and it will only need the farmer to flash the water to the hydroponic gardens which will cause the valve to fall back until the water is full in the flood tank for the next plant watering. This kind of system is responsible for growth of large plants like papayas that require more water and nutrients for growth.

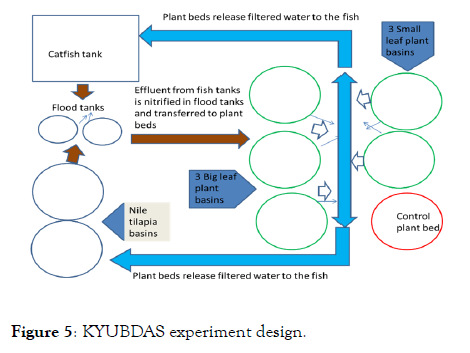

Both a mechanical water pump and valve system and watering can draw system was used in the KYUBDAS. The water from the catfish tank was pumped to the flood tank and the water from the flood tank was released to the plants using a tap valve. The water from the tilapia was drawn by syphoning and by use of a watering can and tranfered to the flood bucket for nitrification and then transferred to the plants. The water from the plant biofilter grow beds was released by tap valves to a jerrican which was used to transfer the water back to the fish tanks [4].

Management practices of plants beds in aquaponic systems

There are many types of aquaponic systems, each with advantages and disadvantages. There are Media bed troughs fed by water from fish tanks, nutrient film plant pipes or beds, and larger ponds that contain water for larger farms. Media filled beds are better for home backyard gardens while deep water culture ponds are used for commercial operations (Figure 3).

Figure 3: Deep water culture.

The main disadvantage of media beds is difficulty in harvesting of whole plants due to entanglement of plant roots in the gravel media.

Plants with simple root structure such as lettuce are easiest grown in other systems but large plants such as tomatoes require the structure and high nutrient profile available in media beds.

The Deep-water culture method uses large volumes of water pumped from fish aquariums into long troughs that are kept at a constant level and plants are suspended above the water in Styrofoam rafts with the root systems dangling down into the water to absorb nutrients.

This method is most commonly used by commercial growers due to its ability to produce large volumes of plants in a relatively small space and ease of harvest due to the roots not clinging to anything (Figure 4).

Figure 4: The nutrient film system.

Nutrient Film Technique (NFT) systems as shown in are constructed of small pipes that run horizontally with a hole per foot measure that plants are planted into. The nutrient rich water is trickled down the pipes and the plant roots dangle down and absorb nutrients out of the thin film of water that moves down the pipe. This system is only suited for small plants that have a low nutrient requirement such as lettuces.

The study implemented a grow bed media system for plants as it would both act as a water bio filter as well as a plant grow bed.

Plant performance in aquaponics

Plant varieties without large rotting roots can be grown in an aquaponics. Plants with low to medium nutrient requirements do best such as, lettuce, herbs, and specialty greens (spinach, chives, basil, and watercress). Fruiting plants such as tomatoes and peppers will grow, though fruit production may not be robust. Ornamental bedding plants, cucumbers, mixed salad greens, and herbs have also been reported in aquaponics systems.

The two names Coriander or Cilantro (Coriandrum sativa) refer to the same plant, although most people use the name cilantro to describe the fresh, leafy herb used in salsas and Thai food. Coriander often refers to the seeds and powder ground from the seed. Whether you want cilantro or coriander, this herb grows rapidly, especially in warm weather. Cilantro seeds are best planted in spring when soil temperatures range between 55 to 68 degrees Fahrenheit. The seeds will germinate within two or three weeks and quickly produce leafy growth. As the weather warms, the leafy growth gives way to flowers, which produce seed heads. The time it takes to grow, and harvest coriander depends mostly on weather conditions. In warm, hot weather, cilantro plants bolt and produce seeds with in four to six weeks after planting. In cool spring weather, the cilantro plants might grow for several months before they produce seeds.

Collards are a popular leafy vegetable locally known as “Sukuma wiki”. The dark green leaves are borne in rosettes around an upright stocky main stem. The long-stemmed leaves resemble cabbage except that they are oval rather than round. Collards grow well in well drained loam soils that are high in organic matter. The seeds are scattered in the furrow, and then covered with light soils. They are sprinkled with water and the seedlings should be able to come out in about 6 to 12 days. Collards require 6 to 8 weeks from the time of sowing to fully mature. The peak time for harvesting is when the leaves are firm, crisp and bright green.

Balancing the fish and plants component calculations

The fish need to supply adequate nutrients to a suitable number of plants that match the use of all the nutrients released, but not in excess to prevent any risk of deficiencies. This ratio depends on the type of plant being grown; fruiting vegetables require about one-third more nutrients than leafy greens to support flowers and fruit development. Leafy green plants need 40–50 g of fish feed per square meter and fruiting vegetables need 50– 80 g of fish feed per square meter. On average, plants can be grown at the following planting density. Leafy green plants 20– 25 plants per square meter and fruiting vegetables 4 plants per square meter (FAO, 2014). FAO also admits that plants are most likely the most profitable part in small-scale aquaponics because of the high turnover rate but can be as vulnerable if the right spacing densities are not met.

In the KYUBDAS, a ratio of 30 tilapia would produce effluent for up to 60 plants. 20 catfish would also produce effluent for 60 plants.

The Nitrification cycle in an aquaponics system

The illustrates the nitrogen flow within a water circulation aquaponics system. Nitrogen that is derived from fish feed and deposits as ammonia will be decomposed into nitrites and then to nitrates that can be consumed by plants as the plant’s biofiltration beds filter the water to be returned to the fish [5].

The aquaponics nitrogen cycle enables symbiotic fertility towards the plants and cleans the water for the fish in a fishplant aquaponics system. The left-over fish food and the fish waste produce ammonia which is digested by nitosomonous bacteria to become nitrite. The nitrite will further be decomposed by nitrobacter to become ammonium nitrate. The ammonium nitrate fertilise the soilless hydroponic plant gardens. Nitrogen needs several variables that must be adjusted in order to keep bacteria alive. Bacteria also need lots of space and they colonize the surfaces in an aquaponics system. Therefore the larger the system, the more bacteria requiring a stronger biological filter to convert ammonia to nitrates. The nitrifying bacteria are best alive between 77-86°F (25-30°C). When temperatures fall below 32°F (0°C) or rise above 120°F (48°C) these bacteria start to die off and system nitrification is halted.

Another factor that must be accounted for is pH of the water. Nitrifying bacteria thrive at a pH between 7.3 and 7.5, when pH falls below 6.0 nitrification ceases and the system can become toxic. Nitrifying bacteria are aerobic and dissolved oxygen in the systems water is important, if dissolved oxygen is too low the bacteria are unable to fix oxygen molecules to the nitrogen and convert ammonia into nitrate.

Nutrients obtained by plants

In general there are three types of nutrients that are needed to grow crops in an aquaponic system: Non-mineral nutrients: Oxygen (O), Hydrogen (H) and Carbon (C) the oxygen is delivered to plants through water which is essentially for growth and development of plants. It is sprayed in the water or availed by creating of water falls in the water to increase dissolved oxygen that plants need. Fish also release carbon dioxide during the night but the plants need this same gas during morning hours. The macronutrients include Nitrogen (N), Phosphorus (P), Potassium (K), Calcium (Ca), Magnesium (Mg), and Sulfur (S). Through ammonia circulation and nitrification bacteria, micro-bacteria located in the bio filter medium convert ammonia to virtually non-toxic nitrate but they also contribute to the processing of particulate matter. This process reduces water pH level since more nutrients are favored by low pH values compared to high pH. Calcium, sulfur and magnesium are most commonly supplemented in aquaponic systems that use pH-raising supplements to moderate pH level. Calcium and magnesium are primarily added in the form of agricultural lime or hydroxide composed of Ca and Mg.

The micronutrients are Iron (Fe), Copper (Cu), Zinc (Zn), Manganese (Mn), Boron (B), Molybdenum (Mo), Chloride (Cl), Fish food has high levels of Copper, Zinc and galvanized steel components. Low levels of Boron and Molybdenum are required in aquaponic systems. Manganese is seldom deficient, and Chloride commonly enters the system with the fish food, and in the form of salts. Provided that the system is stocked with the correct amount of fish, it is not necessary to add nutrients for plants with short cropping cycle, which does not produce fruits (e.g. salads).

Materials and Methods

The sturdy was done in Hoima District where the WGI has aided twenty farmers with aquaponics kits. It shows the geographical scope of the sampled farmers in Mparo division (Hoima Municipality), Kyabigambire and Kihwera sub counties who operate individual aquaponics systems courtesy of the Water Governance Institute (WGI) as the sole initiator and distributor of aquaponic systems in Hoima district.

Due to the remoteness of the Hoima study area, an experimental model of an aquaponics system was made in Kyambogo University to closely monitor plant growth and nutrient adaption, effectiveness of the hydroponic plant bed filters and the performance of fish cultured in domestic aquaponics system. The Kyambogo university experiment was named ‘Kyambogo University Biology Department Aquaponics System (KYUBDAS). Although fish mortality is a nightmare to farmers, it was rare to find records of fish mortalities on Hoima farms, the treatment helped to provide data of fish mortality [6].

The demonstrates the investigation was also conceptualized as a practical means to physically familiarize the challenges faced by aquaponics farmers in Hoima. The diagram shows the Catfish tank on the left and two Nile tilapia containers at the bottom left serving two flood tanks with effluent. The effluent was then channeled by water pump and by watering can to the five hydroponic plant beds. The sixth plant bed (with red rim) is the control plant bed that does not use effluent. Clean filtered water from plant beds was tested and channeled back to the fish tanks (Figure 5).

Figure 5: KYUBDAS experiment design.

To establish the challenges faced by aquaponics farmers in Hoima, a field survey with the aquaponic farmers was carried out. In Hoima, the NGO WGI is helping twenty farmers to carry out aquaponics therefore, the study was purposively focused on five of these farmers. Using QGIS software, was generated to highlight GPS points for five aquaponics farms in Hoima district that represent the sample focus group of farmers in Hoima District. The map in also shows the proximity of Hoima district to Lake Albert. The coordinates were obtained using a Tecno WX3Lite phone Google map GPS system. Uganda sub counties Datasets were derived using the Uganda National Bureau of Statistics (UBOS) sub counties and water bodies databases.

A focus group for farmers was formed, WGI was visited and requested for permission to engage their participants (farmers) into this study. Five farmers in Hoima were interviewed on the challenges they face in aquaponics. For ethical purposes, the five farmers were coded using “R”, an implication for “Respondent”.

A one on one interview with the farmers was done to fill the questionnaires that were formulated for the focus group of Individuals who have aquaponics farms in Hoima District. An investigation into the feasibility of the farms to the farmers in perspective of both the farmers and the WGI organization was done to ascertain the viable means of sustaining the projects to a greater scope.

Experimental study of the performance of fish and plants

O. niloticus of 8 cm average size were divided into 15 per basin, stocked in 2 basins of 1ft diameter and 1.5 ft hollow depth using 35liters of water according to the FAO standard ratios. An air bubbler was used to dechlorinate the tap water. They were fed on fry powder pellets up to 5 tablespoons of powder food per day. A total of twenty Catfish were stocked weighing between 50 and 60 grams in 1 cubic meter tank was used with 90 litres of tap water.

Physico-chemical water parameters

It shows the hydro lab DS5X multi-parameter apparatus that was used to determine the effectiveness of the bio filters in water purification. Dissolved oxygen, total suspended solids, Turbidity, pH, and temperature parameters were measured in the water from fish tanks (effluent). These measurements were done before and after the effluent was used in the plant beds.

Measurements were taken once every month for three consecutive months of the treatment. The readings were then recorded and analysed using Minitab17 to calculate the mean of the parameters in all fish and plant containers.

KYUBDAS tilapia and catfish culture

A total of thirty Nile tilapia fingerings weighing 45 grams were brought from Kajjansi fish Hatchery. Two basins, 1 ft diameter and 35 liters of water content contained 10 fish in each dechlorinated tap water was used for 3 weeks in one basin and spring well water was also used in another basin both using air stones for air flow in the water. Twenty Catfish weighing 50 grams were stocked 1 tank of size 1 cubic meter was used with 90 liters of tap water. This was done according to standards for fish stocking that require 40-50 grams fish being fed on at least 200 grams pellets per day and supplying 50-80 plants.

Plant species

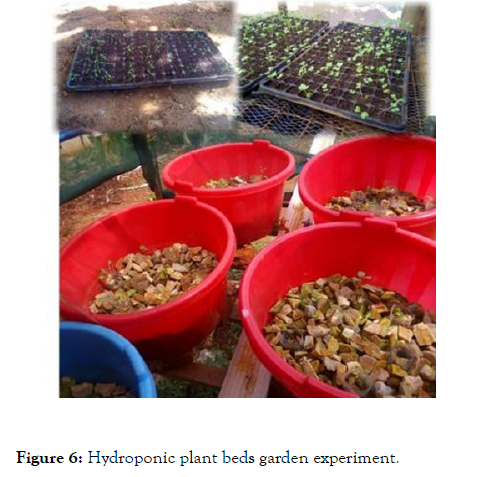

Four vegetable varieties that are commonly used in Uganda were selected. These were planted in plastic basins of 1 ft diameter (40 liters volume). The treatment plant basins were designed in a way that plants with big leaves (B. oleracea and S. oleracea) were mixed in 3 basins and plants with small leaves (S. sativa and L. sativa) were placed in 3 other basins for the trial as shown in (Figure 6).

Figure 6: Hydroponic plant beds garden experiment.

One of the 3 plant basins without effluent with the plants watered with regular rain or spring well water was used as a control. The seedlings for all the plant varieties sampled for this study were sowed on to the aquaponic plant beds. This was done to ascertain that all plants grow at the same rate. The illustrated the sprouting seedlings and the grow beds.

The plants were spaced according to the FAO recommended standards. Depending on the water demands, two trough beds were manually supplied with effluent from tilapia using a watering can. Three troughs were watered mechanically with pumped effluent from the catfish flood tank. One trough was watered with plain water. The plants were put in individual plastic cups filled with 1 inch stones and perforated on the sides to allow root growth. The perforation would also reduce water logging in the cups inserted in the sand and gravel basins/ troughs. The plants were mixed in the troughs where plants with big leaves B. oleracea and S. oleracea used 1 liter of effluent per square foot (1 basin) every 2 days and plants with small leaves and shallow root structures C. sativa and L. sativa used 1 liter every 3 days. There were 10 C. sativa plants in every square foot, 5 L. sativa plants in every ft2, 5 B. oleracea and 6 S. oleracea per square foot (Table 2).

| Plants | Plant Spacing per ft2 | Effluent applied in litres | Number of days |

|---|---|---|---|

| 10 | 1 | 3 | |

| 5 | 1 | 2 | |

| 6 | 1 | 2 | |

| 5 | 1 | 3 |

Table 2: Plant bed effluent demands.

Filtering efficiency

Six large basins were used in the hydroponic component of the system in the KYUBDAS treatment. Four of the plant beds had gravel media measured up to 12 of thickness as a standard requirement for plant beds for deep root crops. Two basins had gravel measuring up to 6 for shallow root crops. The control basin was in the 6 category.

The green house

In the plant containers are sheltered in a greenhouse to reduce the effect of rain. Water from the plants is filtered and taken back for fish use. The figure also shows plant containers using effluent and the control container. The blue pipes above the containers bring effluent from the fish tanks. The greenhouse mesh is transparent enough to allow sunshine to penetrate to the crops so they can attain vitamin D. The plant beds containers are raised to allow the tapping of water and save them from animal pests.

Comparing of plant matter and nutrient content at harvest

Samples of the edible parts of the plant were taken to the Makerere University Food and Technology department Laboratory to do proximate analysis on fresh weight, dry matter content, proteins, and ash, carbohydrates and moisture. For all the nutrients, procedure was followed according to standard oven drying method. To determine the plant fresh weight, plants were removed from the grow beds and the sand was washed off. A paper tissue was used to blot plant leaves gently to remove any free surface moisture. The roots were cut off and the edible matter was weighed immediately to collect fresh weight data. Dry weight data was recorded when the leaves that had been used to capture fresh weight data were cut into small pieces and put in an oven set to low heat (37° C) and left in the oven for 12 hours. The leaves were removed and let to cool at room temperature of 23° C they were then put on a weighing scale to capture their dry matter weight. To determine the crude protein in the plant, the Kjeldhal method was used on 10 grams of the best performing coriander (C. sativa) and Sukuma wiki (B. olerace). The plants were harvested, and the roots were cut off. To determine the Ash content, 10 grams of coriander (C. sativa) and Sukuma wiki (B. oleracea) were dried by heating in a muffle furnace as described in the standard method. The Unicam 919 Atomic Absorption Spectrophotometer (AAS) was used to ash the sample under gradual increase temperature of 50° C /hr.

Data analysis

Using Minitab17 statistical software, the questionnaire responses were analysed. The study made computations of estimated annual financial yield implications of benefits from fish and crops grown by farmers in Hoima and results were obtained. A time series plot graph was presented to show the magnitude in weight of the challenges faced by the aquaponics farmers.

Analysis of fish species data

A t-test was carried out to find the difference between the variances of both catfish and tilapia species as managed in the KYUBDAS treatment. The results of the 2-sample t-test on O. niloticus and C. gariepinus mortality data were intended to ascertain the reason why farmers do not use O. niloticus in their aquaponics systems. The students’t-test was analysed using Minitab statistical software [7].

Plant bed filter analysis

To assess the effectiveness of the hydroponics filters for the water treatment, Minitab17 software was used to form a Pareto effect chart. The pareto effect chart shows the gentle slope in bars from left to right representing a weak pareto effect of filtration or drastic slope in the graph bars representing a strong pareto effect of water filtration.

Plant performance data analysis

The Minitab statistics software was used to analyse the data of the mean and standard deviations of both big leaf plants and small leaf plants. This was to ascertain whether big leaf plants metabolized more proteins and had higher fresh and dry weight compared to the small leaf plants in aquaponics. A students ttest statistic was used on an assumption was made that the variances in the plant crude proteins, dry and fresh weight and moisture of the two species are equal.

Data sources included use of scholarly literature, Hoima farmers, NGOs, government parastatals that are stakeholders in the fisheries subsector and the KYUBDAS treatment.

Monitoring chemical concentrations in the KYUBDAS treatment and monitoring of field farms in Hoima were better rationale to attain better results on the practicality, feasibility and viability of Aquaponics technology as a sustainable fish and crop farming method for both commercial and domestic consumption and development.

Although a total of five aquaponics farmers were visited in Hoima, communication and transport means within Hoima district were not reliable hence more time was used than planned.

Hoima aquaponics survey results

The survey revealed farmers in their ages ranging between 45 and 70 years practicing aquaponics in Hoima. Among the five farmers, two were women and three were men. Four of the five farmers where educated not over ordinary level certificate yet one was not over primary seven level. Each of the five farmers was a parent with children above the ages of 15 years. One of the two women farmers was a widow and another, a single mother. All the farmers had land ranging between 2 and 5 acres of farm land with crops like cassava, bananas, coffee and maize.

Challenges faced by fish farmers in hoima

On analysis of the challenges faced by the Hoima farmers, there were some improvisations and short-term remedies that could help to mitigate the challenges faced by the farmers as per interaction with stakeholders. The Time series plot in the respondents (blue line) and percentage weights (magnitude of response estimated from general farmer population) corresponding with the responses of farmers as computed using the Minitab software.

It indicates that at level 2 of the challenge index, all 5 farmers responded that the aquaponics farms are 100% individually owned and all deal in catfish culture. Level 4 of the challenge index showed a plummeting dive in the weight curve to indicate that 0% of the farmers deal in Nile tilapia culture. Level 9 indicates (80%), 4 of the farmers face water access problems, (20%) make profits from fish sales at level 11 yet level 12 shows that 4 (80%) of the farmers incur losses in fish sales. Level 13 of the challenge index shows that (5) 100% of the farmers buy pellets from Kampala through the WGI and level 14 indicates that 0% of the farmers buy pellets from Hoima town. Level 15 shows that 1 (20%) of the farmers make profits from vegetables [8].

High aquaponics kit expenses

In 2015 the WGI would offer 100% free barkyard kits to the farmers as a startup and models for other farmers to appreciate. In an interview with WGI, kits are now provided to only interested farmers at a price. The 1 m3 Plastic tanks and plant bed with 200 cat-fish and 40 plants respectively priced at shs 3,060,000.

Lack of mechanized applications

It was observed that most farmers either manually drew or siphoned water out of the fish tanks into buckets and carried the water to the hydroponic components. Some fish tanks had flow taps that were opened to let out the water to the transfer buckets. This showed the lack of physics applications that allow the gravitational flow of water from the fish tanks to the plants and otherwise.

Kampala advice monopoly

It was observed that aquaponics farmers would only communicate with merely one or two colleagues in their fraternity, but all would depend on advice from WGI in Kampala. Without such, the systems would be abandoned. This was evidenced by some farmers having structures without fish stock and waiting for supplies from Kampala.

Lack of water testing equipment

Compared to the KYUBDAS investigation that had the hydro lab, Hoima farmers had no sort of water testing equipment but trusted that water from the borehole or spring well was the best for the fish culture and ensured change the water after 8 days of use in the aquaculture component of the system. WGI field staff said that they use litmus paper to test water pH only and then recommend the use of the tested water, but this was a rare case as most farmers are scattered in their rural areas.

Community management failures

Failure of management of aquaponics at community level resulted from lack of sensitization on the benefits to communities. Individual farmers were the main beneficiaries of the 100% aquaponics kits provided by WGI as community groups had no yield to exhibit. The Water Governance Institute halted the facilitation of farmer aquaponics kits to community organisations such as schools and groups in the first year of inception. The groups/schools would always lack coordination and management skills to sustain the projects. R2, one of the farmers has a fish pond dug in the ground with water from a nearby clean water stream but has reduced effort on the smaller aquaponic fish tank and garden boxes because of the necessity to carry water to the fish tank.

Management of aquaponics systems in hoima

A focus group of five farmers was formed as a sample of fish farmers in Hoima who deal with aquaponics (Figure 7).

Figure 7: Hoima aquaponics systems.

WGI Stocking density of fish and plants in hoima

The following stocking ratios of fish and crop yield aquaponics systems for both commercial and domestic consumption were observed in Hoima district. Plate 2 shows in photo 1, 1 m3 tank containing 200 catfish supports up to 40 plants in a combined aquaponic system. Photo 2, Plant Boxes Fish tank of 3 x 2 x 1.2 m3 containing 1200 catfish exchanging water with over 160 plants in boxes of 2 x 1.5 x 0.5 m3. Photo 3, The Multiple grows bed System has 1m3 tank with 200 catfish exchanging water with up to 120 plants. Photo 4, The Concrete large scale aquaponic system pond area of 10 x 5 x 1.5 m3 containing over 7000 catfish and supplying a non-reversed garden of 50 square meters [9].

Management of aquaponics in hoima fish tanks

It was also observed that farmers would feed 200 C. gariepinus with a quarter of a kilogram (250 g) per day. The pellets are bought at shs 6500 per kg and transported by bus from Kampala to Hoima.

Farmer yield from aquaponics

Aquaponics farmers in focus group were interviewed about their proceeds, how much they invest in the fish, and what they earn from the system annually. The farmers provided knowledge of how much fish they are given for re-stocking that is estimated to last a year for the fish to grow (Table 3).

| Stage | No. of tablet tested | Acceptance criteria |

|---|---|---|

| S1 | 6 | Each unit is not less than Q + 5 %. |

| S2 | 6 | Average of 12 units (S1 + S2) is equal to or greater than Q, and no unit is less than Q – 15 %. |

| S3 | 12 | Average of 24 units (S1 + S2 + S3) is equal to or greater than Q, not more than 2 units are less than Q – 15 %, and no unit is less than Q -25% |

Table 3: Fish yield from aquaponics systems.

Amidst the observed challenge of poor record keeping, in reference to illustrates the actual fish stock average of 2239 seed given to the farmers, the farmers however estimate an average 80% of the annual yield of fish, and average sales cash of shs 8,552,000 in the management of fish in their aquaponics systems. Also shows the analysis of the stock less the fatalities and domestically consumed fish. This statistic also provides the estimated fish sales annual cash sales that could be gained by the farmer’s ceteris Paribas [10].

Plant yields

The farmers also narrate that the crop yield provides even more vivid benefits as they earn between shs 20,000 and shs 30,000 per week of sales from a 120-plant garden. Using the multiplier effect, the study estimated the yield from plants to be 1,440,000 per year. Without considering domestically consumed and perished vegetables, a total weekly sale of vegetables worth shs 30,000 per week would earn the small-scale farmer over 1,440,000 from a 120 plant garden (Table 4).

| H2O | Parameters(percentage) | |||||

|---|---|---|---|---|---|---|

| TDSg/L | DOmg/L | DOsatur. % | Temp °c | Turb (NTU) | pH | |

| 0.1 ± 0.06b | 1.02 ± 0.01b | 10.6 ± 0.21b | 21.58 ± 0.03b | 63.47 ± 0.55a | 7.87 ± 0.45b | |

| 0.3 ± 0.10b | 0.83 ± 0.115b | 7.03 ± 0.208b | 21.46 ± 0.046b | 430 ± 11.590b | 7.8 ± 0.1b | |

| Plant beds | 0.1 ± 0.100b | 2.43 ± 0.010b | 25.33 ± 0.153b | 20.87 ± 1.021b | 19.53 ± 0.503b | 8.74 ± 0.721b |

• DO- Dissolved oxygen,

• DO%-Percentage of dissolved oxygen/saturation,

• Temp-Temperature,

• Turb - Turbidity nitrate levels,

• STDV- standard deviation.

Pareto effect of water quality

Results of the analysis indicated in depict a strong Pareto effect characterized by a drastic decline in the bar heights due to the efficiency of the plant media beds in filtering water from fish tanks. The graph in is derived from the data summary and presents the deviation of the quality of the water during the investigation.

Fish survival rates

It was observed that mortalities reduced when a 3 inch rock media was laid beneath the water and a simple net lay on top of the rocks to control turbidity. When astone and sand bed (3 inches) to mimic the natural environment was laid within the basins, it was observed that the tilapia that had turned yellow regained their natural color. There were 6 catfish that showed a stunted growth and mortalities were observed to result from cannibalism characteristics.

A feed with an ingredient composition of fish oil, rice bran, wheat bran, cassava, soy bean meal, limestone, dicalcium phosphate, vitamin and mineral premix was given to tilapia fingerings. Catfish pellets comprised poultry meal, blood meal, fish meal, soya, methionine, lysine, vitamin C and salt. Four tablespoons of powder pellets per day for a stock of 13 O. niloticus fish per 30 liters of water would suffice for juvenile fish weighing 40-60 grams. This enabled the fish to increase by an average of 43 grams every 20 days.

In the KYUBDAS, thirty juvenile O. niloticus were stocked in a container with 35 liters of water, it was observed that characteristic fights for territorial dominance and jumping out of the water caused numerous mortalities. It was also observed that the separation of fish, big and small, and reduction of populations per container minimized mortalities. Shows how the challenges in raising tilapia were managed. It was necessary to separate big tilapia from small ones and ensure 13 fish per 35liters of water where they had enough room swimming. Three inches of stone and sand bed in up to 35 liters of water stone and sand bed medium was laid within the containers to mimic natural conditions and when a simple net was laid on the stones beneath the water, it allowed the water turbidity to remain in the best condition as food remnants and fish deposits remained below the net. There was no more need for the air bubbler as the fish water would stay for 4 days without change and the fish would come to the top for more oxygen [11].

Kyubdas fish mortality

Fish mortality data were compiled and analysed for mean and deviations.

Plant growth

It shows the observed performance of hydroponic grown plants with ammonia nitrates verses those using regular water and the performance of soil based plants using ammonia water. A foot ruler was used to measure leaves, and height of plants in the different hydroponic setting and the length of fish to ascertain plant performance and growth.

Plant nutrients

In show plants using effluent from O. niloticus and C. gariepinus compared to the coriander plant in photo 3 that was in the control basin using only water. The coriander (C. sativa) leaves among were totaling to 25 in the best grown plants using effluent compared to only 5 leaves on the plants using water alone. Plants like C. sativa and L. sativa performed best because they needed much less nutrients than the big leaf plants. The difference in the nutrient consumption arose from the amount of nitrate water applied to the plants. Plants using effluent grow better and produce more leaf cover compared to those that use only regular water be it in the soil or in the hydroponic setting. An added advantage is gained by soil-based plants that utilize nitrate because they gain more potassium and ion from the soil. This study found out that the minimal presence of Potassium and Magnesium macronutrients in the biofilter and effluent enabled the C. sativa to get leaf numbers up to 26 leaves and 18-19cm height per plant and up to 4 leaves per lettuce plant and stronger presence of chlorophyll in the hydroponic beds. The big leaf plants like B. oleracea, and S. oleracea in the biofilter grew 5-7 leaves measuring 7-9 cm leaf midrib length and less chlorophyll strength compared to those in the soil using effluent that attained 18cm of leaf midrib length and stronger chlorophyll.

Plant nutrients in KYUBDAS experiment

It shows the results of nutrients in B. oleracea and C. sativa plants that were grown in the aquaponics system. The nutrients analysed were Proteins, carbohydrates, moisture, ash, fresh and dry weight. It shows that B. oleracea gained dry matter content of 12.79 percent compared to C. sativa that gained a dry matter content of 11.64 percent (Table 5).

| Plant Species | Crude protein% | Fresh wt% | Dry wt% | Moisture% |

|---|---|---|---|---|

| 33.375 ± 0.25a | 44.87 ± 6.1a | 14.42 ± 0.73a | 79.87 ± 3.3a | |

| 32.435 ± 0.17a | 23.415 ± 2.7a | 8.935 ± 1.2b | 83.61 ± 2.1a |

Table 5: Levels of nutrients in plants that were grown with fish tank effluents.

Results and Discussion

Challenges of aquaponics in hoima

According to the study findings, over 80% of the respondents depended on feed provided by the WGI because they couldn’t afford to buy the expensive feed. All the farmers depend on WGI to provide juvenile Catfish with the recommended feed. The juvenile catfish feed prices range between shs 3500-7000 per Kilogram in Kampala. Only about 20% of the farmers in Hoima use other locally improvised feed for their fish as advised by WGI including wasted intestines from pig’s abattoirs and poultry intestines that are not edible to humans but are edible to catfish. This is the case used in Egypt where the black soldier fly’s larvae is developed by feeding them waste from fish and plants for example leaves, rotten fruits and the peels, husks and fish skeletons, Blue Growth Blog. Although farmers are willing to have aquaponics farms, the challenges like lack of water for the farms, dependence on WGI for fish feed, low financial yield from the fish, and having idle plant gardens affect the management of the farms.

One hundred percent of the aquaponics farmers in Hoima depend on the WGI that endeavors to transport fish seed for over 400 km distance from Entebbe to farmers in Hoima so as to sustain the projects. Kajjansi fish hatchery and a few enterprises in Kampala, Wakiso and Entebbe provide quality fish fry. There is need for more hatcheries in the different districts because they require robust inventory [12].

Management of aquaponics at community level

Although 100% of the farmers in this study recommend aquaponics for the region, stakeholders like the WGI registered failures in concerted efforts to manage aquaponics at community level in Hoima. With reference to WGI, farm kits were given to community groups and schools in the inception year 2015. In the same year’s report, all aquaponics farms rendered to the communities failed as individuals in the groups played the blame game when it came to resource management. WGI resorted to providing kits to willing farmers and interested individuals. In reference to section 2.1.4, aquaponics can employ people in organized communities and groups. Some people can sell aquaponics grown fish and plants, sell of equipment, others can earn from consulting fees for design or construction of aquaponics facilities and fees associated with workshops, classes, public speaking and agro-tourism.

Water harvesting for agriculture

In the KYUBDAS experiment, tap water was readily available until the need to test the sustainability of tilapia and catfish in spring water arose and water had to be fetched from a spring well 500 meters away from the system location. The study reveals that less than 20% of farmers in Hoima can afford to dig a well in the aquaponic premise. Over 80% of the farmers in the study still suffer the frustration of water challenges for the aquaponic system. Only rainwater was the better choice as it only needed harvesting from the roof gutters. Aquaponics reduces water usage in irrigation and guarantees sustainable farming and food production practices in countries battling water stress. Studies propose use of hard spring well waters that are free of human activity interference and E. coli bacteria or algal blooms from waste disposal compared to the soft chlorinated tap waters that are used after de-chlorination or contaminated lake waters. Some farmers simply use rainwater that can settle for a day or more. Most farmers in Hoima have not invested in rainwater harvesting and have no containers that can sufficiently contain the rainwater. This study reveals that Hoima district has over 93% chances of torrential rains that bring heavy down pours periodically.

Economic potential of aquaponics

Results of this study revealed that although farmers did not keep records of their annual yield from fish and plant sales, up to shs 37,000,000 is estimated to come from sales of catfish on a largescale aquaponics farm of 7000 catfish stock. A total of shs 1,440,000 could be earned annually if a small-scale farmer sold vegetables at shs 30,000 per week. This study makes a realization that perhaps this is what got farmers interested in the aquaponics business. Previous authors reported that they would not earn profits from fish sales because the proceeds would cover operating costs like power, fish feed, buffers, and seed production on the farm but would earn $87,868 from plant sales on a land area estimated to be 25 yards. Through hydroponics, farmers can get between 450 and 550 tons of vegetables per acre, compared to the average yield of 15 tons per acre using traditional farming (High-tech Agriculture, 2012). This study however shows in results that the small-scale farmer can earn over 1,440,000 from plant sales annually. Therefore, the loss incurred by less fish sales is compensated with profits from the vegetables. The large-scale farmers with 7000 catfish need 35 times more feed compared to the small scale farmer. If 200 fish need shs 546,000 for feed per year, then 7000 fish would require shs 19,110,000 to buy feeds per year in reference. The profit and loss account for the large scale farmer can be determined as follows. If Respondent 2 (R2) sold 82% of 7000 cat fish at 7000 per kilogram, she could earn shs 37,350,000 and shs 19,110,000 would be invested in the feed. Therefore, the large scale farmer will earn an estimated profit of 18,240,000 every year from cat fish per year. It shows that farmers with less than 1200 fish stock will probably sell the fish by 500 g at shs 3500 so that they can make a quick earning and restock after the fish is depleted. The large-scale farmer will probably wait until the fish gain a kilogram or more to reap more in sales [13].

Fish species and mortality

In the KYUBDAS investigation, O. niloticus and C. gariepinus were cultured. It showed the result that O. niloticus registered 7.4 ± 15.23 mortalities compared to C. gariepinus 3.64 ± 0.83. This meant that the average mortality of both species was not significantly different at a p=value 0.306. In Hoima region, only catfish is cultured in aquaponics systems. The proprietors of the system in Hoima only use catfish because it grows faster, its omnivorous feeding habits allow the consumption of both plants, silver fish pellets, and poultry waste. It is also tolerant to high turbidity, low oxygen levels and low water levels in a densely populated container, all these result to less mortalities but on the other hand tilapia prefers clean shallow waters with enough oxygen, feeding on algal blooms, plankton, and pellets that should be given at ratios that do not compromise the water pH. This is also evident in the Farmer’s weekly magazine in South Africa, it was stated that the Nile Tilapia (Oreochromis niloticus) is the fastest growing fish species at a rate of 400-500grams in just nine months if cultured in warm temperatures between 25° C-30° C.

Encouraging tilapia culture in aquaponics

Nile tilapia and catfish culture in the KYUBDAS experiment suggested low stocking density to allow fish ample swimming space and laying gravel medium beneath the water to mimic the natural environment. In Hoima, none of the aquaponics farmers visited cultured Nile tilapia to supplement the catfish culture probably because of its high oxygen demand. This could have been due to the low stocking ratio of 13 fish per 35 liters of water.

It was also realized that a little motion in the water would let in more oxygen and reduce tilapia buoyancy and motivate activity that allows positive food conversion. This would answer many farmers and investor’s worries to engage in tilapia culture if they can afford to change the water every 3 days for more oxygen and steady growth of the fish.

Tap water was de-chlorinated by bubbling or leaving it in the open for over 24 hours or more days but the tilapia fish would still lose the natural skin color, turn blind or even peel and die although not as many as when spring well water was used. This was evidenced by similar studies of the brown blood disease that results from increase in nitrite that binds with the fish’s blood in place of oxygen and keep the fish from getting the oxygen it needs hence the fatality. But if the water is not changed daily or maintaining water temperature between 20° C and 30° C, the ammonia nitrites are known to attract bacteria known as nitrospira which turn the nitrites to nitrates which is non-toxic to both the fish and the plants.

The plant bed efficiency

According to a farmer was reluctant to fill the grow beds with sand and perceived that all plants need the same volume of sand and stones to produce crops. The KYUBDAS study has tested use of the standard volume of grow bed media needed for deep root plants and realizes that the plant growth may differ according to the volume of the grow beds. The standard for plant bed media is 12 inches thickness for the plants like B. oleracea and S. oleracea that need deep root space for support and growth. C. sativa, and L. sativa need the 6 inches thickness of the plant bed media for their shallow roots. In the KYUBDAS, the need for the flood tank to complete the nitrification process of turning ammonium to nitrate would ease the work of the plant media beds especially those with 6 inches of thickness. The effluent would then reach the plants with nitrates that are nontoxic or easily be absorbed by plants. This technique was coined as Deep water Culture where a depth of 10 to 12 inches was deemed adequate for plant root development although beds as shallow as 6 inches work for many plants. In the Hoima focus group however, all the farmers visited did not use flood tanks but poured the effluent directly into the hydroponic plants. To an extent, therefore many could not yield as much from the plant beds despite the 8inch plant media gravel thickness. The direct watering of effluent from the fish tanks/ponds was better for farmers who had large scale hydroponic crop gardens/plant boxes and those with nonreversible systems where effluent would be channeled to the gardens with plants in the soil. In the Nkozi University aquaponics demonstration structure, gravel beds of only 6 inches were used for their deep water plant culture but the plants would turn yellow in color lack of necessary nutrients like potassium and magnesium because all the water would run through the filter beds to the water reservoirs below.

Water tests

Water test results showed that turbidity was high in C. gariepinus water with an overall count of 430 but the plant beds managed to normalize the water quality to a strong Pareto chart effect of average turbidity count mean 19.53. This means the water that would return to the fish tanks was much clearer. Plant beds also enabled an increment in the percentage of dissolved oxygen. Water from the fish tanks indicated lower DO (%) i.e. C. gariepinus water (7.03 ± 0.208) and O. niloticus water (10.6 ± 0.21) compared to water from plant beds (25.33 ± 0.153). Oxygen being a crucial non-mineral for fish was abundant in water from the plant beds. It is therefore necessary to guarantee that the water that has been filtered by the plant beds is free of toxic nitrite ions obtained in the de-nitrification process before discharging the treated water back into the system to reduce the risk of fish mortalities. A pH ranging between 7-8 was maintained in all water from fish. The slightly alkaline nature of water from plants is good for fish as they obtain calcium (Ca) that has been gained from the plant beds. While the treatment utilized water from tap and spring wells, farmers in Hoima used mostly spring well and borehole water for their systems. Water testing in the was done using the hydro lab and the results showed a clear deviation between the quality of water from the fish containers compared to that from the plant grow beds. A turbidity deviation range of 11.590 NTU in catfish water was filtered to a range of 0.503 NTU and a pH of 7-8. This pH level is recommended for a better bacterial nitrification process in the grow bed biofilter. The plats are elevated to the surface of the grow beds by use of plastic cups so as to limit tem to an effluent pH of 6-7. In Hoima, farmers do not test the water that circulates to and from the plant’s beds. This may be a risk to the plants as the farmer may not ascertain the right quality of water to circulate.

Big leaves against small leaf plant nutrient adaption

Although the plant nutrient percentages were relatively different between pants B. oleracea and C. sativa, the results showed no significant difference in the Fresh weight (p=0.077), Moisture (p=0.352), Proteins with (p=0.176). However, Dry weight had a significant difference of (p=0.01). A similar study carried out a ttest on the weight of spinach leaves in aquaponics that was recorded biweekly in two different seasons. The realized significant (P<0.05) differences in leaves weight among the treatments that was found at 26th August 2017 but there was no significant difference of leaves weight in dates within the months of July and September 2017. This study reveals in that the significant (p=0.01) difference in the dry matter weight of the plants depicts a difference in need of nutrients. B. oleracea (big leaf plant) needed a total of 30 days compared to C. sativa (small leaf plants) which need less than 20 days to gain as much moisture (77 and 79 g/100 g). These findings justify the theoretical categorization of Kale (B. oleracea) and Spinach (S. oleracea) plants as medium aquaponics nutrient demand plants while coriander and lettuce are low nutrient demand plants.

KYUBDAS treatment used totally 50 fish and over 5 liters of effluent for 60 plants. Small leaf plants grew better than big leaf plants in the hydroponic media compared to the big leaf plants.