Indexed In

- Open J Gate

- Genamics JournalSeek

- Ulrich's Periodicals Directory

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Proquest Summons

- Scholarsteer

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

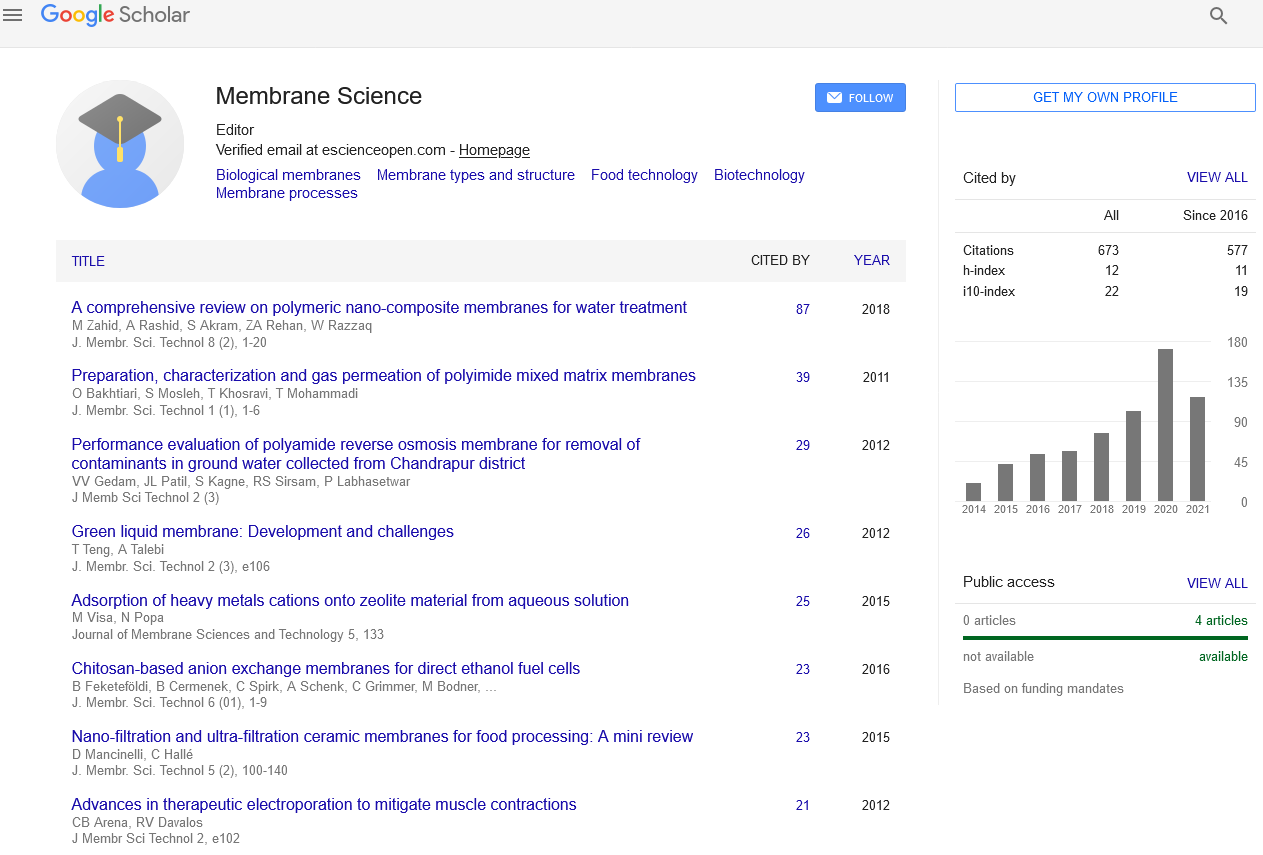

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Opinion - (2020) Volume 10, Issue 2

Membrane of Polymer

Julia Anderson*Received: 10-Jul-2020 Published: 31-Jul-2020, DOI: 10.35248/2155-9589.2020.10.207

Abstract

Nanoscale materials are of basic enthusiasm to the material researchers. The property of mass polymeric material which can change by atomic control in the nano scale locale rather than the basic alteration by substance response or physical methods could have incredible potential for cutting edge layer division applications

Keywords

Membrane; Polymer; TechnologyIntroduction

As a green innovation, layer based detachment is probably going to assume a significant job in numerous mechanical applications. There are numerous preferences of utilizing films for mechanical procedures such as no stage changes, simple to scale up, basic in activity, generally low vitality utilization, low work cost, less space prerequisite and so on [1]. Detachment through layers is generally founded on the particular transport marvel of the atoms through the film lattice. The essentialness of this wonder has prompted the improvement of novel film materials to improve the subatomic transitions in the film network while isolating the particles of intrigue [2]. Two or then again more materials with disparate properties in a specific extent are combined to shape a composite. The individual parts in composites are remaining fortified together by certain physical or on the other hand compound communications, while, holding their physical or concoction personalities. By and large, properties of the composite materials are predominant in numerous regards to those of the individual unadulterated parts. A large portion of the composites are made with engineered polymer (as framework stage), furthermore, manufactured, metallic, silica or glass filler (as scattered stage). Nanoparticles are fascinating nano scale fillers to improve the utilitarian execution of mass polymeric material at extremely low focus (commonly a part contrasted with the grid polymer) [3]. Polymer nano-composites keep on getting gigantic consideration for potential in cutting edge material applications remembering for the novel layer science and innovation.

Polymeric layers are generally utilized in film partition forms for the benefits of their capacity to shape great layer, adaptability, sturdiness, efficient, and astounding partition properties; though, they have hardly any entanglement, for example, constrained mechanical, synthetic, what's more, warm opposition, low mass vehicle (for thick polymeric film) just as a helpless enemy of fouling capacity initiated by their surface properties. Readiness of novel composite polymeric film by auxiliary change of the current framework of polymer film materials to improve their porousness, permselectivity what's more, quality and other utilitarian properties would play a significant job in film science and innovation. Polymeric nano-composite films are set up by blending of nano-sized fillers and polymer framework to upgrade exhibitions, for example, high permselectivity, transitions, good surface morphology because of brilliant fouling opposition contrasted and the unadulterated polymeric framework films [4,5]. Before hardly any years, polymer nano-composite film has been ruling in its application for gas detachment, water and wastewater treatment, desalination, energy component and so on. A definitive properties of a polymeric nanocomposite layer are a lot of reliant on the scattering and dissemination of the strengthening nano-filler in the constant stage, just as interfacial connection between the outside of nanoscale filler and polymer grid [3]. By consolidating nanosize fillers in the polymer arrangement before the film creation, one can change arrangement rheology, modify stage reversal and control film morphology. Forthcoming nano-fillers for polymer nano-composite layer manufacture are carbon nanotubes, graphene oxide, TiO2 , SiO2 , Mg(OH)2 , Al2O3 , ZnO, earth and so forth. Astonishing upgrade of both layer porousness, and selectivity for atomic species during division could be accomplished by fortifying nanofillers in the polymer layer framework. The profoundly great property upgrade in terms of transition and selectivity for polymer nano-composite layer as opposed to the ordinary filler strengthened polymer layer is in all likelihood because of an additional district at the nanofillers polymer interface and additionally interruption of polymer chain pressing because of significant increment of free volume size through which sub-atomic vehicle would happens in the thick nano-composite film network [6,7]. In this way, the two gas detachment just as huge scope water treatment of business furthermore, natural significance could be profited by utilizing polymer nano-composite film.

Conclusion

With the fast increment of worldwide populace and ensuing needs for vitality, new water and waste water treatment films will lead in numerous regions, for example, water treatment (viz. desalination, squander treatment), gas treatment and power devices are not many fields of numerous to states. Innovative work in the polymer nanocomposite layer is promising. In any case, further advancement is required as there are numerous difficulties to defeat before nanocomposite polymeric layer can be considered in the modern full stage applications. So as to fulfill the need for novel applications, following will be testing and fascinating for specialists:

• Finding tale nano-filler for explicit utilizations of nanocomposite layers

• One of the serious issues for nano-composite film is the best possible scattering and dispersion of nano-fillers in the polymer nano-composite film framework

• Surface adjustment of nano-fillers, thus, to improve the interfacial association between the divergent surface of nanofiller and polymer lattice

• Enhancing the transition through the nano-composite polymeric film framework while isolating the focused on part is testing to the film researchers

• Membrane fouling is another obstruction for the layer based partition where nano-fillers could be relevant to improve the film execution

Nano-composite polymeric film could improve the film division process which could be a key patron for tackling worldwide new water flexibly, condition and vitality.

REFERENCES

- Kang GD, Cao YM. Application and modification of poly(vinylidene fluoride) (PVDF) membranes-A review. J Membrane Sci. 2014;463:145-165.

- Kubaczka A. Prediction of Maxwell-Stefan diffusion coefficients in polymer-multicomponent fluid systems. J Membrane Sci. 2014;470:389-398.

- Mondal S, Hu JL. Microstructure and water vapor transport properties of functionalized carbon nanotube reinforced segmented polyurethane composite membranes. Polym Eng Sci. 2018;48:1718-1724.

- Reddy AVR, Mohan DJ, Bhattacharya A, Shah VJ, Ghosh PK. Surface modification of ultrafiltration membranes by preadsorption of a negatively charged polymer. I. Permeation of water soluble polymers and inorganic salt solutions and fouling resistance properties. J Membrane Sci. 2003;214:211-221.

- Yang YN, Zhang HX, Wang P, Zheng QZ, Li J. The influence of nanosized TiO2 fillers on the morphologies and properties of PSFUF membrane. J Membrane Sci. 2014;288:231-238.

- Hinds BJ, Chopra N, Rantell T, Andrews R, Gavalas V. Aligned multiwalled carbon nanotube membranes. Science. 2004;303:62-65.

- Paul DR, Robeson LM. Polymer nanotechnology: Nanocomposites. Polymer. 2014;49:3187-3204.

Citation: Anderson J (2020) Membrane of Polymer. J Membra Sci Technol 10:207. doi: 10.35248/2155-9589.2020.10.207

Copyright: © 2020 Anderson J. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.