Indexed In

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2019) Volume 10, Issue 7

Dehydration of Chamomile Flowers under Different Drying Conditions

El-Sayed G Khater*, Adel H Bahnasawy and Ramy M HamoudaReceived: 13-May-2019 Published: 31-May-2019

Abstract

The main aim of this study is to investigate the possibility of drying chamomile plants under different conditions. The obtained results indicated that the accumulated weight loss of chamomile flowers was (86.27, 84.67, 82.70, 85.04 and 86.53)% for the sun-drying system, shadow-drying system, room-drying system, solar-drying system, and oven-drying system, respectively. The moisture content of chamomile flowers decreased from (508.59 to 14.56)%, (502.77 to 15.43)%, (470.09 to 18.19)%, (537.47 to 13.45) and (444.84 to 5.46)% d.b. for sun-drying system, shadow-drying system, room-drying system, solar-drying system and oven-drying system, respectively. The highest value of equilibrium moisture content was 51.78% at 90% equilibrium relative humidity was found from the Henderson equation under room system. The lowest value of equilibrium moisture contents was 1.38% at 10% equilibrium relative humidity was found for modified Oswin equation for oven system. The chamomile oil content values were (0.66, 0.78, 0.94, 0.73 and 0.59)% for the flowers dried under sun-drying, shadow-drying, room-drying, solar-drying, and oven-drying, respectively. The highest values of Nitrogen, Phosphorus, Potassium, Calcium, and Magnesium contents (2.62, 1.11, 4.10, 1.12 and 0.23)% were obtained when the chamomile dried at room temperature system. The lowest value of the Nitrogen, Phosphorus, Potassium, Calcium and Magnesium content (1.50, 0.83, 3.83, 0.84 and 0.20)% were found at the oven-drying system.

Keywords

Chamomile; Sun-drying; Solar-drying; Oven-drying; Equilibrium moisture content; Oil content

Introduction

Medicinal and aromatic plants cultivated in all over the world particularly in Egypt for both local consumption and export. The chamomile is one of the most important aromatic plants in Egypt. Its area is about 8351 feddans (12.9% of medicinal and aromatic plants), producing about 6949.3 ton/year [1].

Drying is the most common and effective method that increases the shelf life of spicy herbs by inhibiting the growth of microorganisms and preventing the onset of some biochemical reactions that may alter the organoleptic and nutritional characteristics of the dried leaf. However, drying must be performed carefully in order to preserve the aroma, appearance and nutritional characteristics of the raw herbs as much as possible [2]. The drying may cause losses in volatilities or formation of new volatilities as a result of oxidation reactions, esterification reactions [3].

Dried chamomile flower is an age-old medicinal drug that was well known in ancient Egypt, Greece and Rome. In Egypt, chamomile had a religious use as the plant was consecrated to the god of the sun. Chamomile’s popularity grew throughout the middle ages when people used it as a remedy for numerous medical complaints. The word chamomile is derived from the Greek roots ‘chamos’ (ground) and ‘melos’ (apple), referring to the fact that the plant grows low to the ground, and the fresh blooms have a pleasing apple scent.

Moisture sorption isotherm defines the relation between Equilibrium Relative Humidity (ERH) and Equilibrium Moisture Content (EMC) [4]. This information is required for drying and storage of agricultural and food products, for instance, to maintain the quality in the storage period. This knowledge is also required to stop the drying process at the aimed moisture content to avoid quality losses and to save energy [5].

EMC is defined as the moisture content of a hygroscopic material in equilibrium with an environment in terms of temperature and relative humidity. EMC of the product is the result of moisture exchange between the product and the air surrounding the sample. In this condition, the water in a product is in balance with the moisture in the surrounding atmosphere [6]. The relative humidity in this condition is known as the Equilibrium Relative Humidity (ERH) [4]. Moisture sorption isotherms are either measured during desorption (starting from the wet state) or during adsorption (starting from the dry state).

The herbal and medicinal plants are perishable. keeping their quality and prolonging the shelf life is required by drying them, therefore, the main aim of this study to investigate the possibility of drying the chamomile plants under different conditions.

Materials and Methods

The experiment was carried out at Agricultural and Bio-Systems Engineering Department, Faculty of Agriculture Moshtohor, Benha University, Egypt (latitude 30° 21` N and 31° 13` E). During the period of April and May 2017.

Materials

The fresh chamomile was brought from the private company, El- Sharkia Government, Egypt after harvesting for the primary analysis.

Drying systems: The basil was dried using different systems as follows:-

• Sun-drying: Chamomile plants were folded into a thin sheet of paper and placed on a flat plate in direct sunlight over a tray with a dimension of (0.8 m long, 0.6 m wide and 0.1 m high)

• Shadow-drying: Chamomile plants were folded into a thin sheet of paper and placed on a flat plate (0.8 m long, 0.6 m wide and 0.1 m high) in shadow

• Room temperature-drying: Chamomile plants were folded into a thin sheet of paper and placed on a flat plate (0.8 m long, 0.6 m wide and 0.1 m high) in the room for air-drying at ambient temperature

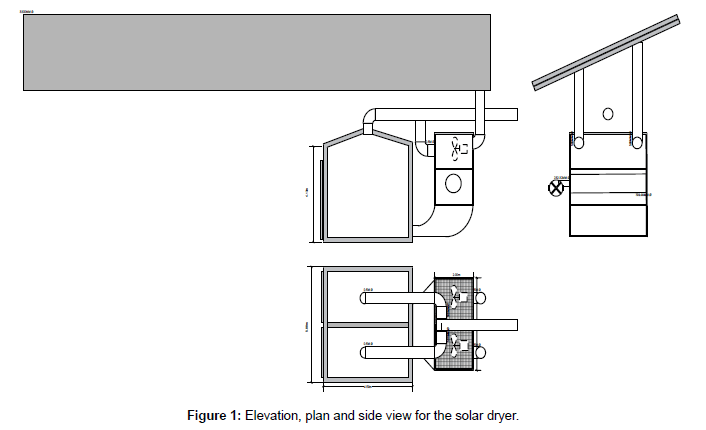

• Solar-drying: The solar dryer consists of solar collector, drying chamber, trolley and trays and fan/blower as shown in Figure 1. The solar collector consists of three major components, namely: The glass cover has 12 sheets of dimensions (2.0 × 2.0) m and 5.5 mm thickness. The reason for selecting this material is due to the structural thermal properties. The absorber plate, (corrugated black aluminum plate). The insulation, (thermal wool with a 5.0 cm thickness). The drying chamber has a length of 2.5 m, a width of 2.3 m and a height of 2.6 m. It is made of galvanized steel (5 mm thickness). The trolley is made from stainless steel and has a length of 2.3 m, a width of 1.1 m and a height of 2.4 m. It is designed in such a way that it allows easy insertion of individual trays at a distance of 0.2 m apart and has tires for easy movement of trays. The trays are made of stainless steel and have a length 1.1 m, width 0.74 m and a depth of 0.03 m. They have a perforated bottom which allows heated air to pass through products. The air blower was used to force and re-circulate the drying air to the drying chamber. Two air blowers (Model C.C.P. Parma-Flow Rate 720 m3 h-1-RPM 2800-Power 1.5 hp 380V 50Hz, Italy) for moving air in the drying chamber (Figure 1)

Figure 1. Elevation, plan and side view for the solar dryer.

• Oven-drying: Chamomile plants were spread evenly on baking sheets and placed in conventional laboratory oven (Fisher Scientific Isotemp Oven, Model 655F Cat. No. 13-245-655, Fisher Scientific, Toronto, Ontario, Canada)

Methods

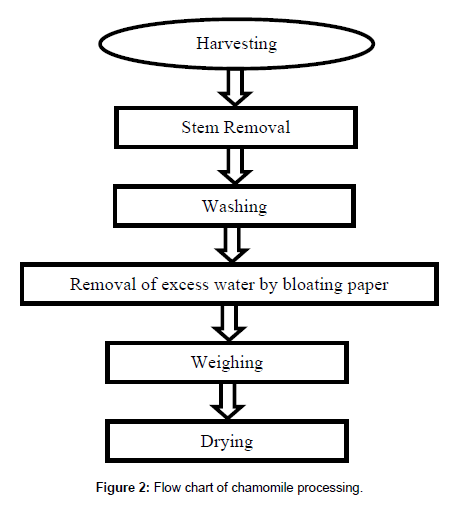

Chamomile was cleaned by removing undesired stems and waste materials as shown in the process through flow chart (Figure 2).

Figure 2. Flow chart of chamomile processing.

• Drying methods: Five different drying methods were used to dry chamomile. The reported data are means of three replications. In each replicate, 5 kg of cleaned fresh chamomile was used

• Sun-drying: Chamomile plants were folded into a thin sheet of paper and placed on a flat plate in direct sunlight at an average temperature of (34.5 ± 1.0)°C and relative humidity of (58.5 ± 2.0)%

• Shadow-drying: Chamomile plants were folded into a thin sheet of paper and placed on a flat plate in shadow at an average temperature of (31.0 ± 1.0)°C and relative humidity of (69.5 ± 2.5)%

• Room temperature-drying: Chamomile plants were folded into a thin sheet of paper and was placed on a flat plate in the room for air-drying at ambient temperature at an average temperature of (29.0 ± 1.0)°C and relative humidity of (58.0 ± 4.0)%

• Solar-drying: Chamomile plants were folded into a thin sheet of paper and placed on a flat plate in the solar dryer at an average temperature of (46.0 ± 6.0)°C and relative humidity of (40.0 ± 13.0)%

• Oven-drying: Chamomile plants were spread evenly on baking sheets and placed in a conventional laboratory oven at a temperature of 65°C

Measurements

The mass was measured by electric digital balance (Model HG- 5000-Range 0-5000 g ± 0.01 g, Japan) daily for sun, shadow and ambient air-drying methods and hourly for solar and oven drying methods. Temperature and relative humidity were recorded by using a HOBO Data Logger (Model HOBO U12 Temp/RH/Light-Range -20°C to 70°C and (05 to 95)% RH, USA) every hour. The total content of macroelements was evaluated after being digested according to [7]. Nitrogen was determined by Kjeldahl digestion apparatus [8]. Potassium, Calcium, and magnesium were determined by Photofatometer (Model Jenway PFP7-Range 0-160 mmol L-1, USA) and phosphorus (P) was determined colorimetrically following the [9] method. The content of oil was determined in basil plants according to [10].

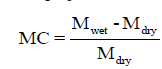

Calculations

Moisture content: The moisture content of the fresh and dried chamomile plants was determined using conventional laboratory oven kept at 105°C until a constant weight was reached. Triplicate determinations were made and the moisture content calculated as the following equation:

(1)

(1)

Where:

- MC is the moisture content,% d.b.

- Mwet is the wet mass of samples (g)

- Mdry is the dry mass of samples (g)

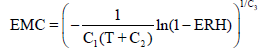

- Equilibrium moisture content

A number of equations have been suggested in the literature to describe the relationship between equilibrium moisture content (EMC) and equilibrium relative humidity (ERH). The modified Henderson modified Oswin and modified Halsey, modified Chung-Pfost and GAB equation [11] have been adopted by the American Society of Agricultural Engineers as standard equations for describing sorption isotherms [12]. We transformed the equations to get EMC as the dependent variable and ERH as the independent variable.

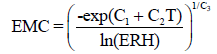

Modified Henderson

(2)

(2)

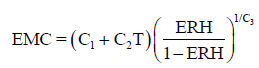

Modified Halsey

(3)

(3)

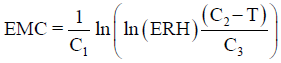

Modified Oswin

(4)

(4)

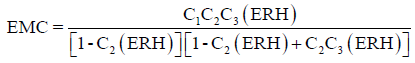

Modified Chung-Pfost

(5)

(5)

GAB equation

(6)

(6)

Where:

• ERH is the equilibrium relative humidity,%

• T is the temperature, °C

• C1, C2 and C3 are the constants

The parameters C2 and C3 in the GAB equation are correlated with temperature using the following equations [13]:

(7)

(7)

(8)

(8)

Where:

• C4, C5, C6 and C7 are coefficients

• Ta is the absolute temperature, K

• R is the universal gas constant, R=8.314 kJ/kmol K

Results and Discussion

Weight loss

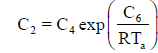

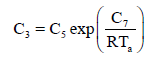

Figures 3 and 4 show the accumulated weight loss of chamomile plants that dried under different drying systems (sun-drying, shadowdrying, room temperature-drying, solar-drying, and oven-drying) at different drying air temperature and relative humidity during the experimental period. The results indicate that the accumulated weight loss of chamomile plants increases with increasing drying period. It could be seen that the accumulated weight loss of chamomile plants increased from (83.63 to 86.270)% when the drying period increased from 1 to 5 days at drying air temperature ranged from (23.91 to 26.54)°C and relative humidity ranged from (58.16 to 61.97)% for the sun-drying system.

Figure 3. The accumulated weight loss of chamomile flowers at different drying systems at different drying air temperature during experimental period.

Figure 4. The accumulated weight loss of chamomile flowers at different drying systems at different relative humidity during experimental period.

For shadow-drying system, the accumulated weight loss of chamomile plants increased from (77.12 to 84.67)%, when the drying period increased from 1 to 8 days at drying air temperature ranged from (22.69 to 24.67)°C and relative humidity ranged from (53.29 to 57.20)%. For room temperature-drying system, the accumulated weight loss of chamomile plants increased from (73.95 to 82.70)%, when the drying period increased from 1 to 12 days at drying air temperature ranged from (20.04 to 22.67)°C and relative humidity ranged from (49.94 to 52.58)%. For solar-drying system, the accumulated weight loss of chamomile plants increased from (54.61 to 85.04)%, when the drying period increased from (1 to 41) hours at drying air temperature ranged from (36.24 to 41.35)°C and relative humidity ranged from (48.97 to 55.37)%. For oven-drying system, the accumulated weight loss of chamomile plants increased from (60.14 to 86.53)%, when the drying period increased from (1 to 8) hours at drying air temperature was 65°C and relative humidity was 10.0%.

The results also indicate that the shorter drying period (8 hours) was occurred under the oven-drying system due to the higher temperature (65°C) and lower relative humidity (10%). Meanwhile, the longer drying period (12 days) was occurred under the room temperature-drying system due to the lower temperature (20.04 to 22.67)°C and higher relative humidity (49.94 to 52.58)%. The results show the highest rate of weight loss occurred on the first day under the sun-drying, shadowdrying and room temperature-drying systems. It could be seen that the weight losses were (83.63, 77.12 and 73.95)% for sun-drying, shadowdrying, and room temperature-drying systems, respectively.

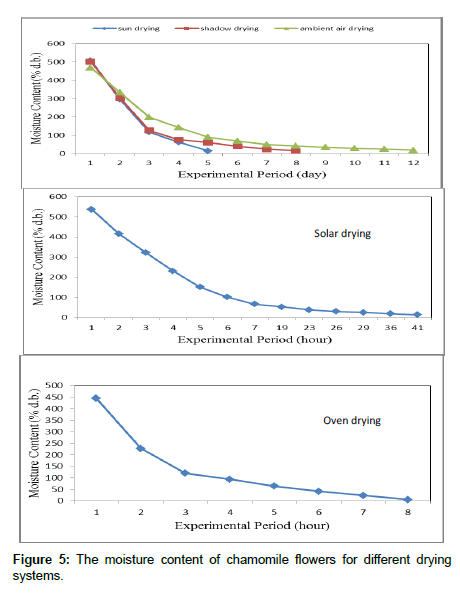

Moisture content

Figure 5 shows the moisture content of chamomile plants under different drying systems (sun-drying, shadow-drying, room temperature-drying, solar-drying, and oven-drying) during the experimental period. The results indicate that the moisture content of chamomile plants decreases with increasing drying period for all drying systems. It could be seen that the moisture content of chamomile plants decreased from 508.59% to 14.56% d.b., (by 97.14%) when the drying period increased from 1 to 5 days for the sun-drying system [14]. For shadow-drying system, the moisture content of chamomile plants decreased from (502.77 to 15.43)% d.b., (by 96.93%) when the drying period increased from 1 to 8 days. For room temperature-drying system, the moisture content of chamomile plants decreased from (470.09 to 18.19)% (by 96.13%), when the drying period increased from 1 to 12 days. For solar-drying system, the moisture content of chamomile plants decreased from (537.47 to 13.45)% d.b., (by 97.50%) when the drying period increased from 1 to 41 hours. For the ovendrying system, the moisture content of chamomile plants decreased from (444.84 to 5.46)% d.b., (by 98.77%) when the drying period increased from 1 to 8 hours. These results agreed with those obtained by Özcan et al. and Arafa [15,16].

Figure 5. The moisture content of chamomile flowers for different drying systems.

The results indicate that the highest rate of the decrease moisture content of chamomile plants (98.77%) happened under the oven-drying system. Meanwhile, the lowest rate of the decrease moisture content of chamomile plants (96.13%) was found at the room system.

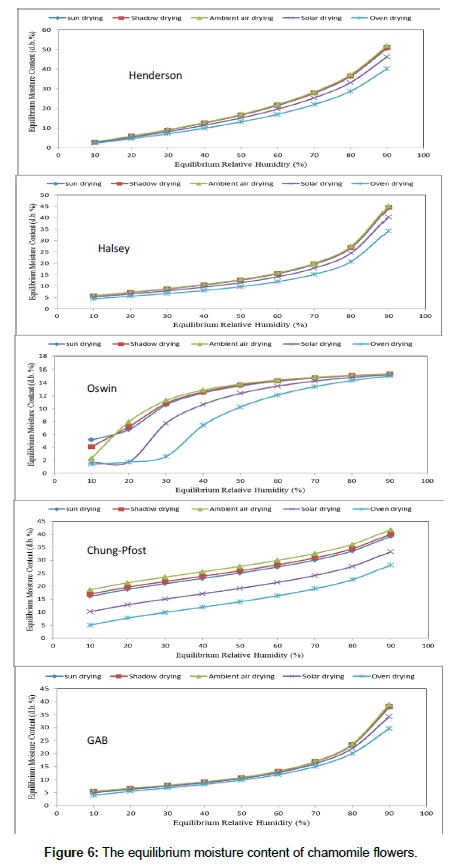

Equilibrium moisture content

Figure 6 shows the equilibrium moisture content of chamomile plants for different drying systems (sun-drying, shadow-drying, room temperature-drying, solar-drying, and oven-drying) and differential equation models (modified Henderson, modified Halsey, modified Oswin, modified Chung-Pfost and Gab models).

Figure 6. The equilibrium moisture content of chamomile flowers.

The results indicate that the equilibrium moisture content of chamomile plants increases with increasing equilibrium relative humidity for different drying systems. It could be seen that the equilibrium moisture content of chamomile plants was increased from (2.86 to 50.61, 2.89 to 51.04, 2.93 to 51.78, 2.62 to 46.27 and 2.27 to 40.11)% for sun, shadow, room temperature, solar and oven drying systems, respectively, when the equilibrium relative humidity increased from (10 to 90)% for modified Henderson equation. For modified Halsey equation, the EMC of chamomile plants was increased from (5.64 to 44.15, 5.69 to 44.50, 5.76 to 45.12, 5.15 to 40.30) and (4.36 to 34.16)% for sun, shadow, room temperature, solar and oven drying systems, respectively, when the equilibrium relative humidity increased from (10 to 90)%. For modified Oswin equation, the EMC of chamomile plants was increased from (5.17 to 15.40, 4.13 to 15.41, 2.35 to 15.42, 1.70 to 15.28 and 1.38 to 15.08)% for sun, shadow, room temperature, solar and oven drying systems, respectively, when the ERH increased from (10 to 90)%. For modified Chung-Pfost equation, the EMC of chamomile plants was increased from (16.13 to 39.20, 16.96 to 40.03, 18.67 to 41.74, 10.20 to 33.27)% and (5.06 to 28.12)% for sun, shadow, room temperature, solar and oven drying systems, respectively, when the ERH increased from (10 to 90)%. For GAB equation, the EMC of chamomile plants was increased from (5.43 to 37.76, 5.47 to 38.12, 5.53 to 38.78, 4.95 to 34.18 and 3.93 to 29.63)% for sun, shadow, room temperature, solar and oven drying systems, respectively, when the ERH increased from (10 to 90)%.

The results indicated that the highest value of equilibrium moisture content was found from the Henderson equation under room system. It could be seen that the equilibrium moisture content was 51.78% at 90% equilibrium relative humidity for room temperature system. Meanwhile, the lowest value of equilibrium moisture content was found for the modified Oswin equation for oven system. It could be seen that the equilibrium moisture content was 1.38% at 10% equilibrium relative humidity for oven system (Table 1).

| Coefficient | Equation | ||||

|---|---|---|---|---|---|

| Henderson | Halsey | Oswin | Chung-Pfost | GAB | |

| C1 | 0.034 | -2.606 | 0.185 | 9.155 | 0.058 |

| C2 | 115.67 | -7.76 × 10-3 | -8.89 × 10-4 | 42.03 | |

| C3 | 1.074 | 1.300 | 1.713 | 305.44 | |

| C4 | 0.626 | ||||

| C5 | 2.23 × 10-3 | ||||

| C6 | 1010 | ||||

| C7 | 25000 | ||||

Table 1: Shows the coefficients for Henderson, Halsey, Oswin, Chung-Pfost and GAB equations of chamomile leaves for different drying systems.

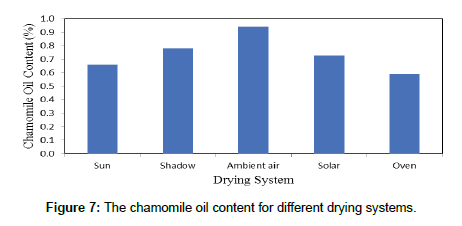

Content of oil

Figure 7 shows the chamomile oil content for different drying systems (sun-drying, shadow-drying, room temperature-drying, solardrying, and oven-drying) at the end of the experiment. It could be seen that the basil oil content values were (0.66, 0.78, 0.94, 0.73 and 0.59)% for the sun-drying, shadow-drying, room temperature-drying, solardrying, and oven-drying, respectively. The results indicate that the highest value of the basil oil content (0.94%) was obtained when the chamomile dried at room temperature system. Meanwhile, the lowest value of the basil oil content (0.59%) was found at the oven-drying system.

Figure 7. The chamomile oil content for different drying systems.

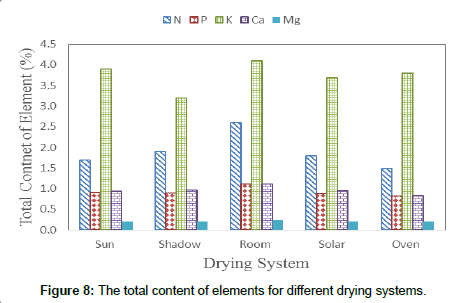

The total content of macro elements

Figure 8 shows the total content of macro elements (Nitrogen, Phosphorus, Potassium, Calcium, and Magnesium) for different drying systems (sun-drying, shadow-drying, room temperature-drying, solardrying, and oven-drying) at the end of the experiment. It could be seen that the highest values of Nitrogen, Phosphorus, Potassium, Calcium, and Magnesium content were (2.62, 1.11, 4.10, 1.12 and 0.23)% were obtained when the chamomile dried at room temperature system. Meanwhile, the lowest value of the Nitrogen, Phosphorus, Potassium, Calcium, and Magnesium content was (1.50, 0.83, 3.83, 0.84 and 0.20)% were found at the oven-drying system.

Figure 8. The total content of elements for different drying systems.

Conclusion

The experiment was carried out to study was conducted to investigate the possibility of drying the chamomile plants under different conditions. The obtained results can be summarized as follows:

The accumulated weight loss of chamomile plants increased from (83.63 to 86.27, 77.12 to 84.67, 73.95 to 82.70, 54.61 to 85.04 and 60.14 to 86.53)% for the sun-drying system, shadow-drying system, room temperature-drying system, solar-drying system, and oven-drying system respectively.

The moisture content of chamomile plants decreased from (508.59 to 14.56, 502.77 to 15.43, 470.09 to 18.19, 537.47 to 13.45 and 444.84 to 5.46)% d.b. for the sun-drying system, shadow-drying system, room temperature-drying system, solar-drying system, and oven-drying system respectively.

The highest value of equilibrium moisture contents were 51.78% at 90% equilibrium relative humidity was found from Henderson equation under room temperature system.

The lowest value of equilibrium moisture contents were 1.38% at 10% equilibrium relative humidity was found for modified Oswin equation for oven system.

The chamomile oil content values were (0.66, 0.78, 0.94, 0.73 and 0.59)% for the sun-drying, shadow-drying, room temperature-drying, solar-drying, and oven-drying respectively.

The highest values of Nitrogen, Phosphorus, Potassium, Calcium, and Magnesium content were (2.62, 1.11, 4.10, 1.12 and 0.23)% were obtained when the chamomile dried at room temperature system.

The lowest value of the Nitrogen, Phosphorus, Potassium, Calcium, and Magnesium content were (1.50, 0.83, 3.83, 0.84 and 0.20)% were found at the oven-drying system.

Acknowledgment

This work is fully sponsored by the utilization of solar energy in herbal plants drying funded by the Support and Development of Scientific Research Center, Benha University.

REFERENCES

- CAGMC (Centeral Authority for General Mobilization and Statistics) (2007) The Annual Statistical Book for A.R.E. 11.

- Crivelli G, Nani RC, Di Cesare LF (2002) Influence of processing on the quality of dried herbs. Atti VI Giornatescientifiche SOI. Spoleto 2: 463-464.

- Diaz-Maroto MC, Pérez-Coello MS, Cabezudo MD (2002) Effect of drying method on the volatilities in bay leaf (Laurusnobilis L.). J Agri Food Chem 50: 4520-4524.

- Soysal Y, Oztekin S (1999) Equilibrium moisture content equations for some medicinal and aromatic plants. J Agri Eng Res 74: 317-324.

- Hamer PJC, Knight AC, McGechan MB, Cooper G (2000) Model for predicting the field drying characteristics of grass conditioned by maceration (severe treatment). J Agri Eng Res 75: 275-289.

- Silakul T, Jindal VK (2002) Equilibrium moisture content isotherms of mungbean. Int J Food Pro 5: 25-35.

- Chapman HD, Partt FP (1961) Methods of analysis of soils, plant and water. California University, pp: 150-200

- Bremner JM (1965) Total nitrogen. Agronomy 9: 1149-1178.

- Kiferle C, Lucchesini M, Mensuali-Sodi A, Maggini R, Raffaelli A, et al. (2011) Rosmarinic acid content in basil plants grown in vitro and in hydroponics. Cent Eur J Biol 6: 946-957.

- Chen C (2002) PH-Pastharvest technology: Sorption isotherms of sweet potato slices. Biosyst Eng 83: 85-95.

- ASAE (2003) Moisture relations of plant-based agricultural products. ASAE Standards; Standards Engineering Practices Data D 245.5: 538.

- Lahsasni S, Kouhila M, Mahrouz M (2004) Adsorption-desorption isotherms and heat of sorption of prickly pear fruit (Opuntia ficus indica). Energy Conv Manag 45: 249-261.

- Arabhosseini A, Huisman W, Van Boxtel A, Müller J (2005) Modeling of the equilibrium moisture content (EMC) of Tarragon (Artemisia Dracunculus L.). Int J Food Eng 1: 1-15.

- Özcan M, Arslan D, Ünver A (2005) Effect of drying methods on the mineral content of basil (Ocimum basilicum L.). J Food Process Eng 69: 375-379.

- Arafa GK (2007) Optimum drying conditions for thin-layer drying of sweet basil. Misr J Ag Eng 24: 540-556.

- Danso-Boateng E (2013) Effect of drying methods on nutrient quality of Basil (Ocimum viride) leaves cultivated in Ghana. Int Food Res J 20: 1569-1573.

Citation: El-Sayed GK, Bahnasawy AH, Hamouda RM (2019) Dehydration of Chamomile Flowers under Different Drying Conditions. J Food Process Technol 10: 803.

Copyright: �?�© 2019 El-Sayed GK, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.