Indexed In

- RefSeek

- Hamdard University

- EBSCO A-Z

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2019) Volume 4, Issue 1

Compliance to Post-Harvest Handling Practices of Beef along the Beef Value Chain in Uganda

Juliet Kyayesimira1*, Grace Kagoro Rugunda1, Lejju Julius Bunny1 and Joseph W. Matofari22Department of Dairy and Food Science and Technology, Egerton University, Egerton, Kenya

Received: 01-Mar-2019 Published: 20-Jun-2019

Abstract

Introduction: Beef handling from slaughter to butchery if not compliant with standard operating requirements may lead to contamination by spoilage and pathogenic microorganisms originating from equipment, surfaces, personnel, water and environment. This mostly depends on level of hygiene. Beef handlers have limited public health education on safe handling, poor meat handling facilities and low enforcement of hygiene rules along the value chain. Sanitation standard operating procedures (SSOPs) in cleaning of equipment/tools and facilities for handling beef were not adhered to from slaughter houses through to butcheries.

Objective: The study was conducted to assess whether the post-harvest beef handling practices and actors involved follow set standards in the beef value chain.

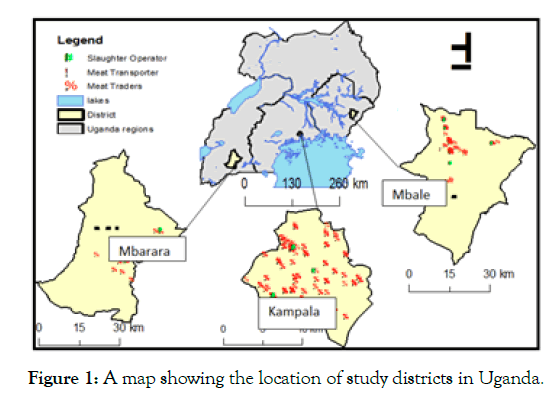

Method: A cross sectional survey covering 601 actors (abattoirs =105, transporters =141 and butcheries =355) in the beef value chain including slaughter house operators, beef transporters and butchers (at beef selling points) was undertaken. Data was collected from June 2017 to January 2018 using a face to face questionnaire as well as observation of handling practices among the various actors in the districts of Mbarara, Kampala and Mbale. Data was analyzed using statistical Package for Social Science (SPSS) version 20.

Results: Most (96.6%) of abattoirs (slaughter houses) were not built to standard specification requirements for example they lacked side facilities like cold rooms, room for offal processing and waste disposal sites. In slaughter slabs, the water used is not treated though about 87.6% of workers at the abattoirs wear gumboots and only 34.3% wear protective clothing. The tools like knives, machete and axes are commonly shared among actors. Cleaning of the surfaces of slaughter slabs/houses is mainly done with water only (60%) compared to use of both water and soap (40%). Transportation is mainly by motorcycles (54.6%). At the butchery, only 22.2% of workers wear protective clothing but 87.6% of them wear gumboots. Meat transfer from the carrier to the butchery is by personnel using bare hands or on shoulders. Some places called butcheries are under tree branches where the meat is hanging airborne.

Conclusion: The handling practices among different actors after slaughter (post-harvest) were below the required hygienic standards set by Uganda National Bureau of Standards (UNBS) at slaughter houses, butcheries, and beef transporters.

Keywords

Beef; Slaughter; Butcher; Transporters; Post-harvest; Handling practices

Abbreviations

SSOPs: Sanitation Standard Operating Procedures; SPSS: Statistical Package for Social Science; UNBS: Uganda National Bureau of Standards; FAO: The Food and Agriculture Organization of the United Nations; WHO: World Health Organisation; FSIS: Food Safety and Inspection Service

Introduction

Standards for handling beef require that it is sold in suitable temperature, humidity and other environmental controls hence adequate facilities and equipment for cooling, chilling and/or freezing of meat should be available [1,2]. Meat is an excellent source of dietary protein than plant foods (except soy bean products) [3,4] and so important for inclusion in human diet. However, meat is a perishable food and a health risk if handled improperly [5,6] and so vulnerable to survival and growth of pathogens and spoilage micro-organisms [7,8] when exposed to unhygienic conditions. Beef has an inherent food safety risk and require caution when handling [9] in order to prevent food borne pathogens. In Uganda, roadside and market stall butcheries which lack cooling facilities and are associated with unhygienic handling of meat account for 75% to 80% off all retailed meat [10]. Post-harvest handling practices of beef begins at the slaughter house/abattoir (immediately after stunning the animal) and thereafter during transporting and then trading (selling the beef) to consumers. Beef handling in Uganda is underdeveloped with obsolete food laws and there is currently no institution or authority that is solely responsible for the Food safety in the country [11]. As a result, there is failure to develop trade partnerships with countries which have a developed food safety system. Beef handlers have limited public health education on safe handling, poor meat handling facilities and poor enforcement of hygiene rules in the meat sector [5] are the root causes food borne diseases.

Cross contamination occurs during storage under inappropriate conditions and also through use of contaminated tools or equipment [12]. Poor handling practices have been identified as contributing factors of food-borne disease outbreaks [13-15]. FAO code of hygiene practice for meat recommends that safety and suitability of meat should be ensured after handling at slaughter, transport and butchery [1]. However, foods become highly contaminated with pathogenic microorganisms and this is an indication of deplorable state of food handlers [16-18]. There is lack of detailed information on the handling practices of beef in these butcheries and other actors in the beef value chain in Uganda. The beef handling practices in Uganda are awful and they hinder governments’ efforts to regulate the sector based on the set standards hence unable to control food contamination and save public health. Therefore, this study was undertaken to collect information on the current trends in the handling practices of beef at slaughter, transport and trade in Uganda.

Materials and Methods

A cross sectional survey was conducted among the slaughter operators, transporters and meat traders (butchers) in the districts of Mbarara, Kampala and Mbale (Figure 1). A total of 602 respondents (abattoirs=105, transporters=141 and butcheries=355) were interviewed using a questionnaire and a check list was used to record observations among the different actors. The data was collected from June 2017 to January 2018 and analyzed using statistical Package for Social Science version 20 (IBM Corp. Armonk, NY: Released 2011).

Figure 1: A map showing the location of study districts in Uganda.

Results

The highest percentage of the slaughter operators were in the age bracket of 18-29 years while beef traders and transporters were between 29-39 years of age. The actors in the post-harvest beef value chain are predominately men with a few women. Most of the beef handlers had attained basic education for example slaughter operators and transporters had primary education (48.6% and 57.4% respectively) while many of meat traders had acquired secondary level education (Table 1).

| Variables | Variable | Slaughter operators | Butchers/meat traders | Transporters |

|---|---|---|---|---|

| Age (years) | 18-28 | 37.1 | 37.2 | 36.2 |

| 29-39 | 32.4 | 38.9 | 42.6 | |

| 40-50 | 19.0 | 20.8 | 17.7 | |

| 51-61 | 6.7 | 2.8 | 2.8 | |

| 62+ | 4.8 | 0.3 | 0.7 | |

| Education | No formal education | 6.7 | 1.4 | 7.1 |

| Primary | 48.6 | 43.4 | 57.4 | |

| Secondary | 33.3 | 46.2 | 26.2 | |

| Tertiary/Vocational | 6.7 | 4.5 | 5.7 | |

| Graduate | 4.8 | 4.5 | 3.5 | |

| Sex | Male | 98.1 | 99.2 | 96.5 |

| Female | 1.9 | 0.8 | 3.5 |

Table 1: The different demographic characteristics of the respondents interviewed.

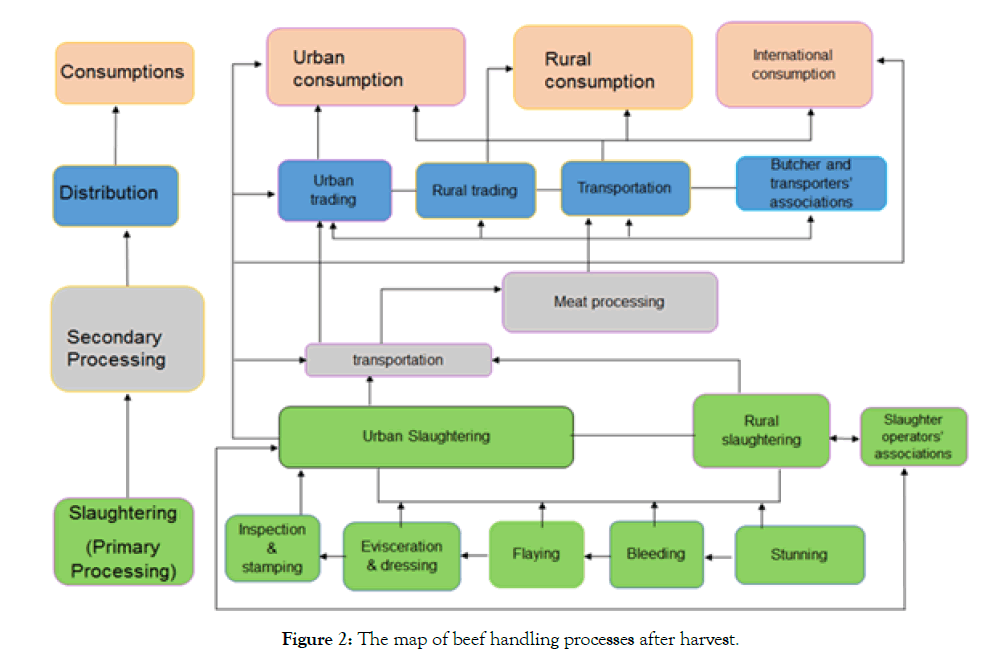

In this study, post-harvest handling practices begin immediately after stunning. Stunning renders the animal immobile or unconscious and this is done immediately prior to slaughtering them for food. After stunning, different actors were involved in the follow up processes of slaughter operations including bleeders, flayers, eviscerators, and carcass dressers. The beef is later inspected and finally stamped if it meets the standard requirements (Figure 2) or condemned. Following stamping, the carcass is then carried by the waiting transporters outside the slaughterhouse who deliver it to the different retail outlets (butchery) using motorcycles, bicycles and wheel barrow and shoulder to shoulder logs.

Figure 2: The map of beef handling processes after harvest.

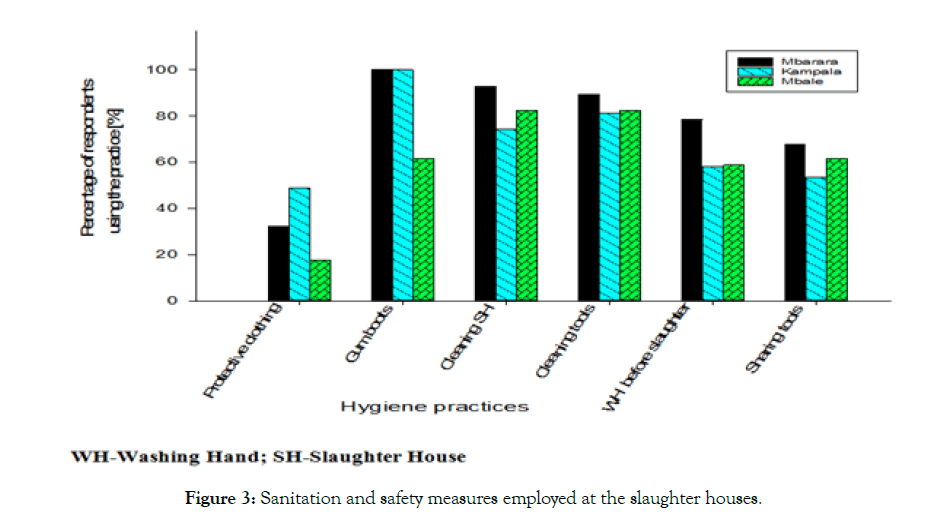

As a safety and sanitation measure in slaughter houses and slabs, it is a requirement that the different personnel should wash hands, put on protective clothing, wear gumboots, clean tools and wash the slaughter house after slaughter. There should be no sharing of tools among these slaughter operators. Results of this study show high compliance in wearing gumboots (87.6%) but sharing of tools was common (60%) in all the districts of the study and this could be a possible area of cross contamination of beef (Figure 3). It should be noted that sharing of tools (knives and machete) among the different butchers is a possible source of contamination and in this study, 60% of respondents shared tools at slaughter houses. The slaughter houses in Kampala district had 100% compliance to ante-mortem inspection. In Mbarara and Mbale, only 25% adhered to ante-mortem inspection. Furthermore, it was found out that it is only licensed slaughter houses which were practicing ante-mortem inspection while at slaughter slabs this was a rare practice. It was observed that there was no veterinary inspector at slaughter slabs and the personnel in charge possessed inspection stamp illegally.

Figure 3: Sanitation and safety measures employed at the slaughter houses.

The unhygienic handling of beef (Figure 4) could lead to beef contamination and hence accelerate deterioration of beef spoilage. In all the districts of the study, cleaning of the surfaces of slaughter slabs/houses are mainly done with water only (60%) compared to use of both water and soap (40%). All the respondents interviewed in the study clean the slaughter tools/equipment employing different modes namely; use of cold water only (50%), wash with cold water and soap (27%), wash with hot water and soap (17%) and used sand (6%).

Figure 4: Operators of slaughter house carrying beef from slaughter house/abattoir (unhygienic practice)

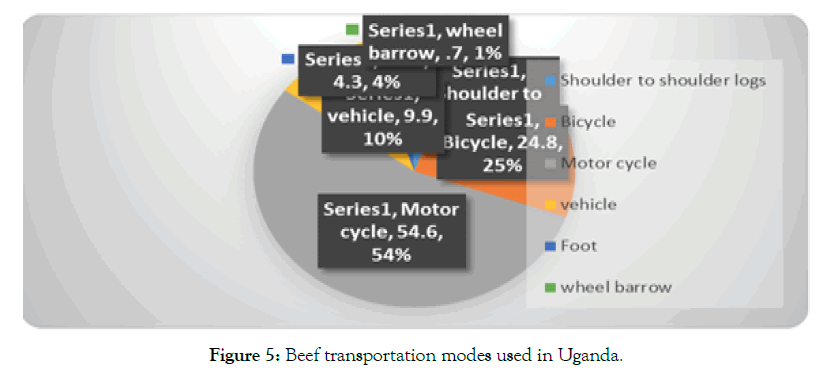

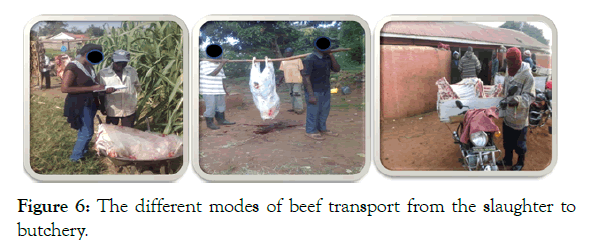

From the slaughter houses to the butchery, 54% of the carcass (beef) is transported by motorcycles followed by bicycles (25%) and 1% used wheel barrows (Figures 5 and 6). The motorcycles are loaded with wooden boxes where beef is placed and then covered during transportation (Figure 6).

Figure 5: Beef transportation modes used in Uganda.

Figure 6: The different modes of beef transport from the slaughter to butchery.

The results from interviews and observation of transporters showed that the commonly used container to carry beef is sack/ polythene (27.1%) followed by open wooden containers (21.4%), closed wooden container (20%) and others include open plastic container, car cabin and wheel barrow carriers.

On arrival at the butchery, beef is off loaded manually (Figure 7) to retail shops (butchery) or hanged on tree branches in the open. Ninety six percent of these retails have no cold chain system for preservation. SSOPs require that meat is transported in clean containers and storage of meat should be at low temperatures to prevent meat quality deterioration. All butcheries in the study area displayed beef by hanging and on tables (Figure 7) for marketing purposes and for those butcheries located near the road side, the beef is exposed to dust raised from vehicles.

Figure 7: Display of beef for sale at a kiosk and under tree.

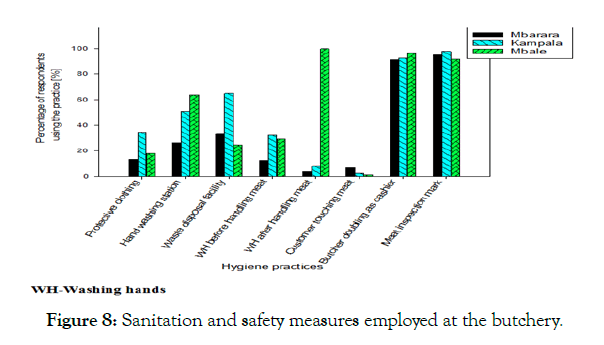

Results on safety and sanitation measures in the butchery showed that washing hands was commonly done after visiting the toilet (97.9%) compared to washing hands before serving beef (0.33%). Washing of hands was mainly done with cold water and soap (82.6%) but there were instances of cleaning hands with a cloth (1.4%). At the butchery, 34% of workers wore protective clothing. Majority (93.5%) of meat handlers doubled as cashiers and this means that they handled money and meat concurrently (Figure 8). Chi-square test also showed no significant difference in the safety handling and sanitation measures at the butchery (protective clothing, washing hands before handling beef and wash hands after holding money) with the butcher’s age (χ2=9.329, df=8, p-value=0.315). This means that age of actors at butchery did not have any relationship with the meat handling practices at butchery level. Chi-square results between education levels and the different handling practices at the butchery showed no significant difference (χ2=11.615, df=8, p-value=0.1692). Education levels of actors at butchery level were not related with wearing protective clothing, washing hands before handling meat and washing hands after holding money (χ2=11.615, df=8, p-value=0.1692). Chi-square results between training meat handling and the different handling practices at the butchery showed no significant difference (χ2=0.605, df=2, p-Value=0.739). The results signify that the training received on meat handling did not have any direct relationship with the wearing of protecting clothing, washing hands before holding meat and washing hands after holding money.

Figure 8: Sanitation and safety measures employed at the butchery.

Discussion

The study showed that the majority of food handlers were in a young age group but the under age (below 18 years) were not encountered meaning there is no child labour unlike in the studies where some of food handlers working at the food establishment were under age [19,20]. The majority of actors were men and these findings are similar to a study in Sudan where food trade is majorly a job for men [21] contrary to the studies where females dominate food handling [22]. Most of the slaughter operators, transporters and meat traders had attained basic education and this means that they could understand food safety requirements. This result is similar to a study in Malaysia where majority of food handlers had primary and secondary level education [23-25].

Slaughter slabs possessed inspection stamp illegally. This means that there is limited monitoring of Sanitation Standard Operating Procedures (SSOPs) that ensure that tools or equipment are clean and sanitized prior to start of operations and appropriate hygiene is maintained during operations [1]. Majority of the meat is transported by motorcycles unlike a study in Kenya where the majority used closed vehicles to transport meat from the slaughterhouse to the butchery followed by motorbikes and then animal (donkey) [26]. Majority of actors transported meat in sacks/polythene bags and though the requirements for meat transportation stipulate that vessels/containers shall be made of impervious materials that are noncorrosive, easy to clean, disinfect and maintain [27], and so most of the containers used do not conform to this. The containers or vehicles used were not refrigerated and this could be because the distance covered during transportation was less than 5 km (below the minimum distance requiring refrigeration of meat during transportation) and the findings are related Chepkemoi et al. [26].

Uganda’s beef is transported in un-recommended manner and sold from inappropriate structures due to lack of enforcement of regulations for operating slaughter houses, butcheries and meat transportation as set by Uganda National Bureau of Standards (UNBS). The obsolete food laws and lack of institution or authority that is solely responsible for the Food safety is a limiting factor [11]. The butcheries lack cooling facilities and therefore only stock meat that can be sold within the day.

Results indicated that majority of the retailers (at butchery) lacked cold storage facilities and this could be because of high expenses involved in acquiring such facilities. However, lack of chilled temperature storage accelerates fresh meat spoilage [6] and so such meat is prohibited in international trade [4]. Uganda has failed to meet the requirements of prospective trade partners with United States [11]. FAO/WHO points out that poor postharvest handling, processing and storage of food are due to inadequate facilities and infrastructure like the absence or shortage of safe water supply, electricity, storage facilities including cold facilities [28]. Meat is exposed to dust because of the proximity of the butcheries to the dusty marram roads. Similar findings are reported by Agriterra in Uganda which found out that meat sold on roadside and market stall butcheries accounted for 75% to 80% sales [10]. The butcheries had no glass screens and so flies and dust easily come into contact with the beef and this contrary to the hygienic requirements for the butcheries in Uganda [2]. The above findings are similar to a study conducted in the abattoir and butcheries in Kampala [29]. Majority of beef handlers wash hands after visiting the toilet and these findings are similar to a study by [24,30] where majority of food handlers washed hands before handling food and after visiting the toilet. In the study 93.5% of beef handlers doubled as cashiers and this is contrary to the hygienic requirements for butcheries where it is recommended that personnel to handle money shall not handle meat [2]. This could be a possible source of contamination and similar findings were reported by studies [18,26,29,31,32].

Relationship between safety and sanitation measures revealed contrary results compared to a study in Sudan [21] where persons with high education level had better personal hygiene practices. In another related study, the personnel who attended training session on hygiene lacked understanding of the knowledge that is taught [33].

Conclusion

Based on the hygienic requirements for slaughterhouses, butcheries and meat transportation in Uganda, the beef handlers use unhygienic practices that favour cross contamination of beef. It is for this reason that Uganda has failed to develop trade partnerships. The prominent unhygienic practices included; meat handlers also double up as cashier, not washing hands before serving meat and sharing of tools among the different handlers. Beef handling is predominately a male job but a few women come in during marketing. Though majority of the beef handlers had primary or secondary education, there was no significant difference between education level and the sanitation/ hygiene practices. The less usage of protective clothing among butchery operators is an indication of increased risk of contamination of beef at this level in the value chain. The majority of the butcheries visited lacked a fly screen and fly infestation is a high possibility. Generally, the study showed non-compliance to standard operating procedure (SOPs) as set by UNBS and FAO in regards to handling of beef at slaughter houses, butchery and transportation. The meat sector did not have an agency responsible for research, enforcement, education and information on food safety issues just like in other countries like US where Food Safety and Inspection Service (FSIS) is responsible for food safety.

REFERENCES

- FAO. CAC/RCP: Code of hygienic practice for meat. 2005; 1: 3-51.

- UNBS. Uganda standard: Hygienic requirements for butcheries. Uganda; 2007; 1-16 p.

- Heinz G, Hautzinger P. Meat processing technology for small- to medium- scale producers. Food and Agriculture Organization of the United Nations. 2007; 1–50 p.

- Damodaran S, Parkin KL, Fennema OR. Fennemas Food Chemistry. Fourth Edn, CRC press, Taylor & Francis Group. 2008; 1–1158 p.

- Adesokan HK, Raji AO. Safe meat-handling knowledge, attitudes and practices of private and government meat processing plants’ workers: Implications for future policy. J Prev Med Hyg. 2014; 55(1):10–16.

- ICMSF. Microorganisms in Foods; Microbial Ecology of food commodities. 2nd Edn. New York: Kluwer Academic/Plenum Publishers; 2005; 1–777 p.

- Rani ZT, Hugo A, Hugo CJ, Vimiso P, Muchenje V. Effect of post-slaughter handling during distribution on microbiological quality and safety of meat in the formal and informal sectors of South Africa : A review. S Afr J Anim Sci. 2017; 47(3): 255-267.

- Ray B. Fundamental food Microbiology. 3rd Edn. Boca Raton: CRC Press Taylor & Francis Group. 2005; 1–625 p.

- Mahon D, Cowan C, Henchion M, Fanning M. Food-handling practices of Irish beef consumers. J Food Saf. 2006; 26(1):72–81.

- Identification of livestock investment opportunities in Uganda. Agriterra. 2012.

- Ejalu BP, Fortin N. U.S. and Ugandan Food Safety Systems: A challenge to create development partners. Food Regulation in the United States. 2008.

- Al Suwaidi AHE, Hussein H, Al Faisal W, El Sawaf E, Wasfy A. Hygienic practices among food handlers in Dubai. Int J Prev Med Reserach. 2015; 1(3):101–108.

- Gilbert SE, Whyte R, Bayne G, Paulin SM, Lake RJ, Van der Logt P. Survey of domestic food handling practices in New Zealand. Int J Food Microbiol. 2007; 117(3):306–311.

- Annual Summary of Outbreaks in New Zealand. Population and Environmental Health Group. 2007.

- Gorman R, Bloomfield S, Adley CC. A study of cross-contamination of food-borne pathogens in the domestic kitchen in the Republic of Ireland. Int J Food Microbiol. 2002; 76(1–2):143–150.

- Okonko I, Adejoye O, Ogun A, Ogunjobi A, Nkang A, Adebayo-tayo B. Hazards analysis critical control points ( HACCP ) and microbiology qualities of sea-foods as affected by handler’s hygiene in Ibadan and Lagos, Nigeria. African J Food Sci. 2009; 3(2):35–50.

- Anderson JB, Shuster TA, Hansen KE, Levy AS, Volk A. A Camera’s view of consumer food-handling behaviors. J Am Diet Assoc. 2004; 104(2):186–191.

- Haileselassie M, Taddele H, Adhana K, Kalayou S. Food safety knowledge and practices of abattoir and butchery shops and the microbial profile of meat in Mekelle City, Ethiopia. Asian Pac J Trop Biomed. 2013; 3(5):407–412.

- Mudey AB, Kesharwani N, Mudey GA, Goyal RC, Dawale AK, Wagh VV. Health Status and Personal Hygiene among Food Handlers Working at Food Establishment around a Rural Teaching Hospital in Wardha District of Maharashtra, India. Glob J Health Sci. 2010; 2(2):198–206.

- Adane M, Teka B, Gismu Y, Ademe M. FoodHygiene and Safety Measures Among Food Handlers In Street Food Shops and Food Establishments of Dessie Town, Ethiopia. PLoS One. 2018; 13(5):1–13.

- Abdeirazig A, Mustafa K, Mohammed M. Hygienic Practices among Food Handlers in Restaurants of Al-Nohod Locality Market-west Kordofan-Sudan-2017. Int J public Heal Saf. 2017; 2(3):2–5.

- Akabanda F, Hlortsi EH, Owusu-Kwarteng J. Food safety knowledge, attitudes and practices of institutional food-handlers in Ghana. BMC Public Health. 2017; 17(1):1–9.

- Rosnani AH, Son R, Mohhidin O, Toh P, Chai L. Assessment of Knowledge, Attitude and Practices Concerning Food Safety among Restaurant Workers in Putrajaya, Malaysia. Food Sci Qual Manage. 2014; 32:2224–6088.

- Isara AR, Aigbokhaode AQ, Onwusor VO, Onyeulo EC, Orumwense SO. Food hygiene and safety practices of food service staff in university of benin teaching hospital, Benin city, Nigeria. J Med Biomed Res. 2013; 12(2):69–76.

- Andargie G, Kassu F, Moges F, Tiruneh M, Huruy K. Prevalence of bacteria and intestinal parasites among food-handlers in Gondar Town, Northwest Ethiopia. J Heal Popul Nutr. 2008; 26(4):451-455.

- Chepkemoi S, Lamuka PO, Abong GO, Matofari J. Sanitation and Hygiene Meat Handling Practices in Small and Medium Enterprise butcheries in Kenya -Case Study of Nairobi and Isiolo Counties. Internet J Food Saf. 2015; 17:64–74.

- UNBS (Uganda National Bureau of Standards). Uganda standard: Requirements for the transportation of meat and meat products. US 779 Uganda. 2007; p.1–14.

- FAO/WHO. Assuring food safety and quality: Guidelines for strengthening national food control systems.

- Bogere P, Baluka AS. Microbiological Quality of Meat at the Abattoir and Butchery Levels in Kampala City, Uganda. Internet J Food Saf. 2014; 16:29–35

- Ifeadike C, Ironkwe O, Adogu P, Nnebue C. Assessment of the food hygiene practices of food handlers in the Federal Capital Territory of Nigeria. Trop J Med Res. 2014; 17(1):10.

- Kubde SR, Pattankar J, Kokiwar RP. Knowledge and food hygiene practices among food handlers employed in food establishments. Int J Community Med Public Heal. 2016; 3(1):251–256.

- Nel S, Lues JF, Buys EM, Venter P. The personal and general hygiene practices in the deboning room of a high throughput red meat abattoir. Food Control. 2004; 15(7):571–578.

- Asmawi MMU, Norehan AA, Salikin K, Rosdi SAN, Munir ATAN, Basri NBM, et al. An assessment of knowledge, attitudes and practices in food safety among food handlers engaged in food courts. Curr Res Nutr Food Sci. 2018; 6(2): 1–7.

Citation: Kyayesimira J, Rugunda GK, Bunny LJ, Matofari JW (2019) Compliance to Post-Harvest Handling Practices of Beef along the beef value chain in Uganda J Nutr Weight Loss 4:116. doi: 10.35248/2593-9793.19.4.116

Copyright: © 2019 Kyayesimira J, et al., This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.