Indexed In

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research - (2019) Volume 10, Issue 7

Application of Germinated Corn Flour on the Reduction of Flow Velocities of the Gruels made from Corn, Soybean, Moringa oleifera Leaf Powder and Cassava

Julie Mathilde Klang*Received: 26-Mar-2019 Published: 09-May-2019

Abstract

Background: In Cameroon, nearly 1 in 3 children under the age of 5 years suffer from protein-energy malnutrition (31.7%). This malnutrition generally appears at weaning age and is the result of weaning food that is not appropriate for children (low nutritional and energy value, high consistency). Cameroonian flora has foods such as maize, soya, cassava and Moringa that could be used in the formulation of quality weaning foods. The use of these different elements in the formulation of infant flours combined with the incorporation of small quantities of germinated corn flours and raw extracts of these germinated flours would reduce the consistency and increase the energy density of the gruels. This technology could therefore help to fight against child malnutrition. The nutritional problems of young children led us to formulate two infant flours in order to contribute to the improvement of the nutritional value of locally available complementary foods.

Aim of the study: The aim of this work is to determine optimal conditions to produce infant flours based on corn, cassava, soya and Moringa olifeira with desired flow, nutritional value and energy.

Material and methods: To lead this study, different flours mentioned above were used. These flours were then chemically characterized; the physical and functional properties were evaluated. The gruels were prepared from these flours and the flow velocities were evaluated.

Results: It appears from this study that formulations based on corn are very rich in proteins (11-12% of DM) and lipids (10.7-11.6% of DM). These two formulations are also good sources of iron and magnesium. Both cassava-based formulations had high calcium levels (26-35 mg/100g of DM). The physical and functional properties were influenced (pË0.05) by the nature of the flour. The use of amylase flour and extract revealed that at concentrations of 2% and 2.5%, respectively, they reduced the consistency of the gruels. Generally, the incorporation of amylases flours during the cooking of the gruels results in a multiplication of the energy density by 2.66 (multiplication factor) for amylase flour to 5.1 (multiplication factor) for amylase crude extract. It also appears that the reduction in consistency and the increase in the dry matter concentration of the gruels are positively correlated with the Ca content and the solubility index.

Conclusion: All this shows that the combination of the formulation and use of amylase flours could be used to fight against protein energy malnutrition in children.

Keywords

Gruel; Amylase crude extract; Corn; Cassava; Soya bean; Moringa olifeira; Germinated corn flour; Flow velocities

Introduction

Supplementary feeding is a process that begins when breast milk alone becomes insufficient to meet the nutritional needs of children. Since from the age of 6 months, young children begin to have energy and nutrient needs that breast milk can no longer fulfill, other foods are needed to accompany breastfeeding [1]. Because of poverty, low levels of nutritional education and low access to health services, this transition period is generally neglected by the majority of the population, which can lead to child malnutrition [2].

In 2006, it was estimated that in developing countries, based on stunting, wasting and underweight, respectively 39%, 11% and 31% of children under the age of five years suffered from Protein-Energetic Malnutrition (PEM) [3]. In Cameroon, more than 33% of children under the age of five years suffer from chronic malnutrition, nearly half of them in its severe form, represented by underweight (15%), iron deficiency of 65% (23% in the form of mild anaemia and 40% in the moderate form) and vitamin A deficiency (40%) which contributes 29% to child mortality [4]. According to the UNICEF-Cameroon report [5], more than 45,000 children die each year from child protein-energy malnutrition. A study conducted by Sikod [6] had revealed that the introduction of complementary foods in children was often too early since 50% of the children surveyed (60 children aged 4-11 months) had received their first gruels before the age of 4 months and the gruels fed were of rather poor nutritional quality since their average energy density was 58 kcal/100 g. Indeed, in developing countries, mothers because of their daily occupations and the lack of mastery of the technology of these household productions prepare light gruels of low energy and nutritive density which are in most cases made from cereal flours (corn), roots (cassava) and tubers (potatoes) easily accessible because of their high local productivity [7]. These flours are prepared alone or in mixtures with other sources of proteins, lipids and microelements such as soya and Moringa. During cooking, the starch contained in these flours thickens and gives a gruel whose viscosity increases rapidly according to the concentration of dry matter, which limits the quantity of flour to be incorporated for its preparation and the quantity ingested by the child due to its low stomach capacity (30 to 40 mL/kg body weight) [8,9]. To remedy this, mothers generally dilute the gruel, which reduces its nutritional and energy value, and affects the growth of children [10]. However, WHO and UNICEF recommends that weaning gruels should have flow velocities between 100 and 160 mm/30 s, a value read on a Botswick consistometer for a dry matter concentration of at least 30% and an energy value of 120 kcal/100 g of gruel [11].

The solutions envisaged to solve these problems could be on one hand the addition of a source of proteins, lipids and micronutrients to improve the energy and nutritional value of the gruels. For example, it was showed that soybean meal and Moringa oleifera leaves powder significantly increased the nutritional value of yam and corn flours respectively [12-14]. On the other hand it was showed that amylase extracts from three plants (Abrus precatorius, Burnatia enneandra and Cadaba farinosa) could improve the nutritional, energy and consistency value of corn, cassava and sorghum-based gruels [14]. Furthermore, the results of Tambo et al. [15] showed that the capacity of germinated yellow corn flour (Atp variety) to reduce the consistency of the gruels depended on their lipid, protein and fiber content. Concerning the application of these germinated and extracted flours during cooking, Tambo et al. [16] have demonstrated that the raw extracts of amylase flours of the Atp corn variety have an optimal activity at 60°C.

This work therefore aims to determine optimal conditions to produce infant flours based on corn, cassava, soya and Moringa olifeira with desired flow, nutritional value and energy and more specifically to evaluate the nutritional composition of the formulated flours and determine the best flour and the best form of incorporation of germinated corn flour to obtain the desired flow, nutritional and energy value.

Material and Methods

Origin and preparation of material

The plant material used for this work consisted of one variety of corn (Atp), a soybean (Glycine max) TGX 1035 10E variety, cassava tubers (Manihot esculenta) and leaves of Moringa oleifera grown in the localities of Dschang and Santchou, Department of Menoua, West Cameroon region. These areas were chosen because of the strong cultivation of these commodities. After purchasing the corn seeds, soybeans and cassava roots from the IRAD multipurpose stations in Dschang and Santchou, respectively; they were transported to the RUBPMAN of the Department of Biochemistry at the University of Dschang, where they were processed into flour. The leaves of Moringa oleifera were harvested at the farm of the Faculty of Agronomy and Agricultural Sciences (FAAS) of the University of Dschang.

Production of different flours:

The corn seeds (Atp variety) obtained previously were separated into two batches. The first batch was sorted by hand, skinned and then crushed using a disc mill. The flour was sieved (Ø=400 μm), then packed in polyethylene bags to prevent moisture exchange and stored in a dry container. The second batch was used to produced amylase rich flours. It was sorted and washed in tap water and soaked in warm water (50°C) for 48 h in order to obtain the humidity between 35% and 40%, necessary for germination. Then we spread the grains on a very clean cloth in the shade that we watered daily (twice/day) in order to maintain sufficient humidity until the process of germination is well began and that the roots appear. This process took 72 h. Drying was carried out in a "venticell" oven at a temperature of 50°C for 24 h, then the grains were ground, sieved (Ø=400 μm) and stored in polystyrene bags. The soybeans were previously sorted, washed and soaked in warm tap water (50°C) for 48 h in order to increase their moisture content. They were then spread on a very clean cloth and shaded for 72 h until the roots appeared. They were then dried at 50°C in a ventilated "venticell" oven for 24 h, skinned, crushed, sieved (Ø=400 μm) and stored. The fresh leaves of Moringa oleifera were washed, dried (50°C, 24 h) in a ventilated "venticell" oven, then crushed using an ordinary mill, sieved (Ø=400 μm) and stored in polystyrene bags. Finally, the cassava roots (sweet cultivar) were peeled, washed and then cut into small parallelepipedic pieces with a kitchen knife. The pieces obtained were entirely immersed in water in a ratio of 1:3 (w/v), which represents the ratio of the grain-water mixture, for 120 h. The fermented pulp was removed from the soaking water, washed with tap water, hand-pressed, spread on grids and dried in a ventilated "venticell" oven (50°C, 24 h). The flours obtained by grinding, were then sieved and roasted before packaging.

Flour formulation

Corn/soya/Moringa and cassava/soya/Moringa formulations will be obtained as mentioned in Table 1. The 6 flours obtained were coded according to the abbreviations below:

| Ingredients | Corn (%) | Cassava (%) | Soya (%) | Moringa (%) |

|---|---|---|---|---|

| Corn | 100 | 0 | 0 | 0 |

| F1C | 82.5 | 0 | 15.0 | 2.5 |

| F2C | 70.0 | 0 | 25.0 | 5.0 |

| Cassava | 0 | 100 | 0 | 0 |

| F1Cav | 0 | 82.5 | 15.0 | 2.5 |

| F2Cav | 0 | 70.0 | 25.0 | 5.0 |

Table 1: Flours formulation process.

Flour 1: Corn and cassava flour, not fortified.

Formulation 1: Corn flour/cassava enriched with 15% soya and 2.5% Moringa leaf flour.

Formulation 2: Corn flour/cassava enriched with 25% soya and 5% Moringa leaf flour.

Preparation of amylase flour crude extract

Cold distilled water (4 mL) was added to a mass of powder (1 g) obtained by grinding the sprouted corn seeds in the ratio of 1:4 (w/v) at 4°C. The mixture was homogenized with a "thermolyne" vortex for 1 minute and then centrifuged at 4500 rpm for 15 minutes [16]. The supernatant obtained was immediately used as a source of enzymes during the preparation of the gruels.

Analysis of the different flours

The flours obtained previously were used for various analyses and for the preparation of gruels whose nutritional and energy values and flow velocities were evaluated.

Functional and physical properties of the different flours: These analyses consisted in determining the swelling rate according to the method described by Okezie [17], the water retention capacity by method described by Leach et al. [18], solubility index by method described by Anderson et al. [19], mass density described by Okaka et al. [20], pH according to the standard method described by Association of Official Analytical Chemists (AOAC) [21] and titratable acidity of different flours according to the standard method described by Association Française de Normalisation (AFNOR) [22].

Chemical characterization of flours: This characterization covered the determination of the water content according to the method described by International Union of Pure Applied Chemistry (IUPAC) [23], the lipid content after extraction with Soxhlet by the AOAC method [20], the protein content which consisted in the determination of mineral nitrogen by the Kjeldahl method, the fiber content, the ash content and the total carbohydrate content according to the methods described by Okaka [20]. The methods described by AOAC [24] allowed the determination of the minerals such as Ca, Mg, P and Fe (these ions were chosen in relation to their importance in physiological processes and the growth of young children). The energy value was determined by applying the Atwater coefficients [25]: 1 g of carbohydrate or protein provides 4 kcal and 1 g of lipid provides 9 kcal of energy. The expression of the energy value per 100 g of dry matter content of flour is given by the following equation:

Ec=(4 × % carbohydrate)+(9 × % fat)+(4 × % protein) (1)

Preparation of the gruels

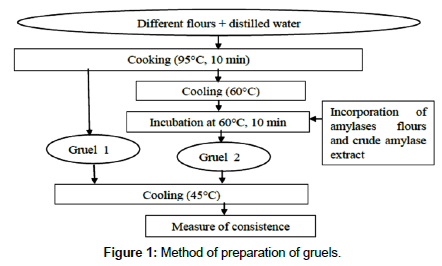

After characterization of the different flours, these were used for the preparation of the gruels with incorporation of the flours and amylase extracts after cooking. The consistency of the gruels was evaluated using the method described by Bookwalter et al. [26]. The Figure 1 represents the method of preparation of the gruels used during this work.

Figure 1. Method of preparation of gruels.

Statistical analysis

The results of the analyses carried out were expressed as averages plus or minus deviations. The means were analysed by the ANOVA test at the 5% probability threshold and the Duncan’s test was used to compare the means using SPSS Version 20 Software. The graphs were drawn using SIGMA PLOT Version 12.0 Software. A correlation matrix and a principal component analysis (PCA) between the physicochemical, functional properties and consistency of the gruels was also performed using XLSTAT 2016 Software.

Results and Discussion

Chemical composition

Table 2 shows the proximate chemical composition of the different flours used in this work. This table shows that the water content of the different flours varies from 10.24% for the first cassava formulation to 6.44% for simple maize flour. This parameter is significantly (p<0.05) influenced by the nature of the sample. These values are similar to those obtained in a previous study on flour formulations made from cereals, vegetables and legumes [27]. Moreover, these results respect the recommendations made by Ndangui [28], which recommends that flour to be preserved over a long period in equatorial zones must have water contents below 14%. Ash content is an indicator of purity for flour [28]. The evaluation of this parameter shows that it is not influenced by the nature of the sample and the formulation. It is also noted that the highest values were obtained with flours having a high percentage substitution in Moringa flour. This would be due to its high proportion of minerals representing the ash content of plants. These results are significantly higher than those of Soro et al. [12], who obtained values between 0.93 and 2.48% on yam flour enriched with soybean. This could be explained by the composition of the samples, the nature of the samples and the treatments applied. The protein content of the different flours varies from 12% for the second corn formulation to 1.7% for cassava flour. No significant difference (p>0.05) was observed between the different formulations but between the formulations and the flours not formulated. These results are justified by the contribution of the protein source represented here by soy, as demonstrated by Soro et al. [12]. The protein intakes of the various infant meals are below the standard (15%) recommended by FAO/WHO (2006) [29] necessary to cover the daily intakes of children in the 6-24 month age group. These results are significantly (p<0.05) lower for wheat and formulations than those of Kouassi et al. [30] which could be explained by the nature of the flours, the treatment applied (fermentation and germination for example) and the composition of the samples. Indeed, it was demonstrated that during germination, there was a reduction in the protein content because these were used in the physiological processes of the plant. It appears from the results of the lipid content that the second corn formulation presented the greatest value (11.65%). In addition, significant differences were observed between the formulations and the flours samples, which would also be justified by the contribution of the lipid source to the simple corn and cassava flours represented here by soybean. In addition, it was observed that the fat content increased with the percentage substitution of soybean meal. These results are not in agreement with those of Shiriki et al. [13] who obtained decreasing lipid levels in proportion to the increase in soybean and peanut levels in the gruels formulations, which would be attributed to the variability of the samples, the composition of the samples and the treatment applied. The lipid contents obtained are generally higher than the recommended value (8%) for FAO/WHO infant meals [29]. Table 1 show that the carbohydrate contents of all flours are significantly higher than other nutrients with values between 68.20% and 91.96% for the second corn formulation and for cassava flour respectively. The difference observed could be related to the fact that the addition of protein and lipid sources contributed to the reduction of carbohydrate sources represented here by corn and cassava flours. The same observations has noted by Soro et al. [12], who found carbohydrate levels between 59.59% and 89.02% for yam flour fortified with soybeans and who also found that the carbohydrate content of yam formulations decreased with the increase in the percentage substitution by soybean and peanut flours. The dietary fibers analysis showed values ranging from 1.02% for cassava and corn flours not formulated to 3.23% for the first corn formulation and the second cassava formulation. There was no significant difference (p>0.05) between the different formulations but between cassava flour, corn flour and formulations. This would be due to the additional fibers intake from soy and Moringa flours. These values do not agree with those of Bharathi and Rajamanickam [27] who found significantly (p<0.05) lower fiber levels than ours in different gruels formulations. This could be explained by the increasing supply of powdered leaves of Moringa oleifera, a vegetable rich in fiber. Dietary fiber is not a nutrient but plays an important role in regulating digestive functions [31]. The values obtained for this parameter in formulated flours are significantly similar to the daily intakes recommended (3.8%) by FAO/WHO (2006) [29] for infant meals. The calorific energy gives us information on the energy intake of each flour studied. The results show that this parameter varies from 447.32 kcal for corn flour to 413.47 kcal for cassava flour. These results show that this parameter is significantly affected (p<0.05) by the nature of the flour (enriched or not). These results are in the same range (414 to 474 kcal) as those reported by Shiriki et al. [13] on corn flours fortified with soybean and groundnuts. The energy values obtained in this work make different flours of food potential to fight against child malnutrition.

| Flours | Moisture content | Ash | Proteins | Lipids | Carbohydrates | Fibers | Energy value |

|---|---|---|---|---|---|---|---|

| (%) | (% of DM) | (% of DM) | (% of DM) | (% of DM) | (% of DM) | (kcal/100 g of DM) | |

| Corn | 6.44 ± 1.00c | 2.15 ± 0.00ab | 6.82 ± 0.30c | 7.20 ± 0.20c | 88.81 ± 0.40b | 1.02 ± 0.00b | 447.32 ± 1.30a |

| F1 c | 8.04 ± 0.30b | 4.00 ± 1.40ab | 11.00 ± 2.80ab | 10.74 ± 0.70ab | 71.03 ± 0.70d | 3.23 ± 0.00a | 424.78 ± 2.10b |

| F2 c | 8.22 ± 0.10b | 5.00 ± 1.40a | 12.00 ± 1.40a | 11.65 ± 1.70a | 68.20 ± 1.70d | 3.15 ± 0.00a | 425.65 ± 13.50b |

| Cav | 9.42 ± 0.30a | 1.00 ± 0.10b | 1.71 ± 0.00d | 4.31 ± 0.20d | 91.96 ± 0.10a | 1.02 ± 0.00b | 413.47 ± 2.00c |

| F1 Cav | 10.24 ± 0.50a | 2.00 ±1.40ab | 8.00 ± 1.40bc | 6.98 ± 0.80c | 79.91 ± 0.70c | 3.11 ± 0.00a | 414.46 ± 9.70c |

| F2 Cav | 9.90 ± 0.20a | 4.00 ± 1.40ab | 9.00 ± 1.40ab | 10.35 ± 0.70b | 73.42 ± 3.50d | 3.23 ± 0.10a | 422.83 ± 2.30b |

Corn: simple corn flour; F1C: First corn formulation (82.5% corn+15% soya+2.5% Moringa); F2C: second corn formulation (70% corn+25% soya+5% Moringa); Cav: simple cassava flour; F1Cav: first cassava formulation (82.5% cassava+15% soya+2.5% Moringa); F2Cav: second cassava formulation (70% cassava+25% soya+5% Moringa).

Table 2: Proximate chemical composition and energy values of the different flours.

Contribution of energy, protein, and fat content of gruel prepared from 100 g of different cassava and corn flours toward RDA for children aged 6-59 months

Table 3 presents the contributions to the daily energy, protein and fat demands of the different flours according to age group. It can be seen from the table that the percentage of contribution in energy, proteins and lipids decreases with age. This would be explained by the increase in the need for each element with age. It should be noted that for the 6-12 month age group, the period during which weaning generally begins, all formulations contribute more than 50% for the parameters mentioned. This is explained by the intake of lipids and proteins from soya flour, which has been used to supplement the various corn and manioc flours. Such observations were also reported by Tumwine et al. [32] who demonstrated that the complementation of millet flour with cowpea leaves, pumpkin seeds, carrots, and skimmed milk powder improved the contribution to the various parameters mentioned below. The percentage of contribution to the daily demands of growth-age children of different age groups in lipids, proteins and energy obtained in this work is higher than that of Tambo et al. [15], which shows the importance of supplementing infant foods with protein and lipid sources. These results also show that the various complementary flours would be a good way to supplement the intake of breast milk and rather supplement this food. The recommended daily allowances (RDA) for energy, proteins and fats for different age groups are given in Table 3 [33,34].

| Variables | Age group (Years) | Recommanded Daily Allowances (RDA) | Contribution (%) of different flours to RDA | |||||

|---|---|---|---|---|---|---|---|---|

| Corn | F1 C | F2 C | Cav | F1 Cav | F2 Cav | |||

| Energy (kcal/day) | 0-0.5 | 650a | 68.8 | 65.2 | 65.4 | 63.5 | 63.7 | 64.9 |

| 0.5-1.0 | 850a | 52.6 | 49.9 | 50 | 48.6 | 48.7 | 49.6 | |

| 1300a | 34.4 | 32.6 | 32.7 | 31.8 | 31.8 | 32.5 | ||

| 1800a | 24.8 | 23.6 | 23.6 | 22.9 | 23 | 23.4 | ||

| Proteins (g/day) | 0-0.5 | 13a | 52.3 | 84.6 | 92.3 | 13.1 | 61.5 | 69.2 |

| 14a | 48.6 | 78.6 | 85.7 | 12.1 | 57.1 | 64.3 | ||

| 0.5-1.0 | 16a | 42.5 | 68.5 | 75 | 10.6 | 50 | 56.2 | |

| 24a | 28.3 | 45.8 | 50 | 7.1 | 33.3 | 37.5 | ||

| Fats (g/day) | 0-0.5 | - | - | - | - | - | - | - |

| 0.5-1.0 | - | - | - | - | - | - | - | |

| 16.70b | 43.1 | 64.1 | 69.5 | 25.7 | 41.3 | 61.7 | ||

| 23.30b | 30.9 | 45.9 | 49.8 | 18.4 | 29.6 | 44.2 | ||

Corn: simple corn flour; F1C: first corn formulation (82.5% corn+15% soya+2.5% Moringa); F2C: second corn formulation (70% corn+25% soya+5% Moringa); Cav: simple cassava flour; F1Cav: first cassava formulation (82.5% cassava+15% soya+2.5% Moringa); F2Cav: second cassava formulation (70% cassava+25% soya+5% Moringa)

Table 3: Contribution (%) of energy, protein, and fat content from 100 g of flour toward RDA for children aged 6-59 month.

Mineral composition

The results obtained for minerals show that potassium (K) is the most representative mineral in the various flours (Table 4). Its proportions vary from 564 mg for the second corn formulation to 124.95 mg for corn flour. Its proportion is significantly affected (p<0.05) by the nature of the flour and the formulation. Next comes phosphorus (P) in proportions ranging from 329 mg for the second corn formulation to 145 mg for simple corn flour. Finally, minerals such as iron (Fe), calcium (Ca) and magnesium (Mg) are the least represented in the different flours studied. Generally, the content of these different ions is affected by the nature of the sample. These results are generally lower than those of Soro et al. [12] on yam flours enriched with soya, but remain higher than the recommended intakes with the exception of Na. The levels of these ions are higher in formulate flours than in non-formulate flours. This is due to the addition of Moringa and soya which are potential mineral sources. The mineral content is significantly higher (p<0.05) in cassava flour compared to corn flour. This is due to the fact that fermentation and germination would increase mineral retention [35]. The presence of these minerals in composite flours is beneficial because they intervene in the development of the organism and in the growth of the child and could limit the appearance of nutritional deficiencies. Thus, iron is involved in the constitution of hemoglobin, myoglobin and numerous enzymes. It is also important for certain metabolic pathways as are sodium and potassium [36]. Calcium and phosphorus ensure bone rigidity and promote growth in children [37]. Calcium is important for optimal ossification. It is involved in the transmission of nerve impulses, thus ensuring the maintenance of heart rhythm [38] and it also plays a role in the enzymatic activity of amylases because it is a cofactor. The high magnesium content of these samples is an advantage for the body since magnesium is essential for the production of energy from carbohydrates and lipids. It is the coenzyme needed in many metabolic voices [39]. Contribution of some minerals content of gruel prepared from 100 g of different cassava and corn flours toward RDA for children aged 6-59 months.

| Flours | P | Na | K | Fe | Ca | Mg |

|---|---|---|---|---|---|---|

| mg/100g of DM | ||||||

| Corn | 145.60 ± 1.20e | 19.15 ± 0.50c | 124.95 ± 1.30e | 1.79 ± 0.00c | 3.00 ± 0.00c | 1.21 ± 0.00e |

| F1 C | 206.00 ± 1.40d | 37.00 ± 2.80b | 466.00 ± 1.40c | 5.80 ± 0.20b | 3.20 ± 1.10c | 74.00 ± 2.80b |

| F2 C | 329.00 ± 1.40a | 53.00 ± 4.20a | 564.00 ± 2.80a | 6.70 ± 0.10a | 4.50 ± 0.20c | 62.00 ± 2.80b |

| Cav | 137.60 ± 0.50f | 24.30 ± 0.10c | 439.25 ± 0.60d | 1.30 ± 0.40c | 2.50 ± 0.70c | 1.51 ± 0.40e |

| F1 Cav | 255.00 ± 2.80b | 37.00 ± 1.40b | 563.00 ± 4.20b | 1.20 ± 0.10c | 35.00 ± 2.80a | 49.00 ± 2.80c |

| F2 Cav | 181.00 ± 1.40d | 53.00 ± 4.20a | 538.00 ± 4.20b | 1.50 ± 0.70c | 26.00 ± 2.80b | 35.00 ± 1.40d |

Corn: simple corn flour; F1C: first corn formulation (82.5% corn+15% soya+2.5% Moringa); F2C: second corn formulation (70% corn+25% soya+5% Moringa); Cav: simple cassava flour; F1Cav: first cassava formulation (82.5% cassava+15% soya+2.5% Moringa); F2Cav: second cassava formulation (70% cassava+25% soya+5% Moringa).

Table 4: Mineral composition of the different flours.

Minerals are very important elements for young children. Indeed, many of them, like calcium, iron, magnesium and phosphorus, are involved in physiological processes such as bone mineralization and oxygen transport. The young growing child therefore requires the intake of all these ions through food as well as through breast milk. It can be seen from Table 5 that the calcium contribution of these different flours varies between 0.4 and 5.0%, depending on the food source and the Moringa flour substitution. The high contribution of cassava-based formulations compared to corn-based formulations is believed to be due to the absorption of this mineral by cassava roots during growth. The calcium intakes of these different flours are very low compared to the recommendations. For iron, corn-based formulations contribute more than half of the percentage of daily recommendations. There has been an improvement in contributions of this iron as Moringa flour substitution becomes more important. This would be due to an iron intake from this source. Odunlade et al. [40] also reported that the iron content and percentage contribution of the daily demand for this mineral changed with the percentage of powder substitution of Telfairia occidentalis leaves. These results suggest that the different corn-based complementary flours may be a way to control iron deficiency in children. Concerning magnesium and phosphorus, it appears that complementation with Moringa leaves would contribute up to 105.7% for daily Mg demands and up to 119.6% for phosphorus. These results once again show the richness of Moringa leaves in ions and as a means of fighting hidden hunger. These results also highlight the value of using these formulations in the preparation of infant foods as they are good sources of ions and a real way to combat micronutrient malnutrition in weaning-age children.

| Variables | Recommanded Daily Allowances (RDA) (mg/100 g) | Contribution (%) of different flours to RDA | |||||

|---|---|---|---|---|---|---|---|

| Corn | F1C | F2C | Cav | F1Cav | F2Cav | ||

| Ca | 700.0a | 0.4 | 0.5 | 0.6 | 0.4 | 5.0 | 3.7 |

| Fe | 10.0a | 18.0 | 58.0 | 67.0 | 13.0 | 12.0 | 15.0 |

| Mg | 70.0a | 1.7 | 105.7 | 88.6 | 2.1 | 70.0 | 50.0 |

| P | 275.0a | 52.7 | 74.9 | 119.6 | 50.0 | 92.7 | 65.8 |

Corn: simple corn flour; F1C: first corn formulation (82.5% corn+15% soya+2.5% Moringa); F2C: second corn formulation (70% corn+25% soya+5% Moringa); Cav: simple cassava flour; F1Cav: first cassava formulation (82.5% cassava+15% soya+2.5% Moringa); F2Cav: second cassava formulation (70% cassava+25% soya+5% Moringa).

Table 5: Contribution (%) of some minerals content from 100 g of flour toward RDA for children aged 6-59 months.

Physical properties of the different flours

The physical properties of flours are shown in Table 6. Note that the mass density varies from 1.5 g/mL for simple cassava flour to 0.9 g/mL for the second cassava formulation. This parameter is not significantly affected (p<0.05) the nature of the flour as well as the substitution rate. These values are higher than those of Tambo et al. [15], which was between 0.6 and 0.9 g/mL. This would be explained by the particle size of the sample [41] and nutrient composition. Low densities (less than 0.5 g/mL) are recommended for the preparation of infant flours. The pH ranges from 6.5 for simple corn flour to 5.3 for simple cassava flour. This parameter is affected (p<0.05) by the nature of the sample and the treatment applied within a sample of the same nature. It is noted that the pH of corn flour decreases with fortification while it increases with cassava flour fortification. The significant decrease (p<0.05) obtained with corn flour as fortification progresses would be due to the addition of free organic acid contained in soybean and Moringa flours. Moreover, the low pH value obtained with cassava flour compared to corn flour would be the consequence of fermentation. Tambo et al. [15] has demonstrated that fermentation lowers the pH of cassava flours following the synthesis of volatile organic compounds from carbohydrate sources. The pH is a factor conditioning not only the ability of flours and extracts of germinated corn flour to reduce the consistency of the gruels and therefore to increase the energy density of the porridges but also the food intake. Tambo et al. [16] have demonstrated that the optimal activity of amylase extracts of Atp germinated maize flour was pH 6 and that between pH 5 and 7, it was stable. The titrable acidity that provides information on free acidity ranges from 18.8 mEq NaOH/100 g MS for the second corn formulation to 6.4 mEq NaOH/100g MS for simple corn flour. We observe that the substitution rate influences this parameter, which is the consequence of the free acidity provided by soy flour. The values found for formulated flours are higher than those of Soro et al. [12]. This can be explained by the addition to corn and cassava flours of soya which has undergone soaking and early fermentation in order to eliminate anti-nutrients and allow germination. Fermentation thus contributed to the production of free organic acids.

| Flours | Mass density (g/mL) | pH | Titrable acidity (mEq NaOH/100 g of DM) |

|---|---|---|---|

| Corn | 1.23 ± 0.12ab | 6.51 ± 0.04a | 6.41 ± 1.07c |

| F1C | 1.45 ± 0.35a | 6.35 ± 0.05b | 11.58 ± 1.25bc |

| F2C | 1.40 ± 0.16ab | 6.23 ± 0.03c | 18.88 ± 2.74a |

| Cav | 1.54 ± 0.42a | 5.28 ± 0.03f | 7.36 ± 0.64c |

| F1Cav | 1.18 ± 0.07ab | 5.81 ± 0.03e | 18.19 ± 5.50a |

| F2Cav | 0.97 ± 0.08b | 5.95 ± 0.01d | 14.06 ± 5.00ab |

Corn: simple corn flour; F1C: first corn formulation (82.5% corn+15% soya+2.5% Moringa); F2C: second corn formulation (70% corn+25% soya+5% Moringa); Cav: simple cassava flour; F1Cav: first cassava formulation (82.5% cassava+15% soya+2.5% Moringa); F2Cav: second cassava formulation (70% cassava+25% soya+5% Moringa).

Table 6: Mass density, pH and titratable acidity values of flours.

Functional properties

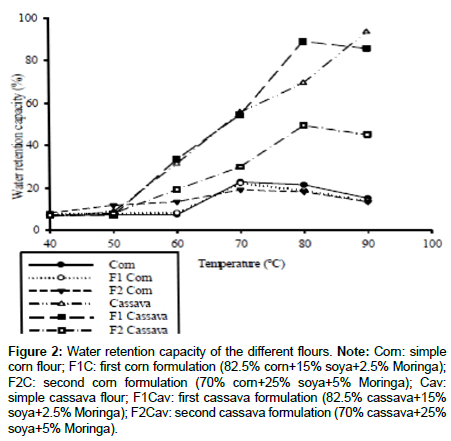

Water retention capacity: Figure 2 shows that the quantity of water retained during gelatinisation increases with the temperature for the various flours but with a drop in this retention capacity to 80°C for the various flours containing corn, which would be the consequence of a break in the hydrogen bonds of the starch molecules and a release of the constituents of low molecular weight (amylose, intermediate material) of the granule, it corresponds to the temperature at the end of gelatinisation of the starches contained in the flours. However, this retention continues gradually up to 90°C for cassava flour and drops from 80°C for cassava-based formulations. This increase is justified by the fact that at high temperatures, the hydrogen bridges stabilizing the semi-crystalline structure of starches open, rupture and are replaced by water molecules [42]. Between 60 and 70°C, there is a strong increase in the water retention capacity of all corn flours which does not corroborate the results of Tambo et al. [15] who observed that it retained water strongly between 70 and 80°C. This could be explained by the chemical composition of the samples. Indeed, the excess of proteins and minerals provided by soya and Moringa would mask the starch granules preventing them from unfolding and retaining water at such temperatures. Similar observations were also observed with formulated and non-formulated cassava flours. In addition, it was observed that formulated flours and not cassava flours retained more water than corn flours. This would once again be due to the nutrient composition, particularly the high protein content in corn flour, which masks the starch and prevents it from fixing the water and thus from swelling. This parameter also allows us to highlight the fact that at the cooking temperature of the gruels, which is 90°C, manioc flours and F1 manioc flours will have higher viscosities, unlike corn flours, which at the administration temperature (45°C) of the gruels will be more viscous.

Figure 2. Water retention capacity of the different flours. Note: Corn: simple corn flour; F1C: first corn formulation (82.5% corn+15% soya+2.5% Moringa); F2C: second corn formulation (70% corn+25% soya+5% Moringa); Cav: simple cassava flour; F1Cav: first cassava formulation (82.5% cassava+15% soya+2.5% Moringa); F2Cav: second cassava formulation (70% cassava+25% soya+5% Moringa).

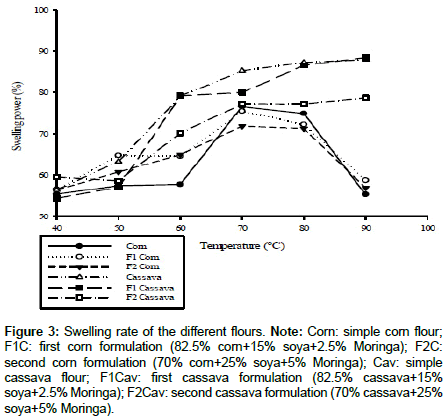

Swelling rate: The swelling rate represents the capacity of a flour to gain volume after water retention. It’s important in bulking and consistency of products as well as in infant food applications. As shown in Figure 3, it shows similar variations explained in water retention capacity. It appears that the swelling increases with temperature. We notice a drop of this one at the temperature of 90°C for the various flours. Between 60 and 70°C, there is a strong increase in swelling then attended stabilisation at 80°C of all flours. Unlike corn-based flours, the rate of swelling of cassava-based flours continues even at 90°C, proof that they have not yet reached their end of swelling temperatures. The reduction of the swelling capacity observed on maize-based formulations could be explained by the composition of maize-based starch in amylose and would make it possible to predict the high consistency of the gruels based on these flours. This would be due to the starch content of each flour including the amylose content. Svihus et al. [43] have shown that starches rich in amylose tend to quickly degrade or lose their swelling power during treatment. It is also linked to the presence of nutrients such as proteins, phosphorus content and lipids and the treatment that the flour has undergone (fermentation for example) [44].

Figure 3. Swelling rate of the different flours. Note: Corn: simple corn flour; F1C: first corn formulation (82.5% corn+15% soya+2.5% Moringa); F2C: second corn formulation (70% corn+25% soya+5% Moringa); Cav: simple cassava flour; F1Cav: first cassava formulation (82.5% cassava+15% soya+2.5% Moringa); F2Cav: second cassava formulation (70% cassava+25% soya+5% Moringa).

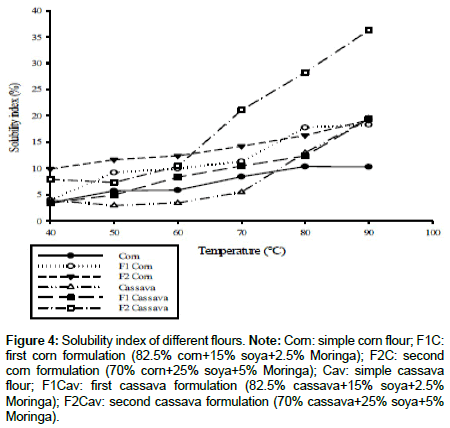

Solubility index: The solubility index (SI) measures the amount of amylose solubilized in an aqueous starch suspension during heating. Figure 4 shows that the highest solubility indices are observed from 80°C and that they continue to increase with temperature. This increase reflects the destruction of the starch molecule under the effect of heat with the release of amylose molecules that diffuse out of the granule and solubilise in the aqueous medium [45]. With the exception of the second cassava formulation, all solubility index values are between 5 and 20%. This would assume that during a preparation with this flour, it would be more likely to downshift at the end of the preparation. In addition, cassava flour formulations were found to have higher solubility indices than corn. This difference would be due to the content of soluble compound in each flour such as amylose, reducing and nonreducing sugars and soluble fibers [46].

Figure 4. Solubility index of different flours. Note: Corn: simple corn flour; F1C: first corn formulation (82.5% corn+15% soya+2.5% Moringa); F2C: second corn formulation (70% corn+25% soya+5% Moringa); Cav: simple cassava flour; F1Cav: first cassava formulation (82.5% cassava+15% soya+2.5% Moringa); F2Cav: second cassava formulation (70% cassava+25% soya+5% Moringa).

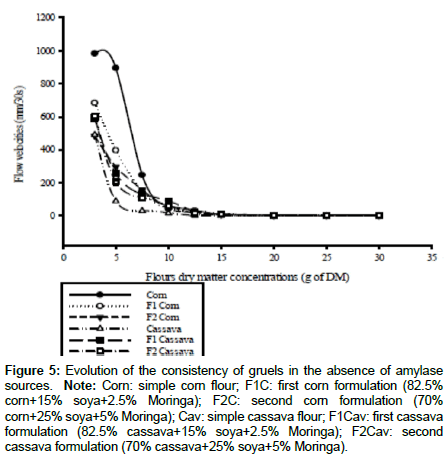

Evolution of the flow velocity of gruels as a function of the dry matter concentration: The evolution of the consistency of corn and cassava gruels and the different formulations is given in Figure 5 which shows that for dry matter values below 12.5%, the flow rates of all prepared gruels increase to values above 400 mm/30 s; the resulting gruels are very liquid but low dry matter concentrations (low energy and nutrient densities). This may partly explain the prevalence of malnutrition observed in developing countries. For dry matter values above 12.5%, these decrease, become heavy, viscous and reach a zero value (0 mm/30 s) but with energy densities above 70 kcal as indicated by the work of Trêche et al. [47]. Because of their heavy consistency, these cannot be consumed by children although energetic. The flow velocities of these gruels are inversely proportional to their dry matter concentrations. During cooking, the increase in consistency of different gruels is attributed by water retention of the starch molecule [11]. Indeed, with the rise in temperature during cooking, the starch grains unfold, open and highlight their hydrophilic groups leading to high water retention and thickening of the gruel [9]. These watery and heavy gruel make a problem for digestion. According to Brown [48] when these are too watery, infants cannot consume a large quantity because of their limited stomach capacity (30 to 40 g/kg body weight or 150 to 200 mL). However, when they are viscous and heavy, they are indigestible and cause a feeling of rapid satiety in infants. They therefore require treatment in order to provide them with satisfactory nutritional and energy value for children.

Figure 5. Evolution of the consistency of gruels in the absence of amylase sources. Note: Corn: simple corn flour; F1C: first corn formulation (82.5% corn+15% soya+2.5% Moringa); F2C: second corn formulation (70% corn+25% soya+5% Moringa); Cav: simple cassava flour; F1Cav: first cassava formulation (82.5% cassava+15% soya+2.5% Moringa); F2Cav: second cassava formulation (70% cassava+25% soya+5% Moringa).

Effect of the incorporation of extract and amylase flour on the flow velocities of gruels with dry matter concentrations of 17.50%: The analysis in Table 7 shows us that in the absence of amylase sources to predigest starch into molecules of low molecular weight (dextrin, maltose, glucose) with a low water retention capacity, the prepared gruels have flow velocities of 0% to 17.50% dry matter concentrations. These gruels are therefore indigestible for children. When 2 g of amylase flour and 2.5 mL amylase extract are added, the trend is reversed. Indeed, the gruels with zero initial flow velocities increase until reaching 606.67 mm/30 s. The incorporation of flour and amylase extract therefore allowed a good fluidification of the gruels. This fluidification would be better with the increase in the rate of amylase sources. An enzyme is effective when it produces the desired effect at low concentrations [49]. This efficiency is also related to the form of incorporation (p<0.05) and the substrate used. This is how the amylase flour allowed a better fluidification of the corn-based gruels and the extract the cassava floursbased gruel. It is also observed that the fluidizing capacity of amylase sources is higher on formulated flours. This can be explained by the content of ions such as Ca and Mg in these flours. Indeed, Tambo et al. [16] have demonstrated that these ions are cofactors of amylase activity that improve activity up to a certain concentration (5 mM). Moreover, we observe that the extracts allowed a better fluidification than the flours as a whole. Therefore, taking into account the results obtained, we can recommend the use of amylase flours and extracts to increase energy intake, nutrients and the flow rate of weaning infants gruels.

| Flours | Without | Amylase flour (2 g) | Amylase extract (2.5 mL) |

|---|---|---|---|

| Corn | 0.00 ± 0.00aC | 111.67±12.58cB | 310.00 ± 10.00cA |

| F1C | 0.00 ± 0.00aC | 325.00 ±10.00aB | 342.33 ± 2.52cA |

| F2C | 0.00 ± 0.00aC | 109.00 ± 7.81cB | 235.67 ± 30.92dA |

| Cav | 0.00 ± 0.00aC | 85.00 ± 2.00dB | 448.33 ± 47.52bA |

| F1Cav | 0.00 ± 0.00aC | 170.00 ± 15.00bB | 484.00 ± 14.42bA |

| F2Cav | 0.00 ± 0.00aC | 118.33 ± 7.64cB | 606.67 ± 35.47aA |

Mean values ± standard deviation of two repetitions carrying the different letters A, B, C in the same row significantly differ (p<0.05);

Corn: simple corn flour; F1C: first corn formulation (82.5% corn+15% soya+2.5% Moringa); F2C: second corn formulation (70% corn+25% soya+5% Moringa); Cav: simple cassava flour; F1Cav: first cassava formulation (82.5% cassava+15% soya+2.5% Moringa); F2Cav: second cassava formulation (70% cassava+25% soya+5% Moringa)

Table 7: Effect of the incorporation of amylase flour or extract on the flow velocities (mm/30s) of gruels with dry matter concentrations of 17.50%.

Dry matter concentrations of flours with desired flow velocities (100-160 mm/30 s): Table 8 shows the dry matter concentrations of the flours to obtain flow rates between 100-160 mm/30 s. It shows that 22.5 g of F1Cav supplemented with 2 g of germinated corn flour and 26.5 g of F1Cav supplemented with 2.5 mL of amylase extract would be required to obtain a flow between 100 and 160 mm/30 s. This result gives us the best floury/amylase combinations unlike the cassava/ amylasic flour and corn flour/amylasic extract mixtures which gave us the bad ratios. However, there was an increase in the dry matter concentration of flour compared to the results in Figure 6. This would be due to the fact that the incorporation of low doses of germinated corn flour (source of α-amylases) in heavy, viscous gruels with initially zero flow velocity leads to an increase in flow velocity associated with an increase in dry matter and energy density [50]. It also appears that the viscous characters of cassava and corn gruels disappear in the presence of germinated corn flour. This is due to the hydrolytic action of amylases which degrade large starch molecules into smaller molecules (maltodextrins, maltose) whose swelling capacity is reduced [15]. The germinated corn flour thus makes it possible to pre-digest the starch in order to make the gruels more digestible and easy to consume. It is also noted that the extracts obtained higher dry matter concentrations than those of amylase flours. This can be explained by the fact that amylase flours, in addition to their amylase content, are also rich in starch which can fix water molecules and hinder the action of amylase catalysts (hydrolases) [51]. Taking into account the results obtained, we can recommend the use of amylase extract for the preparation of the gruels as it has allowed the desired flow velocity to be obtained with dry matter concentrations above 25 g.

| Flours | Amylase flour (2 g) | Amylase extract (2.5 mL) |

|---|---|---|

| Corn | 17.50 ± 1.00 | 19.00 ± 1.00 |

| F1C | 20.00 ± 0.30 | 20.00 ± 0.30 |

| F2C | 17.50 ± 0.10 | 19.75 ± 0.10 |

| Cav | 16.00 ± 0.30 | 21.50 ± 0.30 |

| F1Cav | 22.50 ± 0.50 | 26.50 ± 0.50 |

| F2Cav | 17.50 ± 0.20 | 25.00 ± 0.20 |

Table 8: Gruel concentrations with flow velocities between 100 and 160 mm/30 s.

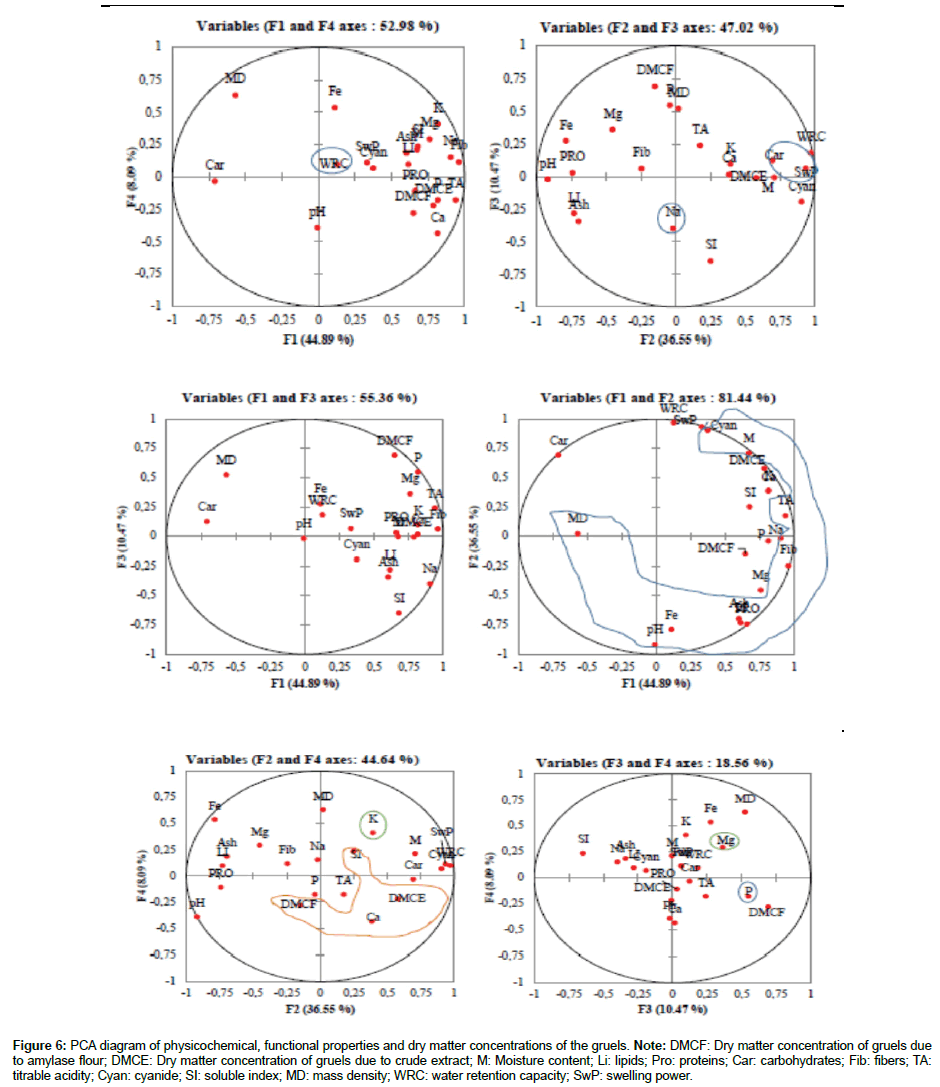

Figure 6. PCA diagram of physicochemical, functional properties and dry matter concentrations of the gruels. Note: DMCF: Dry matter concentration of gruels due to amylase flour; DMCE: Dry matter concentration of gruels due to crude extract; M: Moisture content; Li: lipids; Pro: proteins; Car: carbohydrates; Fib: fibers; TA: titrable acidity; Cyan: cyanide; SI: soluble index; MD: mass density; WRC: water retention capacity; SwP: swelling power.

Effect of the incorporation of amylase flours and crude extracts on the multiplication factor of the nutritional value and energy density of gruels: The analysis in Table 9 shows that the introduction of amylase sources in the preparation of flour-based gruels implies an increase in flour dry matter concentration. As a result, the ratio of gruel and amylase flour to simple gruel varies from 2.05 to 2.6 while the ratio with amylase extract varies from 2.2 to 5.1. These results show that the incorporation of amylase extracts and flours during the preparation of infant gruels improves their nutritional value compared to unsupplemented gruels. Moreover, we observe that the extracts presented the best multiplication factors, which confirms the results obtained previously. The multiplication factors obtained for gruels supplemented with amylase flour are lower than those of Zannou-Tchoko et al. [11] which showed that the introduction of 10% of germinated corn flour in gruels made from attiéké/soya flour and cassava/soya flour allowed to obtain a flow of 120 mm/30 s for a dry matter of 30.5% i.e., a multiplication factor of 3.8 compared to the dry matter concentration of the traditional gruel. Yibeltal et al. [52], has also shown that the use of sprouted maize seeds in the preparation of porridges is accompanied by an improvement in nutritional value and viscosity. This difference can be explained by the nutritional composition of the flours, the treatments applied to them (fermentation, germination, roasting) the proportion of ingredients in the formulation and the incorporation rate of amylase flours.

| Flours | Amylase rich flour (2 g) Amylase extract (2.5 mL) | ||||

|---|---|---|---|---|---|

| WE | W | F | W | F | |

| Corn | 8.50 | 12.50 | 2.00 | 19.00 | 2.20 |

| F1C | 7.50 | 20.00 | 2.60 | 20.00 | 2.60 |

| F2C | 7.50 | 17.50 | 2.30 | 19.70 | 2.60 |

| Cav | 4.20 | 16.00 | 3.80 | 21.50 | 5.10 |

| F1Cav | 7.50 | 22.50 | 3.00 | 21.50 | 3.50 |

| F2Cav | 7.50 | 17.50 | 2.30 | 25.00 | 3.30 |

Table 9: Effect of the incorporation of amylase flours and extracts on the multiplication factor of the nutritional value and energy density of gruels.

Effect of the incorporation of amylase flours and extracts on the energy intake of gruels with flow rates of 100-160 mm/30 s: The analysis shows that in the absence of amylase sources, the prepared gruels have low energy densities (19.50-39.06 kcal) (Table 10). Taking 3 portions of these gruels does not cover the energy needs of children (6-12 months) which is 360 kcal external intake [29]. It appears that the incorporation of flour and amylases extract made it possible to obtain gruels with energy densities of 74.31-100.62 kcal and 87.32-126.75 kcal respectively. The use of these amylase sources allowed to improve the energy density of the gruels compared to the traditionally prepared gruel between 41.37-71.75 kcal for amylase flour and 48.26-90.88 kcal for amylase extract. The incorporation of the amylase extract allowed a better improvement of the energy value of the gruels compared to the flour. Moreover, it also appears that the incorporation of amylase sources generally makes it possible to prepare weaning foods that comply with the recommendations made by Dewey et al. [53] which recommends a minimum energy density of 84 kcal/100 g of gruels for children aged 9-11 months. These results are similar for gruels made from formulated flours to those of Elenga et al. [9] which obtained energy values ranging from 94.2-108.43 kcal/100 mL of gruel. It was also observed that regardless of the form of incorporation of the amylase source, cassava flours had higher energy densities. This difference can be explained by the composition of the flours (protein, lipid, starch content and starch composition), the sudden treatment and the ability of the amylase sources to digest its starch. The contributions (%) and square cosines of variables and observations are presented in Tables 11 and 12, respectively.

| Flours | Amylase flour (2 g) | Amylase extract (2.5 mL) | |||

|---|---|---|---|---|---|

| WE | W | D | W | D | |

| Corn | 39.06 | 80.43 | 41.37 | 87.32 | 48.26 |

| F1C | 35.84 | 95.58 | 59.74 | 95.58 | 59.74 |

| F2C | 35.89 | 83.74 | 47.85 | 94.51 | 58.62 |

| Cav | 19.50 | 74.31 | 54.81 | 99.85 | 80.35 |

| F1Cav | 35.87 | 100.62 | 71.75 | 126.75 | 90.88 |

| F2Cav | 36.39 | 84.92 | 48.53 | 121.31 | 84.92 |

Table 10: Effect of the incorporation of amylase flours and extracts on the energy intake of gruels with flow velocities between 100-160 mm/30 s.

| Variables | Contributions (%) | Square cosines | ||||||

|---|---|---|---|---|---|---|---|---|

| F1 | F2 | F3 | F4 | F1 | F2 | F3 | F4 | |

| M | 4.817 | 6.522 | 0.001 | 2.665 | 0.454 | 0.501 | 0.000 | 0.045 |

| LI | 3.999 | 6.967 | 3.578 | 0.560 | 0.377 | 0.535 | 0.079 | 0.010 |

| PRO | 4.622 | 7.185 | 0.045 | 0.691 | 0.436 | 0.552 | 0.001 | 0.012 |

| Ash | 3.841 | 6.336 | 5.302 | 2.059 | 0.362 | 0.486 | 0.117 | 0.035 |

| Fib | 9.781 | 0.788 | 0.171 | 0.803 | 0.922 | 0.061 | 0.004 | 0.014 |

| Car | 5.331 | 6.266 | 0.700 | 0.060 | 0.503 | 0.481 | 0.015 | 0.001 |

| Cyan | 1.488 | 10.654 | 1.684 | 0.287 | 0.140 | 0.818 | 0.037 | 0.005 |

| MD | 3.430 | 0.006 | 12.503 | 23.634 | 0.323 | 0.000 | 0.275 | 0.401 |

| WRC | 0.171 | 12.258 | 1.515 | 0.569 | 0.016 | 0.941 | 0.033 | 0.010 |

| SI | 4.890 | 0.820 | 19.087 | 3.318 | 0.461 | 0.063 | 0.420 | 0.056 |

| SwP | 1.169 | 11.373 | 0.185 | 0.749 | 0.110 | 0.873 | 0.004 | 0.013 |

| pH | 0.001 | 11.041 | 0.019 | 8.953 | 0.000 | 0.848 | 0.000 | 0.152 |

| TA | 9.337 | 0.400 | 2.622 | 1.851 | 0.880 | 0.031 | 0.058 | 0.031 |

| P | 7.062 | 0.022 | 13.693 | 1.855 | 0.666 | 0.002 | 0.301 | 0.032 |

| Na | 8.672 | 0.005 | 7.201 | 1.401 | 0.817 | 0.000 | 0.158 | 0.024 |

| K | 7.078 | 2.010 | 0.425 | 9.960 | 0.667 | 0.154 | 0.009 | 0.169 |

| Fe | 0.132 | 8.109 | 3.448 | 17.039 | 0.012 | 0.622 | 0.076 | 0.289 |

| Ca | 7.043 | 1.917 | 0.012 | 11.110 | 0.664 | 0.147 | 0.000 | 0.189 |

| Mg | 6.127 | 2.674 | 5.972 | 5.057 | 0.578 | 0.205 | 0.131 | 0.086 |

| DMCF | 4.457 | 0.290 | 21.833 | 4.567 | 0.420 | 0.022 | 0.480 | 0.078 |

| DMCE | 6.553 | 4.357 | 0.003 | 2.810 | 0.618 | 0.334 | 0.000 | 0.048 |

Table 11: Contributions and square cosines of variables.

| Variables | Contributions (%) | Square cosines | ||||||

|---|---|---|---|---|---|---|---|---|

| F1 | F2 | F3 | F4 | F1 | F2 | F3 | F4 | |

| Corn | 33.699 | 11.680 | 1.024 | 33.597 | 0.681 | 0.192 | 0.005 | 0.122 |

| F1C | 2.243 | 41.544 | 8.838 | 27.376 | 0.052 | 0.786 | 0.048 | 0.114 |

| Cav | 22.801 | 34.550 | 0.002 | 22.646 | 0.414 | 0.511 | 0.000 | 0.074 |

| F1Cav | 19.954 | 11.946 | 31.742 | 16.358 | 0.498 | 0.243 | 0.185 | 0.074 |

| F2Cav | 21.304 | 0.280 | 58.394 | 0.023 | 0.606 | 0.006 | 0.387 | 0.000 |

| F2C | 0.289 | 0.581 | 0.037 | 0.093 | ||||

Table 12: Contributions and square cosines of observations.

Study of the correlations between physic-chemical parameters, functional properties and the effect of the incorporation of flour and amylases crude extract on dry matter concentrations of gruels-Principal Component Analysis (PCA): Table 13 presents the correlation matrix between the physicochemical, functional properties and effect of incorporation of amylase flour and crude amylase extract on dry matter concentration of gruels. The correlations marked in bold with are significant; p<0.05 (*) and p<0.01 (**). This matrix shows that the variables are correlated in small groups. Hence, the interest of conducting an analysis in main components in order to visualize the proximities and distances between these variables. Principal component analysis (PCA) allows us to map variables (lipids, fibers, protein, phosphorus, cyanide, water retention capacity, water absorption capacity, solubility index, Ca, Na, Mg, Fe, K, swelling rate, ash, titratable acidity, pH, carbohydrates, mass density and dry matter due to amylase flour and crude amylase extract) according to their correlation and proximity.

| Variables | M | LI | PRO | Ash | Fib | Car | Cyan | MD | WRC | SI | SwP | pH | TA | P | Na | K | Fe | Ca | Mg | DMCF | DMCE |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M | 1 | ||||||||||||||||||||

| LI | -0.082 | 1 | |||||||||||||||||||

| PRO | -0.104 | 0.929** | 1 | ||||||||||||||||||

| Ash | -0.047 | 0.993** | 0.884** | 1 | |||||||||||||||||

| Fib | 0.498 | 0.764* | 0.806** | 0.750* | 1 | ||||||||||||||||

| Car | 0.006 | -0.980** | -0.976** | -0.959** | -0.847** | 1 | |||||||||||||||

| Cyan | 0.908** | -0.371 | -0.438 | -0.33 | 0.134 | 0.336 | 1 | ||||||||||||||

| MD | -0.236 | -0.45 | -0.443 | -0.42 | -0.45 | 0.462 | -0.251 | 1 | |||||||||||||

| WRC | 0.792* | -0.673* | -0.642* | -0.644* | -0.09 | 0.602* | 0.896** | 0.106 | 1 | ||||||||||||

| SI | 0.688* | 0.438 | 0.216 | 0.5 | 0.578 | -0.4 | 0.622* | -0.57 | 0.235 | 1 | |||||||||||

| SwP | 0.909** | -0.486 | -0.485 | -0.45 | 0.106 | 0.417 | 0.965** | -0.07 | 0.971** | 0.45 | 1 | ||||||||||

| pH | -0.740* | 0.636* | 0.720* | 0.57 | 0.172 | -0.623* | -0.859** | -0.27 | -0.936** | -0.3 | -0.908** | 1 | |||||||||

| TA | 0.717* | 0.363 | 0.516 | 0.33 | 0.852** | -0.51 | 0.451 | -0.52 | 0.315 | 0.48 | 0.471 | -0.105 | 1 | ||||||||

| P | 0.48 | 0.36 | 0.606* | 0.3 | 0.807** | -0.53 | 0.15 | -0.29 | 0.146 | 0.15 | 0.247 | 0.089 | 0.921** | 1 | |||||||

| Na | 0.630* | 0.696* | 0.582 | 0.722* | 0.867** | -0.709* | 0.408 | -0.625* | 0.038 | 0.903** | 0.274 | -0.041 | 0.722* | 0.493 | 1 | ||||||

| K | 0.915** | 0.227 | 0.206 | 0.26 | 0.742* | -0.31 | 0.671* | -0.15 | 0.543 | 0.688* | 0.691* | -0.531 | 0.786* | 0.630* | 0.756* | 1 | |||||

| Fe | -0.37 | 0.621* | 0.610* | 0.624* | 0.381 | -0.609* | -0.687* | 0.405 | -0.648* | -0.2 | -0.622* | 0.51 | -0.06 | 0.179 | 0.09 | 0.029 | 1 | ||||

| Ca | 0.728* | 0.173 | 0.301 | 0.14 | 0.638* | -0.3 | 0.619* | -0.722* | 0.436 | 0.54 | 0.581 | -0.191 | 0.913** | 0.735* | 0.656* | 0.639* | -0.441 | 1 | |||

| Mg | 0.252 | 0.725* | 0.818** | 0.704* | 0.898** | -0.817** | -0.174 | -0.07 | -0.248 | 0.24 | -0.115 | 0.289 | 0.669* | 0.786* | 0.597 | 0.598 | 0.700* | 0.324 | 1 | ||

| DMCF | 0.269 | 0.286 | 0.59 | 0.21 | 0.669* | -0.47 | -0.045 | -0.19 | 0.037 | -0.1 | 0.089 | 0.227 | 0.798* | 0.965** | 0.27 | 0.423 | 0.231 | 0.603* | 0.730* | 1 | |

| DMCE | 0.892** | 0.041 | 0.113 | 0.03 | 0.587 | -0.15 | 0.804** | -0.58 | 0.638* | 0.632* | 0.776* | -0.453 | 0.876** | 0.652* | 0.669* | 0.779* | -0.488 | 0.957** | 0.27 | 0.479 | 1 |

DMCF: Dry matter concentration of gruels due to amylase flour; DMCE: Dry matter concentration of gruels due to crude extract; M: Moisture content; Li: lipids; Pro: proteins; Car: carbohydrates; Fib: fibers; TA: titrable acidity; Cyan: cyanide; SI: soluble index; MD: mass density; WRC: water retention capacity; SwP: swelling power.

Table 13: Pearson correlation coefficient (r) matrix between physico-chemical, functional properties and dry matter concentration.

In the case of our analysis, four components F1, F2, F3 and F4 explain 100% of the variations with respective contributions of 44.89%, 36.55%, 10.47% and 8.08%. The PCA diagram of variables, also called variable correlation circles and the variable dendogram allow us to visualise the grouping between these factors. Figure 6 confirms once again the correlations but also the proximity between the different variables studied. According to Figure 6 and Table 8, we observed that the formation of these axes is dependent on the variables; this is how carbohydrates, fibers, solubility index, titrable acidity, P, Na, K, Ca, Mg and dry matter concentration of gruels due to amylase crude extracts allow the formation of the F1 axis. Moisture content, lipids, proteins, as, cyanide content, water retention capacity, swelling power, Fe and pH allow the formation of the F2 axis. Dry matter concentration of gruels due to amylase flour and mass density allow the formation of F3 and F4 axis, respectively. From these analyses, it emerges that the four axes make it possible to group the variables into 8 blocks according to PCA and dendogram (Figure 6 and Table 11).

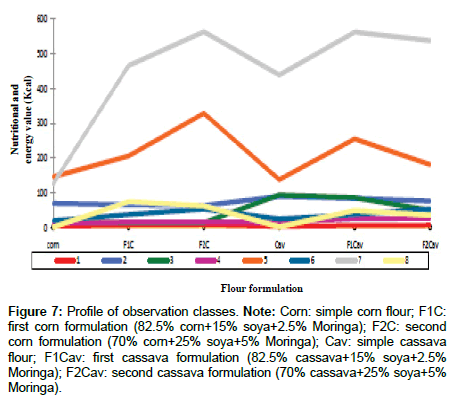

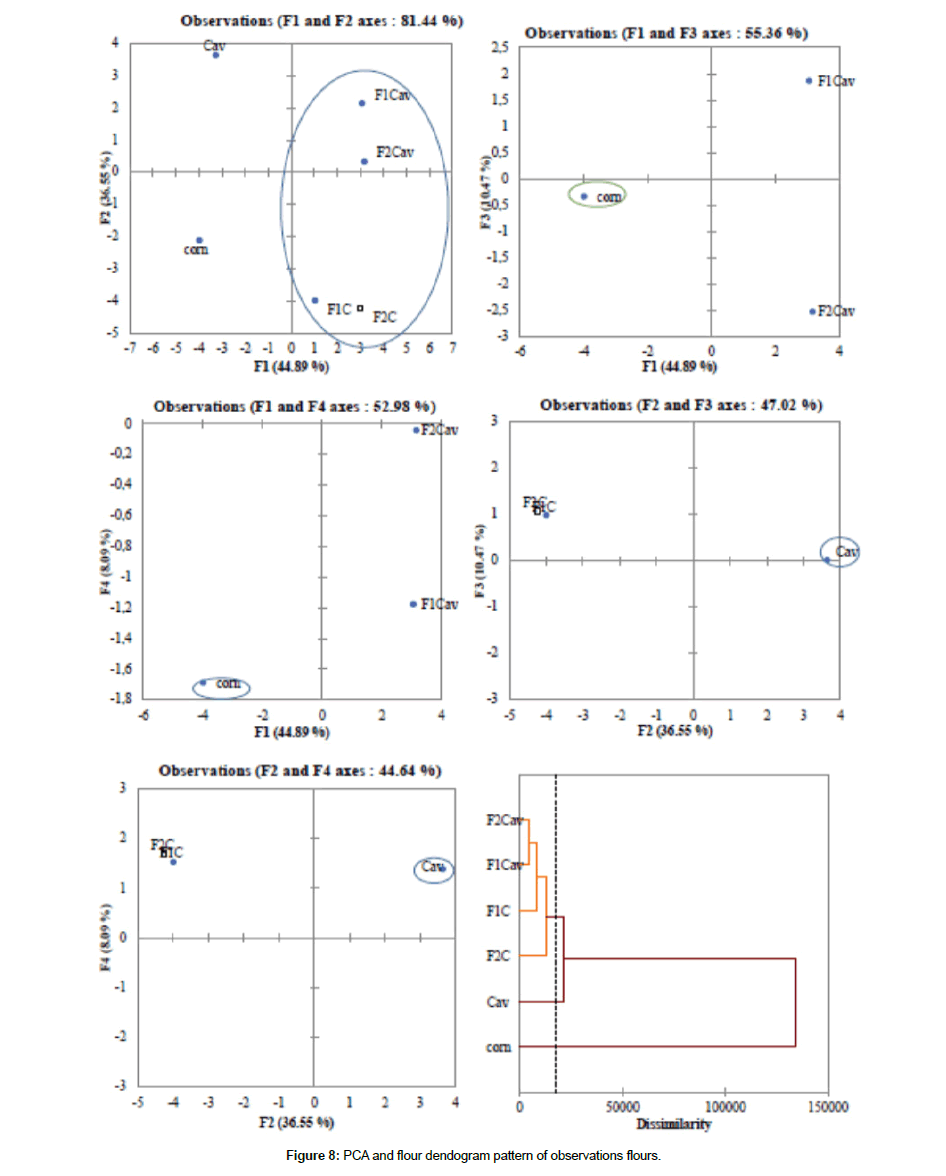

We also subjected the observations to a hierarchical bottom-up classification with a view to sorting the different classes and this allowed us to group them into 3 classes with 5 active observations (Corn, F1C, Cav, F1Cav and F2Cav) and an additional one (F2C) as shown in Table 12 and Figure 7. Still concerning Table 9, it also emerges that axes F1 and F2 are the only two axes whose observations contribute to the training. Thus corn, F1Cav and F2Cav allow the formation of the F1 axis. F1C, Cav and F2C (additional observation) allow the formation of axis F2.

Figure 7. Profile of observation classes. Note: Corn: simple corn flour; F1C: first corn formulation (82.5% corn+15% soya+2.5% Moringa); F2C: second corn formulation (70% corn+25% soya+5% Moringa); Cav: simple cassava flour; F1Cav: first cassava formulation (82.5% cassava+15% soya+2.5% Moringa); F2Cav: second cassava formulation (70% cassava+25% soya+5% Moringa).

From these different tables and figures, it appears that the water content, lipids, proteins, ashes, fibres, cyanide, mass density, titratable acidity, Fe, pH are correlated and form a group. Indeed, the water content is positively correlated to the cyanide content (r=0.908) and to the titratable acidity (r=0.717) but negatively to the pH (r=- 0.740). Cyanogenetic glycosides and free organic acids are watersoluble elements. An abundance of these elements in a matrix would indicate quite intense water activity. As far as pH is concerned, significant water activity tends to dilute the concentration of basic compounds present thereby reducing pH. In addition, cyanide and pH are negatively correlated (r=-0.859). Cyanogenetic compounds are present in plants as glucose-HCN. These compounds are organic acids which once hydrolyzed release HCN (organic acid) which leads to pH reduction [54]. Lipids are also correlated to fibers (r=0.764), protein (r=0.929) and ash (r=0.993). A second grouping (not significant) is that between carbohydrates and swelling power. Carbohydrates are the main compound in cereals and tubers. They are polar molecules with -OH groups on their surfaces that have the ability to bind water molecules and swell. Water retention capacity is the third grouping. This parameter refers to the amount of water retained by a matrix as a function of temperature over a specific time. It also gives an indication of the strength of the hydrogen bonds stabilizing them, the amylose/amylopectin ratio as well as the food quality of a food [55]. Another grouping is that between the solubility index, Ca, DMCE and DMCF. Ca is positively correlated to DMCE (r=0.977) and DMCF (r=0.603) (Table 13). Calcium is a cofactor of amylase activity in crude extracts and amylase flours [16]. The solubility index is positively correlated to the DMCE (r=0.632). Solubility reflects the extent of intermolecular cross bonding within the granule [56]. Solubility is due to compounds of low molecular weight including amylose which consists essentially of bonds α-1,4 easily hydrolysable by amylases present in the crude extract. Indeed, the higher the solubility, the higher the amyloidosis and the greater the amylase's ability to act. The other groupings are represented by P, Na, K and Mg respectively. Significant positive correlation coefficients were observed particularly for phosphorus and K (r=0.630), phosphorus and Mg (r=0.786). Phosphorus is brought into the feed as a negatively charged phosphate group. These phosphate groups have the ability to bind other positively charged ions such as K and Mg, hence the increase in K and Mg contents with that of phosphorus.

Figure 8 presents the profile of the different classes. It appears that corn and cassava flours have similar profiles for groupings 2, 3, 5 and 8. All flours showed similar developments with classes 1 and 4. However in class 3, the formulated flours presented similar profiles with all the other classes.

Figure 8. PCA and flour dendogram pattern of observations flours.

Hierarchical bottom-up classification analysis has defined three classes. These classes are represented by the different formulations (F1Cav, F2Cav, F1C and F2C), cassava and corn flours. These groupings show that the different formulations are very similar in terms of the different parameters evaluated (functional, physical-chemical properties and flow velocities). However, cassava and corn flours are far apart according to this analysis, which is explained by the fact that they are very different in terms of the parameters evaluated. It also appears that the different formulations have the best nutritional and energy values (Figure 6). These are therefore recommended for use in the preparation of infant foods.

Conclusion

At the end of this work, where it was a question of determining the influence of the protein and lipid content of flours on the consistency and nutritional value of flours formulated from corn, cassava, soya and Moringa oleifera, it emerged that the first corn formulation and the first cassava formulation had the best energy densities and the best flow velocities. The proximate chemical composition, in particular the lipid and protein contents of flours vary significantly with the substitution rate of soybean meal. The analysis of the functional and physical properties showed that the different flours have a high water retention capacity and a moderately better swelling rate. The use of crude extract and amylase flour revealed that at 2.5 mL and 2 g, respectively, they reduced the consistency of the gruels with better activity for the crude extract. Generally speaking, the use of amylase sources when cooking gruels resulted in an increase in energy density and nutritional value between 2.66 for amylase flour and 3.53 for amylase extract. It also appears that the fluidising capacity of the various amylase sources was a function of the nature of the flour, its physical and functional properties and its composition.

Acknowledgment

The authors take this opportunity to express their sincere gratitude to Prof. Womeni Hilaire Macaire for his guidance. We recognise the role played by Dr. Teboukeu Gires, Mr. Ndomou Serge, Mr. Kohole Hermann and Mr. Zokou Ronice during sample preparation and evaluation, during the analysis and discussion of results.

REFERENCES

- WHO (World Health Organization) (2013) A world health statistics: A wealth of information on global public health. Progress on the health-related Millennium Development Goals (MDGs). WHO Press, World Health Organization, Geneva, Switzerland.

- WHO (World Health Organization) (2009) Global prevalence of vitamin A deficiency in populations at risk 1995–2005. WHO global database on vitamin A deficiency. WHO, Geneva, Switzerland.

- WHO/UNICEF (World Health Organization/United Nations of International Children’s Emergency Fund) (2006) Planning guide for national implementation of the global strategy for infant and young child feeding. WHO Press, Geneva, Switzerland.

- NIS (National Institute of Statistics) (2014) Demographic and health survey with multiple indicators EDS-MICS, p: 44.

- UNICEF-Cameroon (2009) Poverty and Disparities Among Children in Cameroon, p: 146.

- Sikod F (2001) Constraints to managing urban poverty in Cameroon. Env Urban 13: 201-208.

- NIS (National Institute of Statistics) (2015) Agriculture: Statistic Annuary of Cameroon, p: 20.

- Essien EB, Bene WA, Akaninwor JO (2010) Nutritional evaluation of some traditional weaning foods from Akwa Ibom State, Nigeria. Nigerian J Biochem Mol Biol 25(1): 65-72.

- Elenga M, Massamba J, Silou T (2012) Effect of corn malt incorporation on the fluidity and energy density of corn-pearl porridges for infants and young children. J Appl Biosci55: 3995-4005.

- Trèche S (2004) Fluid porridges, well-fed babies. Information for Agricultural Development in ACP Countries, p: 110.

- Zannou-Tchoko V, Ahui-bitty L, Kouame K, Kouame G, Dally T (2011) Use of corn flour germ source of α-amylases to increase the energy density of weaning porridges based on manioc and its derivative attiéké. J Appl Biosci 37: 2477-2484.

- Soro S, Konan G, Elenga E, N’guessan D, Koffi E (2013) Formulation of infant foods based on yam flour enriched with soya. Afr J Food Agri Nutr Dev13(5): 8313-8339.

- Shiriki D, Igyor M, Gernah DI (2015) Nutritional evaluation of complementary food formulations from maize, soybean and peanut fortified with Moringa oleifera leaf powder. Food NutrSci 6: 494-500.

- Klang JM, Talamond P, Djidimbele N, Tavea F, Ndjouenkeu R (2014) Partial purification and characterization of alpha-amylases from Abrus precatorius, Burnatia enneandra and Cadaba farinosa. J Enzyme Res 5: 66-71.

- Tambo TS, Klang JM, Ndomou HSC, Teboukeu BG, Womeni HM (2019) Characterisation of corn, cassava and commercial flours: use of amylases rich flours of germinated corn and sweet potato in the reduction of the consistency of the gruels made from these flours-influence on the nutritional and energy value. Food Sci Nutr7: 1190-1206.

- Tambo TS, Klang JM, Ndomou HSG, Teboukeu BG, Kohole FHA, et al. (2018) Characterization of crude extracts amylase flours of corn malt (Kassaï and Atp varieties) and sweet potato (Local and 1112 varieties). Int J Adv Res Biol Sci5: 230-240.

- Okezie O, Bello A (1988) Physicochemical and functional properties of winged beans flour and isolate compared with soy isolate. J Food Sci 53: 450-454.

- Leach H, McCowen LD, Schoch I (1959) Structure of the starch granule II: Action of various amylases on granular starches. Cereal Chem 38: 34-46.

- Anderson RA, Conway HF, Pfeiffer VF, Griffin EL (1969) Roll and extrusion cooking of grain sorghum grits. Cereal Sci Today 14: 372-375.

- Okaka J, Okorie P, Ozo O (1991) Quality evaluation of sun dried yam chips. Trop Sci 31: 265-275.

- AOAC (1990) Official methods of Analysis (15thedn). Association of Official Analytical Chemists, Arlington, VA, USA, pp: 125-126

- Association Française de Normalisation (AFNOR) (1982) Compilation of French standards for products derived from fruit and vegetables, fruit juices (1stedn), Afnor (Ed.), Paris, France.

- IUPAC (International Union of Pure Applied Chemistry) (1979) Fat analysis methods (6thedn). Int Dig Health Legis 46: 1-241.

- AOAC (1980) Official methods of Analysis (15thedn). Association of Official Analytical Chemists, Arlington, VA, 132: 877-878.

- Merril AL, Watt BK (1955) Energy value of food, Basis, Methods in Molecular Biology, Humana Press Inc., Washington DC, United States Department of Agriculture, 393: 61-68.

- Bookwalter G, Peplinski A, Pfeifer V (1968) Using a bostwick consistometer to measure consistencies of processed corn meals and their CSM blends. Cereal Sci Today 13: 407-410.

- Bharathi J, Rajamanickam V (2015) Formulation and quality evaluation of cereals, legumes and greens based nutritious mix. Food Sci Res J6(2): 192-200.

- Ndangui CB (2015) Production and characterization of sweet potato flour (Ipomoea batatas Lam): Optimization of bread-making technology (Thesis), University of Lorraine, France, pp:1-134.

- FAO/WHO (2006) Joint FAO/WHO Food Standards Programme. Report of the twenty-seventh session of the Codex Committee on Nutrition and Foods for Special Dietary Uses. ALINOM, p: 105.

- Kouassi KAA, Adouko AE, Gnahe DA, Grodji GA, Kouakou BGD (2015) Comparison of the nutritional and rheological characteristics of infant porridges prepared by germination and fermentation techniques. Int J Biol Chem Sci9: 944-953.

- Dupin H, Cuq J, Malewiak M, Leynaud R, Berthier A (1992) Human Food Nutr. Paris, ESF, p: 1533.

- Tumwine G, Atukwase A, Tumuhimbise GA, Tucungwiirwe F, Linnemann A (2018) Production of Nutrient-enhanced millet-based composite flour using skimmed milk powder and vegetables. Food Sci Nutr 7: 1-13.

- Food and Nutrition Board (1989) Recommended Dietary Allowances (10thedn), Washington DC, National Academies Press, USA.

- Alasfoor D, Rajab H, Al-Rassasi B (2009) Food Based Dietary Guidelines: Technical background and description task force for the development and implementation of the Omani food based dietary guidelines. Ministry of Health, Muscat, Oman.

- Helland MH, Wicklund T, Narvhus JA (2002) Effect of germination time on alpha-amylase production and viscosity of Maize porridge. Food Res Int 35: 315-321.

- Lokombé-Léké A, Mullié C (2004) Infant nutrition and food diversification. Cahiers de Nutrition et Diététique 39: 349-359.

- Kim MH, Choi MK (2013) Seven Dietary Minerals (Ca, P, Mg, Fe, Zn, Cu, and Mn) and their relationship with Blood Pressure and Blood Lipids in Healthy Adults with Self-Selected Diet. Biol Trace Elem Res 153: 69-75.

- Garcia-Chuit CF, Boella C (1993) Minerals salts why? how? how many? éd. Nestec, SA, pp: 5-18.

- Abbott D, Ando F, Curb D (2003) Dietary magnesium intake and the future risk of coronary health disease (The Honolulu Heart Program). Am J Cardiol 92: 665-669.

- Odunlade TV, Famuwagun AA, Taiwo KA, Gbadamosi SO, Oyedele DJ, et al. (2017) Chemical composition and quality characteristics of wheat bread supplemented with leafy vegetable powders. J Food Qual, Article ID 9536716 : 1-7.

- Adebowale A, Sanni S, Oladapo F (2008) Chemical, functional and sensory properties of instant yam breadfruit flour. Niger Food J 26: 2-12.

- Tester R, Karkalas J (1996) Swelling and gelatinization of oat starches. Cereal Chem 73: 271-273.

- Svihus CB, Uhlenb AK, Harstad OM (2005) Effect of starch granule structure, associated components and processing on nutritive value of cereal starch: A Review. Anim Feed Sci Technol 122: 303-320.

- Prinyawiwatkul W, McWatters KH, Beuchat LR, Phillips RD (1997) Functional characteristics of cowpea (Vigna unguiculata) flour and starch as affected by soaking, boiling, and fungal fermentation before milling. Food Chem 58: 361-372.

- McWatters KH, Ouedraogo JB, Resurreccion AVA, Hung Y, Phillips RD (2003) Physical and sensory characteristics of sugar cookies containing mixtures of wheat, Fonio (Digitaria exilis) and cowpea (Vigna unguiculata) flours. Int J Food Sci Technol 38: 403-410.

- Eliasson AC, Gudmundsson M (1996) Starch: Physiochemical and functional aspects, in Carbohydrates in Food, Eliasson AC (Ed.) Marcel Dekker, Inc., New York.

- Trêche S, Giamarchi P, Pezennec S, Gallon G, Massamba J (1992) Weaning porridges in Congo, Composition, nutritional value and methods of use. Paper presented at the 5th GERM International Days. Balaruc, France, pp: 23-27.

- Brown KH (1991) The importance of dietary quality versus quantity for weaning in less developed countries: A framework for discussion. Food and Nutrition Bulletin 13(2): 86-94.

- Trèche S, Mbome Lapé I (1999) Viscosity, energy density and osmolality of gruels for infants prepared from locally produced commercial flours in some developing countries. J Food Sci Nutr 50: 117-125.

- Alvina M, Vera G, Pak N, Haraya H (1990) Effect of the addition of malt flour to extruded pea-rice preparations on food and energy intake by pre-school children. Ecol Food Nutr 24: 189-193.

- Elenga M, Massamba J, Kobawila S, Makosso V, Silou T (2009) Assessment and improvement of the Nutritional Quality of Pasta and Fermented Maize porridges in Congo. Int J Biol Chem Sci 3: 1274-1285.

- Yibeltal J, Menen Z, Pragya S, Hiwot A (2016) Formulation of Maize-Based Complementary Porridge Using Orange-Fleshed Sweet Potato and Bean Flour for Children Aged 6-23 Months in Kachabira Woreda, Southern Ethiopia. Int J Food Sci Nutr Eng 6: 87-101.

- Dewey K, Beaton G, Fjeld C, Lönnerdal B, Reeds P (1996) Protein requirements of infants and children. Eur J Clin Nutr 50: 119-150.

- Bindzi J (2012) Study of the drying and smoking of cassava rust paste (Manihot esculenta Crantz): Physico-chemical and functional characterization of flour and starch. Food Sci Nutr, University of Ngaoundéré, Ngaoundéré, Cameroon, p: 102.

- Richard JR, Asaoka MA, Blanshard JNV (1991) The Physiochemical properties of cassava starch. Trop Sci 31: 189-207.

- Hari PK, Aargs S, Garys SK (1989) Gelatinization of starch and modified starch. Starch 41: 88-91.

Citation: Klang JM (2019) Application of Germinated Corn Flour on the Reduction of Flow Velocities of the Gruels made from Corn, Soybean, Moringa oleifera Leaf Powder and Cassava. J Food Process Technol 10: 800.

Copyright: © 2019 Klang JM. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.