Indexed In

- Open J Gate

- Genamics JournalSeek

- Ulrich's Periodicals Directory

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Proquest Summons

- Scholarsteer

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

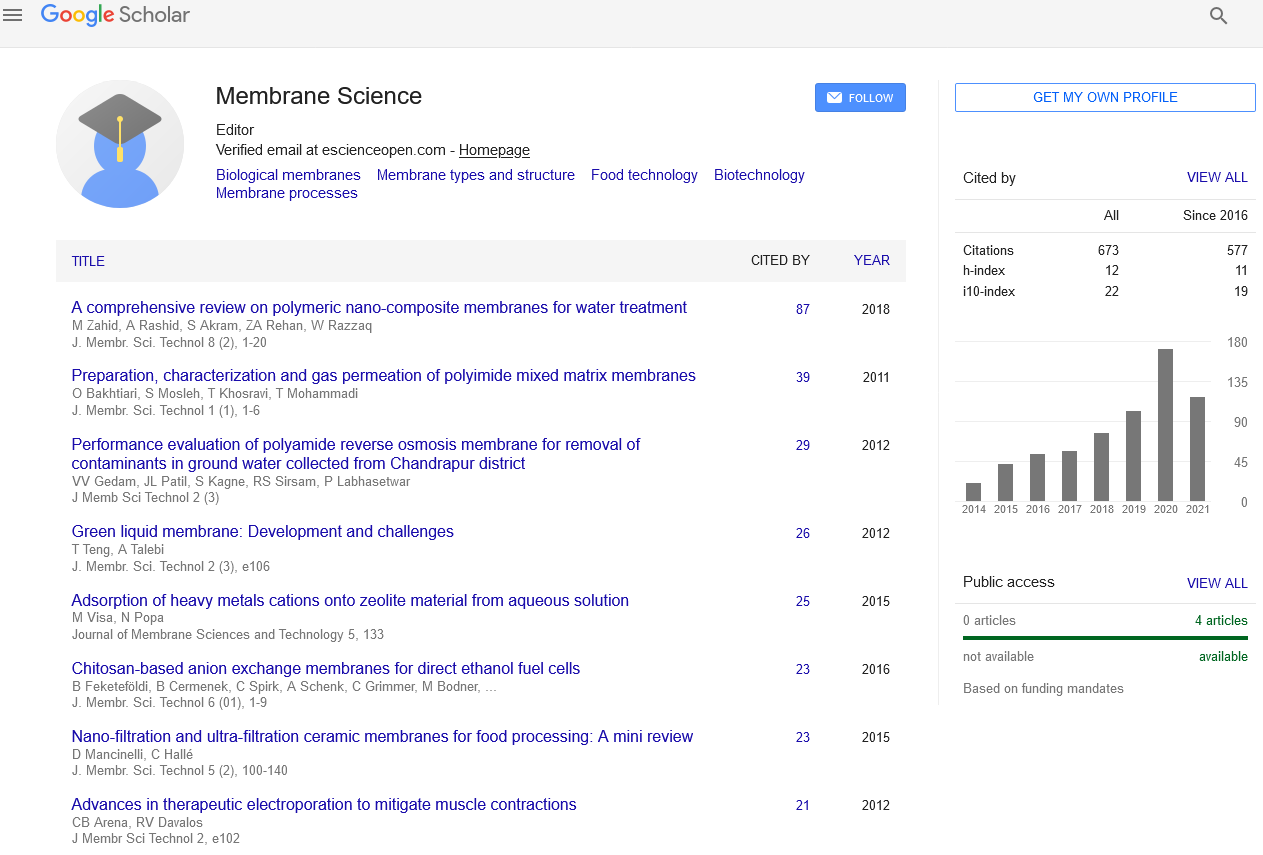

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Abstract

Sintering of the Immersion-Induced Porous Stainless Steel Hollow Fiber Membranes

Haixia Li, Jian Song and Xiaoyao Tan

Porous stainless steel (PSS) hollow fiber membranes have been fabricated by an immersion induced phase inversion and sintering technique. This paper is mainly focused on the sintering process. The influences of the sintering atmosphere as well as the sintering temperature and dwelling time on the microstructure, mechanical strength, and the permeation properties of the hollow fiber have been extensively investigated. Experimental results indicate that a H2-containing sintering atmosphere favors the formation of highly permeable porous PSS membranes with desirable mechanical strength. But the sintering atmosphere with H2 concentration larger than 25% is not necessary as it yields a marginal improvement on the membrane performances. For a sufficient sintering, the sintering temperature should be controlled between 1050 and 1100�C, which ensures not only a desirable mechanical strength but also good membrane porosity. For cost effective and less time consuming, sintering time can be controlled within two hours. The resultant PSS hollow fibers satisfy the longstanding criteria of porous supports for gas separation membranes in terms of high porosity, high fluid permeance and robustness to withstand stress.