Indexed In

- Open J Gate

- Genamics JournalSeek

- ResearchBible

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Publons

- MIAR

- Euro Pub

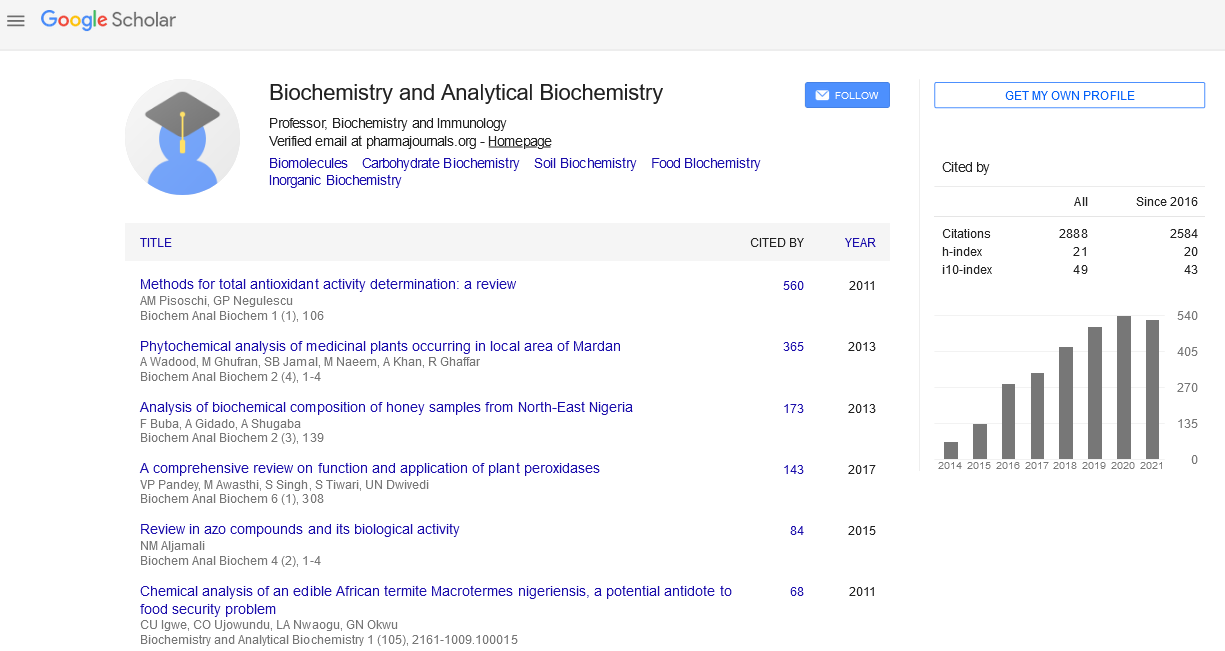

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Abstract

Production, Purification and Characterization of Endopolygalacturonase by Bacillus subtillus

Nayab Munir, Javaid Asad M and Haidri SH

Plant cell wall is made up of complex carbohydrates like cellulose, hemicelluloses and pectin. Pectin is complex carbohydrates made up of galacturonic acid units linked by glycosidic linkage. For breakdown of this pectin microorganism require many different enzymes. Polygalacturonase is a pectinolytic enzyme catalyzed hydrolysis of α 1-4 glycosidic linkage in polygalacturonic acid by the addition of water. Polygalacturonase has two types; endopolygalacturonase and exopolygalacturonase. Endopolygalacturonase catalysis internal α 1-4 glycosidic linkage and exopolygalacturonase catalyze external α 1-4 glycosidic linkage in Pectate molecules. Endopolygalacturonase has various applications especially fruit juice industries used for clarification of juice as well as in food industry for maceration of vegetables. Endo-PG produced by fungus works in acidic pH and at low temperature but the application of endo-PG in food industry and in cloth industry needs an enzyme that works at high temperature and also in alkaline conditions. Bacillus subtillus was used as reference strain. By using different substrates like apple peels, radish peels and citrus peels, it was concluded that citrus peels produce maximum enzyme concentration. Further characterization showed that EPG produced by Bacillus subtillus have optimum temperature of 60°C and optimum PH 5. Maximum fold of purification was observing with Gel filtration. Molecular weight of enzyme was 67 kd. Vmax for EPG produced by Bacillus subtillus was 1.21 mg/ml and Km was 2423 mol/min/mg.