Indexed In

- Open J Gate

- Genamics JournalSeek

- ResearchBible

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Publons

- MIAR

- Euro Pub

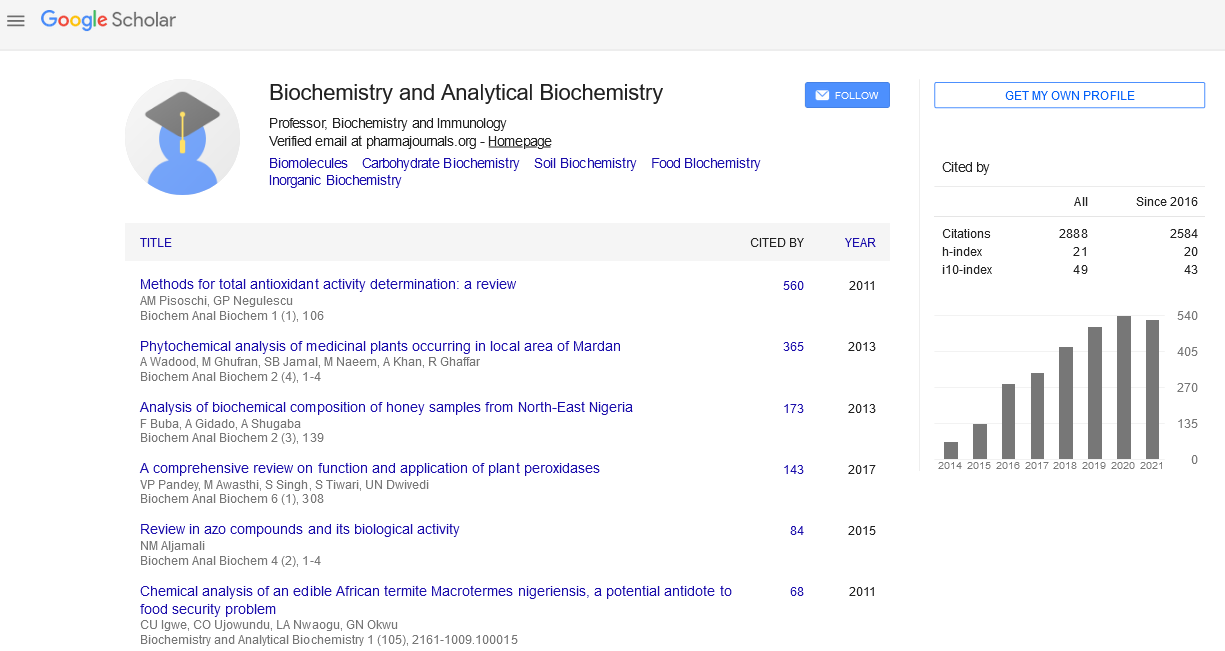

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Abstract

Production of Bio-Oil from Agriculture Waste

Biomass energy which includes producing energy fuel from plant is considered a promising source of renewable energy. This research aims to develop a new method to liquefy two types of agriculture waste and compare between their produced bio-oils in terms of ultimate production conditions, compositions and applications.

Firstly, One gram of two different types of agriculture wastes include Corn sticks (CS) and Palm leaves (PL) were liquefied by autoclaving at 2.5 atm pressure and 220°C temperature. The liquefaction process had been performed in the range of 10 to 80 ml ethanol/g treated solid, and retention time ranges between 10 to 120 min., the produced bio-oil were extracted and separated into three fractions: volatile, light and heavy.

The results show that, the maximum amount (0.04 g/g) of volatile bio-oil can be produced from CS at 40 ml ethanol/g treated solid and 30 min retention time. However maximum amount of light bio-oil (g/g) was obtained from CS at 30 ml ethanol/1 g treated solid and 60 min retention time. For heavy bio-oil, maximum amount (0.25 g/g) was derived from CS when the ratio between ethanol (ml): treated solid (g) is 30:1 and the retention time is 60 min.

Experimental data had been analysed using matlab software to get the modules which give the relations between bio-oil produced, ethanol to solid ratio and retention time in order to get the ultimate conditions of the process. GC-MS and FTIR analysis has been done to identify the bio-oils compositions. The results show that produced bio-oil from CS is highly contained carbon atom from C20-C38 in addition it contains high percentage of C6-C9 atoms. Therefore, the bio-oil from CS can be used as bio-fuel. However, the produced bio-oil from PL is mainly unsaturated acids which has carbon atom from C10-C18. Thus, it has pharmaceutical applications.