Indexed In

- Open J Gate

- Genamics JournalSeek

- Smithers Rapra

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Publons

- Geneva Foundation for Medical Education and Research

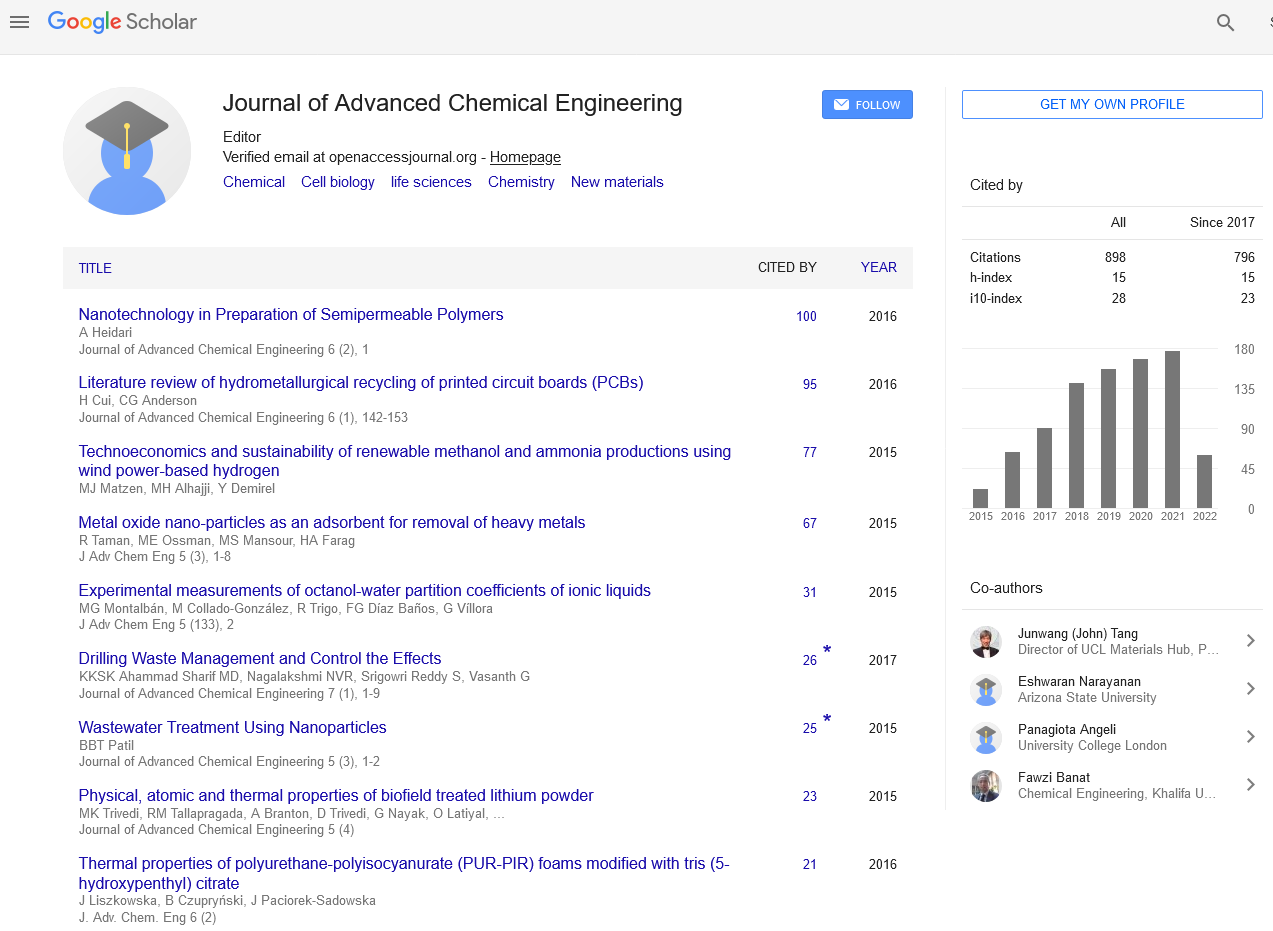

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Abstract

Polymeric materials with nature-based additives and reinforcements towards combined functionalities

Mikko Kanerva

All the research related to terms polymers and plastics have went through an enormous re-definition after the huge pressure established by the global recycling needs, necessary biodegradation, microplastic waste, and the fight for non-fossil source stocks for these materials. Tampere University and the Finnish plastics and composites industry are having its part in the development of new solutions to the challenge. This talk will encompass the latest achievements by our research groups and international partners, related to nano and micro- fibrillated cellulose and its use in conductive films, conductive structural materials, gas barrier membranes, natural additives of rosin and propolis in polymeric multi-filament fibres, antibacterial response of biodegradable plastics with natural components, and interfaces with synthetic and natural fibres in advanced composites. The potential to strong and tough films by the use of nano-cellulose has been for some time known. The work by properly combining optimum dispersion 1 and surfactants with carbon nanotubes is the key to use a minimum amount of nano-additives but reach the world top conductivity 2. In reality, many of the film preparation methods do not allow commercial, mass production implementation and clearly up-scaled production research is necessary for industrial products 3. In the case of up-scaling, the control of thickness-dependent behavior, such as barrier properties, are needed to be improved and they present the current future aspect of these films and parts. Somewhat similarly, the use of nature-derive antibacterial species, such as pine rosin and bee propolis, the potential for medical applications is evident. However, the related microbial response is dependent, in a highly non-linear fashion, on a matrix of factors making the application-related optimization difficult. For example, the environment and type of encounters between material surfaces and bacterial strains is not well known due to the complex structure of natural additives. Moreover, the processing of equivalent products when applying a dosage of natural substance is typically harder.

Published Date: 2020-08-18; Received Date: 2019-10-18