Indexed In

- Open J Gate

- Genamics JournalSeek

- Smithers Rapra

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Publons

- Geneva Foundation for Medical Education and Research

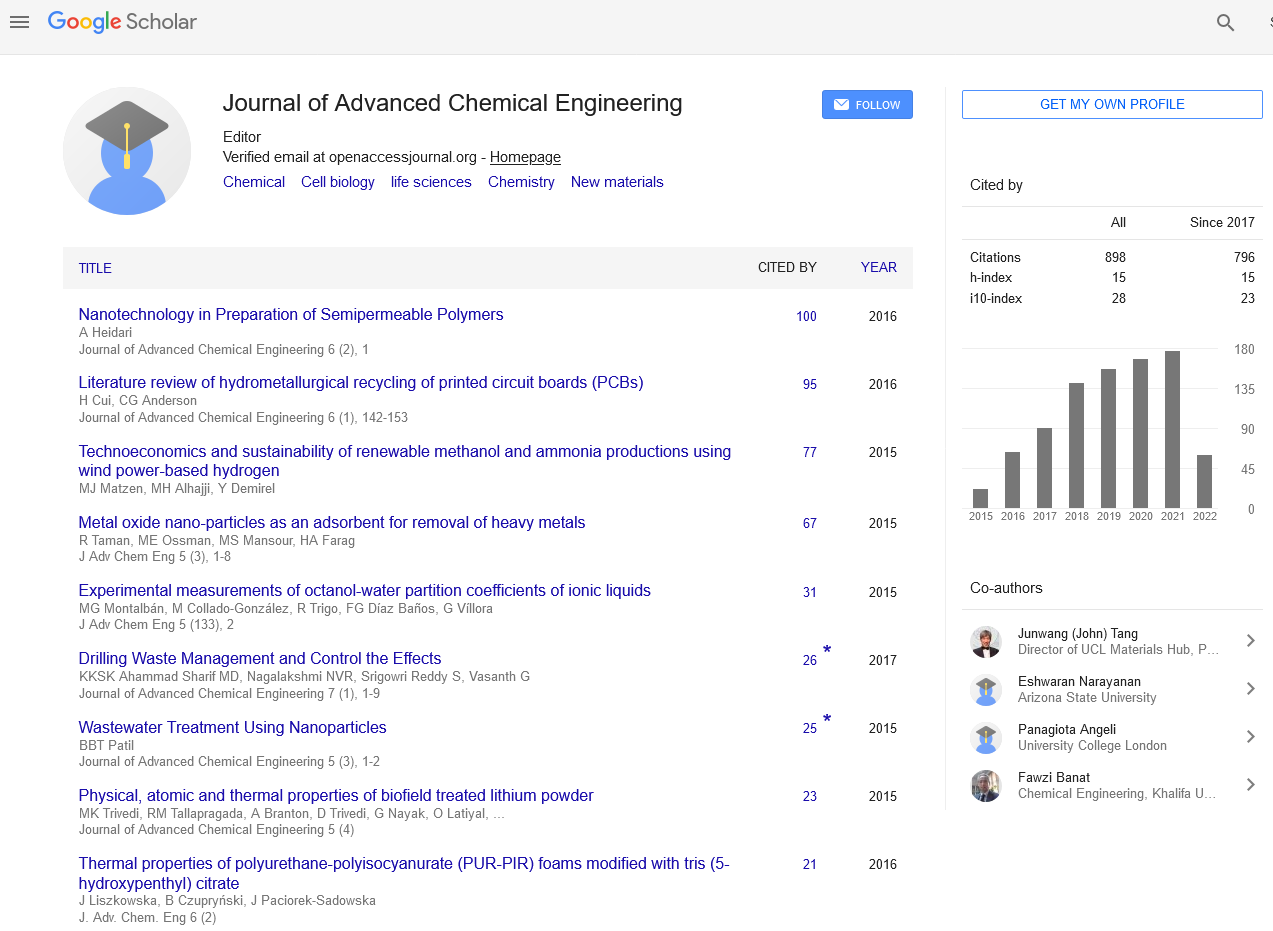

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Abstract

Improvement of the Energy Density of Rice Husk Using Dry and Chemical Treated Torrefaction

Aytenew G, NIgus G and Bedewi B

The main objective of this present study was to investigate the Torrefaction process of lignocellulose biomass ricehusk produced in Ethiopia through dry and chemical treated Torrefaction. Torrefaction is a technology that a partialpyrolysis of biomass which is carried out under atmospheric pressure in a narrow temperature range of 200-300°Cand under an inert environment which yields higher solid yield than pyrolysis. Three different Torre factiontemperatures 230, 255 and 280°C with three different holding times 20, 40 and 60 minutes were considered usingdry and chemical treated torrefaction. The result showed that a net reduction of the volatiles content, mass yield,moisture content, bulk density and atomic oxygen content correlate with increasing torrefaction temperature andreaction time, while atomic carbon content, higher heating value (HHV), fixed carbon content and energy densityincrease with higher torrefaction temperatures in both treatment cases. So, torrefaction temperature and holdingtime had a significant effect on torrefaction process of rice husk. Based on the findings of this study, temperature of280°C and 60 min for dry torrefaction and 280 with a residence time of 40 min for chemical treated torrefaction couldbe suggested for an effective and proper torrefaction process to recycle the agricultural biomass. The energy densityof dry torrefaction was enhanced by 120% and chemical torrefaction was enhanced by 127.4%. Therefore, thetorrefied biomass becomes fuel sources which can be applied to replace with fossil